100% found this document useful (1 vote)

568 views15 pagesSolar Charge Controllers

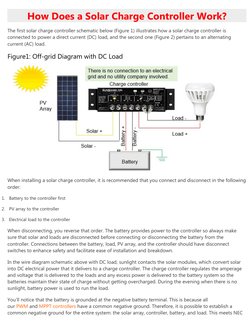

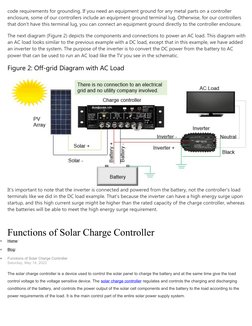

A solar charge controller regulates the voltage and current from solar panels to batteries in an off-grid solar system. It prevents overcharging batteries, allows excess solar energy to power loads, and regulates power flow between components. The document describes how solar charge controllers work, including connection order, grounding, and protecting batteries from high current surges from inverters. It also outlines types of controllers and their functions in maximizing solar power and extending battery life.

Uploaded by

Yasir ButtCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

568 views15 pagesSolar Charge Controllers

A solar charge controller regulates the voltage and current from solar panels to batteries in an off-grid solar system. It prevents overcharging batteries, allows excess solar energy to power loads, and regulates power flow between components. The document describes how solar charge controllers work, including connection order, grounding, and protecting batteries from high current surges from inverters. It also outlines types of controllers and their functions in maximizing solar power and extending battery life.

Uploaded by

Yasir ButtCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd