Professional Documents

Culture Documents

TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.B

TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.B

Uploaded by

rizwan.zamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.B

TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.B

Uploaded by

rizwan.zamanCopyright:

Available Formats

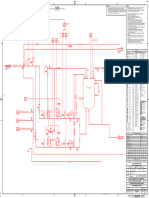

Saudi Aramco 2616-ENG(10/2002)

SAUDI ARABIAN OIL COMPANY

OPRNS

PMT

ENG'G CERT.

MWK

HCK

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

SBK

SBK

JFGP 2

Jafurah Utilities, Sulfur and Interconnecting Systems

DESCRIPTION

(Package 3)

10-14329-0003 ISSUED FOR REVIEW

10-14329-0003 ISSUED FOR REVIEW

Contract No. OOK (6600050506) & IK (6600050503)

JO/EWO

BI No. 10-14329

16-DEC-21

18-FEB-22

DATE

Location JAFURAH, SAUDI ARABIA

REV

NO.

A

DISCIPLINE

ENGINEER

MECHANICAL DATA SHEET

SBK

DATE 18-FEB-22

ENGINEERING

MANAGER

DATE

JHK

18-FEB-22

FOR

CERTIFIED

MWK

LIQUID CORROSION INHIBITOR

DATE

CONSTRUCTION

AGENCY

18-FEB-22

INJECTION PACKAGE

DATE

(863-U-3002)

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B______

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 1

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

OF B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS

PMT

ENG'G CERT. SAUDI ARABIAN OIL COMPANY

MWK

HCK

SBK

SBK

CONTENTS

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

SECTION DESCRIPTION Page No.

1 Introduction 3

2 Process Duty 4

3 Mechanical Design 6

4 Control, Safeguarding and Instrumentation 7

DESCRIPTION

5 Electrical 8

6 Utilities 8

7 Notes 8

8 Package Data 10

9 Dosing Pump 11-12

10 Dosing Pump Motor Data Sheet 13-14

11 Mixer Motor Data Sheet 15-16

10-14329-0003 ISSUED FOR REVIEW

10-14329-0003 ISSUED FOR REVIEW

JO/EWO

16-DEC-21

18-FEB-22

DATE

REV

NO.

A

DISCIPLINE

ENGINEER

SBK

DATE 18-FEB-22

ENGINEERING

MANAGER

JHK

DATE 18-FEB-22

CERTIFIED

MWK

DATE 18-FEB-22

CONSTRUCTION

AGENCY

DATE

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B______

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 2

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

1.0 INTRODUCTION

PMT

1.1 General

ENG'G CERT.

MWK

HCK

This Data Sheet covers the requirements for the Liquid Corrosion Inhibitor Injection Package 863-U-3002, for the

Jafurah Project, JFGP Processing Trains 1 & 2.

SBK

SBK

Corrosion Inhibitor is required to maintain the integrity of the Processing trains 1 & 2 for the condensate lines and

will be injected upstream of the Inlet Condensate Separators (864-D-1002 & 865-D-2002). Corrosion Inhibitor will

be injected on a continuous dosing basis to minimise corrosion and protect equipment during normal and

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

dewatering operations.

The 863-U-3002 Package shall consist of, but not be limited to, the following:

- 1 x 100% vertical bulk storage tank (with mixer if necessary) installed on skid for a required

storage volume of 113.5 ft3 (based on 80% working volume for 30 days consumption of

maximum dosing rate). 315

Tank to be fitted with necessary level gauges & instruments.

DESCRIPTION

- 3 x 100% electrical dual head dosing pumps, one operating and two stand-by.

- All interconnecting piping and instrumentation within the package boundary, including all

isolation, control and relief valves; strainers; calibration pots; pulsation dampers; pressure

gauges, flow meter on metering pump discharge, etc.

- All instrumentation wired to skid edge junction box for wiring to the SCADA (wiring to SCADA by

others).

. . .

- Necessary sample and drain connections.

34-15430-3002 ISSUED FOR REVIEW

10-14329-0003 ISSUED FOR REVIEW

. . .

- Platform and ladder for access to the top of storage tank, as necessary.

- All other mechanical and electrical equipment, instrumentation and controls necessary for safe

and reliable operation.

- Structural steel base frame with sun shades (VTC for sun shades).

JO/EWO

- First fill and supply of chemical containers (VTA). Deleted.

16-DEC-21

18-FEB-22

DATE

1.2 Abbreviations

The following acronyms and abbreviations are used in this document:

REV

NO.

Bbl. US Barrels

DISCIPLINE

ENGINEER

BEDD Basic Engineering Design Data

SBK

DATE 18-FEB-22

DCS Distributed Control System

ENGINEERING MANAGER

GOSP Gas Oil Separation Plant

JHK

JFGP Jafurah Gas Processing Train

DATE 18-FEB-22

CERTIFIED MBCD Thousand Barrels per Calendar Day

MWK

MDB Thousand Barrels per Operating Day

DATE 18-FEB-22

CONSTRUCTION NPS Nominal Pipe Size

AGENCY

PD Positive Displacement

DATE

OPERATIONS

P&ID Process and Instrumentation Diagram

PFD Process Flow Diagram

DATE

PZV Process Safety Valve

CONTROL NUMBER

SCADA Supervisory Control & Data Acquisition

VERIFICATION

EDSD

TBC To Be Confirmed

VTA VENDOR to advise

DATE:

BY:

VTC VENDOR to confirm

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

3

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

1.3 Reference Documents

PMT

This document shall be read in conjunction with the following related project documents:

ENG'G CERT.

MWK

HCK

TD-254011 P&ID - Liquid Inlet Manifolds, JFGP Inlet Storage & Export

TD-204002 PFD - Liquid Inlet Manifolds, JFGP Inlet Storage & Export

SBK

SBK

TD-234002 MSD - Liquid Inlet Manifold, JFGP Inlet Storage & Export

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

TD-821950 Basic Engineering Design Data (BEDD)

TD-821403 Electrical Basis of Design

TD-821310 Control & Instrumentation - Basis of Design

TD-821303 Control & Instrumentation - Package Equipment

DESCRIPTION

1.4 Codes and Standards

All Saudi Aramco standards and procedures shall be followed. EPC Contractor attention is drawn to the

following:

SABP-A-015 Chemical Injection Systems

SABP-A-018 GOSP Corrosion Control

SAES-A-206 Positive Material Identification

10-14329-0003 ISSUED FOR REVIEW

10-14329-0003 ISSUED FOR REVIEW

SAES-H-001 Requirements for Industrial Plants and Equipment

SAES-H-101V Approved SA Data Sheets - Paints and Coatings

SAES-L-310 Design of Plant Piping

SAES-P-111 Grounding

JO/EWO

SAES-D-100 Low Pressure Storage Tanks

17-SAMSS-503 Severe-Duty, Totally Enclosed, Induction Motors to 500 HP

16-DEC-21

18-FEB-22

17-SAMSS-515 Auxiliary Electrical Systems for Skid-Mounted Equipment

DATE

31-SAMSS-009 Positive Displacement Pumps - controlled volume.

