Professional Documents

Culture Documents

BION-HSE-20-000-Iaccident Investigation Report

Uploaded by

Syed AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BION-HSE-20-000-Iaccident Investigation Report

Uploaded by

Syed AhmadCopyright:

Available Formats

ACCIDENT

BSB-HSE-20-000 (Page 1 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

1.0 Purpose

Applicable to major accidents including fatalities,permanent disabilities, major occupational illnesses or damage to property,

other major occurences such as fire, emergencies, legal notice and explosin or major environmental incident, product recall

which can or may have a severe impact to the image of the company.To be reported within 24-Hours (Overall Time Limit)

2.0 Background

Company : Pintaras Geotechnic Sdn Bhd Address : No 8 jln Majistret U1/26,

Telephone : 03-55691516 Hicom Glenmarie Industrial Park,

Date of Incident : 7/15/2020 40150,Shah Alam,

Time of Incident : 6:00 PM Selangor Darul Ehsan

Location of Accident : Riveria City Phase 2,Brickfield Time of Work : Overtime

Machinery Involved : SUMITOMO LS118 (SC500) 50 TON

Equipment I/D : RH2

Crane Reg No. : PMA 84961 Pma Validity 10-Dec-20

Crane Operator Muhamad Ulul Azmi Bin Zainuddin Jkkp Reg. : KN/17/OK/03/00169

Licence valid : 3/14/2021

Investigation Teams :-

Project manager - Mr. daniel Chan Project Engineer - Mr. Azri Kamal

Site Manager - Mr. Leslie nga Sr.Site Supervisor - Mr. Fadzly

PME Dept.Manager - Mr. Leornad swee Site Supervisor - Mr. Megat

Safety Health Officer - Mr. Nazlly

Site Safety Supervisor - Mr. Syed Omar

Investigation Tool Kit :-

1) Record Book 6) Barrier Tape

2) Statement record form 7) Mechanical Tool

3) Camera 8) PPE

4) Torch light

5) Measuring Tape

Others (Please Specify) :

On the day of the incident,the concrete work for Pilecap CB8 Pile no 14&15 in Tower 1 zone 3

were carried out.The work is Incharge by Project Engineer,Site supervisor with two General worker and

Crane operator.Concrete work has been start at 05:30 Pm and is expected to be complete by 07:00 pm.

This concretet work are using a concrete supplier from Buildcon concrete sdn bhd and from Bukit Bintang

Plant and the total concrete is 25m3.An incident was occurred at 0615 Hrs while hoisting concrete from

concrete truck to discharged onto pilecap.

Further details on the accident are presented in initial report explaining the details of the incident before

during and after,The report is attach together.Refer attachment 1

Revision November 2020

ACCIDENT

BSB-HSE-20-000 (Page 2 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

3.0 Method of Investigation

4P Fish Bone Diagram

People Position

EF

T FEC

Parts Papers

3.1 People (Person Involved/person Incharged)

– Identified person Involved

– Interviewing Injured Person,Person Incharged and others.

– Get a statement Immediately

– Interviewing Witness

3.2 Position

– Document the accident area before any changes are made.

i. Location victim

ii. The position of each witness

iii. Sources of machinery,Energy and Chemicals

iv. Other contributing factor

– Take pictures of the incident and draw a scale of diagram.

– Record the size

3.3 Parts

Identify and Record :-

Parts of machinery,building around the accident area before,during or after an accident that could affect the

i. incident

ii. Materials,Plant debrish,Tools,equipment and building

iii. Investigation may require a qualified person to comprehensively inspect or test the advanced equipment

iv. Reports from expert witnesses are part of the evidence of the investigation

3.4 Paper/Document

– Production schedule or process diagram

– Latest work procedures

– Qualification Record

– Training Record

– Corrective action

– Equipment maintenance record

– Accident Record

Revision November 2020

ACCIDENT

BSB-HSE-20-000 (Page 3 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

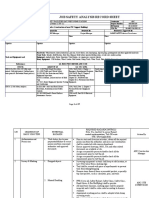

4.0 People (Person Involved/person Incharged)

The first step of our investigation was to hold a meeting of the members of the safety committee to discuss

of the accident,How to identified the cause and how to ensure that accidents can be avoided throughout the

the cause construction is operating. During the discussion on the meeting,The investigation task

was assigned to each committee member to futher facilitate the detection of the cause of the accident.

