Professional Documents

Culture Documents

How To Start Implementing Gasket Standardization Program

How To Start Implementing Gasket Standardization Program

Uploaded by

rizwan.zamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Start Implementing Gasket Standardization Program

How To Start Implementing Gasket Standardization Program

Uploaded by

rizwan.zamanCopyright:

Available Formats

che.

com

Archives Quick Search

reader services | show previews | editorial submissions | subscribe | home

Engineering - Design

Sep 1st, 2003 Print this article

Our Resources Also...

• CE Buyers' Guide

How to START ImplementING a Gasket Standardization: Why and

• CE Buyers' Guide Gasket-Standardization Program How

Update

By Chemical Engineering Editorial Staff How to START ImplementING a

• Preferred Suppliers Gasket-Standardization Program

• Media Kit

Step 1: What kinds of piping do I have? Conduct a review

• Search Archive of all the piping systems in your facility, including FRP, glass- In Previous Issues...

lined steel, and steel. How much of each do you have, and

Editorial Departments

how many flanges are involved?

• Bookshelf

• Cover Story

• Design The difference in piping is important. Glass-lined steel is used

for aggressive chemicals. Because it is easily damaged if too Front Page

• Editor's Page

• Engineering Practice

much torque is applied, it requires a gasket material that can

seal at low bolt loads, and is dimensionally stable in width yet

• Environmental Manager

conformable in height. FRP piping is similar to glass-lined

• ePlant

steel, but without the macro deviations to the flange. It

• Feature Report

requires a conformable material, in many cases an elastomer

• Letters gasket, which can accomplish a gastight seal at very low

• Operations stresses (below 1,500 psi). By contrast, steel flanges can be

and Maintenance used with any material, because high stresses can be applied.

• Pristine Processing Standardization within steel allows for uniform stress across

• Solids Processing all piping systems, but the key is standardizing on a high-

• You and Your Job performance material to eliminate any “weak links” and

improve the overall reliability of your piping system.

News

- Calendar

- Chementator Step 2: What gasketing materials am I using now? You

might be surprised at the number of different materials that

- Economic Indicators

are currently being employed for gaskets. It is in fact possible

- Kirkpatrick Award

to identify several materials being used in each type of pipe

Winners

flange, such as:

- Newsfront

New Products For FRP piping:

- Focus

- Monthly New PTFE envelope elastomer

Products Domestic

- Monthly New

Other elastomer

Products International

Advertisers Filled PTFE

• Literature Review

Expanded PTFE

For glass-lined steel piping:

PTFE-enveloped compressed synthetic fiber

Expanded PTFE

For steel piping:

Filled PTFE (silicone, barium sulfate, or glass)

file://///Specserver/F/Users/P%20Daga/Technical...ntING%20a%20GasketStandardization%20Program.htm (1 of 3) [8/28/2006 11:49:03 AM]

che.com

Graphite

Compressed synthetic fiber

Skived PTFE

Expanded PTFE

Metallic gaskets ( such as spiral wound)

The diameter of the pipe has no bearing on the gasket

materials you use; the key is the right type of gasket material

for the type of piping. Do not forget special considerations for

situations such as highly toxic fluids, slurries, or sanitary

processing, where the choice of gasket material really makes

a difference in chemical inertness, purity, high tightness, and

low stress to seal.

Step 3: How can I reduce the number of gasketing

materials I use? Typically, you’ll want to divide your

processes into those that are below 600°F. and those that are

above, as well as those processes that generate less than

1,500 psi internal pressure versus those that generate more.

Another consideration, affecting hydrocarbon processing in

particular, is the strict requirement for fire and blowout

protection. Make sure that you select a gasket that seals

properly at low stress levels – gastight at 100 psi internal

pressure at a gasket stress of 250 psi – and can successfully

seal all applicable piping gastight according to the

manufacturer’s recommended torque. This will greatly simplify

maintenance based on piping glass, not on the gasket

material used.

Step 4: Where can I go for guidance? Gasket distributors

usually possess a wealth of information about the performance

characteristics of the gasketing products they supply. Another

source consists of the gasket manufacturers themselves. The

manufacturer’s or distributor’s help in answering the following

questions can help you narrow your gasketing materials down

to just a few:

• For what types of piping is the material suitable? Many

gasketing materials will not be suitable for all the piping that

you have in your plant.

• Can I use this material for all chemicals? Which ones aren’t

acceptable?

• What are the maximum temperature and pressure for which

the material is suitable? Above/below 600°F? Above/below

1,000 psi?

• Is the material metallic? (The answer is of relevance for

flammable fluids and high-temperature or high-pressure

applications, as well as the need for gaskets that resist fire

and blowout.) Or is it nonmetallic? (For non-metallic gaskets

capable of above 1,000 psig using flanges of the 600- and 900-

lb class, you should contact the manufacturer for specific

installation instructions.)

file://///Specserver/F/Users/P%20Daga/Technical...ntING%20a%20GasketStandardization%20Program.htm (2 of 3) [8/28/2006 11:49:03 AM]

che.com

• How well does the material seal at low stress levels (e.g.,

below 1,500 psi)? What stress is required to get a T-3 gastight

seal? This information is particularly important for considering

glass-lined or FRP flanges.