REV

32-SAMSS-002 Manufacture of Fibreglass-Reinforced Plastic (FRP) Storage Tanks

NO.

DISCIPLINE 32-SAMSS-038 Shop - Fabricated skid mounted units.

ENGINEER

32-SAMSS-030 Manufacture of Small Metallic Atmospheric Storage Tanks

SBK

DATE 18-FEB-22

34-SAMSS-831 Instrumentation for Packaged Units

ENGINEERING MANAGER AD-036821-001 Material Guide for Centrifugal Pumps

JHK

DATE 18-FEB-22

2.0 PROCESS DUTY

CERTIFIED

MWK

2.1 Design Parameters

DATE 18-FEB-22 Liquid Corrosion Inhibitor Package is to provide sufficient dosing for normal operation and during dewatering.

CONSTRUCTION

AGENCY

The package shall be available 24 hours/day, 365 days/year.

DATE

Dosing will be fully automatic with minimum operator intervention during normal operation.

OPERATIONS The Liquid Corrosion Inhibitor Package shall have one storage tank feeding the injection chemical directly to

the dosing pumps.

DATE No day tank is required in the design in order to minimise liquid handling.

chemical vendor.

CONTROL NUMBER

Corrosion inhibitor type and properties to be provided by the Vendor during detailed engineering.

VERIFICATION

EDSD

2.2 Discharge Conditions, Dosing Rates and Tank Volume

DATE:

BY:

The dosing pumps discharge requirements and tank volumes shown in table 1 below shall be sufficient for

APPROVAL/CERTIFICATION REQUIREMENTS,

supplying the selected injection chemical, which has a maximum operating pressure of 280 psig and a design

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

pressure of 1300 psig. Design case is Y6 Rich Winter Case, Mixed Condensate from Liquid

REVISION CERTIFICATE

Transmission Lines to Train 1 & 2 (Stream No. 117).

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

4

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS

SAUDI ARABIAN OIL COMPANY

Separator PZV set pressure - 1300 psig.

PMT

Liquid Corrosion Inhibitor dosing pumps shall provide the specified dosing concentration and dosing flow rates

ENG'G CERT.

MWK

HCK

of the corrosion inhibitor for normal operation to the injection point as shown in table 1.

Table 1: Corrosion Inhibitor Dosing Rates and Tank Volumes per Train

SBK

SBK

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Inlet Cond. Separator

Description

Chemical Liquid Corrosion Inhibitor

Case Description Y6 Rich Case Winter

Dosing Conc. (ppmv) 15 10

Per Train 1

Water flow / Train (USGPM) 290.6 113.2

0.013

DESCRIPTION

Dosing Rate (USGPM) 0.0043 0.0017

Design Dosing Rate (USGPM) (Design Case) per pump head 110% / Head 0.005 0.0019 0.014

Tank Working Capacity (ft3)* -

Tank Design Cap. (ft3) 133.5 157.5

Exact dosing concentration depends on Corrosion Inhibitor selected and will be confirmed by EPC Contractor in

Deleted.

16-DEC-21 10-14329-0003 ISSUED FOR REVIEW

18-FEB-22 10-14329-0003 ISSUED FOR REVIEW

Detail Engineering.

* Based on 30 days consumption, 80% working volume and considering common storage tank for two

trains, minimum 1000 gallon tank. Corrosion Inhibitor - CORR11011B

3000 maximum dosing rate= 1.486 USGPH

Specific Gravity= 0.922

JO/EWO

2.3 Type and Properties of Chemicals pH= N/A

Liquid Corrosion inhibitor type and properties - To be confirmed by EPC Contractor in Detail Engineering.

DATE

2.4 Additional Process Requirements

The pump must be able work and operate under relief + 10% accumulation without damaging the motor.

REV

NO.

Pulsation damper to be provided to damp flow rate and pressure to ± 3 %.

DISCIPLINE

ENGINEER 2.5 Equipment Design Requirements

SBK

The design life for Liquid Corrosion Inhibitor Injection Package 863-U-3002 shall be 20 years.

DATE 18-FEB-22

ENGINEERING MANAGER The Package shall include controlled volume dual head pumps, tank, level gauges, strainer, filter, pressure

relief valves, sight glasses and flow metering/monitoring devices, check valves, hand valves, a power source for

JHK the pump and instrumentation to control the injection and to monitor its effectiveness.

DATE 18-FEB-22

CERTIFIED

Electrical dosing diaphragm pumps shall be used. Dosing pumps shall be provided with appropriate alarms and

automated controls to provide immediate switchover from running to standby pump, in case of pump failure or

MWK the need for maintenance.

DATE 18-FEB-22

Each pump shall have an adjustable stroke length to achieve turndown ratio from maximum flow.

CONSTRUCTION AGENCY

Alteration of the stroke length shall be possible without shutting the pump down.

DATE Stroke length to be adjustable, both locally and by a control signal from the remote control room. Mechanical lost

OPERATIONS motion capacity adjustment is not permitted. Hydraulic lost motion capacity is not permitted for duties with motor

rating > 1 HP.

DATE Dosing will be designed for unattended and minimum operator intervention during normal operation and

automatic safe shutdown without the operator intervention

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

5

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS

PMT SAUDI ARABIAN OIL COMPANY

3.0 MECHANICAL DESIGN

3.1 Design Conditions

ENG'G CERT.

MWK

HCK

While the design conditions of the equipment and piping within the package shall be determined by the Vendor

based on the specified operating pressures (refer section 2.2) and criteria detailed in the Basic Engineering

SBK

SBK

Design Data, BEDD, and applicable Aramco standards, the following criteria shall be followed:

a) Design temperature shall be set at 50ºF above the maximum operating temperature. The minimum

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

upper design temperature shall be 185ºF (for solar gain, higher local temperature in summer).

b) The maximum operating temperature is defined as the highest material balance temperature.

Consideration shall also be given to other conditions such as start-up, shut-down etc. Such

temperatures should be considered on a case by case basis to establish if they should be taken as the

maximum operating temperature.

c) The minimum design temperature for which the package equipment must be designed will normally

be specified as the minimum operating temperature. Where there is no specified minimum design

temperature data the (metal - MMDT) temperature for this equipment 41°F shall be used.

DESCRIPTION

d) Design Pressure for pumped systems: process piping and equipment which form part of a pumped

hydraulic system, and which may operate liquid full, shall be designed for the maximum pressure that

can be developed by the pump.

e) A pressure relief valve must be installed on the pump discharge to vent fluid back into the chemical

tank or suction line if pressure builds up. The pump internal relief valve setting shall be between 110%

and 120% of the rated discharge pressure.

