Professional Documents

Culture Documents

A Learning From Mistakes

A Learning From Mistakes

Uploaded by

rizwan.zamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Learning From Mistakes

A Learning From Mistakes

Uploaded by

rizwan.zamanCopyright:

Available Formats

Engineers India Limited

CASE STUDIES

– A LEARNING FROM MISTAKES

Delivering Excellence Through People

October 06, 2022

Case Study-1

Brief description of Incident:-

- Excavation for drain work was in progress at Site by deploying an excavator which was being

operated by an operator.

- The bed level of the drain was being recorded by surveyor and the victim was holding the

leveling staff inside the excavated trench of drain under consideration (depth-1.2 to 1.5 mtrs).

- After completion of the task, victim was trying to come out from excavated trench.

- However, to come out of the trench, victim had opted to use excavator’s bucket. As the

operator was trying to move the bucket for reaching an approximate height of 2 Mtrs above the

bed level, during this process, victim lost his body balance & fell inside the trench and sustained

injury/pain in his neck area.

- Victim was rescued immediately by nearby workers and shifted to nearest local hospital.

Delivering Excellence Through People

2

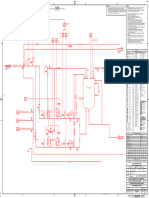

Photograph

Delivering Excellence Through People

3

Case Study-1

Probable Cause of Incident:

- After completion of the task, victim was trying to come out from excavated trench where

excavated earth was already kept like a bund (with an average height of approx.1 Mtr.).

- However, to come out of the trench, he had opted to use excavator’s bucket instead of walking

approximately 15 mtrs along the length of the trench.

- He was already holding a Levelling Staff and with that he stepped into the excavator’s bucket,

signaled the operator to lift the bucket.

- As the operator was trying to move the bucket, upon attaining an approximate height of 2 Mtrs.

because of it’s sideways movement and jerking, victim lost his body balance, fell into the

trench, and sustained injury in his neck area.

Delivering Excellence Through People

4

Case Study-1

Lesson Learnt / Recommendations:

- Proper access (i.e. ladder or ramp arrangements) to be provided at the interval of Max. 15-20 m

for going down and coming up in each and every excavated area (foundation/ trench etc.).

- Do’s and Don’ts of heavy mobile equipment (e.g. excavators/dozers/hydra etc.) in pictorial form

to be pasted in operator’s cabin.

- Operators of the excavators to be sensitized that excavators are not meant for lifting workmen

or shifting of materials and they should not allow any worker to get into the bucket of

excavators.

- Signal Man shall be available all the time during heavy mobile equipment operations.

Delivering Excellence Through People

5

Case Study-2

Brief description of Incident:-

- A worker along with team entered inside the Sump for assigned job.

- While he was performing the chipping activity by using electrical hand breaker at the bottom

end of pile head for removal of the pile head suddenly the pile head gave away at mid point

during this process.

- Resulting in victim sustained severe cut injury on his left leg. He was rescued immediately by

nearby workers.

- Subsequently victim was shifted to hospital for medical treatment.

Delivering Excellence Through People

6

Photograph

Delivering Excellence Through People

7

Case Study-2

Probable Cause of Incident:

- The Victim had chipped 0.8mtr of the pile head approximately from pile cut of level (height of

pile head was found 2.4mtrs from the cut off level) to expose the steel reinforcement and

subsequently cut all exposed reinforcement by grinding machine.

- While he started making V-Groove on bottom of the pile head at pile cut off level by using

electrical hand breaker during this process Pile head sheared from 1.6mtrs due to vibration and

fell down on the victim left leg.

Delivering Excellence Through People

8

Case Study-2

Lesson Learnt / Recommendations:

- More emphasis on job specific tool box talk to be conducted for working crew by the concerned

job supervisor and all associated hazards to be communicated to workers.

- Availability of immediate job supervisor to be ensured prior to start any critical activities

- Before breaking the pile head, wherever pile casting is done 1.5mtrs beyond the pile cut off

level anchoring should be done by providing minimum two numbers of Guy Rope which will be

anchored in earth/adjacent pile prior to start of chipping, so that fall of pile head can be

ensured in the desired direction (opposite to chipper).

- After exposing the reinforcement and bending the same outwards, concrete block (concrete

free from reinforcement) should be removed safely by farana/suitable equipment /manually

under supervision of job engineer/supervisor of contractor.

Delivering Excellence Through People

9

Case Study-3

Brief description of Incident:-

- The victim along with fellow worker was engaged for de-shuttering works of RCC foundation

when the incident happened.

