Professional Documents

Culture Documents

PCBA Quality Control

Uploaded by

jackCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCBA Quality Control

Uploaded by

jackCopyright:

Available Formats

RAYMING PCB & ASSEMBLY

PCBA Quality Control

PCB Assembly Quality

Control System

X-Ray Inspection for BGA

Assembly

Our automated X-ray inspection systems are able to monitor a variety

of aspects of a printed circuit board in assembly production. The

inspection is done after the soldering process to monitor defects in

soldering quality. Our equipment is able to”see” solder joints that are

under packages such as BGAs, CSPs and FLIP chips WHERE the solder

joints are hidden.

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

This allows us to verify that the assembly is done right. The defects and

other information detected by the inspection system can be quickly

analyzed and the process altered to reduce the defects and improve

the quality of the final products. In this way not only are actual faults

detected, but the process can be altered to reduce the fault levels on

the boards coming through. Use of this equipment allows us to ensure

that the highest standards are maintained in our assembly.

Components Quality control

To make sure the components to be used are good quality, there are

several processes that we follow:

1. An overview of the visual electronic components inspection process

includes:

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

* Packaging examined:

-Weighed and checked for damage

-Taping condition inspected-dented package etc.

-Original factory sealed vs. non-factory sealed

* Shipping documents verified

-Country of origin

-Purchase order and sales order numbers match

* Manufacturer P/N, quantity, date code verification, RoHS

* Moisture barrier protection verified (MSL)-vacuum sealed

and humidity indicator with specification (HIC)

* Products and packaging (photographed and cataloged)

* Body marking inspection (faded markings, broken text, double

print, ink stamps, etc.)

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

* Physical conditions inspection (lead bands, scratches, chipped

edges, etc.)

* Any other visual irregularities found

Once our visual distribution inspection is completed, products are

escalated to the next level-electronic components engineering

distribution inspection for review.

2. Engineering Components Inspection

Our highly skilled and trained engineers receive the components for

evaluation at a microscopic level to ensure consistency and quality. Any

suspect parts or discrepancies that are discovered in the visual

inspection process will either be verified or discounted by taking a

product sampling of the material/parts.

The engineering electronic components distribution inspection

process includes:

* Review visual inspection findings and notes

* Purchase and sales orders numbers verified

* Verification of labels (bar codes)

* Manufacturer’s logo and date log verification

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

* Moisture sensitivity level (MSL) and RoHS status

* Extensive marking permanency tests

* Review and comparison to manufacturer datasheet

* Additional photos taken and cataloged

* Solderibility Testing, the samples undergo an accelerated ‘aging

‘ process before being tested for solderibility, to take into

consideration the natural aging effects of storage prior to board-

mounting; In addition to the Engineering Components Inspection

we have a higher level of inspection under the customer request.

3. By customer request, all components can pass a thorough final

inspection in our Assembly facility.

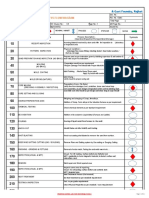

Detectable defects list

Automated

Selected

Defect Defect Detection by

Inspection Defect Class

No. Description final proto

Technology(s)

type

1 Dry joints AOI Soldering No

4 BGA voiding X-ray Soldering Yes

5 BGA bridging X-ray Soldering Yes

6 BGA tilted X-ray Soldering Yes

BGA missing

7 X-ray Soldering Yes

balls

PCB Manufacturing & Assembly Services https://www.raypcb.com/

RAYMING PCB & ASSEMBLY

BGA poor Not reliable

8 X-ray Soldering

wetting detection

9 BGA poor reflow X-ray Soldering Yes

Leaded CC poor

10 X-ray Soldering No

heel joint

Leaded CC

13 AOI Soldering No

lifted leads

SOT SOIC lea Not reliable

14 AOI Soldering

d lift detection

15 Solder balls AOI Soldering Yes

PTH solder

16 AOI Soldering No

poor fill

PTH poor lead

17 AOI Soldering No

wetting

Heat

SAM/Active

18 plane delamin Board Yes

thermography

ation

Plastic

SAM/Active

19 Encapsulated Components Yes

thermography

Delamination

Chip capacito

20 SAM/X-ray Components Yes

r crack

Missing

21 AOI Placement Yes

component

22 Tomb-stoning AOI Soldering Yes

23 Flipped AOI Soldering/Placement Yes

24 Tilted AOI Placement Yes

Passive

25 Solder short Soldering Yes

thermography

https://www.raypcb.com/pcba-quality-control/

PCB Manufacturing & Assembly Services https://www.raypcb.com/

You might also like

- What Is An AOI Test in SMTDocument15 pagesWhat Is An AOI Test in SMTjackNo ratings yet