ISSUED FOR REVIEW

00-Jan-00 10-14329-0003 ISSUED FOR REVIEW

3.2 Materials of Construction

Materials of construction shall be selected by VENDOR in line with Company and Project standards. Materials

shall be appropriate for process design, compatible with all intended process fluids, and suitable for intended

application. Minimum material grade shall be SS316L. Wetted faces of instrumentation shall be compatible with

process fluid without coating or lining. VENDOR shall ensure material selections and coatings are suitable for

16-DEC-21 10-14329-0003

JO/EWO

external environment in accordance with BEDD requirements.

3.3 Noise

DATE

The Package shall be limited to a maximum noise level of 85dB(A) at 1m.

REV

NO.

3.4 Piping

A

DISCIPLINE

ENGINEER All threaded joints downstream of the pump discharge shall be seal welded.

SBK

DATE Piping to be adequately supported to avoid vibration. Pipes to be anchored at skid edge. Refer to SAES -L-310

00/01/1900

ENGINEERING MANAGER

Section 17.

JHK Y-strainers shall be installed on the suction to each pump.

DATE 00/01/1900

CERTIFIED Each pump shall have an external PSV with independent discharge line piped back to the tank above the high

high liquid level.

MWK

DATE 00/01/1900

Check valves shall be external type; not integral to any other inline fitting.

CONSTRUCTION AGENCY

Nozzle loads permitted at all terminal points shall be agreed with BUYER. ‘Zero Load’ condition shall not be

DATE accepted.

OPERATIONS

The three pumps shall have their discharge piping arranged so that:

DATE

- Each pump head is capable of delivering corrosion inhibitor to either train

CONTROL NUMBER

VERIFICATION

- Both heads of each pump are able to deliver to each train

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

6

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3) of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

3.5 Tanks

315

PMT

The storage tank shall be sized for 30 days storage at maximum dosing rate for two trains, minimum 133.5 ft3

ENG'G CERT.

(80 working volume).

MWK

HCK

Storage tank may be free standing if sizing prohibits skid mounting.

SBK

SBK

Tanks shall be manufactured in accordance with 32-SAMSS-030 by an approved Saudi Aramco fabricator.

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

VENDOR may propose a non-metallic tank as an alternative design for approval by Saudi Aramco. The Package

VENDOR shall complete tank data sheet Form SA-2696 for review by BUYER.

Chemical storage tanks shall, as a minimum, be equipped with fill nozzle, utility nozzle, vent, pressure relief,

overflow, discharge, low point drain, level and temperature instrumentation.

Connections smaller than 1½ " or smaller shall be gusseted to prevent potential damage.

Anti-swirl baffles (vortex breakers) shall be provided on liquid outlet nozzles upstream of a pump suction side.

Manways for vertical tanks shall be specified as follows:

DESCRIPTION

(1) One 750 mm (30 in) NPS shell manway.

(2) One 750 mm (30 in) NPS roof manway for tanks larger than 10,000 gallons capacity.

Tanks with mixers shall be provided with at least one manway that does not require removal of the mixer.

Tanks smaller than 36 inches in diameter shall be povided with minimum of two flanged NPS 4 openings.

10-14329-0003 ISSUED FOR REVIEW

ISSUED FOR REVIEW

Block valves shall be installed directly at the tank nozzles. If more than one line connects to the same nozzle,

valves shall be installed in each line, in addition to the nozzle block valve.

Connections for venting devices shall be designated only to provide protection against overpressure / vacuum

conditions. No other devices shall be installed in combination with venting devices without agreement with

BUYER.

18-FEB-22 10-14329-0003

JO/EWO

Tank shall be earthed to skid.

3.6 Calibration Tube

16-DEC-21

DATE

A clearly graduated calibration tube, vented back to tank above the high liquid level, shall be installed on the

suction piping to each chemical injection pump. Calibration tube shall be provided with all necessary valves

and fittings so the injection rate can be checked during operation.

REV

NO.

DISCIPLINE Calibration pot shall be robust design with calibrated toughened glass enclosed in steel guard.

ENGINEER

SBK

Main line chemical feed and calibration tube shut-off valves shall be ¼ turn ball valves and shall be positioned

DATE

such that the operator can easily and simultaneously operate both valves during calibration.

18-FEB-22

ENGINEERING MANAGER 3.7 Pumps

JHK Each pump shall be equipped with a variable speed drive and shall have two heads which can be

DATE 18-FEB-22 independently controlled. There shall be two discharge headers, one for injection at each train

CERTIFIED production manifold. The discharge from each pump head shall have connections to both headers.

Initially one head shall be dedicated to a line going to each train. If post start up experience shows more

MWK

DATE

chemical has to be injected than the capacity of one head, then both heads shall be dedicated to one

18-FEB-22

train.

CONSTRUCTION AGENCY

Dosing pumps shall be API 675, controlled volume positive displacement type. Pumps shall be provided from

Saudi Aramco approved manufacturer and meet the requirements of 31-SAMSS-009.

DATE

OPERATIONS

Pump shall be double diaphragm type with a diaphragm failure signalling system.

Pump shall have an electronic automatic adjustable stroke length, capable of being controlled remotely by a

DATE control signal from the control room and locally. Alteration of the stroke length shall be possible without shutting

the pump down.

CONTROL NUMBER

VERIFICATION

Each pump shall have an minimum operating capacity of 10 - 110% of the recommended dosing rate based on

stroke adjustment and further lower turndown possible based on variable speed drive.

EDSD

Each pump should be capable of being set to zero (no strokes per minute) for conditions when the condensate

DATE:

line is not in service.

BY:

Dosing pumps shall meet the specified area classification.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

Mechanical lost motion capacity adjustment is not permitted. Hydraulic lost motion capacity adjustment is not

REVISION CERTIFICATE

permitted for pumps with motors or higher than 0.746 kW (1 hp).

VENDOR to confirm that the pump hydraulic fluid is compatible with the intermediate fluid of the double

diaphragm and the process fluid.

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 7

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

3.8 Pulsation Damper

PMT

A pulsation damper is to ensure an even chemical application, shall be provided in each pump head discharge

line and shall be sized to provide sufficient degree of damping. Any fitting required for charging the pulsation

ENG'G CERT.

MWK

HCK

dampers shall be provided. Suppression devices shall be furnished as necessary to meet the following criteria.

Unfiltered peak to peak pulsation levels shall not exceed +/- 3% as per SABP-A-015 of:

SBK

SBK

• Rated suction pressure or 100 kPa gauge (15 psig) whichever is less;

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

• Rated discharge pressure or 100 kPa gauge (15 psig) whichever is less.

The following situations shall be avoided:

• Cavitation in the suction or discharge of the pump;

• Over delivery due to suction losses or uncontrolled delivery;

• Exceeding maximum allowable working pressure of pressure containing parts.

DESCRIPTION

Any fittings required for charging the pulsation dampers shall be securely connected to the discharge piping and

accessible from grade/skid. Pulsation dampers shall be designed so that no solids settle in the interior of these

devices.

