Professional Documents

Culture Documents

A320-214 Transit Check Sheet Pictorial Issue-07 Dated Jul 19,2021

Uploaded by

nobertadilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A320-214 Transit Check Sheet Pictorial Issue-07 Dated Jul 19,2021

Uploaded by

nobertadilCopyright:

Available Formats

Pakistan International Airlines

Engineering & Maintenance Department

A320-200 Transit Check Card Page 1 of 4

(Card #: A320-PK-TR) Issue-07 Dated Jul 19,2021

Item Task Description

0.00 Arrival Items

Ensure following tasks are accomplished:

Wheel chocks are in position.

Towing lever in “ Towing Position” and pin installed

Carry out safety check of flight compartment for proper

position of Controls.

Energize the aircraft electrical network.

Upon arrival of the aircraft and prior to removal of cargo,

Inspect the Forward and Aft cargo door surrounds and sealing

sections for damage.

Review Aircraft Technical Log,Post Flight Report(PFR) and

undertake corrective action as required (Ref :RRB approval

No:RRB/3/A320-003/21)

1.00 Walk Around Check

1.01 General visual inspection of forward fuselage.

Overpressure indicator of crew oxygen supply green disc in

place.

Radome: no damage or evidence of lightning strike, latches

positively locked.

Static ports, pitot tubes, temperature probe, angle of attack

sensor normal condition

Static ports: no distortion (for example: scratches, dents etc)

around the static ports in the area of red marks on the fuselage.

Note: Visual inspection of RVSM

Perform visual check / inspection of skin Air inlet and outlet

Valves for any Blockage ( as directed in the Minutes of RRB

meeting # 05/21 )

Pakistan International Airlines

Engineering & Maintenance Department

A320-200 Transit Check Card Page 2 of 4

(Card #: A320-PK-TR) Issue-07 Dated Jul 19,2021

Item Task Description

1.02 General visual inspection of nose landing gear and wheel well.

Shock absorber sliding tube: correct extension, cleanliness.

Torque links: safe fasteners to secure the nut on the center hinge

in position

Wheels: rim damage, sheared/missing tie bolts

Tires: wear, damage

1.03 General visual inspection of lower center fuselage.

Anti-collision light, Landing lights clean and no damage

Antennas: no damage

Passenger oxygen cylinder overboard discharge indicator: green

disc in place. (if applicable)

1.04 General visual inspection of RH power plant and pylon

Inlet cowls, acoustic panels, nose domes, visible fan blades: no

damage

T12(CFM56) sensor in place

Fan exhaust: acoustic lining, exit vanes and thrust reverser

blocker-doors no damage

Turbine exhaust: 4th stage LPT blades(CFM56), nozzle and tail-

cone no damage and no metal or oil deposit

Drain mast and pylon drain: no obstruction and evidence of

leakage

Engine nacelle and pylon exterior: no damage and leakage,

cowlings and access panels closed and locked

1.05 General visual inspection of RH wing.

Wing engine anti-ice lights clean and no damage

Navigation light, strobe light clean and no damage

Fuel tank overpressure protective cell in the normal position

Static dischargers in place

1.06 General visual inspection of right main landing gear and wheel well.

Shock absorber sliding tube: correct extension, cleanliness.

Torque links: safe fasteners to secure the nut on the center

hinge in position

Wheels: rim damage, sheared/missing tie bolts

Tires: wear, damage

No leakage or overheating on brake units, heat-pack wear

indicators normal

Pakistan International Airlines

Engineering & Maintenance Department

A320-200 Transit Check Card Page 3 of 4

(Card #: A320-PK-TR) Issue-07 Dated Jul 19,2021

Item Task Description

1.07 General visual inspection of empennage and APU area, including:

Logo light and Navigation: no damage.

Fuselage tail skid for damage of ground contact during take off.

Outflow valve :no obstruction

THS, elevators, Fin and rudder

Air intake: flap normal

Red discharge indicator of APU extinguisher in place

Static dischargers in place

1.08 General visual inspection of LH main landing assembly according to

following:

Shock absorber sliding tube: correct extension, cleanliness.

