Professional Documents

Culture Documents

HE by Roberts - Robert Serth

HE by Roberts - Robert Serth

Uploaded by

rizwan.zamanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HE by Roberts - Robert Serth

HE by Roberts - Robert Serth

Uploaded by

rizwan.zamanCopyright:

Available Formats

5/198 DESIGN OF SHELL-AND-TUBE HEAT EXCHANGERS

5.7.2 Tubing selection

The most frequently used tube sizes are 3/4 and 1 in. For water service, 3/4 in., 16 BWG tubes are

recommended. For oil (liquid hydrocarbon) service, 3/4 in., 14 BWG tubes are recommended if

the fluid is non-fouling, while I in., 14 BWG tubes should be used for fouling fluids. Tube lengths

typically range from 8 to 30 ft, and sometimes longer depending on the type of construction and the

tubing material. A good value to start with is 16 or 20 ft.

5.7.3 Tube layout

Triangular and square layouts are the most common, but rotated square pitch is also used. A fourth

configuration, rotated triangular pitch, is seldom used. With triangular pitch the tubes are more

closely packed in the bundle, which translates to more heat-transfer surface in a given shell and

somewhat higher pressure drop and heat-transfer coefficient. However, the clearance between tubes

is typically the larger of 0.25 in. and 0.25 Do, and with triangular pitch this is not sufficient to allow

cleaning lanes between the tube rows. Although chemical cleaning may be possible, triangular

pitch is usually restricted to services with clean shell-side fluids. Rotated square pitch provides

some enhancement in the heat-transfer coefficient (along with higher pressure drop) compared

with square pitch, while still providing cleaning lanes between the tubes. This configuration is

especially useful when the shell-side Reynolds number is relatively low (less than about 2000).

To summarize, the most commonly used tube layouts are either triangular or square, with a pitch

of 1.0 in. (for 3/4-in. tubes) or 1.25 in. (for 1-in. tubes).

5.7.4 Tube passes

For typical low-viscosity process streams, it is highly desirable to maintain fully developed turbu-

lent flow in the tubes. Although this may not be practical with high viscosity liquids, turbulent

flow provides the most effective heat transfer. Once the tube size and number of tubes have been

determined, the number of tube passes can be chosen to give an appropriate Reynolds number, i.e.,

Re- 4rhnp > 104 (5.27)

rcDint# -

Except for single-pass exchangers, an even number of tube passes is almost always used so

that the tube-side fluid enters and exits at the same header. With U-tubes, this is the only feasible

arrangement, and accommodating nozzles on internal (type S or T) floating heads in order to provide

an odd number of passes is very cumbersome.

Fluid velocity can also be used as a criterion for setting the number of tube-side passes. It is

desirable to maintain the liquid velocity in the tubes in the range of about 3-8 ft/s. Too low a velocity

can cause excessive fouling, while a very high velocity can cause erosion of the tube wall. Some

material-specific maximum velocities are given in Appendix 5.B. Harder tubing materials, such as

steel, can withstand somewhat higher velocities than softer metals such as copper or aluminum, for

example. Maximum vapor velocities are also given in Appendix 5.B.

5.7.5 Shell and head types

Shell and head types were presented in Figure 3.3. The single pass type E shell is standard. If multiple

shell passes are required, as indicated by the logarithmic mean temperature difference(LMTD)

correction factor, E shells can be connected in series. Alternatively, a two-pass type F shell can be

used, although the longitudinal baffle may be subject to leakage. An F Shell can also be used with

two tube passes to obtain the equivalent of a 1-1 (true counter flow) exchanger. The other shell

types listed in Figure 3.3 are used for more specialized applications, including reboilers (G, H, K,

X) and units, such as condensers and gas coolers, that require low shell-side pressure drops (J, X).

The most important consideration with respect to head type is fixed tubesheet versus floating head.

A fixed-tubesheet design is cheaper and less prone to leakage. However, the tube bundle cannot

be removed to clean the exterior surfaces of the tubes. Therefore, fixed-tubesheet exchangers

D E S I G N OF S H E L L - A N D - T U B E HEAT E X C H A N G E R S 5/199

are usually restricted to services with clean shell-side fluids. Also, if the temperature difference

between the two inlet streams is greater than about 100~ an expansion joint is required in the

shell of a fixed-tubesheet exchanger to accommodate the differential thermal expansion between

the tubes and shell. The added cost of the expansion joint largely offsets the cost advantage of the

fixed-tubesheet design.