4.0 CONTROL, SAFEGUARDING AND INSTRUMENTATION

The package / equipment shall be automated with equipment control, monitoring and safety functions

incorporated and controlled by the Supervisory Control & Data Acquisition (SCADA).

ISSUED FOR REVIEW

ISSUED FOR REVIEW

Safeguarding shall be incorporated in the Emergency Shutdown system (ESD). VENDOR shall provide the

functional specification for the control and logic diagrams or similar for the safeguarding.

The incorporation of the control in SCADA and safeguarding in the ESD is by Others.

The liquid corrosion inhibitor flow rate to injection point will be measured and flow controlled through the

16-DEC-21 10-14329-0003

18-FEB-22 10-14329-0003

SCADA. The injection pumps will have adjustable strokes that will be used to control the flow when the pumps

JO/EWO

are in remote mode.

The dosing package tank shall be provided with a local level gauge and 2 off level transmitters to provide remote

level indication, including high and low level alarms.

DATE

Temperature gauge shall be supplied on the tank for indication of bulk fluid temperature.

REV

NO.

The pumps shall be provided with a local panel with start/stop facility, emergency stop, selector switch and

DISCIPLINE running indication. Remote running indication, pump selection and pump start/stop/trip shall also be provided.

ENGINEER

Pump shall be provided with a selector switch for the standy pump to start on failure of the running

SBK

DATE pump.

18-FEB-22

ENGINEERING MANAGER Pressure indication shall be supplied on each pump suction and discharge line.

JHK Pressure and flow transmitters (coriolis) shall be supplied on the discharge lines per head.

DATE 18-FEB-22

CERTIFIED Double diaphragm pumps shall be provided with a diaphragm failure signal system.

MWK Instrumentation shall be wired to skid edge Junction Box or the local control panel. Wiring to the SCADA shall be

DATE 18-FEB-22 by Others.

CONSTRUCTION AGENCY

Control facilities to be provided to auto start standby-pump in case of operating pump trip.

Instrumentation and Control shall be in accordance with the minimum requirements specified in ‘Control and

DATE Instrumentation Basis of Design’, TD-821310, ‘Control & Instrumentation - Package Equipment’, TD-821303 and

OPERATIONS ‘Instrumentation for Packaged Units’, 34-SAMSS-831.

DATE

5.0 ELECTRICAL

CONTROL NUMBER

VERIFICATION

Corrosion Inhibitor Injection package is installed in an area classification: TBC.

EDSD

Hazardous Materials Schedule area classification for the Liquid Corrosion Inhibitor Package to be confirmed in

the Detail Design Enginnering phase once the Corrosion Inhibitor is selected.

DATE:

BY:

Chemical Hazardous Area Classification to be confirmed by EPC contractor during detailed engineering.

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B______

All electrical equipment shall be fully in accordance with Electrical Design Basis TD-821403 and Basic

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

Engineering Design Data TD-821950.

REVISION CERTIFICATE

All electrical equipment shall meet voltage levels and supply voltage variations as stated in Electrical Design

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

8

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS SAUDI ARABIAN OIL COMPANY

Electrical installation shall be in accordance with 'Auxiliary Electrical Systems for Skid-Mounted Equipment'

PMT

17-SAMSS-515, and all applicable referenced specifications and standards.

ENG'G CERT.

All electrical equipment shall meet ambient conditions as stated in Electrical Design Basis TD-821403.

MWK

HCK

All equipment installed in hazardous (classified) areas, electrical equipment/component meeting the

SBK

SBK

requirement of IEC 60079 shall be labelled, listed, or certified by any of the agencies in the Approved IECEx

Certification Bodies (ExCBs) under the IECEx Certified Equipment Scheme. Method of protection must be

marked and must correspond with NEC Article 505 requirements for suitable protection method(s) for the

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

hazardous area where the equipment is applied.

Vendor shall provide single-phase power outlets (120V) on the skid for maintenance purposes.

Vendor shall provide Low Voltage power panels and protection system as applicable Saudi Aramco

standards.

Power cablings to motors will be provided by CONTRACTOR directly to the motor terminal boxes. VENDOR

shall provide on-skid supporting cable tray for the incoming power cables.

DESCRIPTION

All on-skid grounding and bonding connection shall be wired to skid-edge earth busbars. CONTRACTOR shall

provide cabling up to these earth busbars. The grounding and bounding shall be as per SAES-P-111.

Electrical control cabling on skid shall be wired to skid-edge junction boxes by VENDOR. CONTRACTOR

shall provide control cabling up to these junction boxes.

Main drive motors shall be sized for relief valve settings including accumulation.

ISSUED FOR REVIEW

ISSUED FOR REVIEW

6.0 UTILITIES

Following utilities are envisaged to be required for the Liquid Corrosion Inhibitor Package. VENDOR to

indicate requirement of any other utilities.

- Electrical Power 460V / 3Phase / 60Hz (at Users)

16-DEC-21 10-14329-0003

18-FEB-22 10-14329-0003

JO/EWO

- Control Power 230V / 1Phase / 60Hz

- Utility Water

DATE

- Instrument Air

REV

NO.

For operating and design conditions of utilities, refer to the ‘Basic Engineering Design Data’ BEDD document -

A

DISCIPLINE TD-821950.

ENGINEER

SBK

DATE 18-FEB-22 7.0 NOTES

ENGINEERING MANAGER

1. Liquid Corrosion Inhibitor Injection skid will be installed in a relative humidity from zero to 100%

JHK (condensing) and exposed to heat and sand.

DATE 18-FEB-22

2. Skid mounted injection system shall be designed, inspected and tested as per 32-SAMSS-038. Nameplate

CERTIFIED

and stamping requirements shall follow 32-SAMSS-038..

MWK

DATE 18-FEB-22

3. Skid shall be equipped wit adequate drainage and drip tray in the event of chemical spill.

CONSTRUCTION AGENCY 4. VENDOR shall provide a complete P&ID for the Liquid Corrosion Inhibitor Package.

5. VENDOR shall identify all risks associated with the equipment and provide necessary measures for the

DATE elimination or minimisation of such risks. VENDOR shall supply all information necessary for the safe

OPERATIONS operation of the equipment, in particular to evaluate potential sources of ignition.

6. VENDOR shall include for any required special tools

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

9

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 2616-ENG(10/2002)

OPRNS

SAUDI ARABIAN OIL COMPANY

Pump Tag No TBC

PMT

Rev.0A

No. of Pumps 3x100% (1 duty/2 standby)

No. of Heads/Pump 2

CERT.

MWK

HCK

Service Liquid Corrosion Inhibitor

ENG'G

Chemical Ref. section 2.3

SBK

SBK

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Flow per Head USGPM Ref. section 2.2

Discharge Pressure psig Ref. section 2.2

TANK TANK MIXER Remove mixer requirement.