Torque links: safe fasteners to secure the nut on the center hinge

in position

Wheels: rim damage, sheared/missing tie bolts

Tires: wear, damage

No leakage or overheating on brake units, heat-pack wear

indicators normal

1.09 General visual inspection of LH wing, according to following:

Wing engine anti-ice lights clean and no damage

Navigation light, strobe light clean and no damage

Fuel tank overpressure protective cell in the normal position

Static dischargers in place

1.10 General visual inspection of LH power plant and pylon, according to

following:

Inlet cowls, acoustic panels, nose domes, visible fan blades: no

damage

T12(CFM56) sensor in place

Fan exhaust: acoustic lining, exit vanes and thrust reverser

blocker-doors no damage

Turbine exhaust: 4th stage LPT blades(CFM56), nozzle and

tail-cone no damage and no metal or oil deposit

Drain mast and pylon drain: no obstruction and evidence of

leakage

Engine nacelle and pylon exterior: no damage and leakage,

cowlings and access panels closed and locked

Pakistan International Airlines

Engineering & Maintenance Department

A320-200 Transit Check Card Page 4 of 4

(Card #: A320-PK-TR) Issue-07 Dated Jul 19,2021

Item Task Description

2.00 Cockpit Check

2.01 a) Review technical logbook and cabin note book to undertake corrective actions as

required-

bFor modified Latch L1 of Fan cowl Doors- Check that the Keys (1000KM1 and

1000KM2) are required to open FCDs and to be placed in the box at the back of the LG pins

stowage location in coat stowage area after FCDs are closed and secured, place the keys back

in the same.

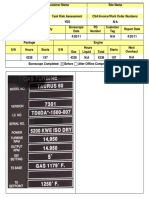

For CFM56: check engine oil quantity on ECAM LOWER DISP. ENG. PAGE in the

2.02 limitation of14.5 quart within 5-30 minutes after engine shut-down. If indication is below the

standard hereinbefore, check engine oil level at tank sight-glass, top-up as required with

BP Turbo oil 2380 and record uplift(s) in technical log book.

WARNING:DO NOT REMOVE THE ENGINE OILTANK CAP FOR 5 MINUTES

AFTER ENGINE SHUT-DOWN

Refer latest AMM : 12-13-79 for Engine OIL Servicing.

3.00 Servicing Check and Dispatch

3.01 Obtain fuel samples from bouser prior to refueling & check for water contamination. Fuel

sampling & fuel contamination check to be performed by refueller and to be witnessed by

Certifying Staff for fuel contaminationcheck of source, prior to departure".(Ref :RRB

approval No: RRB/01/A320-004/21 , dated 18/02/2021)

Make sure if the aircraft down time more than 1.5 hours and no operation with all

engines after fuel filling, fuel drainage and check must be done before next flight (more

than 1.5 hours & no engine running) YES / NO

3.02 Ensure all the routine work finished and signed off, all the faults have been rectified or

deferred legally.

3.03 Fill out the TechnicalLog Book and sign off for dispatch.

3.04 Carry out a final A/C walk around before towing or running the engine:

Ensure all cabin doors, cargo compartment doors and service panels are

properly closed and secured.

Ensure no damage has been caused by ground equipment or during baggage

loading.

Ensure the door and access panel of the potable water and toilet system is no

evidence of any leakage.

Ensure the refuel access panel is in place and secured and no evidence of

leakage.

3.05 Visually check around the aircraft before closing cabin doors, Ensure:

No leakage occurs at the access panels of the potable water and toilet system.

The refuel access panel is properly closed, and no leakage is found.

You might also like

- B737NG Walk-AroundDocument14 pagesB737NG Walk-AroundSli Der100% (3)

- YF-22 Prototype Demonstrates Thrust Vectoring ManeuverabilityDocument13 pagesYF-22 Prototype Demonstrates Thrust Vectoring Maneuverabilityscg0015No ratings yet

- AIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610From EverandAIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610No ratings yet

- Pilot Manual Transporting Mach 4Document468 pagesPilot Manual Transporting Mach 4Sinazo100% (2)

- JAR25 Change 11Document467 pagesJAR25 Change 11uanaa hyy71% (7)

