Professional Documents

Culture Documents

715f96a0 2951235

Uploaded by

joaica5046Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

715f96a0 2951235

Uploaded by

joaica5046Copyright:

Available Formats

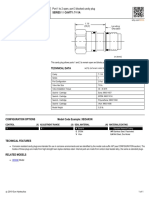

Product Specifications

3M™ Low-Profile Headers

Series 25XX

78-5102-0002-1 Rev D

Released: 02-24-21

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

78-5102-0002-1 Rev D 2 of 7

3M™ Low-Profile Headers, Series 25XX

Table of Contents

Section Page

1. Scope …………………………………….……………...…………………………………………..…………………….………………………………………..

3

2. 3M Customer Documents ……………………………………………...…….……..………………………………………………..…………………………………………….

3

3. Performance and Test Descriptions …………………..…………………………………………………………………………………………………………….

3

4. Requirements Overview………………...…...…...…...……………………………………………………………………… 3

5. Test Results Summary………………………………………………………………………………………………………… 4

6. Test Sequences……………………………………………………………………………………………………………………………….4

7. Figures……………...………….………………………………………………...……………………………………………………….. 5

8. Agency Listings………………………………………………………………………………………………………………………………………..

6

Important Notice ……………………………………………………………………………………………………………………………………………………………

7

Steven A. Neu: Approved: 07-24-12

Sandra J. Stuckert: Approved 07-24-12

Jim W. Wessman: Approved 07-24-12

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

78-5102-0002-1 Rev D 3 of 7

3M™ Low-Profile Headers, Series 25XX

1. Scope

This document summarizes test methods, test conditions and product performance requirements for the 3M™ Low Profile

Headers. Listings of materials, finishes, test conditions, and test standards are included in this specification. In the event of

conflict between this specification and any documents listed below, the listed documentation supersedes this specification.

2. 3M Customer Documents

78-5100-0770-7 TS-0770, Technical Data Sheet for 25XX Series Four‑Wall Header

78-9100-7795-3 Instruction Sheet for 3M™ Polarizing Key 3518

3. Performance and Test Description

Unless otherwise specified, all tests shall be mated to 3M Wiremount Sockets 3425, .100 pitch with 3M Cable 3365 at ambient

environmental conditions per EIA-364. Unless otherwise specified, all values and limits are typical of those obtained by

qualification testing of the subject product. All specifications are subject to revision and change without notice from 3M.

4. Requirements Overview

4.1 Ratings

Dielectric withstanding voltage: 1000 VRMS @ Sea Level

Temperature: -65°C to +105°C

Insulation resistance: >1 x109Ω at 500 VDC

Current: ( EIA-364-070 method 2, 30°C maximum temperature rise. )

1.75 Amperes, All contacts powered

3.00 Amperes, 6 contacts powered

5.00 Amperes, 1 contact powered

4.2 Materials

Header

Insulation: Glass Filled PCT

Latch Insulation: Nylon

Cover Clip: Stainless Steel with Gray Polyurethane Coating

Pin Contact: Copper Alloy

4.3 Finishes

Plating:

TS-0770 25XX Series Four‑Wall Header

Nickel: 50-150 µ inches, ASTM B689-97, SAE AMS-QQ-N-290

Gold: 30 µ inches, MIL-G-45204 Type II, Grade C, ASTM B488-01

Sn: 200-300 µ" Matte Tin

D25XX Series Four‑Wall Header

Nickel: 50 - 150 µ inches, ASTM B689-97, SAE AMS-QQ-N-290

Gold: 10 µ inches, MIL-G-45204 Type II, Grade C, ASTM B488-01

Sn: 40-120 µ" Matte Tin

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

78-5102-0002-1 Rev D 4 of 7

3M™ Low-Profile Headers, Series 25XX

4.5 Regulatory Compliance

See the Regulatory Information Appendix (RIA) in the “RoHS compliance” section of www.3Mconnector.com for

compliance information. See customer drawings for regulatory specifics on each connector.