The meeting was attended by :-

Project manager - Mr. daniel Chan Project Engineer - Mr. Azri Kamal

Site Manager - Mr. Leslie nga Sr.Site Supervisor - Mr. Fadzly

Sr. Site Manager - Mr. Khoo Teow Guan Site Supervisor - Mr. Megat

Safety Health Officer - Mr. Nazlly Site Supervisor - Mr. Azrul

Site Safety Supervisor - Mr. Syed Omar PME Dept.Manager - Mr. Leornad swee

Crane Operator.

4.1 The investigation began by identified and interviewing the witnesses and employees involved:-

Name of person involved : Ali Md Hossain

Age : 31 y.old Nationality : Bangladesh

Gender : Male Passport no. :BL 0787864

Designation :General Worker

Type of work when accident happened : Concrete workers

Condition of person affected A Bangladeshi worker was hit on his left hip.

Name of person involved : Jumaing Bin Baba

Age : Nationality : Malaysia

Gender : Male Passport no. :

Designation :Concrete Truck Driver

Type of work when accident happened : Driver

Condition of person affected Shocked

Name of person involved : Muhammad Ulul Azmi Bin Zainuddin

Age : 26 yld Nationality : Malaysia

Gender : Male I/c no. : 941221-03-5835

Designation :Crane Operator

Type of work when accident happened : Crane Operator

Condition of person affected Shocked

Name of witnesses : Muhammad Azri Bin Kamal

Revision November 2020

Age : 30 Nationality : Malaysia

Gender : Male I/c no. : 900625-08-5723

Designation :Project Engineer

Type of work when accident happened : Person Incharged Works

ACCIDENT

BSB-HSE-20-000 (Page 4 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

4.2 Statement

Ali Md Hossain statement :-

Pada 15/7/2020 saya melakukan kerja seperti biasa,saya diarah untuk menjaga konkrit semasa kerja-kerja

konkrit pilecap. Saya menungu arahan dari ketua untuk memulakan kerja konkrit.Apabila lori konkrit tiba,saya

diarah untuk menjaga konkrit di lori tersebut.Semasa sedang bekerja seperti biasa,saya terdengar dentuman kuat dari

atas kepala,apabila saya tengok keatas boom kren itu jatuh diatas lori konkrit tersebut.saya betindak melarikan diri dari

situ untuk mengelakan boom jatuh diatas saya.Saya sempat mengelak dari ditimpa boom tersebut tetapi tangan kiri

saya terkena libasan wirerope tersebut.Saya terus dibawa ke klinik untuk pemeriksaan lanjut.Saya Cuma mendapat

cuti satu hari dan ubat sapu.

Jumain Baba statement:-

Pada 15/7/2020 jam 4:15 ptg sy menerima tempahan konkrit untuk dihantar ke tapak bina Riveria City dari syarikat

Pintaras Geotehcnics sebanyak 8M³.selepas selesai bancuhan dari Plant bukit bintang saya pon terus begerak ke

tapak bina tersebut pada jam 5.15 ptg dan tiba disana pada jam 5.45 ptg.Setelah sampai saya diarahkan oleh pekerja di

tapak bina untuk meletakan lori saya di tempat yang disediakan untuk mengeluarkan konkrit.Semasa kerja-kerja

konkrit berjalan saya memerhati dari bahagian depan lori,tiba-tiba saya perasan boom kren tersebut turun laju dan

menghempap bahagian atas buyung konkrit,saya sempat melarikan diri ke tempat yang selamat.Tetapi lori saya

menghadapi kerosakan yang agak teruk.Semua kerja-kerja dihentikan dan saya pergi melihat keadaan pekerja konkrit

yg berada di bahagian belakang lori,dan pekerja itu sempat melarikan diri dan hanya cedera ringan.