- The victim was standing on the concrete surface by the side of the foundation and was trying to

remove shuttering supports.

- Apparently due to recent rains, the soil condition might have loosened which could have

resulted into collapse of side soil and the victim got stuck up in between the shuttering board

and collapsed soil heap.

- He was immediately rescued by site personnel and shifted to Occupational Health Center by

Ambulance.

- Subsequently, the victim was shifted to Apollo Hospital for medical treatment.

Delivering Excellence Through People

10

Photograph

Delivering Excellence Through People

11

Case Study-3

Probable Cause of Incident:

- Excavated loose soil was stacked nearby the excavated pit. Due to effect of the rain and/or

activities being performed by the victim, the side soil collapsed into the pit.

- In previous day rain, the pit was filled with some rainwater, which might have weakened the toe

of the excavated pit.

- This workplace was very near to main material entry road on which heavy vehicles were plying

on regular basis which might have produced vibrations leading to weakening of the side soil.

Delivering Excellence Through People

12

Case Study-3

Lesson Learnt / Recommendations:

- Suitable side slope/step cutting to be adopted wherever excavation is carried out. Edges of

excavated area to be protected by providing shoring & strutting.

- Excavated soil to be kept minimum 1.5 meter away from the edge of the excavated pit or

removed

- Safety points mentioned in HIRAC/JSA for activity to be implemented at workplace.

- Avoid dividing/separation wall between two adjacent excavated pit/area. Further, deep

excavation should not be kept open for a longer duration.

- Hard barricading to be ensured all around the excavated pit.

- Vehicles movement should be restricted minimum three meters away from the excavated pit.

Hard barricading with warning signage to be ensured.

- Recent excavation/backfilling history of area to be known & shared among all concerned

working crew and construction activities to be planned accordingly.

Delivering Excellence Through People

13

Case Study-4

Brief description of Incident:-

- Two workers were engaged in scaffold dismantling activity at 72.0mtrs height in Technological

Structure.

- One worker (victim) has mistakenly dismantled the scaffold pipe in which he was anchoring his

full body safety harness & got unbalanced resulting in victim fell down from 72.0mtrs height to

ground level and sustained severe injury on his body.

- The victim was immediately rescued by nearby workers and shifted to Hospital by ambulance.

However, he succumbed to his injuries.

Delivering Excellence Through People

14

Photograph

Delivering Excellence Through People

15

Photograph

Delivering Excellence Through People

16

Case Study-4

Probable Cause of Incident:

- The injured worker was engaged in scaffold dismantling activity along with one more worker.

- During the investigation, it was found that the injured person might have first opened farther

side clamp and then the clamp of scaffolding pipe tightened with column and after that he

might be trying to open the third clamp, before that he got unbalanced and fallen down,

during falling some jerks might came on the scaffold pipe on which he had anchored his

harness due to that the scaffold pipe got opened and his harness hook slipped from the

scaffold pipe and he fell down to the ground.

- Non availability of secondary fall protection measures like Retractable type fall arrestor.

Delivering Excellence Through People

17

Case Study-4

Lesson Learnt / Recommendations:

- Job specific Tool Box Talk to be carried out by immediate supervisor prior to start the

construction activity. In generic nature Tool Box Talk to be avoided.

- Specialized Training to be ensured among workers prior to deploy them at workplace for all

critical activity.

- Erection / modification/ dismantling activity of scaffold to be carried out in sequential

manner.

- Availability of secondary fall protection measures like Retractable type fall arrestor to be

ensured.

Delivering Excellence Through People

18

Case Study-5

Brief description of Incident:-

- Pile boring work was under progress in Flare area by Hydraulic Rotary Drilling Rig, during this process a

fault was detected in Radiator suction hose pipe by rig machine operator.

- The faulty Hose pipe was replaced & Mechanic checked Rig Machine for running & positioned the

Kelley in vertical position thereafter operator switch off the Rig Machine & came out from the Cabin of

the Rig Machine.

- During site visit in flare area by night shift supervisors, noticed that a fire caught in Rig Machine.

- Site Staff immediately tried to extinguish the fire by using the fire extinguishers but they were unable

to control the fire & thereafter immediately intimated to Fire & Safety Dept., staff rushed to incident

spot and controlled the fire by using the Fire Tender.

Delivering Excellence Through People

19

Photograph

Delivering Excellence Through People

20

Case Study-5

Probable Cause of Incident:

- Since Pile boring works by Hydraulic Rig was under progress in close proximity of

running flare and after closing the day activity, Rig Machine was switched off and was

left as is condition by the operator in unmanned position at the same working

location.

