Professional Documents

Culture Documents

Mogas Tank

Uploaded by

rhannie garciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mogas Tank

Uploaded by

rhannie garciaCopyright:

Available Formats

3 PROJECT DESCRIPTION

3.1 MOGAS STORAGE TANK DESCRIPTION

The MOGAS tank is designed based upon the API 650 Standard, which determines the minimum

requirements for the design, material, fabrication, erection, and inspection of the tank. The tank will

have a vertical and cylindrical shape of diameter 12m and height 12m and will consist of an internal

floating cover under their fixed cone roof. Table 3-1 illustrates the characteristics of the Mogas

storage tank.

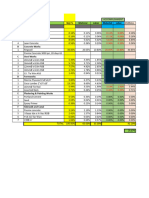

REF. PRODUCT DIAMETER HEIGHT TANK SURFACE NOMINAL CAPACITY (m3)

TANK (m) (m) AREA (m2) AT HEIGHT 10.5m

1 MOGAS 12 12 113.10 1000

Table 3-1 Characteristics of the Mogas Storage Tank

The tank will consist of the following:

A 8” inlet line

A 6” outlet line

A draw-off line

Internal floating roof

Fixed cone cover

Vents and breather valves

Roof and shell manholes

Earthing Bosses

Bottom sloped equipped with drain sump

Galvanised Steel stairways and handrails

Spiral Stairway Access

Fire-fighting equipment

As specified in the Standards available from EPML, the following was considered while designing the

tank:

The minimum distance between tanks in different dike areas is 15m as indicated in the

Standard PTS 20.158b – Sites and Layouts, Figure 03.05.02.

ENVIRONMENT IMPACT ASSESSMENT

DOC ID: 140105-EN-001-EIA REPORT-REV2 Page 13 of 58

The minimum distance between the tank shell and the bund wall is at least 1.5m as indicated

in the Standard SANS10089-1: 2008 in Section 4.5.2.1.

The minimum distance between the tank shell and the boundary of the property is 15m as

indicated in the Standard PTS 20.158b – Sites and Layouts, Appendix 03.05.05.

3.2 DIKE AREA DESCRIPTION

A new dike shall be designed and constructed to encompass Tank 6 and the existing Tank 5, separated

by the existing intermediate bund wall as illustrated in the Site Plan enclosed in ANNEX 3. The dike is

designed to contain any spillage or leakage from the tank and the pipelines and facilitate clean-up

operations. It is also used for fire protection and product recovery.

The wall height of the bund area shall be 1.5m and the total area required for the combined bund is

1514m2. The height of the existing intermediate bund wall is 1.5m.

The dike area will consist of:

Concrete bund wall

Concrete floor

Concrete foundations to be designed according to the geotechnical investigation report

Crossing of pipes within and around the dike area

Low point connection within the dike area for storm run-off/oil spillage washing to oil-water

separator

Appropriate impermeable membrane to avoid any leakage

ENVIRONMENT IMPACT ASSESSMENT

DOC ID: 140105-EN-001-EIA REPORT-REV2 Page 14 of 58

3.3 FIRE-FIGHTING SYSTEM

The purpose of a total fire protection package is to reduce the risk of fire by detectingthe possible

hazards. The fire-fighting system for the tank was designed according toPTS 20.158i - Fire Protection.

The possible scenarios considered are as follows:

Dike fire

In case of fire,the dike is injected with premix from the dike foam boxes at a flow rate of 6.5

L/min/m2 for aduration of 60 min. The Mogas tank inside the dike area shall be cooled with

premix at a flow rate of 17 L/min/m on the tank shell and at a flow rate of 1.7 L/min/m2 on

the tank roof via the cooling rings for a duration of 60min. Likewise, all the neighbouring

premises within 40mas listed below shall be cooled with water simultaneously using

theirrespective sprinkler system.