ACCESSORIES

Equip. No. TBC Equipment No. TBC Pulsation Dampeners. Suction / Discharge

315

Working Vol. 133.5 ft3 (min. 30 days) Manufacturer VTA Level Instruments: Gauge YES

Dia (ft) x Height (ft) VTA Model VTA High Alarm YES

Thickness VTA Impeller Dia VTA Low Alarm YES

Design Pressure Atmos. + static head Shaft Dia VTA Pump Trip YES

DESCRIPTION

Material VTA (NOTE 1) Shaft Length VTA Strainers: per System / Pump / Head

Corrosion allowance NIL Shaft Seal arrangement VTA Calibration: Level Gauge / Calibration Gauge

Lid YES Material Wetted Parts (Note 1) VTA Relief Valve External to Pump YES

Access YES Mounting Arrangement VTA Pressure Gauges ON DISCHARGE

Atmospheric Vent / Purge System VTA Motor 460 Volts 3 Ph 60Hz kW VTA Diaphragm failure signal system : YES

Dissolving Basket N/A Chemical Mixed VTA

Relief Valve N/A Mixing Time . VTA .

10-14329-0003 ISSUED FOR REVIEW

10-14329-0003 ISSUED FOR REVIEW

SKID DETAILS TERMINAL POINTS

DIMENSIONS WEIGHTS No. DUTY FLANGE SIZE FLANGE RATING

LENGTH VTA ft DRY VTA lbs TP01 CHEMICAL INLET VTA TBC

WIDTH VTA ft OPERATING VTA lbs TP02 DRAIN (TANK) VTA TBC

HEIGHT VTA ft SHIPPING VTA lbs TP03 DRAIN (PIPEWORK) VTA TBC

Sunshade VTA TP04 VENT (ANTI SIPHON) VTA TBC

JO/EWO

Lifting Lugs YES TP05 VENT (CALIBRATION POT) VTA TBC

Earthing Bosses YES TP06 DISCHARGE VTA TBC

16-DEC-21

18-FEB-22

VTA (NOTE 1) TBC TBC

DATE

Piping Spec: TP07 INSTRUMENT AIR

Hazardous Area Classification: TBC - See section 5 TP08 PULSATION DAMPER (VENT) TBC TBC

Weather Rating SEE BEDD DOCUMENT (TD-821950) TP09 PRESSURE GAUGE (VENT) TBC TBC

REV

NO.

A

DISCIPLINE

NOTES

ENGINEER

SBK

1) Materials of construction shall be suitable for the concentrated chemical solution. Refer to Section 3.2.

DATE 18-FEB-22

2) Equipment Tag Nos shall be confirmed by EPC Contractor during Detailed Design phase. will be finalized later.

ENGINEERING

3) VTA = Vendor to advise. TBC = To be confirmed.

MANAGER

JHK

DATE 18-FEB-22

CERTIFIED

MWK

DATE 18-FEB-22

CONSTRUCTION

AGENCY

DATE

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B______

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR INJECTION

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 10

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 8010-ENG(11/2010)

OPRNS

SAUDI ARABIAN OIL COMPANY

POSITIVE DISPLACEMENT PUMP DATA SHEET

NOTE: INDICATES INFORMATION TO BE COMPLETED BY THE PURCHASER; BY MANUFACTURER

PMT

DESIGN OPERATING DATA PERFORMANCE DATA

ENG'G CERT.

A. SERVICE E PUMP CHARACTERISTICS (REFER - NOTES 2, 3 & 4)

MWK

HCK

1. CONTINUOUS INTERMITTENT STAND BY 1. RATED CAPACITY USgal/hr

2. ATTENDED UNATTENDED 2. TURNDOWN RATIO

SBK

SBK

3. PUMP FUNCTION CORROSION INHIBITOR INJECTION 3. LINEARITY %

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

4. STEADY STATE ACCURACY %

B. LIQUID CHARACTERISTICS (HOLD) 5. FLOW REPEATABILITY %

1. LIQUID PUMPED LIQUID CORROSION INHIBITOR (TBC) 6. MAX./MIN. ALLOWABLE SPEED RPM -

2. FLOW TEMPERATURE °F AMB 7. MAX./MIN. ALLOWABLE TEMP. °F -

.1 MAX. FLOW TEMPERATURE °F 131 8. BHP CONS. AT MAX. CAPACITY (C.1)* BHP

3. SPECIFIC GRAVITY AT FLOW TEMP./ MAX. TEMP. 0.922 0.98 1.03 9. BHP CONS. AT MAX. CAP. AND 110% OF E.12* BHP

4. VISCOS. AT FLOW TEMP./ MAX. TEMP. cP 2.5 3.5 10. MAX. DISCH. PRESSURE psig

5. VAPOR PRESSURE AT FLOW TEMP. psi(a) 0.07 Negligible 11. MAX. RELIEF VALVE SETTING psig

DESCRIPTION

.1 V.P AT MAX. FLOW TEMP. psi(a) Negligible 12. ACTUAL RELIEF VALVE SETTING psig

6. PRINCIPAL CORROSIVES 0.07 13. PLUNGER DIAMETER in

14. STROKE LENGTH (MAX.) in

15. NPSHR AT MAXIMUM CAPACITY (NOTE

n 1) ft

.1 pH OR pH RANGE OF LIQUID PUMPED 16. MAX. ALLOW. WORKING PRESS.

C. RATED OPERATING CONDITIONS (REFER - NOTE 1) ( AT °F psig

MIN. MAX NORMAL 17. MINIMUM REQ. DIFFERENTIAL PRESS. psig

1.635 1.486

10-14329-0003 ISSUED FOR REVIEW

FOR REVIEW

1. CAPACITY RANGE Usgpm VTA

VTA 0.0019 VTA *) E.8 AND E.9 TO INCLUDE GEAR AND COUPLING LOSSES

Usgph 0.149

2. NPSH AVAILABLE AT SUCTION PORT ft VTA EQUIPMENT DATA

3. SUCTION PRESS. MIN/RATED psi(g) VTA VTA F. PUMP AND COUPLING MODEL,

18-FEB-22 10-14329-0003 ISSUED

4. TOTAL DIFFERENTIAL PRESSURE psi VTA WEIGHTS, LUBRICATION

5. RATED DISCHARGE PRESSURE psi(g) VTA 1. MANUFACTURER

6. LOCATION .1 TYPE/SIZE

JO/EWO

OFFSHORE ONSHORE OUTDOOR .2 SERIAL NUMBER(S)

7. AREA CLASSIFICATION TBC

VENDOR

16-DEC-21

DATE

CLASS ZONE GROUP TEMP. 2. PUMP EQUIPPED WITH : REQ'D

SUPPLY

8. SUCTION/DISCHARGE PIPE

.1 DRIVER ( INCL. COUPLING

TOTAL ACTUAL LENGTH ft / AND GUARD IF REQUIRED)

REV

NO.

