Professional Documents

Culture Documents

1.ooreedoo - RA For Maintenance of Chillers. Revised

Uploaded by

starwingsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.ooreedoo - RA For Maintenance of Chillers. Revised

Uploaded by

starwingsCopyright:

Available Formats

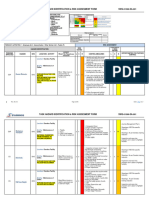

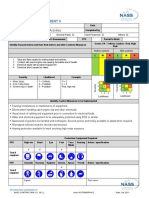

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM SWQ-01099-SA-001

Ooredoo- Maintenance Services

RISK ANALYSIS Risk Level Matrix ( R ) Hierarchy of Controls

Consequence Eliminate

of HVAC & Refrigeration CONSEQUENCE (C) of 1 2 3 4 5 Substitute

Contract Project: Results 5 H H E E E Engineer

Likelihood

equipment's. 4 M H H E E Administrative Control

1 - Insignificant 3 L M H E E PPE

2 - Minor 2 L L M H E

1 L L M H H

3 - Moderate Controls should be selected based

Site Name: Ooredoo Facility, Maintenance

4 -of

Major E = Extreme H = High on the Hierarchy of Controls

M = Moderate L = Low

Nominated Work chillers. 5 - Catastrophic

LIKELIHOOD (L) of

Date Develop: 20/11/2023 Occurrence

1 - Rare

2 - Unlikely Risk Acceptance

Date Reviewed: NA 3 - Moderate Risk Level

Name of Employee Accepting

Signature

Risk Level

4 - Likely Extreme (Contract Manager

StarwingsRA NO ORD-HIRA-HVAC-001

5- Almost Certain High (Site Manager)

Moderate (Deputy Manager / Supervisor

Low (Supervisor)

PERSON’S AFFECTED: 1. Employee (E) 2. Subcontractor / Other Worker (S) 3. Public (P) RISK ASSESSMENT

CONTROLLE

RISK

HAZARD IDENTIFICATION D RISK

RATING

RATING

EFFECT

PERSONS OPPORTUNITIES FOR FURTHER

HAZARD OHS LOCATION / ACTIVITY What if the Hazard was L C R CONTROL MEASURES L C R

AFFECTED CONTROL

released?

1. Identify and verify the correct

Location: Ooredoo Facility equipment/facilities/services

where maintenance is to be

carried out.

2. Engage the right person ( trained

Activity: Maintenance of and skilled )who can be capable of

Chiller. carrying out the job safely Starwings – HSE Site specific

Induction

3. Conduct a toolbox talk (

Minor / Major injury to briefing)before the start of work Starwings - As per Ooredoo

Human Behavior PCB AND ISOLATOR FUSE personnel due to training induction

ESP OHS incident caused by 3 3 H 1 3 M

HOLDER 4. Talk to the employees about their

REPLACEMENT,GAS LEAK human error capability to handle the job, Inspection and near-miss

RECTIFICATION OF knowledge, and understanding of programs are in place to highlight

CHILLER PLACED AT ROOF the work to be carried out hazards.

LEVEL

5. Ensure that members of the

workforce had not worked

prolonged hours in the previous

shift

6. Follow the approved method

statement where applicable

Rev. No: 01 Page 1 of 6 21-11-2023

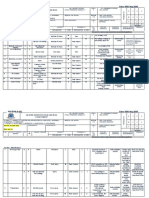

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM SWQ-01099-SA-001

Location: Ooredoo Facility Journey Management Plan's

1. Competent Driver

2. Proper periodic inspection Starwings– HSE Site specific

3. Daily visual inspection Induction

Activity: Maintenance of 1. Fatality

ESP Workplace OHS 3 4 E 4. Defensive Driving training 1 4 M

Chiller. 2. Injury

Transport 5. Driving safety awareness program Starwings- As per Ooredoo training

3. Loss of vital organs

6. Seat belts and hand grips installed induction

MATERIAL TRANSPORT 4. Damage to equipment

and worn

FROM ENTRANCE TO 7. Follow MSR

BUILDING PREMISES. Inspection and near-miss

programs are in place to highlight

hazards.