Shell and roof of Tank 5 for 120min

Shell and roof of Tank 4 for 120min

Hydrocarbon Pump Station for 180min

HFO Loading Bay for 120min

Transfer Pump Station for 120min

Additization Unit for 120min

White Oil Loading Bay for 120min

Tank fire

In case of fire inside the tank, premix shall be injected inside the tank via the foam pourer at a

flow rate of 4 L/min/m2 for a duration of 45min. Both the tank shell and roof shall be cooled

with premix at a rate of 17 L/min/m and 1.7 L/min/m2 respectively, via the cooling rings for a

duration of 120 min.Additionally, all the neighbouring premises within 46m as listed below

shall be cooled with water simultaneously using their respective sprinkler system.

Shell and roof of Tank 5 for 120min

HFO Loading Bay for 120min

Transfer Pump Station for 120min

Additization Unit for 120min

White Oil Loading Bay for 120min

Fire in neighbouring tanks

ENVIRONMENT IMPACT ASSESSMENT

DOC ID: 140105-EN-001-EIA REPORT-REV2 Page 15 of 58

In case of fire in TANK 5, both the shell and the roof of the MOGAS tankshallbe cooled with

water at a flow rate of 17 L/min/m and 1.7 L/min/m2 respectively, for a duration of 120 min.

The firefightingsystem shall consist of the following:

Water line supplying water to all the firefighting equipment connected to this line.

Foam line connecting the foam tank to the automatic proportioner before mixing of water

and foam to form premix.

Premix line supplying foam mixture to all firefighting equipment connected to this line.

Mixed line supplying either water or foam mixture at a time to all the fire-fighting equipment

connected to this line. This is dependent on the fire scenarios being considered for the

project.

The MOGAS tank shall be equipped with a cooling ring with sprinklers around the shell and on

the roof, which will carry both foam and water, one at a time depending on the fire scenarios

discussed above.

The dike shall be provided with foam boxes and the tank shall be equipped with a foam

generator.

ENVIRONMENT IMPACT ASSESSMENT

DOC ID: 140105-EN-001-EIA REPORT-REV2 Page 16 of 58

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Design PhilosophyDocument7 pagesDesign Philosophymohit19dNo ratings yet

- Oisd 117Document78 pagesOisd 117poojaupes67% (3)

- OISD-117 Fire Protection System for Oil Storage TanksDocument29 pagesOISD-117 Fire Protection System for Oil Storage TanksBALAKRISHNANNo ratings yet

- Oisd ReqDocument2 pagesOisd ReqvivekvpsfeNo ratings yet

- Fire Fighting Sprinkler TanksDocument32 pagesFire Fighting Sprinkler TanksPetar TopicNo ratings yet

- Water Deluge Protection of LPGDocument20 pagesWater Deluge Protection of LPGVivi OktaviantiNo ratings yet

- Tankfarm Area DesignDocument10 pagesTankfarm Area DesignPrasanna kumar subudhi100% (1)

- Engineering ManualDocument27 pagesEngineering ManualThousif Rahman67% (3)

- Tank PipingDocument29 pagesTank PipingDRJULIUSJORDAN100% (1)

- Fire Fighting SystemDocument29 pagesFire Fighting SystemAnonymous F3Ekm6HBs50% (2)

- Fire Fighting Sprinkler TanksDocument32 pagesFire Fighting Sprinkler TanksfisplNo ratings yet

- Fire Fighting Water Tanks: Balmor Al Tank SDocument32 pagesFire Fighting Water Tanks: Balmor Al Tank SAditya SinghNo ratings yet

- BMW Incinerator GuidelinesDocument3 pagesBMW Incinerator GuidelinesManish PatelNo ratings yet

- Advantages of Membrane TechnologyDocument5 pagesAdvantages of Membrane TechnologyGopalNo ratings yet

- Design Basis Dtd.3.12.2013Document10 pagesDesign Basis Dtd.3.12.2013Adil MominNo ratings yet

- SMPV Rules for Unfired Pressure VesselsDocument41 pagesSMPV Rules for Unfired Pressure VesselsAbhishek AgnihotriNo ratings yet

- Ammonia storage regulations and design guidelinesDocument2 pagesAmmonia storage regulations and design guidelinesZeroRecoNo ratings yet

- Oisd 144Document21 pagesOisd 144Ritika VermaNo ratings yet

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Document10 pagesES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNo ratings yet

- Clean Steam Products - 3rd EditionDocument16 pagesClean Steam Products - 3rd EditionferreirapinguimNo ratings yet