Project Engineer statement:-

Pada 15/7/2020 saya melakukan tugas seperti biasa, saya melakukan persiapan untuk kerja-kerja konkrit

pilecap cb8 P14/15. Kerja ini mengunakan kren untuk mengankut konkrit dari lori konkrit ke pilecap

yang hendak dikonkrit.Semasa kerja-kerja konkrit dijlankan aktiviti tersebut berjalan lancar,

setelah selesai tuangan keempat diisi dari lori konktrit tersebut, kren memulakan pidahan tong konkrit tersebut

tiba-tiba boom kren terhempas kebawah dan terkena lori konnkrit tersebut dan jatuh ke tanah.

Kerja-kerja telah dihentikan serta merta atas dasar keselamatan.

Crane Operator statement:-

Pada 15/7/2020 saya telah diarah oleh pegawai tapak untuk mengendalikan jentera kren RH2 untuk kerja-kerja

konkrit CB8 P14/15. Seperti biasa sebelum memulakan kerja,saya membuat pemeriksaan pada jentera sebelum

mengendalikannya untuk memastikan semua dalam keadaan baik.Sementara menunggu persiapan yang dibuat oleh

jurutera di kawasan yang hendak dikonkrit saya melakukan kerja-kerja mengalihkan besi rebar.Pada jam 5:45 ptg

lori konkrit tiba di tapak bina saya pon mula melakukan kerja konrit seperti biasa. Saya telah menuang konkrit

pilecap tersebut sebanyak tiga kali,Apabila kali keempat setelah selesai tong konkrit diisi dari lori konkrit

saya menaikan boom pada 35° untuk dituang pada pilecap tersebut, Tiba-tiba satu bunyi yang pelik kedengaran

dan Boom pon jatuh dengan tiba2 diatas lori konkrit tersebut.Saya sempat hayun kren jauh dari pekerja konkrit

Revision November 2020

yang berada di bawah. Setelah itu saya terus mematikan enjin kren dan memberhentikan kerja serta merta.

ACCIDENT

BSB-HSE-20-000 (Page 5 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

5.0 Position

5.1 Location Of Victim,Witness and Machinery :-

After being interviewed on all involved victim,truck driver,operator and witnesses who witnessed the incident,

had an initial glimpse of their position,position of the machinery and concrete truck involved during the incident.

Sketch of the picture incident before and after has been made,where in the sketch shows the position of all those

involvedin the accident.from the information that has been obtain as a result of the interviewing sesion.

refer attcment 2:-

5.2 Sources of machinery,Energy and Chemicals :-

Equipmet or machinery used during the incident is as follows:-

Construction Equipment name : Crawler Crane

Specification : Sumitomo LS118,SC500 (50 ton) Equiipment I/d : RH2

Model : Sumitomo LS 118RH

Pma No. : PMA 84961 Pma Validity : 10 DEC 2020

Registered Company : Pintaras Jaya Berhad

Crawler crane was used for hoisting concrete from concrete truck to discharged onto pilecap.Which is

Operate by competent Crane operator Mohd ulul Azmi.machinery has been inspected by crane operator and

Supervisor using Daily inspection checklist (Refer attachment 3) and monthly checklist done by Crane operator

and Safety supervisor using Monthly Checklist (Refer attachment 4).Enclosed machinery certificate of fitness

and crane operator licence.Refer attachment 5

6.0 Parts

Identify and Record :-

6.1 Parts of machinery,building around the accident area before,during or after an accident that could affect the

incidentTo identify the cause of the accident,the team from Machinery department went down to the field

with site team to check the condition of the damage part to find the cause of the failure.

To identifying the damaged item ,they inspected all the damaged parts or items was affected causes of the

incident by means of :-

1) To check boom hoist system by checking mast head of the machinery.

2)To dismantle mast head to inspect the all the Pulley bearing.

3)To inspect the broken wire rope and the parts of the machinery which make the wire rope can be broken

4)Identified damaged boom parts as cause of the incident by Checking all boom structure and boom

connection

Revision November 2020

Estimate loss due to accident : RM10,000.00

- Costs including property damage,loss of

working hour,investigation costs,costs oh

handling the victim etc.