- Therefore, Fire ball from Flare vertical riser might have fallen on the floor of Hydraulic

Rig Machine, which must have been wet with diesel, a flammable substance, has

resulted in fire inside the Hydraulic Rig Machine.

Delivering Excellence Through People

21

Case Study-5

Lesson Learnt / Recommendations:

- Hydraulic rig machine or any diesel /petrol driven equipment must be

relocated/parked in safe location after completion of day activity.

- No equipment’s/vehicles shall be kept in unmanned condition in flare area.

- Strict supervision by site supervisors/engineers needs to be implemented for work

and also availability of supervisory staff must be ensured at all work places during

changeover of shift.

- Arrangement of adequate quantity of fire extinguishers to be ensured at workplace to

meet the any exigency.

- Regular inspection of equipment’s to be done by experienced P&M Person.

Delivering Excellence Through People

22

Insert the Sub Title of Your Presentation

THANK YOU

Delivering Excellence Through People

23

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HE by Roberts - Robert SerthDocument2 pagesHE by Roberts - Robert Serthrizwan.zamanNo ratings yet

- How To Start Implementing Gasket Standardization ProgramDocument3 pagesHow To Start Implementing Gasket Standardization Programrizwan.zamanNo ratings yet

- Gasket Standardization - Why & HowDocument4 pagesGasket Standardization - Why & Howrizwan.zamanNo ratings yet

- Log-Based Mechanical EarthDocument26 pagesLog-Based Mechanical Earthrizwan.zamanNo ratings yet

- OISD-TopHol Hzard FDocument28 pagesOISD-TopHol Hzard Frizwan.zamanNo ratings yet

- GI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)Document68 pagesGI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)rizwan.zamanNo ratings yet

- TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.BDocument16 pagesTE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.Brizwan.zamanNo ratings yet

- Mind Evaluation Questionaire - 12Document5 pagesMind Evaluation Questionaire - 12rizwan.zamanNo ratings yet

- Memory WorkbookDocument48 pagesMemory Workbookrizwan.zaman100% (1)

- TE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.BDocument13 pagesTE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Ta-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - UpdatedDocument1 pageTa-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - Updatedrizwan.zamanNo ratings yet

- Ta-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)Document1 pageTa-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)rizwan.zamanNo ratings yet

- Underground Blowout ControlDocument25 pagesUnderground Blowout Controlrizwan.zamanNo ratings yet

- Ta-249779-004 - C - P&id - Produced Water Chemcial Dosing - UpdatedDocument6 pagesTa-249779-004 - C - P&id - Produced Water Chemcial Dosing - Updatedrizwan.zamanNo ratings yet

- 80 SL 205 AT0240 A1AS (A2A) IH (IBR) - ModelDocument3 pages80 SL 205 AT0240 A1AS (A2A) IH (IBR) - Modelrizwan.zamanNo ratings yet

- 50 CL 205 55 At0258 A2as (A31a) PP (Ibr)Document1 page50 CL 205 55 At0258 A2as (A31a) PP (Ibr)rizwan.zamanNo ratings yet

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- 50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- TE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.BDocument16 pagesTE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Steam Out (002) - 28.02.2023Document1 pageSteam Out (002) - 28.02.2023rizwan.zamanNo ratings yet

- STD 3 Road Signs To Draw in The Note BookDocument2 pagesSTD 3 Road Signs To Draw in The Note Bookrizwan.zamanNo ratings yet

- 50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- CH 1 Question AnswerDocument11 pagesCH 1 Question Answerrizwan.zamanNo ratings yet

- Valve ConsolidationDocument5 pagesValve Consolidationrizwan.zamanNo ratings yet

- Class 3 - IPO Cycle WorksheetDocument1 pageClass 3 - IPO Cycle Worksheetrizwan.zamanNo ratings yet

- CH 2 Class 6 Geography 1Document18 pagesCH 2 Class 6 Geography 1rizwan.zamanNo ratings yet

- Z2K RT CS 215044Document5 pagesZ2K RT CS 215044rizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come FromDocument3 pagesImportant Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come Fromrizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 7 Getting To Know PlantsDocument6 pagesImportant Question For Cbse Class 6 Science Chapter 7 Getting To Know Plantsrizwan.zamanNo ratings yet

- Important Questions For CBSE Class 6 Maths Chapter 2 Whole NumbersDocument4 pagesImportant Questions For CBSE Class 6 Maths Chapter 2 Whole Numbersrizwan.zamanNo ratings yet