- Storage Tank Protection With High Flow Involving Large Storage Tanks It Would BeDocument22 pagesStorage Tank Protection With High Flow Involving Large Storage Tanks It Would BeAyoub BenkaouhaNo ratings yet

- 3844 - Installation of Internal Hydrants & Hose ReelDocument22 pages3844 - Installation of Internal Hydrants & Hose ReelSiyaram PatidarNo ratings yet

- Water Tanks For Fire ProtectionDocument4 pagesWater Tanks For Fire Protectionwfjerr100% (1)

- Oil Storage Tank PDFDocument19 pagesOil Storage Tank PDFalmadhagiNo ratings yet

- 3.1 Design BriefDocument5 pages3.1 Design BriefRaj KamalNo ratings yet

- Air Foam Chamber: Fire Fighting Equipment Data SheetDocument8 pagesAir Foam Chamber: Fire Fighting Equipment Data SheetMihir JhaNo ratings yet

- Va Nca 23 13 23Document6 pagesVa Nca 23 13 23Ali AlomyNo ratings yet

- Appendix - 33A Requirements For Underground Water Tank and Fire PumpsDocument1 pageAppendix - 33A Requirements For Underground Water Tank and Fire PumpsBasil OguakaNo ratings yet

- Comm-Op Aspect Refrigerated LPG TerminalDocument11 pagesComm-Op Aspect Refrigerated LPG TerminalMikiRoniWijayaNo ratings yet

- Design Study of LNG ShipDocument21 pagesDesign Study of LNG ShipssnisharNo ratings yet

- TCVN 5307-2009Document44 pagesTCVN 5307-2009sooner123456100% (3)

- Fire Tender SpecificationsDocument13 pagesFire Tender Specificationskaranbhadu50% (2)

- Fire protection design briefDocument10 pagesFire protection design briefRK PROJECT CONSULTANTS100% (1)

- 3472 Vol 2b-Pac Tech.-Spec.Document123 pages3472 Vol 2b-Pac Tech.-Spec.Satadal LahiriNo ratings yet

- 05 V PattabathulaDocument16 pages05 V Pattabathulapcorreia_81No ratings yet

- Gap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101Document13 pagesGap Analysis of Kandla Site With Respect To Fire Protection and Control Document Number 0101kirandevi1981No ratings yet

- Fire Protection MesuresDocument6 pagesFire Protection MesuresEmilioTSNo ratings yet

- Thermax BoilerDocument10 pagesThermax Boileramitrawal0100% (1)

- 2-Aa Storage Tank - Basic Training Rev 2Document52 pages2-Aa Storage Tank - Basic Training Rev 2mohamedbadawyNo ratings yet

- FSS 1.5 refuge floor standardsDocument7 pagesFSS 1.5 refuge floor standardsjaimonjoyNo ratings yet

- Oregon LNG Tank SpecDocument16 pagesOregon LNG Tank Specdr61gt100% (3)

- Central HeatingDocument6 pagesCentral Heatingsumit11235No ratings yet

- Boil-Off in Refrigerated Ammonia TanksDocument3 pagesBoil-Off in Refrigerated Ammonia TanksashmitharajaNo ratings yet

- Standard S Eci Cation of Multipurpose Fire TenderDocument9 pagesStandard S Eci Cation of Multipurpose Fire TenderaravindappiNo ratings yet

- Project Description of LPG PlantDocument8 pagesProject Description of LPG PlantEnoch TwumasiNo ratings yet

- Foam Chamber Model FDocument6 pagesFoam Chamber Model FMaulia SabrinaNo ratings yet

- Foam ChamberFCADocument6 pagesFoam ChamberFCAarachman297988No ratings yet

- TechDocument4 pagesTechcliffordtanNo ratings yet

- 800 Fire and Safety DesignDocument31 pages800 Fire and Safety Designjhon smith100% (1)

- Fire Services Policy 0014 Above Ground Water Storage For Fire Fighting PurposeDocument11 pagesFire Services Policy 0014 Above Ground Water Storage For Fire Fighting PurposeWangunNo ratings yet