5.0 Test Results Summary

5.1 General

5.2 Environmental

Items Specification Test Method

Environmental • 50 Insertions/Withdrawals EIA-364-09

Durability (30µ" Au) •Max. ΔR: <10 mΩ

• 10 Insertions/Withdrawals EIA-364-09

Durability (10µ" Au) •Max. ΔR: <10 mΩ

• No physical abnormalitities after test EIA-364-26

Salt Spray •Max. ΔR: <10 mΩ

Thermal Shock • No physical abnormalitities after test EIA-364-32, Table 2, Condition II, -65

•Max. ΔR: <10 mΩ to +105 ⁰C, 5 Cycles

Temperature Life • No physical abnormalitities after test EIA-364-17, Method A, Condition 3D,

(Thermal Aging) 105 ⁰C, 1000 hours

•Max. ΔR: <10 mΩ

Humidity EIA-364-31, Method IV, 25-65 ⁰C, -10

Max. ΔR: <10 mΩ

⁰C subcycle, 80-100%RH, 10 cycles

5.3 Mechanical

Items Specification Test Method

Mechanical Vibration • No physical abnormalitities after test EIA-364-28, Method V, Condition A,

• Max. ΔR: <10 mΩ Table II

• No electrical discontinuity > 10 n sec

Mechanical Shock • No physical abnormalitities after test EIA-364-27, Test Condition A,

•Max. ΔR: <10 mΩ Table 1

• No electrical discontinuity > 10 n sec

Contact Retention 3.5 lb. min EIA-364-29

5.4 Electrical

Items Specification Test Method

Electrical Low Level Contact Resistance Max. ΔR: <10 mΩ EIA-364-23

Dielectric Withstanding Voltage 1000 Vrms @ Sea Level, 1 min EIA-364-20

Insulation Resistance 1 x 109 @ 500 Vdc EIA-364-21

Current Rating 1.75 Amp, All Lines Powered EIA-364-70A, Method 2, 30°C

3.00 Amp, 6 Lines Powered Temperature Rise Limit.

5.00 Amp, 1 Line Powered

5.4 Physical

Items Specification Test Method

Physical Visual No defects such as deformation, blister, EIA-364-18

damage, crack, etc.

Nickel Underplating Thickness 50-150 μ" EIA-364-48, C

Gold Thickness 30 μ" Average of random measurements

10 μ" from any 3 lots

Matte Tin Thickness 200-300μ"

Solderability >95% Coverage of solderable area EIA-364-52

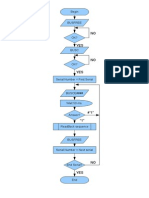

6.0 Test Sequence

6.1 Sequenced Tests TEST FLOW

Sequence Numbers for Test Group

Test

A B C D

Visual 1 1

Low Level Connection Resistance (LLCR) 1,3,5,7 1,3 2,4,6 2,4,6

Vibration 3

Physical Shock 5

Durability (with Environmental) 2 3

Temperature Life (Thermal Aging) 2

Humidity 6

Thermal Shock 4

Salt Spray 5

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

78-5102-0002-1 Rev D 5 of 7

3M™ Low-Profile Headers, Series 25XX

6.2 Independent Tests

1. Plating Thicknesses

2. Header Solderability

3. Header Pin Retention

4. Dielectric Withstanding Voltage

5. Current Rating

6. Insulation Resistance

7.0 Figures

7.1 Temperature vs. Current

3M™ Low-Profile Headers

Temperature vs. Current Derating Curve

All Contacts Powered

5

4.5

4

Maximum Current (Amp)

3.5

Base Curve

3

Derated 20%

2.5

2 30°C T-Rise Limit- Derated (1.75A) 30C T-Rise Derated

1.5

1

0.5

0 Max. Operating Temperature Limit (105°C)

0 10 20 30 40 50 60 70 80 90 100 110

Ambient Temperature (°C)

3M™ Low Profile Headers

Temperature vs. Current Derating Curve

6 Contacts Powered

9

8

Maximum Current (Amp)

7

Base Curve

6

Derated 20%

5

4 30C T-Rise Derated

3 30°C T-Rise Limit- Derated (3.00A)

2

0

Max. Operating Temperature Limit (105°C)

0 10 20 30 40 50 60 70 80 90 100 110

Ambient Temperature (°C)

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

78-5102-0002-1 Rev D 6 of 7

3M™ Low-Profile Headers, Series 25XX

3M™ Low Profile Headers

Temperature vs. Current Derating Curve

1 Contact Powered

14

13

12

11 Base Curve

Maximum Current (Amp)

10

Derated 20%

9

8 30C T-Rise Derated

7

6 30°C T-Rise Limit- Derated (5.00A)

5

4

3

2

1

0 Max. Operating Temperature Limit (105°C)

0 10 20 30 40 50 60 70 80 90 100 110

Ambient Temperature (°C)

8. Agency Listings

8.1 Underwriters Laboratories (UL)

Agency File No.