1. Inspection of power tools (if any)

Location: Ooredoo Facility and electrical connections. Starwings– HSE Site specific

2. Ensure the provision of earthing. Induction

3. LOTO procedure if it needs

4. Wear suitable PPE.

Starwings- As per Ooredoo training

ES OHS Activity: Maintenance of Major/Minor injuries or 3 5 E 5. Isolating the Electrical Connection 1 5 H

Electricity Chiller. death to personnel due from MDB to Chiller. induction

to electrical shock. 6. Work should be carried out under

PCB AND ISOLATOR FUSE HOT WORK PTW. Inspection and near-miss

HOLDER REPLACEMENT 7. Use properly insulated tools. programs are in place to highlight

8. Only a competent person shall hazards.

allow to carry out the task.

9. Proper supervision.

Location: Ooredoo Facility 1. Do not operate the machine while

on a ladder. Starwings– HSE Site specific

2. Always maintain 3-point contact Induction

while working on the ladder.

Activity: Maintenance of 3. Use a buddy system of work while

Starwings- As per Ooredoo

Chiller. working on the ladder.

ES OHS Major/Minor injuries or 4 5 E 1 5 H training induction

4. Use the buddy system of work.

Fall from Height death to personals due

PCB AND ISOLATOR FUSE 5. TBT

to fall from height. Inspection and near-miss

HOLDER REPLACEMENT 6. Proper Supervision and

monitoring. programs are in place to highlight

7. Proper PPE hazards.

8. Proper anchoring of lanyards.

9. Proper Edge Protection.

Rev. No: 01 Page 2 of 6 21-11-2023

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM SWQ-01099-SA-001

Location: Ooredoo Facility

1. Tool Box to be conducted

2. Use a proper ladder with a valid Starwings– HSE Site specific

inspection tag Induction

Activity: Maintenance of

3. Engage trained and competent

Chiller.

1. Personal Injury/Public person for the job

Slip / Trip & Fall Injury 4. Proper selection of ladder Starwings- As per Ooredoo training

ES OHS PCB AND ISOLATOR FUSE 3 2 M 1 2 L induction

2. Damage to 5. Keep surface clean and dry

HOLDER Property/equipment 6. Ensure proper Housekeeping

REPLACEMENT,GAS LEAK 7. Highlight the trip hazards with Inspection and near-miss

RECTIFICATION OF reflecting tapes and signages. programs are in place to highlight

CHILLER PLACED AT ROOF 8. PPE hazards.

LEVEL 9. Avoid working near the roof

barricade periphery.

Location: Ooredoo Facility Starwings– HSE Site specific

Induction

1. Usage of proper PPE. Starwings- As per Ooredoo training

Activity: Maintenance of 2. Avoid continuous exposure. induction

1. Major/Minor Hearing

ESP OHS Chiller. 5 2 H 3. Alternate the assigned workers 1 2 L

problems

Noise Daily to reduce the continuous Inspection and near-miss

2. Discomfort

GAS LEAK RECTIFICATION exposure. programs are in place to highlight

3. Head Ache.

OF CHILLER PLACED AT 4. Erect temporary acoustic barriers. hazards.

ROOF LEVEL 5. use ear protection if required.

Signage's should be displayed in

the required area to promote the

usage of ear protection.

Location: Ooredoo Facility

1. Task-specific Risk Assessment &

Method Statement.

2. Carry out LMRA.

# Mechanical 3. Mechanical & Electrical Isolation

Hazards Activity: Maintenance of

5. LOTO and Verification As per Ooredoo Site training

- Friction/Abrasion Chiller. 1. Personal Injury/Public 6. Communication with

- Entanglement Injury clients/tenants.

- Cut/crush PCB AND ISOLATOR FUSE 2. Loss of vital organs

ES OHS 3 2 M 7. Competent Workers. 2 2 L Site Specific Induction

- Drawing in HOLDER 3. Damage to 8. Ensure that machine guards are

- Impact REPLACEMENT,GAS LEAK Property/equipment fitted properly and the emergency

- Sharing RECTIFICATION OF 4. Health Effect stop button was working. Inspection and near-miss programs

- Sheathing CHILLER PLACED AT ROOF

9. Loose clothes and Jewellers are in place to highlight hazards.

LEVEL

should be avoided.