• What is the leak-retention capability of the gasketing

relative to alternative materials? This information provides you

with the gross leak rate at given stress levels, which helps

confirm the achievable tightness of the seal and can aid you in

claiming overall emission reduction for pipe flanges once

standardization is implemented. (According to the European

Sealing Assn., process pipe flanges account for 5 to 25% of

overall VOC emissions at a plantsite)

If you follow the steps above, you’ll likely be able reduce the

number of gasketing materials used in your facility,

simplifying your life and reducing both complexity and risk. In

addition, you may well find that your actual gasketing costs

will remain the same, or even decrease.

Home | Editorial Submissions | Subscribe | Media Kit | Archive | Buyers Guide | Events

Copyright 2000 Chemical Week Publishing

110 William St., New York, 10138. Tel: (212) 621-4900; Fax: (212) 621-4949

[Privacy Policy] [Contact Us]

All rights reserved. Reproduction in whole or in part, in any form or medium without express written permission is prohibited.

file://///Specserver/F/Users/P%20Daga/Technical...ntING%20a%20GasketStandardization%20Program.htm (3 of 3) [8/28/2006 11:49:03 AM]

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HE by Roberts - Robert SerthDocument2 pagesHE by Roberts - Robert Serthrizwan.zamanNo ratings yet

- OISD-TopHol Hzard FDocument28 pagesOISD-TopHol Hzard Frizwan.zamanNo ratings yet

- Mind Evaluation Questionaire - 12Document5 pagesMind Evaluation Questionaire - 12rizwan.zamanNo ratings yet

- Gasket Standardization - Why & HowDocument4 pagesGasket Standardization - Why & Howrizwan.zamanNo ratings yet

- GI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)Document68 pagesGI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)rizwan.zamanNo ratings yet

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- Log-Based Mechanical EarthDocument26 pagesLog-Based Mechanical Earthrizwan.zamanNo ratings yet

- Memory WorkbookDocument48 pagesMemory Workbookrizwan.zaman100% (1)

- A Learning From MistakesDocument23 pagesA Learning From Mistakesrizwan.zamanNo ratings yet

- Underground Blowout ControlDocument25 pagesUnderground Blowout Controlrizwan.zamanNo ratings yet

- TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.BDocument16 pagesTE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.Brizwan.zamanNo ratings yet

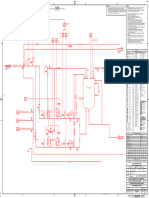

- Ta-249779-004 - C - P&id - Produced Water Chemcial Dosing - UpdatedDocument6 pagesTa-249779-004 - C - P&id - Produced Water Chemcial Dosing - Updatedrizwan.zamanNo ratings yet

- TE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.BDocument16 pagesTE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- TE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.BDocument13 pagesTE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Ta-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - UpdatedDocument1 pageTa-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - Updatedrizwan.zamanNo ratings yet

- Ta-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)Document1 pageTa-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)rizwan.zamanNo ratings yet

- 80 SL 205 AT0240 A1AS (A2A) IH (IBR) - ModelDocument3 pages80 SL 205 AT0240 A1AS (A2A) IH (IBR) - Modelrizwan.zamanNo ratings yet

- Class 3 - IPO Cycle WorksheetDocument1 pageClass 3 - IPO Cycle Worksheetrizwan.zamanNo ratings yet

- 50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- 50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- 50 CL 205 55 At0258 A2as (A31a) PP (Ibr)Document1 page50 CL 205 55 At0258 A2as (A31a) PP (Ibr)rizwan.zamanNo ratings yet

- Steam Out (002) - 28.02.2023Document1 pageSteam Out (002) - 28.02.2023rizwan.zamanNo ratings yet

- Valve ConsolidationDocument5 pagesValve Consolidationrizwan.zamanNo ratings yet

- Z2K RT CS 215044Document5 pagesZ2K RT CS 215044rizwan.zamanNo ratings yet

- CH 2 Class 6 Geography 1Document18 pagesCH 2 Class 6 Geography 1rizwan.zamanNo ratings yet

- CH 1 Question AnswerDocument11 pagesCH 1 Question Answerrizwan.zamanNo ratings yet

- Important Questions For CBSE Class 6 Maths Chapter 2 Whole NumbersDocument4 pagesImportant Questions For CBSE Class 6 Maths Chapter 2 Whole Numbersrizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 7 Getting To Know PlantsDocument6 pagesImportant Question For Cbse Class 6 Science Chapter 7 Getting To Know Plantsrizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come FromDocument3 pagesImportant Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come Fromrizwan.zamanNo ratings yet

- STD 3 Road Signs To Draw in The Note BookDocument2 pagesSTD 3 Road Signs To Draw in The Note Bookrizwan.zamanNo ratings yet