A

INTERNAL DIAMETER in / .2 BASE PLATE

DISCIPLINE

.3 SUCTION STRAINER ( Y-TYPE )

ENGINEER

SBK D. PUMP/DRIVER/TRANSMISSION TYPE .4 SUCTION MANIFOLD

SUCTION PULSATION BOTTLE ( IF

DATE 1. PUMP TYPE .5

18-FEB-22 REQUIRED )

ENGINEERING

SIMPLEX

MANAGER .6 INTEGRAL ADJUSTABLE

SINGLE DIAPHRAGM DOUBLE DIAPHRAGM HYDRAULIC RELIEF VALVE

JHK

.7 DISCHARGE PULSATION BOTTLE ( IF

DATE PLASTIC DIAPHRAGM (S) METAL DIAPHRAGM (S)

18-FEB-22 REQUIRED )

CERTIFIED .8 DISCHARGE MANIFOLD

.1 SPEED OR SPEED RANGE RPM 3. COUPLING MAKE TYPE MODEL

MWK

DATE .2 DIRECTION OF ROTATION CW CCW 4. WEIGHTS

18-FEB-22

CONSTRUCTION

( LOOKING FROM DRIVING END ) 1. PUMP lbs

AGENCY

2. ELECTRIC MOTOR DRIVER CONST. SPEED 2. DRIVER ( INCL. COUPLING) TOTAL WEIGHT lbs

DATE VARIABLE SPEED 5. LUBRICANTS

OPERATIONS .1 SPEED/SPEED RANGE RPM .1 BEARING LUBRICANT ISO VG 46 (VTC)

.2 RATED BHP (EXCLUD. SERVICE FACTOR) BHP SAUDI ARAMCO EQUIV.

DATE .3 HORIZONTAL VERTICAL .2 LUBRICANT

.4 FLANGE MOUNTED FOOT MOUNTED SAUDI ARAMCO EQUIV.

CONTROL NUMBER

VERIFICATION

.5 SHAFT EXTENSION: STANDARD SPECIAL: .3 HYDRAULIC FLUID

EDSD

3 INTERMEDIATE TRANSMISSION SAUDI ARAMCO EQUIV.

GEAR BOX RATIO :

DATE:

MAKE AGMA FACTOR UTILITY DATA

BY:

MODEL G. UTILITIES

APPROVAL/CERTIFICATION REQUIREMENTS,

4. INTEGRAL SPEED REDUCER, TYPE 1. ELECTRIC POWER AVAILABLE

THIS INDICATES THAT REV NO ____B______

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

AC PHASE

RATIO : AGMA FACTOR DC VOLTS HERTZ

REVISION CERTIFICATE

5. COUPLING .1 MAIN ELECTRIC DRIVER AC DC 460 3PH / 60Hz

FLEXIBLE .2 CONTROL AC 230 1PH / 60Hz

NONE (INTEGRALLY MOUNTED)

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR INJECTION

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 11

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 8010-ENG(11/2010)

OPRNS SAUDI ARABIAN OIL COMPANY

POSITIVE DISPLACEMENT PUMP DATA SHEET

NOTE: INDICATES INFORMATION TO BE COMPLETED BY THE PURCHASER; BY MANUFACTURER

PMT

PUMP OPERATING DATA BUYER'S REFERENCE

ENG'G CERT.

H. MATERIALS OF CONSTRUCTION

MWK

HCK

ASTM OR EQUIVILANT 1. DRIVER DATA SHEET Page 12-13 (17-SAMSS-503)

1. LIQUID END VTA 2.

SBK

SBK

2. PLUNGER VTA 3.

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

3. CONTOUR PLATE VTA

4. HYDRAULIC DIAPHRAGM VTA NOTES

5. PLUNGER DIAPHRAGM VTA 1) Reported NPSHa is referenced at the pump center line and does not

6. PLUNGER PACKING VTA include any margin. Vendor to ensure NPSHa exceeds NPSHr

7. FRAME VTA by at least 3.3ft at rated flow. No further design margin is required

8. SUCTION PULSATION BOTTLE VTA when considering NPSHr at 120% of rated capacity.

9. DISCHARGE PULSATION BOTTLE VTA 2) Minimum pump differential pressure required to ensure guaranteed

10. CHECK VALVE/BALLS VTA accuracy shall be specified by Vendor.

DESCRIPTION

11. RELIEF VALVE, SEAT AND TRIM VTA 3) Single head positive displacement pump with variable stroke

12. BASEPLATE VTA length and control on pump head.

13. PIPEWORK VTA 4) Dose rate initially set using calibration pot. Subsequent increases or

decreases can be controlled through operator control of dose ratio

J. PUMP CONSTRUCTION in DCS.

1. PUMP NOZZLE

.1 SUCTION SIZE ASME RATING FACING POSITION

10-14329-0003 ISSUED FOR REVIEW

FOR REVIEW

THREADED IN. ASME B2.1 TAPERED

FLANGED IN.

18-FEB-22 10-14329-0003 ISSUED

.2 DISCHARGE SIZE ASME RATING FACING POSITION

THREADED IN. ASME B2.1 TAPERED

FLANGED IN.

JO/EWO

2 CAPACITY ADJUSTMENT

.1 MECHANICAL, TYPE

16-DEC-21

DATE

HYDRAULIC STROKE SPEED ADJUSTMENT

.2 ADJUST. WHILE RUNNING/AND DURING STAND STILL

.3 LOCAL MICROMETER REMOTE BOTH NOTES 3 & 4)

REV

NO.

A

.4 MANUAL INCL. LOCKING DEVICE AUTOMATIC

DISCIPLINE

.5 MANUAL TO AUTO SWITCH

ENGINEER

.6 4 20mA INPUT SIGNAL & 4 20mA REMOTE SIGNAL

SBK

DATE 18-FEB-22

3. PULSATION BOTTLES, TYPE

ENGINEERING

.1 SUCT.-VOL./CHARG. PRESS. cu.ft./psi(g)

MANAGER

.2 DISCH.-VOL./CHARG. PRESS. cu.ft./psi(g)

JHK

DATE 18-FEB-22

.3 CHARGING MEDIUM:

CERTIFIED 4. VALVES

.1 SUCTION VALVES SINGLE DOUBLE

MWK

DATE 18-FEB-22

SIZE BALL OTHER

CONSTRUCTION

.2 DISCHARGE VALVES SINGLE DOUBLE

AGENCY

SIZE BALL OTHER

DATE .3 BRINELL HARDNESS: VALVE SEAT

OPERATIONS 5. LUBRICATION

.1 PUMP, GEAR, BEARINGS

DATE SPLASH SUBMERGED FORCED - FEED

.2 DRIVER

CONTROL NUMBER

VERIFICATION

SPLASH SUBMERGED

EDSD

6. TYPE OF DOUBLE DIAPHRAGM PUMPS OF THE SAME TYPE & SIZE IN OPERATION

7. TYPE OF DOUBLE DIAPHR. RUPTURE SIGNALING PUMPS MARK NO. INQ./ORDER NO. DATA SHEET NO.

DATE:

REFER SECTION 4.0 -G-

BY:

8. VOLUMETRIC VENTING VALVE REQUIRED

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS DATA SHEET COVERS 2 PUMP(S)

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

K. SPECIAL REQUIREMENTS PUMPS MARK NO(S).

REVISION CERTIFICATE

PUMP TO COMPLY WITH 31-SAMSS-009

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 12

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 17-SAMSS-503 (04/00)

OPRNS SAUDI ARABIAN OIL COMPANY

17-SAMSS-503, SEVERE DUTY TOTALLY ENCLOSED SQUIRREL CAGE INDUCTION MOTORS

APPLICABLE TO: Inquiry Proposal Purchase As Built

PMT

Plant: JFGP JFGP Plant No. 863 Driven Equipment: LIQUID CORROSION INHIBITOR INJECTION

PUMP MOTOR - (TAG No. - TBC)

ENG'G CERT.