10. Basic PPE (Helmet, Dust Mask,

Safety Glass, Gloves etc.

11. Proper Supervision.

Rev. No: 01 Page 3 of 6 21-11-2023

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM SWQ-01099-SA-001

Location; Ooredoo Facility

1. Refer to the material safety data Starwings– HSE Site specific

sheet of the chemicals being used Induction

Cleaning of

Activity: and the supervisor ensure that

components/parts with workmen abide by the guidance

Starwings- As per Ooredoo training

stated it.

chemicals.(chemical Major/Minor health induction

ES OHS 4 5 E 2. Keep the chemical container 1 5 H

wash if required) issues to personnel due

Chemical Hazard. tightly closed when not in use.

to exposure to Inspection and near-miss

3. Provide a proper spill kit.

GAS LEAK RECTIFICATION chemicals programs are in place to highlight

4.COSHH assessment

OF CHILLER PLACED AT 5. Usage of proper PPE as hazards.

ROOF LEVEL. mentioned in COSHH/MSDS.

6. Storage as per HSE chemical HSE Chemical approval.

storing standards.

Location: Ooredoo Facility

1. Proper storage and method of use

of flammable objects. Starwings– HSE Site specific

1.Major /minor medical Induction

Activity: Maintenance of 2. work supervision and monitoring.

problems to personnel

Chiller. 3. Annual Mock drills

due to fire (burns and

4. Firefighting equipment. Starwings- As per Ooredoo training

ESP OHS other injuries) or death. 3 5 E 1 5 H

GAS LEAK RECTIFICATION 5. Assigned Fire Wardens. induction

Fire

OF CHILLER PLACED AT 6. Remove all combustible materials

2. Damage to plant

ROOF LEVEL.(Related to from the site if it is possible. Inspection and near-miss

premises &

Brazing & Welding of 7. Qatar Civil defence & emergency programs are in place to highlight

environmental impact.

defective coil) medical assistance on call. hazards.

8. Starwings Fire Fighting training

1. Avoid the accumulation of nitrogen

if you are working in a confined

space. Starwings– HSE Site specific

Location; Ooredoo Facility Induction

2. Keep all windows and doors open

during the activity.

3. Use a nitrogen pressure regulator Starwings- As per Ooredoo training

ES OHS Major/Minor injury or 4 4 E 2 4 H

to control the flow of nitrogen. induction

Suffocation Activity; Flushing of the death due to non-

4. Keep the cylinder in a secured

system by nitrogen availability of oxygen.

place (with a hand truck designed for Inspection and near-miss

cylinder movement to prevent it from programs are in place to highlight

GAS LEAK RECTIFICATION

toppling). hazards.

OF CHILLER

5. Keep the cylinder cap on the valve

when not in use to protect the valve

from damage.

Rev. No: 01 Page 4 of 6 21-11-2023

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM SWQ-01099-SA-001

6. Use the valve key to open and

close the valve instead of using the

spanner.

1. Task-Specific RA & EAI

2. Specific RA for Heat stress.

Location; Ooredoo Facility

1.Personal Injury 3. Water bottle As per Ooredoo training

ES 2. Dehydration 3 5 4. Additional rests & Rest shelters 1 5

Heat stress/Hot OHS E H

2. Loss of near working areas

work Hazards Activity; Brazing/Welding

consciousness 5. Qatar Labor Law Summer working Inspection and near-miss

4. Death hours programs are in place to highlight

GAS LEAK RECTIFICATION

6. TBT , hazards.

OF CHILLER

7. Health Surveillance

8. PPE

1. Use gauge manifold for refrigerant

changing and ensure that gauge

manifold has a valid calibration Starwings– HSE Site specific

Location; Ooredoo Facility certificate. Induction

2. Do not attempt to repair, connect

and modify any fittings when the

Starwings- As per Ooredoo training

ESP OHS 4 4 E system is under pressure. 2 4 H

Leakage of Minor/Major injury to induction

Activity; Refrigerant 3. Ensure that the refrigerant leak

refrigerant personnel.

changing. detection system (if available) is in

working condition. Inspection and near-miss

GAS LEAK RECTIFICATION 4. Ensure the working area have programs are in place to highlight

OF CHILLER effective ventilation. hazards.

