Professional Documents

Culture Documents

New Daily Facility Walk Form

Uploaded by

Ariel Vergara0 ratings0% found this document useful (0 votes)

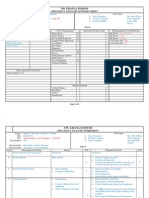

6 views4 pagesThis document is a daily facility inspection form for Seiwa Kaiun Philippines, Inc. It contains checklists to inspect various areas of the facility including floors, stairs, pallet racks, forklifts, fire safety, electrical systems, personal protective equipment, safety posters, the building and yard, trucking and other vehicles, and general safety. Inspectors mark either "O" for compliance or "X" for non-compliance and can note any remarks. The form is signed off by the safety officer, safety lead, general supervisor, and HR manager after completion.

Original Description:

Original Title

NEW DAILY FACILITY WALK FORM

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a daily facility inspection form for Seiwa Kaiun Philippines, Inc. It contains checklists to inspect various areas of the facility including floors, stairs, pallet racks, forklifts, fire safety, electrical systems, personal protective equipment, safety posters, the building and yard, trucking and other vehicles, and general safety. Inspectors mark either "O" for compliance or "X" for non-compliance and can note any remarks. The form is signed off by the safety officer, safety lead, general supervisor, and HR manager after completion.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views4 pagesNew Daily Facility Walk Form

Uploaded by

Ariel VergaraThis document is a daily facility inspection form for Seiwa Kaiun Philippines, Inc. It contains checklists to inspect various areas of the facility including floors, stairs, pallet racks, forklifts, fire safety, electrical systems, personal protective equipment, safety posters, the building and yard, trucking and other vehicles, and general safety. Inspectors mark either "O" for compliance or "X" for non-compliance and can note any remarks. The form is signed off by the safety officer, safety lead, general supervisor, and HR manager after completion.

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

Seiwa Kaiun Philippines, Inc.

Daily Facility Inspection Form

Month Legends O - Compliance

X- Non-compliance

Checkpoints Mon Tue Wed Thu Fri Sat Remarks

Date

FLOORS

No wet / Slip hazard

No Trip Hazard

No Falling Hazard

No electric cords across walkways

Floors are swept / clean

STAIRS and RAMPS

Lightning is adequate

Non-slip surface in good condition

Handrails - installed and secure

PALLET/RACKS/STORAGE PALLET

Warehouse capacity guidelines followed to avoid

overcrowding

Stacks are well constructed using the bonding

method ( Present of slip sheet if double stocking)

Pallet in good condition ( no splinters, protruding

nails)

Empty pallet correctly stored

Heavier material on lower shelves

Warehouse is free of chemicals, lubricants, fuels,

vehicle tires or hazardouz materials

FORKLIFT

Forklift truck correctly maintained and operated

Safe charging area for forklift truck

Certification badge is posted

Properly parked

Checklist properly filled-up

FIRE SAFETY

Fire extinguisher accessible

Fire extinguisher tagged, service

Fire exits correctly marked and illuminated

Exits clear and unobstructed

Fire exits are unlocked while building is occupied

Atleast two fire exit doors are accessible

NO smoking allowed inside the warehouse

ELECTRICAL

Extension cords used only for temporary work

Permanent wiring correctly installed

Electrical panel has 90cm clearance

Electrical panel clearly marked

Electrical wires and cords in good condition ( No

exposed wire or frayed cords)

PERSONAL PROTECTIVE EQUIPMENT

Personal protective equipment (PPE) available:

Helmet

Safety shoes

Back support Belt

Carrying aids available i.e. hand trucks,pallet jacks,

cart

SAFETY POSTERS

Safety posters are posted or available when needed:

Safety and Quality

Forklift Zone

Human Zone

BUILDING AND YARD

Roof is leak free

Warehouse yard is clean, free of trash and grass /

plant are cut short

Warehouse walls are free of crack or holes

Water flow effectively to drains

TRUCKING AND OTHER VEHICLES

Separate loading and Unloading areas designated

Traffic movement( deliveries etc.) are safe and well

signed

Vehicle exhaust minimized and well-ventilated

Tractor head in good operating condition (Tire, body)

Container Chasis in good condition ( Landing gear,

Body, lightning, Tire, etc.)

Container in good condition

Stopper place when on loading/Unloading activity and

while on parking.

GENERAL SAFETY

First-aid kit available

Emergency phone number posted

Emergency procedure posted

Emergency lightning functions

Lightning is adequate

Tools/Equipment are in safe condition

Number of employees in warehouse are posted

Area free of potential falling object

Sinks and restroom are accessible and well

maintained

Soap and water are available for hand washing

Note: Photo of non-compliance must attached in this form. Non-compliance findings must be address to concern PIC. And both

parties may agreed on the action need to made.