- Storage TankDocument10 pagesStorage TankJacekNo ratings yet

- Retrofitting API 12F Storage Tanks for Venting ComplianceDocument8 pagesRetrofitting API 12F Storage Tanks for Venting CompliancedgswaltonNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"From EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"No ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- SWAPDocument1 pageSWAPrhannie garciaNo ratings yet

- Item Description WGT % Material Labor Material Labor 3Ml VST Foundation A EarthworksDocument1 pageItem Description WGT % Material Labor Material Labor 3Ml VST Foundation A Earthworksrhannie garciaNo ratings yet

- MS - TTLR Driveway Crack Repair UpdatedDocument12 pagesMS - TTLR Driveway Crack Repair Updatedrhannie garciaNo ratings yet

- PerifenceDocument1 pagePerifencerhannie garciaNo ratings yet

- Me-Mom-Spi-2023-02-005 Mabini 02.28.23Document2 pagesMe-Mom-Spi-2023-02-005 Mabini 02.28.23rhannie garciaNo ratings yet

- SCHEDULEDocument3 pagesSCHEDULErhannie garciaNo ratings yet

- Weekly Accompishment Report Format WPR 002 (18 - 24) February 2023Document29 pagesWeekly Accompishment Report Format WPR 002 (18 - 24) February 2023rhannie garciaNo ratings yet

- WAR - Seaoil Mabini Phase III For SiteDocument2 pagesWAR - Seaoil Mabini Phase III For Siterhannie garciaNo ratings yet

- Umeguard HS 6174 20100430RDocument2 pagesUmeguard HS 6174 20100430Rrhannie garciaNo ratings yet

- Attachment #4 (Site Issues and Concerns) 062323Document1 pageAttachment #4 (Site Issues and Concerns) 062323rhannie garciaNo ratings yet

- Excel Construction Project Management Templates Construction Documentation Tracker Template V1Document1 pageExcel Construction Project Management Templates Construction Documentation Tracker Template V1rhannie garciaNo ratings yet

- Consent Privacy Notice 2022Document3 pagesConsent Privacy Notice 2022rhannie garciaNo ratings yet

- Materials and supplies inventory listDocument14 pagesMaterials and supplies inventory listrhannie garciaNo ratings yet

- Tema Spi MabiniDocument4 pagesTema Spi Mabinirhannie garciaNo ratings yet

- SEAOIL ProjectDocument71 pagesSEAOIL Projectrhannie garciaNo ratings yet

- SodapdfDocument15 pagesSodapdfrhannie garciaNo ratings yet

- Spi MabiniDocument16 pagesSpi Mabinirhannie garciaNo ratings yet

- Fab Order MabiniDocument4 pagesFab Order Mabinirhannie garciaNo ratings yet

- Manpower Mob StatusDocument5 pagesManpower Mob Statusrhannie garciaNo ratings yet

- Environmental Screening and Scoping Report for Road Project in MaharashtraDocument94 pagesEnvironmental Screening and Scoping Report for Road Project in MaharashtraRahul RanaNo ratings yet

- Practical Foundation EngineeringDocument1,152 pagesPractical Foundation EngineeringMark Anthony Olinares100% (1)

- 1.sustainability Assessment of Transport Infrastructure Tools and MethodDocument28 pages1.sustainability Assessment of Transport Infrastructure Tools and MethodMinh LaNo ratings yet

- S.ST Scheme of Work P 5 Term 1 2019Document17 pagesS.ST Scheme of Work P 5 Term 1 2019maserekasimonricksonNo ratings yet

- Urh-Air Purifier CataloDocument10 pagesUrh-Air Purifier CataloGerardo BoisNo ratings yet

- Fdocuments - in - Gas Boiler System Commissioning Checklist Gas Boiler System Commissioning ChecklistDocument2 pagesFdocuments - in - Gas Boiler System Commissioning Checklist Gas Boiler System Commissioning Checklistkapster KannourNo ratings yet

- About Jordan's PolicyDocument20 pagesAbout Jordan's PolicySaeed Al-SaeedNo ratings yet

- JNTUH B.Tech ResultsDocument2 pagesJNTUH B.Tech ResultsWajeed YabaNo ratings yet