- SAAB 35 Draken 3.0 Flight ManualDocument80 pagesSAAB 35 Draken 3.0 Flight Manualrpiereck100% (2)

- Exec 90 Maintenance Manual 3 03Document95 pagesExec 90 Maintenance Manual 3 03najmul100% (1)

- Effective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Document3 pagesEffective From 17.07.19 PFI Boeing 737NG & MAX Issue 5, Rev-8Naresh Kumar PrajapatNo ratings yet

- B1900D Check Lists PRO Lite Vr1.1Document99 pagesB1900D Check Lists PRO Lite Vr1.1jorge100% (7)

- Cirrus SR22 Systems DescriptionsDocument13 pagesCirrus SR22 Systems DescriptionsGourav DasNo ratings yet

- Boeing B 737 NG - Exterior InspectionDocument56 pagesBoeing B 737 NG - Exterior InspectionAakash SawaimoonNo ratings yet

- JT15D Ata 75Document12 pagesJT15D Ata 75Egor8550% (2)

- Asme 19.2 1987Document145 pagesAsme 19.2 1987Popescu Alin100% (3)

- PC-12 Series 10 - CH1 Aircraft GeneralDocument36 pagesPC-12 Series 10 - CH1 Aircraft GeneralBjorn Dahlen100% (1)

- Aircraft InstrumentsDocument38 pagesAircraft Instrumentsmonawar100% (8)

- PA 38 TomahawkDocument38 pagesPA 38 TomahawkEric MOUNIENo ratings yet

- AF-5000 Install Manual GuideDocument245 pagesAF-5000 Install Manual Guidewilfredo jose guaricucoNo ratings yet

- Undercowl Pocket Guide RRDocument32 pagesUndercowl Pocket Guide RRbnmmauricio100% (3)

- Helicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsFrom EverandHelicopter Maneuvers Manual: A step-by-step illustrated guide to performing all helicopter flight operationsRating: 5 out of 5 stars5/5 (1)

- A320-200 WEEKLY CHECK (Daily) : Airworthiness ManagementDocument7 pagesA320-200 WEEKLY CHECK (Daily) : Airworthiness ManagementOmair Aziz Rabbani100% (3)

- Crane Insp Work SheetDocument3 pagesCrane Insp Work SheetPao Barillas100% (1)

- Giv QRHDocument592 pagesGiv QRHKellee Valentine100% (13)

- Prifligh 737 MaxDocument6 pagesPrifligh 737 MaxPipe'steam CastrillonNo ratings yet

- A319/A320/A321 Transit CheckDocument2 pagesA319/A320/A321 Transit CheckHiram ThomasNo ratings yet

- Flight InstrumentsDocument48 pagesFlight InstrumentsBonty MwashiNo ratings yet

- b737ng Walk AroundDocument10 pagesb737ng Walk AroundAnonymous afPplXbcNo ratings yet

- b737ng Walk AroundDocument10 pagesb737ng Walk AroundAnonymous afPplXbcNo ratings yet

- 767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07Document3 pages767-05-20-04 B767 48 HR SERVICE CHECK (ELAPSED TIME) TFL, Iss 07samyghallabNo ratings yet

- B737-300F Aircraft Daily ChecklistDocument10 pagesB737-300F Aircraft Daily ChecklistUmer JavedNo ratings yet

- CSP 900rmm 3 - I1r12p PDFDocument942 pagesCSP 900rmm 3 - I1r12p PDFrobinyNo ratings yet

- A320 Family Line Maintenance Task Card - Weekly Check: CockpitDocument4 pagesA320 Family Line Maintenance Task Card - Weekly Check: CockpitSuman BajracharyaNo ratings yet

- Weekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFDocument10 pagesWeekly Check A320 (ISSUE 01 REV 00 01-JUN-15) PDFSabeeka BatoulNo ratings yet

- Boroscopeo Turbina PDFDocument9 pagesBoroscopeo Turbina PDFegr00No ratings yet

- Transit A320 R 17Document9 pagesTransit A320 R 17Vinay100% (2)

- Quick Engine Change and CowlsDocument4 pagesQuick Engine Change and CowlsLahu KureNo ratings yet