- What Is SMT Soldering Process Step by StepDocument12 pagesWhat Is SMT Soldering Process Step by StepjackNo ratings yet

- What Are The Benefits of AOI PCBADocument11 pagesWhat Are The Benefits of AOI PCBAjackNo ratings yet

- What Is PCB X-Ray InspectionDocument12 pagesWhat Is PCB X-Ray InspectionjackNo ratings yet

- Dye and Pry Sample ReportDocument13 pagesDye and Pry Sample ReportTakahiko OtowaNo ratings yet

- BBP CBF - Function TestDocument21 pagesBBP CBF - Function TestAmr ElkadyNo ratings yet

- Odf Sliding, 24f, Sc-Upc SMDocument1 pageOdf Sliding, 24f, Sc-Upc SMOdetallah MajedNo ratings yet

- What Are The Criteria For PCB InspectionDocument15 pagesWhat Are The Criteria For PCB InspectionjackNo ratings yet

- What Are The Common Problems With PCB and PCBADocument14 pagesWhat Are The Common Problems With PCB and PCBAjackNo ratings yet

- Pipeline HSS Coating Inspection ReportDocument1 pagePipeline HSS Coating Inspection Reportcsc EXPERTISENo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-W-2026 31-Aug-11 WeldAnonymous 4e7GNjzGW100% (1)

- Irs-T - 19-2020Document57 pagesIrs-T - 19-2020ssepway yprNo ratings yet

- Inclusion Voiding in Gull Wing Solder JointsDocument12 pagesInclusion Voiding in Gull Wing Solder Jointsruzicda3No ratings yet

- PCB Manufacturing Process PDFDocument21 pagesPCB Manufacturing Process PDFAnima RahdriyaNo ratings yet

- c-12Document28 pagesc-12gagandeep isherNo ratings yet

- Detection of Defects of BGA by Tomography ImagingDocument5 pagesDetection of Defects of BGA by Tomography Imagingmalk10No ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- Laser Welding Audit SummaryDocument3 pagesLaser Welding Audit Summaryalfredo garciaNo ratings yet

- 18 Document of Part Wise Inspection ProcessDocument111 pages18 Document of Part Wise Inspection ProcessQAD LotusNo ratings yet

- Electronic MFG Overall - ShrunkDocument48 pagesElectronic MFG Overall - ShrunkShubham SharmaNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Jul-18 MechjahaanNo ratings yet

- BGA InspectionDocument115 pagesBGA InspectionezonelineNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerEagle SpiritNo ratings yet

- Welder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Document1 pageWelder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Ahmad Nabil ElsharkawyNo ratings yet

- Saic D 2024Document9 pagesSaic D 2024Md ShariqueNo ratings yet

- Fabrication Inspection of Bow String GirdersDocument46 pagesFabrication Inspection of Bow String GirdersHabib Ur Rahman100% (1)

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Datasheet for Saisanket Pressure Relief ValveDocument4 pagesDatasheet for Saisanket Pressure Relief ValveYogesh GawadeNo ratings yet

- Datasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFDocument4 pagesDatasheet, Drawings & QAP For Pressure Relief Valve DN400 PN16-LBC - 180920 PDFYogesh GawadeNo ratings yet

- Inspection Report: General InformationDocument22 pagesInspection Report: General InformationShamsul AffendiNo ratings yet

- FmeaDocument5 pagesFmeaBuiTrungNo ratings yet

- POTENTIAL FAILURE MODES AND EFFECTS ANALYSIS FOR LEAD FREE ELECTRONICS ASSEMBLY PROCESSESDocument5 pagesPOTENTIAL FAILURE MODES AND EFFECTS ANALYSIS FOR LEAD FREE ELECTRONICS ASSEMBLY PROCESSESLow SnNo ratings yet