- Ergonomical Design of WorkplaceDocument8 pagesErgonomical Design of WorkplaceraraNo ratings yet

- RSSA Assesses Functionality and Sustainability of Roads, Bridges and Flood Control ProjectsDocument2 pagesRSSA Assesses Functionality and Sustainability of Roads, Bridges and Flood Control ProjectsRichard MendezNo ratings yet

- The Political Environment of International BusinessDocument22 pagesThe Political Environment of International BusinessdinescNo ratings yet

- Ashley Evans James Jordan Sierra Law Chris Wiebe Jasmine KurywczakDocument31 pagesAshley Evans James Jordan Sierra Law Chris Wiebe Jasmine KurywczakSierra LawNo ratings yet

- Ecological Solid Waste Management Awareness and PracticesDocument5 pagesEcological Solid Waste Management Awareness and PracticesHOPLOPZ GAMINGNo ratings yet

- Monthly Committee Accomplishment ReportdocxDocument7 pagesMonthly Committee Accomplishment ReportdocxLan So NessNo ratings yet

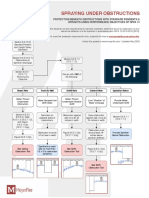

- Sprinkler Obstruction CheatsheetDocument1 pageSprinkler Obstruction CheatsheetKarkare89100% (1)

- Powers of Central Government Under The Environmental Protection Act 1986Document4 pagesPowers of Central Government Under The Environmental Protection Act 1986Akash RamNo ratings yet

- Penerapan Pola Pertanian Vertikal (Larian) Di Lahan Pegunungan Oleh Masyarakat Suku Tengger Dalam Perspektif Hukum LingkunganDocument25 pagesPenerapan Pola Pertanian Vertikal (Larian) Di Lahan Pegunungan Oleh Masyarakat Suku Tengger Dalam Perspektif Hukum Lingkunganputri muziraNo ratings yet

- EVA Copolymer SDS PDFDocument8 pagesEVA Copolymer SDS PDFdiablolcNo ratings yet

- MSC QHSE PolicyDocument1 pageMSC QHSE Policysuhara hussainNo ratings yet

- Wireless Turbidity Sensor Node Using PIC16F877A and X-Bee: P.M.Gavhane, P.P. Tadwalkar, V. D. Bachuwar, D.S.SutraveDocument3 pagesWireless Turbidity Sensor Node Using PIC16F877A and X-Bee: P.M.Gavhane, P.P. Tadwalkar, V. D. Bachuwar, D.S.SutraveSou TVNo ratings yet

- Research FlattenDocument21 pagesResearch FlattenParth ShewaleNo ratings yet

- 3-A Accepted Practice For Plant Environmental Air Quality, Number 612-00Document12 pages3-A Accepted Practice For Plant Environmental Air Quality, Number 612-00CHRISTIAN ZAVALANo ratings yet

- Iloilo City's 2013-2019 Development FrameworkDocument4 pagesIloilo City's 2013-2019 Development FrameworkGigi EstanocoNo ratings yet

- Reducing Global Warming Through Conservation And EfficiencyDocument6 pagesReducing Global Warming Through Conservation And EfficiencyAsina HarianjaNo ratings yet

- Artificial Groundwater Recharge-EEDocument8 pagesArtificial Groundwater Recharge-EEDhiraj YNo ratings yet

- Geotechnical - Investigation - For Bilika PV - Hybrid - Power - PlantDocument20 pagesGeotechnical - Investigation - For Bilika PV - Hybrid - Power - Plantmessay100% (1)

- Biol 1122 Learning Journal Unit 5Document5 pagesBiol 1122 Learning Journal Unit 5Tosin JeremiahNo ratings yet

- Excreta and Sewage DisposalDocument51 pagesExcreta and Sewage DisposalMel Izhra N. MargateNo ratings yet

- The Impacts of Environmental Pollutants On Microalgae and CyanobacteriaDocument124 pagesThe Impacts of Environmental Pollutants On Microalgae and CyanobacteriaDeepakNo ratings yet

- BiodiversityDocument19 pagesBiodiversityGill0% (1)