Identified Damage Item : Boom wire rope,Pulleys ,boom top and intermidiate section & Pulleys bearing

ACCIDENT

BSB-HSE-20-000 (Page 6 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

6.2 To take data from everything related to accident for example such as lifted Materials,Plant debrish,

Tools,equipment and building which can also cause accident by looking at the load being lifted does it exceed

the proper load,the distance between the loads to be lifted is in the appropriate range as in the load chart,

the situation around the work activity enaugh space and equipment such as lifting gear is used according to the

suitblity of the load being lifted. After examining from the privious aspect, it was found that the incident was

not caused by it,because everyting in terms of that aspect has followed the specification and the proper way.

Otherwise the incident was involved third party which is concrete truck from BUILDCON CONCRETE

and has caused damage to the pitcher drum and attached ladder when the Crane boom was hit the truck

and the total lost has been send by the Buildcon representative.

Name Company : Buildcon Concrete Sdn Bhd

Roc no : 397618-w

Adress : 6th Floor, Yeoh Tiong lay Plaza, 55 Jalan Bukit Bintang,55100 Kuala Lumpur

Batching Plant : TRX TUN RAZAK

Driver Name : Jummaing Bin Baba

Nationality :Malaysia

Positition : Lorry Driver

Estimate loss due to accident : RM25,000

- Costs including property damage,loss of

working hour,investigation costs,costs oh

handling the victim etc.

Identified Damage Item : drum was partially dented and attached ladder was damaged.

6.3 Investigation may require a qualified person to comprehensively inspect or test the advanced equipment

as a result of identifying the damaged part, an investigation to identify the cause of the damage is carried out

Revision November 2020

by looking at the trend system pulley works to see which part causes the wirerope

cooperation and assistance from the source Pme Department section has been identified that the bearing is

and is stuck, and has caused one of the pulleys to not rotate while the boom is being lifted.

When pressure or coercion occurs on the pulley the pulley will be attracted or compete with the pulley

other and cause the pulley to rupture and produce fragments and sharp surfaces on the pulley

And at the same time the wire rope keeps running and is exposed to debris and the surface

ACCIDENT

BSB-HSE-20-000 (Page 7 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

6.4 Reports from expert witnesses are part of the evidence of the investigation

Report on damage to machinery parts and repair process has been issued by pme dept.In the report states the

type of goods exchanged and damaged goods.please refer attachment 6(Technical Report)

7.0 Paper/Document

7.1 – Production schedule or process diagram

Refer Attachment 7

7.2 – Latest work procedures

Safe operating procedure for lifting work have been improved to ensure safe working methods.

Refer attachment 8

7.3 – Qualification Record

Qualification for machinery and crane operator during the incident are also included once in this report.

refer attchment 9

7.4 – Corrective action

Apprpriately train all employees

– Need to makesure to provide appropriate health and safety training to all employees so they are competent

at their jobs.By training the employees it can be increase workplace safety,statisfaction and profit as to

reduce injuries,fatalities,accidents and sickness absence.

– Ensure employees know they must not stand under loads and ensure operators never lift a load over an

employees

– Know, understand and comply with the lifting operation and lifting equipment regulation

– To carry out routine Mantainance and repairs of all on-site equipment at appropriate intervals such as

•Daily crane inspection –Refer attchment 3

Revision November 2020

•Montly crane Inspection –Refer attchment 4

•Ensure a supervisor is present on site at all times when crane are in operation

•Make employees aware of, and strictly enforce, your load and lifting limits

•Ensure clear warning signals are displayed on site when needed.

•Sellect appropriate PPE for all Employess

•Properly safety-plan all jobs before starting work and decide who's in charged of pre job safety planing for

permit to work and lifting plan –Refer attchment 10

• Revised Hirarc for improvement

ACCIDENT

BSB-HSE-20-000 (Page 8 of

INVESTIGATION

7)

REPORT

HEALTH SAFETY & ENVIRONMENTAL

8.0 CONCLUSION

The results of the investigation into the crane boom that fell on the construction site found fault with

self management. Caused damage to one of the parts of the machinery involved causing failure on

equipment and parties the pulley system because it does not keep the equipment or machinery in a safe condition.