UL E68080

CUL E68080

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

78-5102-0002-1 Rev D 7 of 7

3M™ Low-Profile Headers, Series 25XX

3M is a trademark of 3M Company.

Important Notice

All statements, technical information, and recommendations related to 3M’s products are based on information believed to be

reliable, but the accuracy or completeness is not guaranteed. Before using this product, you must evaluate it and determine if it is

suitable for your intended application. You assume all risks and liability associated with such use. Any statements related to the

product which are not contained in 3M’s current publications, or any contrary statements contained on your purchase order shall

have no force or effect unless expressly agreed upon, in writing, by an authorized officer of 3M.

Warranty; Limited Remedy; Limited Liability

Regulatory: For regulatory information about this product, contact your 3M representative.

Technical Information: The technical information, recommendations and other statements contained in this document are based

upon tests or experience that 3M believes are reliable, but the accuracy or completeness of such information is not guaranteed.

Product Use: Many factors beyond 3M’s control and uniquely within user’s control can affect the use and performance of a 3M

product in a particular application. Given the variety of factors that can affect the use and performance of a 3M product, user is

solely responsible for evaluating the 3M product and determining whether it is fit for a particular purpose and suitable for user’s

method of application.

Warranty, Limited Remedy, and Disclaimer: Unless an additional warranty is specifically stated on the applicable 3M product

packaging or product literature, 3M warrants that each 3M product meets the applicable 3M product specification at the time 3M

ships the product. 3M MAKES NO OTHER WARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE OF DEALING, CUSTOM OR USAGE

OR TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M’s option,

replacement of the 3M product or refund of the purchase price.

Limitation of Liability: Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M product,

whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including warranty, contract,

negligence or strict liability.

© 3M 2021. All rights reserved.

Electronics Materials Solutions Division

Interconnect Solutions

3M Company

13011 McCallen Pass, Bldg C

Austin, TX 78753-5380

1-800-251-8634 phone

www.3M.com/interconnect

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

3M:

N3518 N2526-5003-RB N2536-5002-RB N2514-6V0C-RB-WD N2520-6V0C-RB-WE N2524-6V0C-RB-WE N2530-

6V0C-RB-WF N2550-6V0C-RB-WG N2560-6V0C-RB-WH 3518 N2540-6V0C-RB-WG 3505-8120 3505-8110 3505-

8116 3505-8134 3505-8140 3505-8034 3505-8050 3505-8020 3505-8040 3505-8016 3505-8030 3505-33B

D2514-6002-AR D2516-6002-AR D2520-6002-AR D2524-6002-AR D2526-6002-AR D2534-6002-AR D2550-6002-

AR D2510-6V0C-AR-WD D2514-6V0C-AR-WD D2520-6V0C-AR-WE D2524-6V0C-AR-WE D2530-6V0C-AR-WF

D2516-5002-AR D2524-5002-AR D2526-5002-AR D2530-5002-AR D2534-5002-AR D2540-5002-AR N2508-6002-

RB N2508-6V0C-RB-WD N2506-6002RB N2506-6V0C-RB-WD 3505-33C

You might also like

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- Metal Detectable PE1000 Data SheetDocument2 pagesMetal Detectable PE1000 Data SheetPrashant MalikNo ratings yet

- RT-Duroid 5880 PropertiesDocument2 pagesRT-Duroid 5880 PropertiesJesus GarciaNo ratings yet

- SpecificationsDocument4 pagesSpecificationsDeepa DevarajNo ratings yet

- Especificaciones Tecnicas Solmax Hdpe Metric EspanolDocument3 pagesEspecificaciones Tecnicas Solmax Hdpe Metric EspanolAlfredo OvandoNo ratings yet

- PMT Am Tims ltm6300 pcm45f ptm5000 Series Data SheetDocument1 pagePMT Am Tims ltm6300 pcm45f ptm5000 Series Data Sheetmajor crossNo ratings yet