- What Is Automatic Optical InspectionDocument13 pagesWhat Is Automatic Optical InspectionjackNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Sac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API TanksDocument14 pagesSac Inspection Checklist: SACIC-W-2076 21-Sep-21 Weld Procedure Review: Method Statement & Repair Procedure For API Tankshusnain aliNo ratings yet

- BGA Rework Station ZM-DGC900 Software SolutionsDocument31 pagesBGA Rework Station ZM-DGC900 Software SolutionsbryanyamiNo ratings yet

- Job Scope For Over Hauling of Power Transformers - FinalDocument7 pagesJob Scope For Over Hauling of Power Transformers - FinalrambihariNo ratings yet

- SalesShipment WHPC51940 10000 C51940001Document1 pageSalesShipment WHPC51940 10000 C51940001Radoslav bakalovNo ratings yet

- Stage Inspection ModifiedDocument116 pagesStage Inspection ModifiedEngr Saeed AnwarNo ratings yet

- 2005 S003 NBPG Rfi 04957 - R00Document1 page2005 S003 NBPG Rfi 04957 - R00RPDeshNo ratings yet

- QAP - ITP - Steel Girder ApproachDocument21 pagesQAP - ITP - Steel Girder ApproachPartha Gangopadhyay100% (1)

- STR Siq 0114Document5 pagesSTR Siq 0114Mohammad AkilNo ratings yet

- Welding Procedure B69AWDocument2 pagesWelding Procedure B69AWMastram HatheshNo ratings yet

- Saudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechDocument2 pagesSaudi Aramco Inspection Checklist: Ferroxyl Test Per ASTM A380 (Overlay Weld Cracking) SAIC-Y-2001 24-Mar-16 MechRijwan MohammadNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalDocument5 pagesSaudi Aramco Typical Inspection Plan: Welding of API Tanks SATIP-W-017-01 31-Dec-14 MechanicalpravinNo ratings yet

- Saudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalDocument4 pagesSaudi Aramco Typical Inspection Plan: Welding of Pressure Vessel SATIP-W-010-01 31-Dec-14 MechanicalpravinNo ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- How To Design Voice Activated LightsDocument13 pagesHow To Design Voice Activated LightsjackNo ratings yet

- Ferrite in Stainless Steel Weld MetalDocument1 pageFerrite in Stainless Steel Weld MetalElizabeth SpenceNo ratings yet

- S0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationDocument42 pagesS0442 GPS L XXX SP 0005 - 0 - Specification For Piping Fabrication and InstallationThành TrịnhNo ratings yet

- Mrir (Al-Ez Format)Document4 pagesMrir (Al-Ez Format)adeel akbarNo ratings yet

- Aramco CBT Questions-Answere For QAQC Welding-PART-03Document11 pagesAramco CBT Questions-Answere For QAQC Welding-PART-03Abdul Hafeez100% (1)

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Solder VoidingDocument27 pagesSolder VoidingRobert MartosNo ratings yet

- Lead Free Reliability Study by BoeingDocument23 pagesLead Free Reliability Study by Boeingsmtdrkd100% (1)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 4 out of 5 stars4/5 (1)

- Why You Should Choose The Shengyi S7439G PCB MaterialDocument5 pagesWhy You Should Choose The Shengyi S7439G PCB MaterialjackNo ratings yet

- Why Is The Home Energy Monitor ImportantDocument7 pagesWhy Is The Home Energy Monitor ImportantjackNo ratings yet

- Why 3D Print PCBs Matter in Today's Electronics ProductionDocument4 pagesWhy 3D Print PCBs Matter in Today's Electronics ProductionjackNo ratings yet

- Why Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBDocument4 pagesWhy Non Recurring Engineering Cost (NRE Charge) Is Important For Your PCBjackNo ratings yet

- Why OEM Circuit Boards Are Ideal For Use in Several ApplicationsDocument6 pagesWhy OEM Circuit Boards Are Ideal For Use in Several ApplicationsjackNo ratings yet

- Why Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsDocument4 pagesWhy Is The Panasonic R-F705S Useful For Mobile and Automotive ProductsjackNo ratings yet