And cause damage to machinery and third parties.The investigation into the dangerous incident is due

mechanical faults. In the investigation, those who are eligible to make the investigation are asked to participate

as well as to identify and help bring the accident investigation to a quick conclusion and logic.

Investigations are conducted by the safety committee members involved and are lead by Pme officers and two

people from the department of machinery and machinery maintenance. Where the investigation was conducted on

July 16-18, After a three-day investigation, officers from the Pme dept were able to conclude that the

machinery was not perfectly mechanical.Crank crawler Sumitomo LS118, SC500 intended load capacity 50 tons.

At the time of the crane incident in good condition without knowing the actual condition of the pulley bearing

condition while carrying out the concrete transfer activity the crane boom has fallen and hit the back of

the concrete truck and injured nearby workers, and the truck suffered damage to the pitcher.

while the worker involved was only slightly injured in the left arm and get a day off.

Conclusions can be drawn and found to fail to make a detailed scheduled inspection on each equipment embedded

in the crane boom movement system and failed to record the inspection.Inspection basics by operators and

supervisors working in a visual way is not enough to ensure each part qualified to inspect on the machinery

is safe.Detailed scheduled inspection by the operator and the supervisor machinery needs to be made

and recorded for future use. Daily inspection by operators and safety representatives ensure the condition

of the machinery is always in a safe condition, And monthly inspection by Pme dept can also ensure that

the use of machinery is properly regulated. Every job is also necessary have a perfect and safe plan

by having complete notifications and inspections.

Revision November 2020

Submitted by : Verified by : Approved by :

Name :

Designation : Designation : SHO Designation : Project Manager

Date : Date : Date :

Revision November 2020

damage to property,

dent, product recall

Overall Time Limit)

Revision November 2020

Revision November 2020

Revision November 2020

tnessed the incident,

ed during the incident.

e position of all those

crane operator and

one by Crane operator

certificate of fitness

Revision November 2020

ifted does it exceed

sed according to the

at the incident was

Revision November 2020

he report states the

hey are competent

Revision November 2020

ery in a safe condition.

e asked to participate

me officers and two

ation was conducted on

d load capacity 50 tons.

f the pulley bearing

ch equipment embedded

Revision November 2020

You might also like

- Incident Report (Gantry Crane Rope Broken)Document11 pagesIncident Report (Gantry Crane Rope Broken)Nilesh NigadeNo ratings yet

- Cable Damage Incident ReportDocument11 pagesCable Damage Incident ReportNagur ShareefNo ratings yet

- 14-08-2020 - 2200 Hrs - LS 4G1 - DO - Fire Fighting PVC Pipe - DraftDocument12 pages14-08-2020 - 2200 Hrs - LS 4G1 - DO - Fire Fighting PVC Pipe - DraftJohn Vincent Macatangay CleofeNo ratings yet

- Ir # Schaffer MaterialDocument2 pagesIr # Schaffer MaterialShah MuzzamilNo ratings yet

- Weekly Report As of September 12Document45 pagesWeekly Report As of September 12Cesar DuriasNo ratings yet

- Rubatek SARL-Near Miss Incident Report - (Section-A, B, C&D)Document8 pagesRubatek SARL-Near Miss Incident Report - (Section-A, B, C&D)siame festusNo ratings yet

- UOI-F-SHE-028 Form Laporan Investigasi Insiden 12.2Document5 pagesUOI-F-SHE-028 Form Laporan Investigasi Insiden 12.2herlin cahyakusumaNo ratings yet

- MS Confined Space B.DamansaraDocument47 pagesMS Confined Space B.DamansaraHana SeiadiNo ratings yet

- Chennai Radha Engineering Works (P) LTD.: Near Miss / Incident Report & Investigation FormDocument2 pagesChennai Radha Engineering Works (P) LTD.: Near Miss / Incident Report & Investigation FormsamNo ratings yet

- Incident Investigation & Analysis ReportDocument7 pagesIncident Investigation & Analysis ReportaddienwardimanNo ratings yet