Prepared by Checked by Confirmed by Noted by

Ariel Vergara Doan Leaño Judy Gulapa

Safety Officer SL Safety Officer GA Supervisor HRGA Manager

1

You might also like

- Safety Industrial Safety Inspection ChecklistDocument2 pagesSafety Industrial Safety Inspection ChecklistAhmadi HasanNo ratings yet

- Construction Safety ChecklistDocument2 pagesConstruction Safety Checklistwirnos100% (1)

- Sample Workplace Inspection ChecklistDocument5 pagesSample Workplace Inspection ChecklistDoaa GamalNo ratings yet

- Fire Safety Self - Inspection Checklist: Quarterly Building ReportDocument7 pagesFire Safety Self - Inspection Checklist: Quarterly Building ReportnmzharifNo ratings yet

- Daily Observation Form and ChecklistDocument2 pagesDaily Observation Form and ChecklistABDUL RISHAD KunduthodeNo ratings yet

- Workplace Inspection Checklist TemplateDocument5 pagesWorkplace Inspection Checklist Templatemyo lwinNo ratings yet

- Barge Form Checklist: No. Check Item Condition Remarks Y N N/A I Manning (Crew) DeckDocument4 pagesBarge Form Checklist: No. Check Item Condition Remarks Y N N/A I Manning (Crew) DeckHermawan Alief100% (1)

- Warehouse Staff Safety Guide - Christina GagliardiDocument18 pagesWarehouse Staff Safety Guide - Christina GagliardiJi SungNo ratings yet

- L4C - Working PlatfornDocument3 pagesL4C - Working PlatfornArif RizwanNo ratings yet

- Toolbox Talk - Access Egress Stairs WalkwaysDocument2 pagesToolbox Talk - Access Egress Stairs WalkwaysKashif ImranNo ratings yet

- Sample Checklist For Temporary Worker SafetyDocument5 pagesSample Checklist For Temporary Worker SafetySafety and Health magazineNo ratings yet

- JSA FormDocument6 pagesJSA FormAjeesh CochinNo ratings yet

- # Monthly Inspection Check List-PDDocument7 pages# Monthly Inspection Check List-PDArjun KoiralaNo ratings yet

- F-HSE-01 Daily Inspection Checklist (AutoRecovered)Document1 pageF-HSE-01 Daily Inspection Checklist (AutoRecovered)gilNo ratings yet

- Facility Risk Assessment QuestionnaireDocument5 pagesFacility Risk Assessment QuestionnaireGrayNo ratings yet

- Sor 220706 MF3 & TF5Document2 pagesSor 220706 MF3 & TF5Justine JoseNo ratings yet

- JSA No 3 - Operate Dozer - Push ScraperDocument3 pagesJSA No 3 - Operate Dozer - Push ScraperBenjamin Fabin100% (1)

- Construction Site ChecklistDocument5 pagesConstruction Site ChecklistKutbuddin J TunkiwalaNo ratings yet

- Jsa SKDocument10 pagesJsa SKEngr Tahir UL Haq100% (2)

- Handout PSSR 2018 PDFDocument37 pagesHandout PSSR 2018 PDFDanica Joy PepeNo ratings yet

- CanteenDocument4 pagesCanteenRydel CuachonNo ratings yet

- Thermal Powertech Corporation India LTD: 33kva Substation - Safety ReportDocument5 pagesThermal Powertech Corporation India LTD: 33kva Substation - Safety Reportkannagi198No ratings yet

- Sample HSE Walkthrough ChecklistDocument4 pagesSample HSE Walkthrough ChecklistFelix EbikineiNo ratings yet

- Bucket Truck Inspection ChecklistDocument2 pagesBucket Truck Inspection ChecklistRony Medina75% (4)

- Office and Administration AreasDocument3 pagesOffice and Administration Arease cubeNo ratings yet

- Check List: Managing Industrial Technology & Design WorkspacesDocument5 pagesCheck List: Managing Industrial Technology & Design Workspacesmohammed sameeullahNo ratings yet

- Grade D BookDocument13 pagesGrade D Bookmorne9ferreira97% (35)

- 2022-08-01 DC-96 - Akim Mid TafoDocument5 pages2022-08-01 DC-96 - Akim Mid Tafoka71431No ratings yet

- Pre Spud InspectionDocument8 pagesPre Spud InspectionAgus Alexandri100% (2)