With floating-head and U-tube exchangers, the entire tube bundle can be pulled out of the shell

from the front (stationary head) end. This allows mechanical cleaning of the exterior tube surfaces,

usually by high-pressure jets of water, steam or supercritical carbon dioxide. (Of course, square

or rotated square pitch must be used to provide cleaning lanes.) Also, since only one tubesheet is

attached to the shell (at the front end), the tubes are free to expand or contract relative to the shell

due to temperature differences.

Another consideration with respect to head type is bonnet versus channel. Bonnets are cheaper

and less prone to leakage. However, to gain access to the tubesheet for inspecting or cleaning

the tubes, the stationary head must be disconnected from the process piping and removed from

the shell. With a channel-type head, access to the tubesheet is obtained simply by unbolting and

removing the channel cover. Thus, a channel-type stationary head is preferable if the tubes will

require frequent cleaning.

Other factors that may affect the choice of head type are given in Appendix 5.D. The most widely

used floating-head design in the process industries is the AES exchanger. U-tube exchangers are

less expensive and are also widely used. The advent of equipment for cleaning the interiors of

U-tubes using high-pressure water jets has mitigated the problem of cleaning the return bends,

leading to increased use of these exchangers [10].

5.7.6 Baffles and tubesheets

Single segmental baffles are standard and by far the most widely used. In order to provide good

flow distribution on the shell side, the spacing between baffles should be between 0.2 and 1.0 shell

diameters (but not less than 2 in.). However, the maximum baffle spacing may be limited by tube

support and vibration considerations to less than one shell diameter [11,12] (see also Appendix

5.C). As previously noted, the no-tubes-in-window option can be used to extend the baffle spacing

in these situations. For good flow distribution, the baffle cut should be between 15% and 45%. For

single-phase flow, however, a range of 20-35% is recommended [9]. With the Simplified Delaware

method, the baffle cut is fixed at 20%.

Although baffle spacing and baffle cut are ostensibly independent parameters, in practice they

are highly correlated. Figure 5.4 shows the recommendations given by Taborek [11], who states:

"A sound design should not deviate substantially from the recommended values, which are based

on a vast amount of practical experience as well as on studies of the shell-side flow patterns." If the

baffle cut is set at 20% for the Simplified Delaware method, then Figure 5.4 indicates that the baffle

spacing should be in the range of 0.2 to about 0.4 shell diameters for single-phase flow.

Baffle thickness is not required for the Simplified Delaware method, but it is used in the Stream

Analysis method and in commercial computer programs. It varies from 1/16 to 3/4 in., and generally

increases with shell size and baffle spacing. If this parameter is not specified as input, most computer

programs will default to the standard values given in Table 5.2.

Tubesheet thickness is another parameter used in commercial computer programs. It varies

from about 1 to 6 in., and generally increases with shell size and operating pressure. As a rough

approximation, a value equal to the larger of I in. and 0.1 times the shell ID can be used [11]. Detailed

methods for calculating required tubesheet thickness based on bending and shear stresses are given

in Ref. [12].

5.7.7 Nozzles

Nozzles can be sized to meet pressure drop limitations and/or to match process piping. The

guidelines given by Kern [4] and reproduced in Table 5.3 are useful as a starting point.

Other considerations in sizing nozzles are tube vibration and erosion. The fluid entering the shell

through the inlet nozzle impinges directly on the tube bundle. If the inlet velocity is too high,

excessive tube vibration and/or erosion may result. TEMA specifications to prevent tube erosion

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- OISD-TopHol Hzard FDocument28 pagesOISD-TopHol Hzard Frizwan.zamanNo ratings yet

- Mind Evaluation Questionaire - 12Document5 pagesMind Evaluation Questionaire - 12rizwan.zamanNo ratings yet

- A Learning From MistakesDocument23 pagesA Learning From Mistakesrizwan.zamanNo ratings yet

- How To Start Implementing Gasket Standardization ProgramDocument3 pagesHow To Start Implementing Gasket Standardization Programrizwan.zamanNo ratings yet