- JSA-03 ConcreteDocument2 pagesJSA-03 ConcreteSujith KSNo ratings yet

- Case 1 - Finger Crushed by Door During TowDocument9 pagesCase 1 - Finger Crushed by Door During TowTeodor Ioan Ghinet Ghinet DorinaNo ratings yet

- Hazard Identification Plan, HIP, RevDocument16 pagesHazard Identification Plan, HIP, RevGhassan Ul HaqNo ratings yet

- COREN Olatunde TanimolaDocument43 pagesCOREN Olatunde TanimolaAdeola JosephNo ratings yet

- 02 - Accident ReportDocument6 pages02 - Accident ReportDhaneswar SwainNo ratings yet

- MS Concrete Crack RepairDocument5 pagesMS Concrete Crack Repairjoseph guiyab100% (1)

- Method Statement Core Drilling WorksDocument7 pagesMethod Statement Core Drilling WorksUgur100% (1)

- NH Method StatementDocument5 pagesNH Method StatementblackcoutureconsultationsNo ratings yet

- MS For Street Lightning and Allied WorksDocument18 pagesMS For Street Lightning and Allied WorksDeepu Sivadas100% (1)

- PMA Workpack Structure Inspection 2020 - Rev1Document16 pagesPMA Workpack Structure Inspection 2020 - Rev1Raznan Ramli100% (1)

- OTSReportDocument16 pagesOTSReportRohit KumarNo ratings yet

- My 06 PH 2 Pmxhseincidentreportfor 12720231Document7 pagesMy 06 PH 2 Pmxhseincidentreportfor 12720231Sjkt BekokNo ratings yet

- Accident Investigation FormDocument5 pagesAccident Investigation FormMostafa KhalifaNo ratings yet

- Orange Stripe#18-English-TSMDocument2 pagesOrange Stripe#18-English-TSMSheikh ShahidNo ratings yet

- AysalDocument9 pagesAysalmani narayananNo ratings yet

- March SHO Monthly ReportDocument6 pagesMarch SHO Monthly ReportNidurazi Ideris60% (10)

- Jsa For BlastingDocument7 pagesJsa For BlastingMOHD SUHAILNo ratings yet

- Accidents and Emergencies - Emergency Preparedness Pit Area ProcedureDocument6 pagesAccidents and Emergencies - Emergency Preparedness Pit Area ProcedureWelma JohnsonNo ratings yet

- Traffic Management - BTGDocument71 pagesTraffic Management - BTGBasuki Rahmat Hakim100% (1)

- Ashok Nall ADocument129 pagesAshok Nall ASephali MoharanaNo ratings yet

- PS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)Document27 pagesPS-11 (SA-ABC-JSA-PS11-03) Civil Works (Construction of New PIC Support Building)RABIE EL MAGHWRY ABDELKHALEK ELGHAMRY0% (1)

- Incident Investigation Report REDDYDocument4 pagesIncident Investigation Report REDDYSahadeo ReddyNo ratings yet

- Mthod Statement FOR Spider Glazing: Al Mouj Community HubDocument11 pagesMthod Statement FOR Spider Glazing: Al Mouj Community HubPE ShahinNo ratings yet

- 8 - WMS - Turpentine - Plinth BeamDocument4 pages8 - WMS - Turpentine - Plinth BeamVikramaditya NayakNo ratings yet

- Fairbreeze Environmental Audit Report - August 2020Document55 pagesFairbreeze Environmental Audit Report - August 2020Digital MarketingNo ratings yet

- Termite ControlDocument18 pagesTermite Controlriel ramosNo ratings yet

- IM-WI-09-SOP-S20 Site Specific SOP For Precast Boundary Wall InstallationDocument11 pagesIM-WI-09-SOP-S20 Site Specific SOP For Precast Boundary Wall InstallationBalasubramaniamkamarajNo ratings yet

- JHA Scaffolding ErectionDocument12 pagesJHA Scaffolding ErectionChayank TiwariNo ratings yet

- OSH Case Study SofiDocument26 pagesOSH Case Study Sofijohncena100% (1)

- ISG F M: Acilities AnagementDocument1 pageISG F M: Acilities AnagementhaniNo ratings yet