- EHS Officer Inspection-SAB, RosslynDocument6 pagesEHS Officer Inspection-SAB, RosslynAmukelaniNo ratings yet

- Daily Inspection Checklist (Revised 02)Document14 pagesDaily Inspection Checklist (Revised 02)Dlraje DlrajeNo ratings yet

- Cargo Claims:: Bulk Carriers/ General Cargo/ ReefersDocument44 pagesCargo Claims:: Bulk Carriers/ General Cargo/ ReefersCan Yigit Dinc100% (1)

- Hse Audit Checklist (Safety)Document8 pagesHse Audit Checklist (Safety)mohd_azaruddin100% (4)

- Construction Safety Inspection Checklist PDFDocument4 pagesConstruction Safety Inspection Checklist PDFShuhaib MD100% (1)

- Handling of MaterialsDocument34 pagesHandling of MaterialsJerome GarganeraNo ratings yet

- Workplace Inspection Checklist - Workshop EnvironmentDocument2 pagesWorkplace Inspection Checklist - Workshop Environmentjustine84480% (1)

- Weekly Health and Safety ChecklistDocument4 pagesWeekly Health and Safety Checklistgilbert cruzNo ratings yet

- JSA For Fab Erec of STRL Steel StackDocument5 pagesJSA For Fab Erec of STRL Steel StackkrishnakumarNo ratings yet

- Petronas Energy Philippines DegassingDocument1 pagePetronas Energy Philippines DegassingboyettNo ratings yet

- Warehouse Audit ChecklistDocument2 pagesWarehouse Audit ChecklistNada GHAZOUANI100% (1)

- Facility Safety Checklist: Personal Protective Equipment Emergency/Osha Related ItemsDocument2 pagesFacility Safety Checklist: Personal Protective Equipment Emergency/Osha Related Itemscahenke100% (2)

- Method Statement Analysis: Basic Job Steps Remarks High Risk Iedntified Mitigation Steps To Reduce/Eliminate The RiskDocument14 pagesMethod Statement Analysis: Basic Job Steps Remarks High Risk Iedntified Mitigation Steps To Reduce/Eliminate The RiskShanavas MuhammedNo ratings yet

- Site ObservationDocument8 pagesSite ObservationAzhari KlewanNo ratings yet

- Construction Safety Checklist RevisedDocument2 pagesConstruction Safety Checklist RevisedManuel GarciaNo ratings yet

- Quarterly Building Inspection ReportDocument12 pagesQuarterly Building Inspection Reportvishwas salunkheNo ratings yet

- SOPDocument8 pagesSOPbiplob nandyNo ratings yet

- Random Safety Audit Checklist & Score CardDocument6 pagesRandom Safety Audit Checklist & Score Cardpatilrvaibhav123No ratings yet

- 5 SDocument9 pages5 Sarai29733No ratings yet

- Field Inspection Report ExampleDocument35 pagesField Inspection Report Examplejinyuan7450% (4)

- Safety Inspection ChecklistDocument5 pagesSafety Inspection ChecklistAnuj Kjoy67% (3)

- Asia Pacific Weekly Incident Summary 08-Jul-2014 (Indonesia)Document15 pagesAsia Pacific Weekly Incident Summary 08-Jul-2014 (Indonesia)Anonymous cKdbnUHNo ratings yet

- IGC2 Soft Copy1Document48 pagesIGC2 Soft Copy1Abdallah R. AwadNo ratings yet

- Ctpat Security QuestionnaireDocument8 pagesCtpat Security QuestionnaireCarlos MorenoNo ratings yet

- Site Visit Report (07) 08-02-2021Document3 pagesSite Visit Report (07) 08-02-2021Laith SalmanNo ratings yet

- Home EconomicsDocument3 pagesHome EconomicsDawnNo ratings yet

- IMCASF - Jun 18Document4 pagesIMCASF - Jun 18Shivkumar JadhavNo ratings yet

- Warehouse Safety Checklist Sample ReportDocument14 pagesWarehouse Safety Checklist Sample ReportPIROM_C100% (1)

- Emergency Response Guidebook: A Guidebook for First Responders during the Initial Phase of a Dangerous Goods/Hazardous Materials Transportation IncidentFrom EverandEmergency Response Guidebook: A Guidebook for First Responders during the Initial Phase of a Dangerous Goods/Hazardous Materials Transportation IncidentNo ratings yet