- Specification and Performance Characteristics of Serial Ata Cable AssembliesDocument12 pagesSpecification and Performance Characteristics of Serial Ata Cable Assembliesanon_14005973No ratings yet

- RO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Document4 pagesRO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Juliano Rodrigues BrianezeNo ratings yet

- 240 Pin VLP DDR-III Soldertail Sockets: Product Design ObjectiveDocument8 pages240 Pin VLP DDR-III Soldertail Sockets: Product Design Objectivejerome_testNo ratings yet

- 108-10614020 Product Specification: Industrial M8 and M12 Series Circular ConnectorDocument6 pages108-10614020 Product Specification: Industrial M8 and M12 Series Circular ConnectorSebastian EspinozaNo ratings yet

- SP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemDocument9 pagesSP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemSaravoot MetahNo ratings yet

- Textured HDPE Geomembrane Technical Data SheetDocument1 pageTextured HDPE Geomembrane Technical Data SheetAndrew Zapanta Jr.No ratings yet

- CTJ 10 10 3004 BK PX FSDocument14 pagesCTJ 10 10 3004 BK PX FSwebmaster5813No ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNo ratings yet

- Ford - Wsk-m4d684-A2 Abs - PC ConsoleDocument5 pagesFord - Wsk-m4d684-A2 Abs - PC ConsoleCamila SanchesNo ratings yet

- HOSTAPHAN® Polyester films..PETDocument10 pagesHOSTAPHAN® Polyester films..PETsreeeragNo ratings yet

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocument2 pagesPC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNo ratings yet

- PC Abs Spec SheetDocument2 pagesPC Abs Spec SheetAli YudiNo ratings yet

- RO4500 Antenna Grade Laminates For High Volume ApplicationsDocument4 pagesRO4500 Antenna Grade Laminates For High Volume ApplicationsMeenakshi Sundaram KaruppiahNo ratings yet

- 3m Ecdst 9750 TdsDocument4 pages3m Ecdst 9750 TdsGhost_suolNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous yz5MQGtNo ratings yet

- High Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFDocument12 pagesHigh Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFrahul05singhaNo ratings yet

- Bushing Connection Animal Cover: Energy DivisionDocument2 pagesBushing Connection Animal Cover: Energy Divisionjorge_moralesmNo ratings yet

- ABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersDocument2 pagesABS-M30: Production-Grade Thermoplastic For FDM 3D PrintersSINo ratings yet

- Spec Sheet - ABS-M30 ENDocument2 pagesSpec Sheet - ABS-M30 ENTUSHAR BANGERANo ratings yet

- TestDocument716 pagesTestdovesnest_inNo ratings yet

- Multi-B SDN BHD Translite MF Bus Duct Special FeaturesDocument30 pagesMulti-B SDN BHD Translite MF Bus Duct Special FeaturesSourp VartanNo ratings yet

- tds-500-seriesDocument3 pagestds-500-seriesmmrNo ratings yet

- Bushing Protector WildlifeDocument2 pagesBushing Protector WildlifeCarlos BallesterosNo ratings yet

- 3M Embedded Capacitance Material DatasheetDocument2 pages3M Embedded Capacitance Material Datasheettrivesh7No ratings yet

- 3M TC-2707-TDSDocument4 pages3M TC-2707-TDSJavierNo ratings yet

- High Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionDocument12 pagesHigh Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionPriyanka ChoudharyNo ratings yet

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNo ratings yet

- 3M Bus Bar Data SheetBBI 2016 NewDocument8 pages3M Bus Bar Data SheetBBI 2016 Newvivek jayswalNo ratings yet

- 3M Power Industry SolutionsDocument44 pages3M Power Industry Solutionstony6868No ratings yet

- WWW - Techsil.co - Uk: Technical BulletinDocument3 pagesWWW - Techsil.co - Uk: Technical BulletinJackson PhinniNo ratings yet

- Propriedades Das Matrizes PolimericasDocument7 pagesPropriedades Das Matrizes PolimericasllepsterlNo ratings yet

- Dynatel: Qualification Test Set 950ADSL2 PlusDocument8 pagesDynatel: Qualification Test Set 950ADSL2 PluspieroalessNo ratings yet