- Near Miss Report JSPL FormatDocument9 pagesNear Miss Report JSPL FormatPrajnay ShettyNo ratings yet

- OSH Full Investigation Report - Injury Incurred Adverse EventDocument21 pagesOSH Full Investigation Report - Injury Incurred Adverse EventGian Carlo MiguelNo ratings yet

- Incident Investigation Report-LBernacer Car Crash IncidentDocument6 pagesIncident Investigation Report-LBernacer Car Crash IncidentNelz PelaezNo ratings yet

- 7-28 Accident & Incident Reporting (RV)Document3 pages7-28 Accident & Incident Reporting (RV)Lee JungNo ratings yet

- Excavation Trench Permit Ex 1 F0206Document5 pagesExcavation Trench Permit Ex 1 F0206emeka2012No ratings yet

- 5 Smfe HDD Mos HDDDocument20 pages5 Smfe HDD Mos HDDshamiraNo ratings yet

- Project NewDocument33 pagesProject Newceeyem83% (12)

- Method Statement WeldingDocument9 pagesMethod Statement Weldingkiki270977No ratings yet

- Dengue VirusDocument5 pagesDengue Virusyelsa otreblaNo ratings yet

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- PIC R-7507 2015.30.03.5907 CHEC DSIR CommentsDocument6 pagesPIC R-7507 2015.30.03.5907 CHEC DSIR CommentsMohammed Jai Sujiya KhanNo ratings yet

- KAFD Programmed Abnormal Event Report FormDocument4 pagesKAFD Programmed Abnormal Event Report Formfaisal nadeemNo ratings yet

- Construction of SS 83S8-MISK CITY: AlbabtainDocument3 pagesConstruction of SS 83S8-MISK CITY: AlbabtainShafie ZubierNo ratings yet

- 10 - WMS - Turpentine - Tie BeamDocument6 pages10 - WMS - Turpentine - Tie BeamVikramaditya NayakNo ratings yet

- Safe Work Procedure: Trade Entrepreneur Engineering Pte LTDDocument6 pagesSafe Work Procedure: Trade Entrepreneur Engineering Pte LTDRachel NoraNo ratings yet

- Occupational Safety, Health, and Environment-2022Document48 pagesOccupational Safety, Health, and Environment-2022Brian GilchristNo ratings yet

- 3) Daily KY TrainingDocument2 pages3) Daily KY TrainingNitesh KumarNo ratings yet

- Job Safety Procedure - TSEILDocument13 pagesJob Safety Procedure - TSEILRavi thokalNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile CapknabpshoNo ratings yet

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsFrom EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNo ratings yet

- SHASSIC Audit Checklist - (OHS MS) - Revised - 2022-DoneDocument13 pagesSHASSIC Audit Checklist - (OHS MS) - Revised - 2022-DoneSyed AhmadNo ratings yet

- A.ENV.0160 - Appendix 2 - Hazard and Risk Assessment Biogas Systems - 1Document52 pagesA.ENV.0160 - Appendix 2 - Hazard and Risk Assessment Biogas Systems - 1Syed AhmadNo ratings yet

- Audit Plan For (Contractor Audit) - PCHDocument1 pageAudit Plan For (Contractor Audit) - PCHSyed AhmadNo ratings yet

- 15 Electric Passenger & Goods Lift Reg 1970Document10 pages15 Electric Passenger & Goods Lift Reg 1970Syed AhmadNo ratings yet

- 22 Clean Air 1978Document9 pages22 Clean Air 1978Syed AhmadNo ratings yet

- Inventory of Work ActivitiesDocument1 pageInventory of Work ActivitiesSyed AhmadNo ratings yet

- 9.2 - HSE Program 20xxDocument1 page9.2 - HSE Program 20xxSyed AhmadNo ratings yet

- HSE Monthly ReportDocument18 pagesHSE Monthly ReportSyed AhmadNo ratings yet

- Session Plan Lo2Document4 pagesSession Plan Lo2abegail capistranoNo ratings yet

- Guideline Perkeni 2019Document29 pagesGuideline Perkeni 2019Tiens MonisaNo ratings yet