- DVX KatDocument4 pagesDVX KatNagaraja MVNo ratings yet

- Sample Company OSHA Diagnostic Audit ReportDocument15 pagesSample Company OSHA Diagnostic Audit ReportAndrewNo ratings yet

- Only For Reference Do No Copy 4Document24 pagesOnly For Reference Do No Copy 4Sindhi ChowkrowNo ratings yet

- MHE ChecklistDocument7 pagesMHE ChecklistJesonNo ratings yet

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDocument13 pagesRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- TCM FB 1.8-3.5 Ton BrochureDocument7 pagesTCM FB 1.8-3.5 Ton BrochureAndy100% (1)

- Frame: B60Z (A230) W60Z (A231) W65Z (A229) B80Z (A233) W80Z (A234) B60Z (B230) B80Z (B233)Document12 pagesFrame: B60Z (A230) W60Z (A231) W65Z (A229) B80Z (A233) W80Z (A234) B60Z (B230) B80Z (B233)Christian BedoyaNo ratings yet

- Pva Manual PDFDocument234 pagesPva Manual PDFcarlosNo ratings yet

- Banks Man Awareness TrainingDocument11 pagesBanks Man Awareness Trainingalpha ToolsNo ratings yet

- Risk Assessment - Erection of LP Heater 2Document5 pagesRisk Assessment - Erection of LP Heater 2Hanu JemberNo ratings yet

- Team (Formal) JSA: Job Safety AnalysisDocument1 pageTeam (Formal) JSA: Job Safety AnalysisSujeed AbdulNo ratings yet

- A Short Survey of Image Processing in Logistics: PreprintDocument7 pagesA Short Survey of Image Processing in Logistics: PreprintParanjay MenariaNo ratings yet

- Manual Yale Diagrama EBDocument28 pagesManual Yale Diagrama EBCarlos83% (6)

- Cat Forklift Nr4500 36v Schematic Operation Maintenance ManualDocument27 pagesCat Forklift Nr4500 36v Schematic Operation Maintenance Manualfrankstewart270488qny100% (83)

- Simulation Method in Research On Material-Flow in A WarehouseDocument12 pagesSimulation Method in Research On Material-Flow in A WarehouseSuvin NambiarNo ratings yet

- Manitou MI 50 D - MI 100 D (EN)Document12 pagesManitou MI 50 D - MI 100 D (EN)ManitouNo ratings yet

- Safe Lifting and SlingingDocument61 pagesSafe Lifting and SlingingAlan Sharp100% (2)

- Still Fork Truck Rx60 Parts CatalogDocument20 pagesStill Fork Truck Rx60 Parts Catalogveronica100% (59)

- EZ Grout Brochure-12 PageDocument12 pagesEZ Grout Brochure-12 PagedwilfranNo ratings yet

- Clark Forklift 2022 Service Manual Operator Manual Parts Catalog PDF DVDDocument38 pagesClark Forklift 2022 Service Manual Operator Manual Parts Catalog PDF DVDtraceylucas251087sjo99% (132)

- Manitou Carix: Manual Pallet TrucksDocument4 pagesManitou Carix: Manual Pallet TrucksManitou100% (1)

- Parts Manual ERP040DH, ERP050DH, ERP060DH (D216) : Yale Materials Handling CorporationDocument280 pagesParts Manual ERP040DH, ERP050DH, ERP060DH (D216) : Yale Materials Handling CorporationErisson100% (1)

- Woko Manual de OperaçãoDocument12 pagesWoko Manual de OperaçãoRicardo Fernandes Sales100% (1)

- Assignment On Machine and Tools SafetyDocument2 pagesAssignment On Machine and Tools Safetydilshad.ba13No ratings yet

- Still Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts ManualDocument20 pagesStill Steds Diesel Fork Truck Rx70 40 Rx70 45 Rx70 50 Rx70!50!600 Parts Manualhannah100% (48)

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurNo ratings yet

- ECX20Document6 pagesECX20Martin Israel Cordero CastilloNo ratings yet

- Toyota Forklift 50-4FD100 - 135, 50-4FDK150, 160 Service Repair ManualDocument56 pagesToyota Forklift 50-4FD100 - 135, 50-4FDK150, 160 Service Repair Manualmãi bên em100% (1)

- Cat Forklift Pd10000 Pd11000 Pd12000 Pd8000 Schematic Service Operation Maintenance ManualDocument27 pagesCat Forklift Pd10000 Pd11000 Pd12000 Pd8000 Schematic Service Operation Maintenance Manualmichellemacias080283gfz100% (52)

- Hyster LPG ForkliftDocument7 pagesHyster LPG Forkliftncthanhck100% (1)