5. Wear suitable and appropriate

PPE during the activity.

1. RA & MOS

Release &

2. Conduct LMRA As per Ooredoo training

Contact with

3. Ooredoo PTW

refrigerant gases Location; Ooredoo Facility

4. EIA Register

OHS/ 1. Cold burn 5. Cylinder inspection

ESP Bursting of pipes Activity; 3 4 2 4 Site Specific Induction

ENV 2. Personal Injury 6. Barricade the area

and leakage of E H

3. Pollution 7. ECM waste management

refrigerant Pressure testing and Gas 4. Damage to equipment procedure Inspection and near-miss

charging

8.MSR-3 programs are in place to highlight

Compressed Gas / GAS LEAK RECTIFICATION

9. Use a Recovery system hazards.

Pressurized System OF CHILLER

10.PPE

11. Third-party certified manifold

gauge.

Rev. No: 01 Page 5 of 6 21-11-2023

TASK HAZARD IDENTIFICATION & RISK ASSSESMENT FORM SWQ-01099-SA-001

1. Task-Specific RA & MOS

2. Ooredoo PTW

Location; Ooredoo Facility 1. Personal Injury 3. Usage of a dust mask FFP 1/2.

ESP OHS 2. Allergy/sickness 3 2 4. Wet down outside areas before 1 2 As per Ooredoo Site training

Exposure to 3. Chest pain, and M working. L

dust Activity; breathing difficulties due 5. Conduct LMRA

to dust inhalation 6. Employee’s regular health check- Inspection and near-miss

GAS LEAK RECTIFICATION 4. Eyesight issues and ups and monitoring by ECM Staff programs are in place to highlight

OF CHILLER eye irritation. nurse. hazards.

5. Limit the exposure by taking short

intervals (10 mins/hour)

Starwings– HSE Site specific

Induction

1. Risk Assessment Method

Statement

Starwings- As per Ooredoo training

2. KM PTW

Location: Ooredoo Facility 3. Housekeeping induction

Slip, Trip ,

ESP Waste Management OHS 3 2 M 4. Wrest strap / Tools lanyard for 1 2 L

Environmental impact Inspection and near-miss

Activity: Maintenance of securing the tools against falling

and related health programs are in place to highlight

Chiller. 5. Generated waste to be disposed

problems. hazards.

of through an approved waste

AFTER THE WORK ON management company

DAILY BASIS 6. Proper segregation of wastes Housekeeping Inspections

Assessed By: Reviewed & Approved By: Approved By:

Name: Eng.Shibin Shouckath Name: Eng. Nazim Shajahan Name: Eng. Sibin Gerson Sabu Name: Harikrishanan

Date: 21/11/2023 Date: 21/11/2023 Date: 21/11/2023 Date: 21/11/2023

Signature: Signature: Signature: Signature:

Rev. No: 01 Page 6 of 6 21-11-2023

You might also like

- 1.ooreedoo - RA For Maintenance of Chillers. Rev.02 20.11.2023Document6 pages1.ooreedoo - RA For Maintenance of Chillers. Rev.02 20.11.2023starwingsNo ratings yet

- 1.ooreedoo - RA For Maintenance of Chillers. Rev.0322.11.23Document8 pages1.ooreedoo - RA For Maintenance of Chillers. Rev.0322.11.23starwingsNo ratings yet

- Risk Assesment - Floor Chasing and ScreedingDocument3 pagesRisk Assesment - Floor Chasing and Screedingirfan vpNo ratings yet

- Ra - Acoustic Wall Panel - Rev 01Document3 pagesRa - Acoustic Wall Panel - Rev 01ameen jouharNo ratings yet

- HIRA TECHNOX Rev 04Document12 pagesHIRA TECHNOX Rev 04jogender kumarNo ratings yet