- Chapter-PSQ PSQ 1Document6 pagesChapter-PSQ PSQ 1balaji srinivasanNo ratings yet

- Prof Ed 4Document23 pagesProf Ed 4Trexie Hannah SagadalNo ratings yet

- Assessment of Student Learning 1Document10 pagesAssessment of Student Learning 1Gerald TacderasNo ratings yet

- Food Safety For Food Security Relationship Between Global Megatrends and Developments in Food SafetyDocument16 pagesFood Safety For Food Security Relationship Between Global Megatrends and Developments in Food SafetyWayne0% (1)

- Winnicott ch1 PDFDocument18 pagesWinnicott ch1 PDFAlsabila NcisNo ratings yet

- Human Values PracticalDocument13 pagesHuman Values Practicalisha 249No ratings yet

- Data For Accident: (Refer Table 3)Document6 pagesData For Accident: (Refer Table 3)aminNo ratings yet

- WTTH-Managing Exposure To PermethrinDocument3 pagesWTTH-Managing Exposure To PermethrinCabinet VeterinarNo ratings yet

- IGH1993 09 V03n01-CompleteDocument28 pagesIGH1993 09 V03n01-CompletejepoNo ratings yet

- Laboratory ManagementDocument6 pagesLaboratory ManagementJamille CarayuganNo ratings yet

- WAIVER FOR PLAYERS - Docx 1Document1 pageWAIVER FOR PLAYERS - Docx 1Aldrin Joseph CamposNo ratings yet

- Penggunaan Obat Farmasi 2018 FinalDocument106 pagesPenggunaan Obat Farmasi 2018 FinalSintha DewiNo ratings yet

- Lab Worksheet 1 Cranial NervesDocument6 pagesLab Worksheet 1 Cranial NervesDale P. PolvorosaNo ratings yet

- Dang Chooi Ping V Lim Eng KokDocument10 pagesDang Chooi Ping V Lim Eng KokLavernyaNo ratings yet

- Macrobiotic DietDocument2 pagesMacrobiotic DietMarcio AurélioNo ratings yet

- Chapter-7: Indigenous Knowledge SystemsDocument27 pagesChapter-7: Indigenous Knowledge SystemsNatty Nigussie100% (4)

- Sleep E Book Power of SleepDocument36 pagesSleep E Book Power of Sleepstrgates34100% (1)

- Is 9473 2002 PDFDocument34 pagesIs 9473 2002 PDFvijayaNo ratings yet

- Easa Management System Assessment ToolDocument40 pagesEasa Management System Assessment ToolAdam Tudor-danielNo ratings yet

- Task Performance EuthenicsDocument3 pagesTask Performance EuthenicsKimberly MarquezNo ratings yet

- Health Safety and Nutrition For The Young Child 9th Edition Marotz Test BankDocument21 pagesHealth Safety and Nutrition For The Young Child 9th Edition Marotz Test BankJosephWilliamsinaom100% (13)

- Artificial Intelligence (AI) - New Trends in HealthcareDocument3 pagesArtificial Intelligence (AI) - New Trends in HealthcareBoniface Wahome KingsNo ratings yet

- DownloadDocument6 pagesDownloadDoraNo ratings yet

- Pearson's Correlation Coefficient: BMJ (Online) July 2012Document3 pagesPearson's Correlation Coefficient: BMJ (Online) July 2012Randy Rafael Asencio AlvaradoNo ratings yet

- LAW200.4 Group AssignmentDocument13 pagesLAW200.4 Group AssignmentShaekh Maruf Skder 1912892630No ratings yet

- Mrs - Jagadeeswari.J M.SC NursingDocument13 pagesMrs - Jagadeeswari.J M.SC NursingBhawna JoshiNo ratings yet

- Jurding - Varikokelektomi - Irma Suryani - 112019131Document5 pagesJurding - Varikokelektomi - Irma Suryani - 112019131Abraham WilliamNo ratings yet

- Review Related Literature Noise PollutionDocument8 pagesReview Related Literature Noise Pollutionafdtwbhyk100% (1)