MWK

HCK

Purchaser’s Data to Be Supplied With Inquiry:

SBK

SBK

BASIC DATA

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Volts: 460 Phase: 3 Hertz: 60 Nameplate: kW hp

Full Load RPM: Speed Range for Variable Speed Drive:

Rotation When Facing Motor Opposite Drive End:

Clockwise Counter-Clockwise Bi-Directional

Motor Thrust Loads: None Other

Type Load: Direct Coupled Belt Driven Other

NEMA Torque Design: “B” (normal) Other (specify)

DESCRIPTION

SITE DATA

Area Classification: Non-Hazardous

Hazardous (Classified) Class: HOLD Zone HOLD Group: HOLD

Temperature Class: HOLD

Elevation (Specify if Above 3000 ft.): ft

STARTING

ISSUED FOR REVIEW

ISSUED FOR REVIEW

Full Voltage Reduced Voltage % and Type

Variable Frequency Drive Unit Type

VFD Details Attached (If motor purchased separately from drive unit.)

MOUNTING

10-14329-0003

10-14329-0003

Horizontal Vertical Shaft Up Vertical Shaft Down

JO/EWO

Foot Mounted Flange Mounted, NEMA Type

16-DEC-21

18-FEB-22

ENCLOSURE

DATE

TEFC TENV Explosion Proof Other

Main Terminal Box Conduit Hub Size: in.

REV

NO.

A

DISCIPLINE

ENGINEER Space Heaters

SBK Space Heater Required for motors rated less than 75kW (100HP); Operating Voltage: 120 V, 1 ph

DATE 18-FEB-22 Other Voltage Max. Surface Temp. at Operating Volts ºC

ENGINEERING

MANAGER Heater Leads: Main Terminal Box Separate Heater Terminal Box

JHK

DATE 18-FEB-22

CERTIFIED

MWK

DATE 18-FEB-22

CONSTRUCTION

AGENCY

DATE

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 13

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 17-SAMSS-503 (04/00)

OPRNS

SAUDI ARABIAN OIL COMPANY

17-SAMSS-503, SEVERE DUTY TOTALLY ENCLOSED SQUIRREL CAGE INDUCTION MOTORS

PMT

ENG'G CERT.

Vendor Data: LIQUID CORROSION INHIBITOR INJECTION PUMP MOTOR

MWK

HCK

GENERAL INFORMATION

SBK

SBK

Manufacturer Model Serial No.

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

MOTOR DATA

Rating Data at 1.0 Service Factor:

Nameplate Power kW (hp) Voltage 460 Phase 3 Hertz 60

Full Load Speed RPM Enclosure Type Frame Size

Rotation When Facing Motor Opposite Drive End:

Clockwise Counter-Clockwise Bi-Directional

DESCRIPTION

Torque:

Speed-Torque Curve No. Speed-Current Curve No.

Design Data at 1.0 Service Factor and Rated Voltage

No Load Current Amps

Load 25% 50% 75% Full

Amperes

ISSUED FOR REVIEW

ISSUED FOR REVIEW

Power Factor

Nominal Efficiency

Guaranteed Efficiency

Locked Rotor Amps at Rated Voltage

10-14329-0003

18-FEB-22 10-14329-0003

JO/EWO

Insulation System

Class Temperature Class ºC above ºC ambient at 1.0 SF

16-DEC-21

DATE

Bearing Information

Coupling End Bearing: Manufacturer’s Type Part No.

REV

NO.

A

Outboard End Bearing: Manufacturer’s Type Part No.

DISCIPLINE

ENGINEER

SBK Certification: Class Group Division Agency

DATE 18-FEB-22

ENGINEERING

MANAGER Weights/Dimensions

JHK Net Weight lb Rotor Weight lb

DATE 18-FEB-22

CERTIFIED Space Heaters: (Operating Conditions)

MWK Voltage V Wattage kW hp Max. Surface Temp. ºC

DATE 18-FEB-22

CONSTRUCTION

AGENCY

DATE

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B_____

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR INJECTION

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 14

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 17-SAMSS-503 (04/00)

OPRNS

SAUDI ARABIAN OIL COMPANY

17-SAMSS-503, SEVERE DUTY TOTALLY ENCLOSED SQUIRREL CAGE INDUCTION MOTORS

APPLICABLE TO: Inquiry Proposal Purchase As Built

PMT

Plant: JFGP Plant No. 863 Driven Equipment: LIQUID CORROSION INHIBITOR INJECTION

ENG'G CERT.

CHEMICAL TANK MIXER MOTOR - (TAG No. -

MWK

HCK

TBC)

Purchaser’s Data to Be Supplied With Inquiry:

SBK

SBK

BASIC DATA

Volts: 460 Phase: 3 Hertz: 60 Nameplate: kW hp

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Full Load RPM: Speed Range for Variable Speed Drive:

Rotation When Facing Motor Opposite Drive End:

Clockwise Counter-Clockwise Bi-Directional

Motor Thrust Loads: None Other

Type Load: Direct Coupled Belt Driven Other

NEMA Torque Design: “B” (normal) Other (specify)

DESCRIPTION

SITE DATA

Area Classification: Non-Hazardous

Hazardous (Classified) Class: HOLD Zone HOLD Group: HOLD

Temperature Class:

Elevation (Specify if Above 3000 ft.): ft

STARTING

ISSUED FOR REVIEW

ISSUED FOR REVIEW

Full Voltage Reduced Voltage % and Type

Variable Frequency Drive Unit Type

VFD Details Attached (If motor purchased separately from drive unit.)

MOUNTING

10-14329-0003

10-14329-0003

Horizontal Vertical Shaft Up Vertical Shaft Down

JO/EWO

Foot Mounted Flange Mounted, NEMA Type

16-DEC-21

18-FEB-22

ENCLOSURE

DATE

TEFC TENV Explosion Proof Other

Main Terminal Box Conduit Hub Size: in.