- Xilinx XAZU2EG-1SBVA484I Fpga ApplicationDocument5 pagesXilinx XAZU2EG-1SBVA484I Fpga ApplicationjackNo ratings yet

- Why The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsDocument4 pagesWhy The Arlon 49N PCB Material Is Useful in High Temperature or High Performance ApplicationsjackNo ratings yet

- Why A PCB Ground Plane Is Crucial For PCB FunctioningDocument3 pagesWhy A PCB Ground Plane Is Crucial For PCB FunctioningjackNo ratings yet

- What Is The Significance of Home Electronics PCBDocument6 pagesWhat Is The Significance of Home Electronics PCBjackNo ratings yet

- Where To Buy Rogers RT Duroid 5880 LaminateDocument5 pagesWhere To Buy Rogers RT Duroid 5880 LaminatejackNo ratings yet

- What Is Xilinx Spartan-7 Its Datasheet and Reference DesignsDocument20 pagesWhat Is Xilinx Spartan-7 Its Datasheet and Reference DesignsjackNo ratings yet

- Who Are The Leading Electrical Coil ManufacturersDocument5 pagesWho Are The Leading Electrical Coil ManufacturersjackNo ratings yet

- Where Does The QuickLogic Eclipse FPGA Architecture Family Play A RoleDocument11 pagesWhere Does The QuickLogic Eclipse FPGA Architecture Family Play A RolejackNo ratings yet

- What Is Xilinx Virtex-5 FPGADocument8 pagesWhat Is Xilinx Virtex-5 FPGAjackNo ratings yet

- What Is The Significance of ENIG Plating ThicknessDocument4 pagesWhat Is The Significance of ENIG Plating ThicknessjackNo ratings yet

- What Is Xilinx Kintex UltraScale UltraScale+Document8 pagesWhat Is Xilinx Kintex UltraScale UltraScale+jackNo ratings yet

- What Is The Difference Between Clean Flux and No Clean Flux Off PCBDocument13 pagesWhat Is The Difference Between Clean Flux and No Clean Flux Off PCBjackNo ratings yet

- What Is Through Hole PCB AssemblyDocument12 pagesWhat Is Through Hole PCB AssemblyjackNo ratings yet

- What Is Thermal Consideration in PCB DesignDocument6 pagesWhat Is Thermal Consideration in PCB DesignjackNo ratings yet

- What Is The Difference Between ARM and FPGA ProcessorsDocument9 pagesWhat Is The Difference Between ARM and FPGA ProcessorsjackNo ratings yet

- What Is The Significance of IOT in AgricultureDocument8 pagesWhat Is The Significance of IOT in AgriculturejackNo ratings yet

- What Is Taconic TSM-DS3b PCBDocument7 pagesWhat Is Taconic TSM-DS3b PCBjackNo ratings yet

- What Is Taconic TSM-DS3b PCBDocument7 pagesWhat Is Taconic TSM-DS3b PCBjackNo ratings yet

- What Is The Difference Between FFC Connector and FPC ConnectorDocument14 pagesWhat Is The Difference Between FFC Connector and FPC ConnectorjackNo ratings yet

- What Is The Melting Point of SolderDocument4 pagesWhat Is The Melting Point of SolderjackNo ratings yet

- What Is The Purpose and Applications of A PCB MotherboardDocument4 pagesWhat Is The Purpose and Applications of A PCB MotherboardjackNo ratings yet

- What Is Signal Integrity A Comprehensive OverviewDocument9 pagesWhat Is Signal Integrity A Comprehensive OverviewjackNo ratings yet

- What Is Signal Integrity A Comprehensive OverviewDocument9 pagesWhat Is Signal Integrity A Comprehensive OverviewjackNo ratings yet

- IPD2400 Block DiagramDocument1 pageIPD2400 Block DiagramBradyXuerebNo ratings yet

- Research Article A Review of Different Comparative Studies On Mobile Operating SystemDocument5 pagesResearch Article A Review of Different Comparative Studies On Mobile Operating SystemrameezaranaNo ratings yet

- ICT Revision PapersDocument55 pagesICT Revision PapersjohnNo ratings yet

- Enterprise Orchestration & ManagementDocument4 pagesEnterprise Orchestration & ManagementmanikNo ratings yet