- Emirates Daily CHK B777 Rev.99 (Qaf0336) PDFDocument12 pagesEmirates Daily CHK B777 Rev.99 (Qaf0336) PDFabu72100% (1)

- 2AB Daily Check A319Document8 pages2AB Daily Check A319Umer JavedNo ratings yet

- EC-135 T1 (CDS) Normal ProceduresDocument16 pagesEC-135 T1 (CDS) Normal ProceduresHighspeed Flyboy100% (1)

- 11.5.1 Instrument Systems (ATA 31) - B1 - NewDocument178 pages11.5.1 Instrument Systems (ATA 31) - B1 - NewEvaldNo ratings yet

- Boeing 737: Preflight CheckDocument4 pagesBoeing 737: Preflight CheckDenysadenisaNo ratings yet

- Transit CheckDocument2 pagesTransit Checka.teamwork2016No ratings yet

- Neo-Stayover-Check R5 PDFDocument11 pagesNeo-Stayover-Check R5 PDFLE THAI HONG VINHNo ratings yet

- Trip Check A330Document4 pagesTrip Check A330Omair Aziz RabbaniNo ratings yet

- 412 MM CH95Document50 pages412 MM CH95Ibrahim AsifNo ratings yet

- A320 36-Hour Checklist: Nose to Tail Visual InspectionDocument15 pagesA320 36-Hour Checklist: Nose to Tail Visual InspectionThax NgeNo ratings yet

- 767-05-20-02 B767 PRE FLIGHT CHECK Iss 22Document2 pages767-05-20-02 B767 PRE FLIGHT CHECK Iss 22samyghallabNo ratings yet

- Transit 737-400 19th September 2016Document4 pagesTransit 737-400 19th September 2016Iftikhar JawedNo ratings yet

- ATR 72 Pre-Flight and Anti-Sabotage ChecklistDocument6 pagesATR 72 Pre-Flight and Anti-Sabotage ChecklistRahul Unnikrishnan100% (1)

- A320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsDocument32 pagesA320 Daily Check Sheet (N) Issue 20 Dated Oct 29,2021 With NOV 2021 Task CardsnobertadilNo ratings yet

- Transit Pre Flight Task Card AirbusDocument8 pagesTransit Pre Flight Task Card AirbusAbhijeet ChinchaneNo ratings yet

- 737-05-20-02-JT - PRE FLIGHT Iss 01 Rev 02Document2 pages737-05-20-02-JT - PRE FLIGHT Iss 01 Rev 02samyghallabNo ratings yet

- Daily Checksheet 1Document8 pagesDaily Checksheet 1demi.carson0001No ratings yet

- 737-05-20-02-NG - PRE FLIGHT Iss 13Document2 pages737-05-20-02-NG - PRE FLIGHT Iss 13samyghallabNo ratings yet

- Aircraft Useful Info - Must ReadDocument10 pagesAircraft Useful Info - Must Readsyedumarahmed52No ratings yet

- Module 7 (Maintenance Practices) Sub Module 7.18 (Aircraft Disassembly, Inspection, Repair and Assembly Techniques) PDFDocument67 pagesModule 7 (Maintenance Practices) Sub Module 7.18 (Aircraft Disassembly, Inspection, Repair and Assembly Techniques) PDFshareyhou0% (1)

- Ceo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFDocument2 pagesCeo - Insa320ttw019 - Issue - 01 - Pre Flight Check PDFLE THAI HONG VINHNo ratings yet

- Weekly Check A320 PDFDocument7 pagesWeekly Check A320 PDFTDHNo ratings yet

- Weekly Check A320Document7 pagesWeekly Check A320TDHNo ratings yet

- 01 Preflight CheckpdfDocument4 pages01 Preflight CheckpdfM Lio MelendezNo ratings yet

- QA AssesmentDocument6 pagesQA AssesmentBanglar Song -বাংলার গানNo ratings yet

- Daily Check PDFDocument6 pagesDaily Check PDFMUHANDES UKRAINENo ratings yet

- Daily Check A320 (Issue 02 Rev 04)Document8 pagesDaily Check A320 (Issue 02 Rev 04)Junaid YounusNo ratings yet