REV

NO.

A

DISCIPLINE

ENGINEER Space Heaters

SBK Space Heater Required; Operating Voltage: 120 V, 1 ph

DATE 18-FEB-22 Other Voltage Max. Surface Temp. at Operating Volts ºC

ENGINEERING

MANAGER Heater Leads: Main Terminal Box Separate Heater Terminal Box

JHK

DATE 18-FEB-22

CERTIFIED

MWK

DATE

18-FEB-22

CONSTRUCTION

AGENCY

DATE

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B______

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

INJECTION PACKAGE

JFGP INLET, STORAGE & EXPORT DAT

15

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

Saudi Aramco 17-SAMSS-503 (04/00)

OPRNS SAUDI ARABIAN OIL COMPANY

17-SAMSS-503, SEVERE DUTY TOTALLY ENCLOSED SQUIRREL CAGE INDUCTION MOTORS

PMT

ENG'G CERT.

Vendor Data: LIQUID CORROSION INHIBITOR CHEMICAL TANK MIXER MOTOR (TAG No - TBC)

MWK

HCK

GENERAL INFORMATION

SBK

SBK

Manufacturer Model Serial No.

THIS DRAWING AND THE INFORMATION CONTAINED WITHIN HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR PART SHALL BE OBTAINED FROM THE DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

MOTOR DATA

Rating Data at 1.0 Service Factor:

Nameplate Power kW (hp) Voltage 460 Phase 3 Hertz 60

Full Load Speed RPM Enclosure Type Frame Size

Rotation When Facing Motor Opposite Drive End:

Clockwise Counter-Clockwise Bi-Directional

DESCRIPTION

Torque:

Speed-Torque Curve No. Speed-Current Curve No.

Design Data at 1.0 Service Factor and Rated Voltage

No Load Current Amps

Load 25% 50% 75% Full

Amperes

10-14329-0003 ISSUED FOR REVIEW

10-14329-0003 ISSUED FOR REVIEW

Power Factor

Nominal Efficiency

Guaranteed Efficiency

Locked Rotor Amps at Rated Voltage

JO/EWO

Insulation System

Class Temperature Class ºC above ºC ambient at 1.0 SF

16-DEC-21

18-FEB-22

DATE

Bearing Information

Coupling End Bearing: Manufacturer’s Type Part No.

REV

NO.

A

Outboard End Bearing: Manufacturer’s Type Part No.

DISCIPLINE

ENGINEER

SBK Certification: Class Group Division Agency

DATE 18-FEB-22

ENGINEERING

MANAGER Weights/Dimensions

JHK Net Weight lb Rotor Weight lb

DATE 18-FEB-22

CERTIFIED Space Heaters: (Operating Conditions)

MWK Voltage V Wattage kW hp Max. Surface Temp. ºC

DATE 18-FEB-22

CONSTRUCTION

AGENCY

DATE

OPERATIONS

DATE

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV NO ____B______

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

(DCC) NO. ___________________________

REVISION CERTIFICATE

MECHANICAL DATA SHEET FOR LIQUID CORROSION INHIBITOR INJECTION

DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

PACKAGE

JFGP INLET, STORAGE & EXPORT DAT 16

863 U TE-419896-001

JFGP 2 Jafurah Utilities, Sulfur and Interconnecting Systems (Package 3)

of B

JAFURAH SAUDI ARABIA JO/EWO- 10-14329-0003 16

DOC CLASS: 2 DSN:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HE by Roberts - Robert SerthDocument2 pagesHE by Roberts - Robert Serthrizwan.zamanNo ratings yet

- How To Start Implementing Gasket Standardization ProgramDocument3 pagesHow To Start Implementing Gasket Standardization Programrizwan.zamanNo ratings yet

- Gasket Standardization - Why & HowDocument4 pagesGasket Standardization - Why & Howrizwan.zamanNo ratings yet

- Log-Based Mechanical EarthDocument26 pagesLog-Based Mechanical Earthrizwan.zamanNo ratings yet

- OISD-TopHol Hzard FDocument28 pagesOISD-TopHol Hzard Frizwan.zamanNo ratings yet

- A Learning From MistakesDocument23 pagesA Learning From Mistakesrizwan.zamanNo ratings yet

- Ta-249779-004 - C - P&id - Produced Water Chemcial Dosing - UpdatedDocument6 pagesTa-249779-004 - C - P&id - Produced Water Chemcial Dosing - Updatedrizwan.zamanNo ratings yet

- GI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)Document68 pagesGI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)rizwan.zamanNo ratings yet

- Mind Evaluation Questionaire - 12Document5 pagesMind Evaluation Questionaire - 12rizwan.zamanNo ratings yet

- TE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.BDocument13 pagesTE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Ta-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - UpdatedDocument1 pageTa-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - Updatedrizwan.zamanNo ratings yet

- Ta-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)Document1 pageTa-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)rizwan.zamanNo ratings yet

- Underground Blowout ControlDocument25 pagesUnderground Blowout Controlrizwan.zamanNo ratings yet

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- 80 SL 205 AT0240 A1AS (A2A) IH (IBR) - ModelDocument3 pages80 SL 205 AT0240 A1AS (A2A) IH (IBR) - Modelrizwan.zamanNo ratings yet

- 50 CL 205 55 At0258 A2as (A31a) PP (Ibr)Document1 page50 CL 205 55 At0258 A2as (A31a) PP (Ibr)rizwan.zamanNo ratings yet

- Memory WorkbookDocument48 pagesMemory Workbookrizwan.zaman100% (1)

- 50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- TE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.BDocument16 pagesTE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Steam Out (002) - 28.02.2023Document1 pageSteam Out (002) - 28.02.2023rizwan.zamanNo ratings yet

- STD 3 Road Signs To Draw in The Note BookDocument2 pagesSTD 3 Road Signs To Draw in The Note Bookrizwan.zamanNo ratings yet

- 50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- CH 1 Question AnswerDocument11 pagesCH 1 Question Answerrizwan.zamanNo ratings yet

- Valve ConsolidationDocument5 pagesValve Consolidationrizwan.zamanNo ratings yet

- Class 3 - IPO Cycle WorksheetDocument1 pageClass 3 - IPO Cycle Worksheetrizwan.zamanNo ratings yet

- CH 2 Class 6 Geography 1Document18 pagesCH 2 Class 6 Geography 1rizwan.zamanNo ratings yet

- Z2K RT CS 215044Document5 pagesZ2K RT CS 215044rizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come FromDocument3 pagesImportant Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come Fromrizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 7 Getting To Know PlantsDocument6 pagesImportant Question For Cbse Class 6 Science Chapter 7 Getting To Know Plantsrizwan.zamanNo ratings yet

- Important Questions For CBSE Class 6 Maths Chapter 2 Whole NumbersDocument4 pagesImportant Questions For CBSE Class 6 Maths Chapter 2 Whole Numbersrizwan.zamanNo ratings yet