- WSS M99P32 D1Document6 pagesWSS M99P32 D1jose luisNo ratings yet

- 12.1 Đầu Cáp Ngầm Ngoài Trời 24kV- (1x300) Mm2 - GIẢMDocument124 pages12.1 Đầu Cáp Ngầm Ngoài Trời 24kV- (1x300) Mm2 - GIẢMhoangtinbkNo ratings yet

- WSS M4D924 B11.Document8 pagesWSS M4D924 B11.JOSENo ratings yet

- 3M™ Cold Shrink End Caps EC-SeriesDocument3 pages3M™ Cold Shrink End Caps EC-Seriessmsm280No ratings yet

- Me6052 PDS Reg - World en V4 PDS World 4158 10058878Document3 pagesMe6052 PDS Reg - World en V4 PDS World 4158 10058878TANMAY NAYAKNo ratings yet

- 3M™ Adhesive Transfer Tape 9471 - 20231201Document8 pages3M™ Adhesive Transfer Tape 9471 - 20231201dsfasdfafsNo ratings yet

- Scotchkote: Fusion-Bonded Epoxy Coating 206N LGDocument1 pageScotchkote: Fusion-Bonded Epoxy Coating 206N LGSohail TisekarNo ratings yet

- Separable Connectors: Asymmetrical T-Type Connectors 630A 1250A Umax 36kVDocument3 pagesSeparable Connectors: Asymmetrical T-Type Connectors 630A 1250A Umax 36kVLizbeth Lizbeth AmesquitaNo ratings yet

- Datasheet PDFDocument2 pagesDatasheet PDFAnonymous jKNubumNo ratings yet

- ZTT Technical Spec for Duct & Direct Buried Optical CableDocument8 pagesZTT Technical Spec for Duct & Direct Buried Optical CableEnzo del PradoNo ratings yet

- Datasheet: 33kV Cold-Shrink Inline Joint With Cold-Shrink Re-Jacketing, Including ConnectorsDocument2 pagesDatasheet: 33kV Cold-Shrink Inline Joint With Cold-Shrink Re-Jacketing, Including ConnectorsMohammed MustafaNo ratings yet

- RO3000 Pour Rogers 3006 PDFDocument4 pagesRO3000 Pour Rogers 3006 PDFTeddy112No ratings yet

- Crs 000008Document2 pagesCrs 000008ahetesham marufNo ratings yet

- 20201002114953-DIWETEN 355+M 08 2020 E-AktuellDocument6 pages20201002114953-DIWETEN 355+M 08 2020 E-AktuellHAINo ratings yet

- FD4010B12W5 71 VgaDocument3 pagesFD4010B12W5 71 VgaKristopherWindsorNo ratings yet

- Prefabricated Vertical Drain Test ReportDocument1 pagePrefabricated Vertical Drain Test Reporttrichandra maharjanNo ratings yet

- DAHRENTRAD - DAMIDFIBRE - Przewody Emalia-SzkłoDocument4 pagesDAHRENTRAD - DAMIDFIBRE - Przewody Emalia-SzkłoSzymonNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Abm3B: Parameters Standard SpecificationsDocument3 pagesAbm3B: Parameters Standard SpecificationsVICTOR MARCOSNo ratings yet

- MLX81116 Product Flyer Melexis 2Document2 pagesMLX81116 Product Flyer Melexis 2joaica5046No ratings yet

- DigitalMultimeters SellSheet wr-3133025Document5 pagesDigitalMultimeters SellSheet wr-3133025joaica5046No ratings yet

- Sliy 007Document8 pagesSliy 007joaica5046No ratings yet

- SpicePlus 3030 Multi Color S6RTB-THG - v5Document15 pagesSpicePlus 3030 Multi Color S6RTB-THG - v5joaica5046No ratings yet

- Spartan6 Product TableDocument1 pageSpartan6 Product Tablejoaica5046No ratings yet

- Spectrometer Rev4Document5 pagesSpectrometer Rev4joaica5046No ratings yet

- Daisy Chain FlowDocument1 pageDaisy Chain Flowjoaica5046No ratings yet

- How To Increase Speed of USB Connection To The LED Analyser in WindowsDocument2 pagesHow To Increase Speed of USB Connection To The LED Analyser in Windowsjoaica5046No ratings yet

- Paldex Seminar-1 - Stress Analysis PDFDocument36 pagesPaldex Seminar-1 - Stress Analysis PDFThapelo100% (1)