- Honeywell - MPA2 Flyer - V2 - US PDFDocument2 pagesHoneywell - MPA2 Flyer - V2 - US PDFArouna GoudiabyNo ratings yet

- tms320f28377d PDFDocument226 pagestms320f28377d PDFPhan VănNo ratings yet

- Diff - Op Amp PDFDocument5 pagesDiff - Op Amp PDFPoonam mirkaleNo ratings yet

- Performance Analysisof Siliconand Ga As Single JunctionDocument11 pagesPerformance Analysisof Siliconand Ga As Single JunctionMadhiyah YahayaNo ratings yet

- LM Ic 3205 PDFDocument26 pagesLM Ic 3205 PDFAbu alwardNo ratings yet

- Info AgeDocument21 pagesInfo Ageroland uadan jrNo ratings yet

- 2200 Pcie Nvme SSD Product BriefDocument2 pages2200 Pcie Nvme SSD Product BriefbunklyNo ratings yet

- APW8715A: Features General DescriptionDocument26 pagesAPW8715A: Features General Descriptionmben osbiNo ratings yet

- Old Paper - 202201 - A6-R5 - COMPUTER ORGANIZATION AND OPERATING SYSTEMDocument8 pagesOld Paper - 202201 - A6-R5 - COMPUTER ORGANIZATION AND OPERATING SYSTEMJacks LibrearyNo ratings yet

- MONTESTO-TenderSpecs Ver002 27.05.2019Document6 pagesMONTESTO-TenderSpecs Ver002 27.05.2019Mridu Ranjan SrivastavaNo ratings yet

- Optical Trigger Generator Data SheetDocument9 pagesOptical Trigger Generator Data Sheetreza yousefiNo ratings yet

- Internet of Things (Iot) and Cloud Computing For AgricultureDocument62 pagesInternet of Things (Iot) and Cloud Computing For Agricultureحسين سعيد حسنNo ratings yet

- Voltage ReferencesDocument9 pagesVoltage ReferencesNirmala KNo ratings yet

- Improved, SPST/SPDT Analog Switches: - General Description - New FeaturesDocument12 pagesImproved, SPST/SPDT Analog Switches: - General Description - New FeatureslodeNo ratings yet

- Cloud Networking Portfolio: Universal Cloud Network and EcosystemDocument4 pagesCloud Networking Portfolio: Universal Cloud Network and EcosystemmethanoxyNo ratings yet

- DFT study tunes 2D material propertiesDocument4 pagesDFT study tunes 2D material propertiesSaga AbdallaNo ratings yet

- AM335x Android eMMC booting guideDocument8 pagesAM335x Android eMMC booting guidedevesh.ehrenNo ratings yet

- Introduction To Microprocessor & MicrocomputersDocument33 pagesIntroduction To Microprocessor & MicrocomputersDileepmk85No ratings yet

- BHT300B Users Manual EDocument182 pagesBHT300B Users Manual Esan nguyễn vănNo ratings yet

- Iot-Notes PDFDocument97 pagesIot-Notes PDFRajan SahotaNo ratings yet

- Captive Earth Station A.C.Subudhi DDG (E)Document18 pagesCaptive Earth Station A.C.Subudhi DDG (E)Shishir GuptaNo ratings yet

- Creativity Lab - Ee 223 B Experiment No. 4: AIM: To Make An Automatic Visitor Counter Circuit Using CD4026 IC and LDRDocument6 pagesCreativity Lab - Ee 223 B Experiment No. 4: AIM: To Make An Automatic Visitor Counter Circuit Using CD4026 IC and LDRhloNo ratings yet

- Electronics 08 00238 - 2Document8 pagesElectronics 08 00238 - 2Houcine NaimNo ratings yet

- 3ee13 PLC RegisterDocument7 pages3ee13 PLC RegisterAll in one video shared as commentNo ratings yet

- Digital 1Document24 pagesDigital 1muhamnedcandemirNo ratings yet

- CPO-RL2 - ComfortPoint Open - Room ControllerDocument14 pagesCPO-RL2 - ComfortPoint Open - Room ControllerDinesh ChandranNo ratings yet