- PMS 2Document3 pagesPMS 2Manuel CoronelNo ratings yet

- Asb 80 0182Document6 pagesAsb 80 0182Donald SimsNo ratings yet

- Section 2 Normal ProceduresDocument38 pagesSection 2 Normal ProceduresFidel ArellanoNo ratings yet

- Aircraft Disassembly, Inspection, Repair TechniquesDocument63 pagesAircraft Disassembly, Inspection, Repair TechniquesAamir JavaidNo ratings yet

- Aviation Maintenance Alerts July 2006 Issue Provides Updates on Aircraft, Engine, and Component IssuesDocument192 pagesAviation Maintenance Alerts July 2006 Issue Provides Updates on Aircraft, Engine, and Component IssuesAllyamacita NaibahoNo ratings yet

- Weekly Check A320 (Issue 02 Rev 05)Document13 pagesWeekly Check A320 (Issue 02 Rev 05)Junaid YounusNo ratings yet

- Answers (1) (2) (1) (1) (1) (1) 1Document3 pagesAnswers (1) (2) (1) (1) (1) (1) 1tirunehdefaru1No ratings yet

- Aeroplane EssaysDocument12 pagesAeroplane EssayscollinsNo ratings yet

- 5-30Document4 pages5-30Sergio LópezNo ratings yet

- Final Report Piston Engine Practical IiDocument18 pagesFinal Report Piston Engine Practical IiLubi Adam FakihNo ratings yet

- 737-05-20-05 JT - 14 DAY Iss 01 Rev 02Document3 pages737-05-20-05 JT - 14 DAY Iss 01 Rev 02samyghallabNo ratings yet

- For Aircraft LearningDocument4 pagesFor Aircraft Learningkairol nizam bin mansorNo ratings yet

- Checking Turbocharger Charge PressureDocument17 pagesChecking Turbocharger Charge Pressurejromero_rpgNo ratings yet

- Air Crash Investigations - Uncontained Engine Failure - The Accident of Delta Air Flight 1288From EverandAir Crash Investigations - Uncontained Engine Failure - The Accident of Delta Air Flight 1288No ratings yet

- Bombardier CRJ 200-Flight InstrumentsDocument134 pagesBombardier CRJ 200-Flight InstrumentsJuan Daniel Granada Arias100% (3)

- Visual Tutorial: Adobe (Formerly Macromedia) Flash RequirementsDocument14 pagesVisual Tutorial: Adobe (Formerly Macromedia) Flash RequirementsBuican GeorgeNo ratings yet

- Preston Pressure PS 425 Operation and Maintenance Manual PDFDocument19 pagesPreston Pressure PS 425 Operation and Maintenance Manual PDFtest1No ratings yet

- WS.1933.31JAN24 - Annual InspectionDocument3 pagesWS.1933.31JAN24 - Annual InspectionpauucoxNo ratings yet

- Static Pitot Tube: Flow MeasurementDocument23 pagesStatic Pitot Tube: Flow MeasurementMuthu KarthikNo ratings yet

- Kas297a Altitude Selector Im 006 00512 0002 2Document21 pagesKas297a Altitude Selector Im 006 00512 0002 2Marcus DragoNo ratings yet

- North Carolina Wing - Aug 2009Document20 pagesNorth Carolina Wing - Aug 2009CAP History LibraryNo ratings yet

- TX 3022 Independent InspectionDocument33 pagesTX 3022 Independent Inspectionเอกราช เจริญผลNo ratings yet

- Instrument Nav Test SolvedDocument16 pagesInstrument Nav Test SolvedPunyaaNo ratings yet

- 25 Questions Answers That Every Pilot Should Know-1Document5 pages25 Questions Answers That Every Pilot Should Know-1arebuNo ratings yet

- BOEING 737-Resumo Checks ManutençãoDocument4 pagesBOEING 737-Resumo Checks ManutençãoWendler PaivaNo ratings yet

- Savannah Flight ManualDocument38 pagesSavannah Flight ManualFabian cardonaNo ratings yet

- Basics of aircraft control surfacesDocument12 pagesBasics of aircraft control surfacesSantosh KumarNo ratings yet