- Thermo Multiple Streams Sample QuestionsDocument4 pagesThermo Multiple Streams Sample QuestionsCarloNo ratings yet

- Glass Architecture - Unit 1 - Types of GlassDocument18 pagesGlass Architecture - Unit 1 - Types of GlassPriya PriyaNo ratings yet

- Dealwis - Silande Company ProfileDocument28 pagesDealwis - Silande Company ProfileLoui BarciaNo ratings yet

- DtexDocument2 pagesDtexSayed Diab AlsayedNo ratings yet

- Difference Between Annealing and NormalizingDocument3 pagesDifference Between Annealing and NormalizingoxmanamouNo ratings yet

- Mechanical Properties of AluminiumDocument8 pagesMechanical Properties of AluminiumChandan KumarNo ratings yet

- DIN 2605 (Elbows) PDFDocument3 pagesDIN 2605 (Elbows) PDFAleksandarSashaStankovichNo ratings yet

- Biomaterials For Dental Implants: PART II Basic SciencesDocument29 pagesBiomaterials For Dental Implants: PART II Basic SciencesAna-Maria RoșuNo ratings yet

- Design of Hydroelectric Power Plants.Document54 pagesDesign of Hydroelectric Power Plants.Sanjay Singh0% (1)

- Mobile Home Recycling: A Feasibility Study ofDocument46 pagesMobile Home Recycling: A Feasibility Study ofTracy PattersonNo ratings yet

- Manual Mantenimiento Grúa PórticoDocument38 pagesManual Mantenimiento Grúa PórticoOSCAR DAGA CARAVANTESNo ratings yet

- Reinforcement Detail of RCC Barrel: NotesDocument1 pageReinforcement Detail of RCC Barrel: NotesAvinash SahuNo ratings yet

- Drill String Design BHA DesignDocument97 pagesDrill String Design BHA DesignAhmed SallamNo ratings yet

- LASTO®HDRB International EN (Eversion)Document4 pagesLASTO®HDRB International EN (Eversion)SanjaNo ratings yet

- MEC2403 Lecture 1Document34 pagesMEC2403 Lecture 1Annie Yap0% (1)

- Polimer Dan Pemrosesannya: Darminto Jurusan Fisika FMIPA ITSDocument24 pagesPolimer Dan Pemrosesannya: Darminto Jurusan Fisika FMIPA ITSNaqiibatin NadliriyahNo ratings yet

- Cemi42.5n SR3LH enDocument2 pagesCemi42.5n SR3LH enmouazen mostafaNo ratings yet

- Verification Manual AFNOR 5.2Document77 pagesVerification Manual AFNOR 5.2Virginie ChalonNo ratings yet

- Beams & Ribs DesignDocument7 pagesBeams & Ribs DesignمحمدلحلوحNo ratings yet

- Hood Design Data - Range of Capture VelocitiesDocument3 pagesHood Design Data - Range of Capture VelocitieszshehadehNo ratings yet

- Heat Trace DesignDocument60 pagesHeat Trace DesignnbsmaniannNo ratings yet

- Depth of Cure of Dental Resin Composites: ISO 4049 Depth and Microhardness of Types of Materials and ShadesDocument5 pagesDepth of Cure of Dental Resin Composites: ISO 4049 Depth and Microhardness of Types of Materials and ShadesPRADNJA SURYA PARAMITHANo ratings yet

- Chapter Objectives: 2005 Pearson Education South Asia Pte LTDDocument29 pagesChapter Objectives: 2005 Pearson Education South Asia Pte LTDhidayahazranNo ratings yet

- Steam Curing Advantages and MethodsDocument1 pageSteam Curing Advantages and MethodsVanny Gimotea BaluyutNo ratings yet

- Fatigue Analysis of BearingDocument4 pagesFatigue Analysis of BearingGRD Journals100% (1)

- Design Report Final PDFDocument550 pagesDesign Report Final PDFHorizon InfradesignsNo ratings yet

- Cavity Plug XEOA - Full - en - Us - LetterDocument1 pageCavity Plug XEOA - Full - en - Us - LetterHassan KhattabNo ratings yet

- MDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsDocument12 pagesMDB Lesson 4 Poisson's Ratio-Biaxial and Triaxial DeformationsChan MirandaNo ratings yet