- GI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)Document68 pagesGI Home Furniture Range Catalogue v3L July2020 (Full, Low-Res)rizwan.zamanNo ratings yet

- TE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.BDocument13 pagesTE-419893-001 - 862-U-2902 - HYPOCHLORITE DOSING PACKAGE - Rev.Brizwan.zamanNo ratings yet

- Gasket Standardization - Why & HowDocument4 pagesGasket Standardization - Why & Howrizwan.zamanNo ratings yet

- TE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.BDocument16 pagesTE-419896-001 - 863-U-3002 - Liquid Corrosion Inhibitor Injection Package - Rev.Brizwan.zamanNo ratings yet

- Memory WorkbookDocument48 pagesMemory Workbookrizwan.zaman100% (1)

- Underground Blowout ControlDocument25 pagesUnderground Blowout Controlrizwan.zamanNo ratings yet

- Log-Based Mechanical EarthDocument26 pagesLog-Based Mechanical Earthrizwan.zamanNo ratings yet

- TE-419843 - Rev.A - MR For Chemical Injection PackageDocument76 pagesTE-419843 - Rev.A - MR For Chemical Injection Packagerizwan.zamanNo ratings yet

- TE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.BDocument16 pagesTE-419892-001 - 862-U-2302 - COOLING WATER SYSTEMS CHEMICAL INJECTION PACKAGE - Rev.Brizwan.zamanNo ratings yet

- 80 SL 205 AT0240 A1AS (A2A) IH (IBR) - ModelDocument3 pages80 SL 205 AT0240 A1AS (A2A) IH (IBR) - Modelrizwan.zamanNo ratings yet

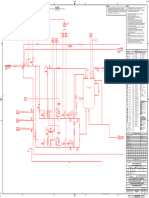

- Ta-249779-004 - C - P&id - Produced Water Chemcial Dosing - UpdatedDocument6 pagesTa-249779-004 - C - P&id - Produced Water Chemcial Dosing - Updatedrizwan.zamanNo ratings yet

- Ta-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - UpdatedDocument1 pageTa-249771-011 - C - P&id - Gas Corrosion Inhibitor Injection Package - Updatedrizwan.zamanNo ratings yet

- Valve ConsolidationDocument5 pagesValve Consolidationrizwan.zamanNo ratings yet

- 50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0248 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- 50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 ModelDocument1 page50 CL 205 AT0246 A2AS (A31A) PP (IBR) - SHT - 1 Modelrizwan.zamanNo ratings yet

- Ta-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)Document1 pageTa-249813-022 - C - P&id - BFW Chemical Dosing Package (Oxygen Scavenger)rizwan.zamanNo ratings yet

- STD 3 Road Signs To Draw in The Note BookDocument2 pagesSTD 3 Road Signs To Draw in The Note Bookrizwan.zamanNo ratings yet

- Steam Out (002) - 28.02.2023Document1 pageSteam Out (002) - 28.02.2023rizwan.zamanNo ratings yet

- CH 2 Class 6 Geography 1Document18 pagesCH 2 Class 6 Geography 1rizwan.zamanNo ratings yet

- 50 CL 205 55 At0258 A2as (A31a) PP (Ibr)Document1 page50 CL 205 55 At0258 A2as (A31a) PP (Ibr)rizwan.zamanNo ratings yet

- Class 3 - IPO Cycle WorksheetDocument1 pageClass 3 - IPO Cycle Worksheetrizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 7 Getting To Know PlantsDocument6 pagesImportant Question For Cbse Class 6 Science Chapter 7 Getting To Know Plantsrizwan.zamanNo ratings yet

- Z2K RT CS 215044Document5 pagesZ2K RT CS 215044rizwan.zamanNo ratings yet

- Important Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come FromDocument3 pagesImportant Question For Cbse Class 6 Science Chapter 1 Food Where Does It Come Fromrizwan.zamanNo ratings yet

- CH 1 Question AnswerDocument11 pagesCH 1 Question Answerrizwan.zamanNo ratings yet

- Important Questions For CBSE Class 6 Maths Chapter 2 Whole NumbersDocument4 pagesImportant Questions For CBSE Class 6 Maths Chapter 2 Whole Numbersrizwan.zamanNo ratings yet