- Gadzoom Sample Activity Hazard Analysis TemplateDocument8 pagesGadzoom Sample Activity Hazard Analysis TemplateΝικολιδάκης ΒαγγέληςNo ratings yet

- Aha Crane Lifting InspectionDocument2 pagesAha Crane Lifting InspectionTakiNo ratings yet

- Generator Installation - AHADocument9 pagesGenerator Installation - AHATravis PhillipsNo ratings yet

- NC-FRM-DRA 6-2 Rev.0 Workshop ActivitiesDocument2 pagesNC-FRM-DRA 6-2 Rev.0 Workshop ActivitiesPatrick Bibila NdansiNo ratings yet

- Hse Hra FF 02Document8 pagesHse Hra FF 02R. Ayyanuperumal AyyanuperumalNo ratings yet

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- Approved By: ClauseDocument4 pagesApproved By: ClauseMohammed Imran100% (1)

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document9 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay50% (2)

- 05 - RISK ASSESSMENT-Winch MechineDocument3 pages05 - RISK ASSESSMENT-Winch Mechine287100% (1)

- RA For Summer Heat Stress Management A71Document4 pagesRA For Summer Heat Stress Management A71Sajid Shah100% (1)

- Activity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Document14 pagesActivity Hazard Analysis (AHA) : Overall Risk Assessment Code (RAC) (Use Highest Code)Anthony Macatangay100% (2)

- RA For Installation & Dismantling of Loading Platform A69Document8 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- 02-RA For Panel InstallationDocument5 pages02-RA For Panel Installation287100% (1)

- Logo Food Safety Management System Doc No: Subject: Risk Assessment Compiled By: Approved By: Date: Rev No: 00Document2 pagesLogo Food Safety Management System Doc No: Subject: Risk Assessment Compiled By: Approved By: Date: Rev No: 00Abhishek Kumar SinghNo ratings yet

- 01-Risk Assessment For Survey WorkDocument7 pages01-Risk Assessment For Survey Work287100% (3)

- Rebar Lifting Jha 001Document4 pagesRebar Lifting Jha 001Justin JuniorNo ratings yet

- L Risk Assessment Code (RAC) MatrixDocument6 pagesL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- RA For Builders Work A59Document11 pagesRA For Builders Work A59Sajid ShahNo ratings yet

- 04 - RISK ASSESSMENT CradleDocument5 pages04 - RISK ASSESSMENT Cradle287100% (4)

- JSA For MobilizationDocument3 pagesJSA For MobilizationHossain amjad Hossain100% (1)

- HIRA For DAHU - EXH Unit Romp 05Document8 pagesHIRA For DAHU - EXH Unit Romp 05syed khaja misbhuddinNo ratings yet

- Risk Assessment 004 NGSCHDocument2 pagesRisk Assessment 004 NGSCHsheraaz87100% (1)

- #410 Heavy LiftDocument3 pages#410 Heavy LiftTolias EgwNo ratings yet

- Crane-Hydra-deployment For Lifting-Lowering-Risk AssessmentDocument4 pagesCrane-Hydra-deployment For Lifting-Lowering-Risk AssessmentAhmed El-sherpiniNo ratings yet

- AHA Ductbank InstallationDocument5 pagesAHA Ductbank InstallationYug DobariyaNo ratings yet

- Bidaa Tower Risk Assessment From CALISTO UpdatedDocument5 pagesBidaa Tower Risk Assessment From CALISTO Updatedirshad gNo ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- JHA-Mechanical Lifting1Document2 pagesJHA-Mechanical Lifting1john jaycoh veranoNo ratings yet

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Run Diesel Driven Fishing Unit Risk AssesmentDocument2 pagesRun Diesel Driven Fishing Unit Risk Assesmentmikewebster76No ratings yet

- Confined Space EntryDocument4 pagesConfined Space Entrykwame fosterNo ratings yet

- Hiradc SF Merge - SurveyorDocument2 pagesHiradc SF Merge - SurveyorUDAWSA2 WKENo ratings yet

- CRA For Beam Stregthening WorksDocument4 pagesCRA For Beam Stregthening WorksVikki P ReddiNo ratings yet

- Activity Title Boiler: 1. Hazard Identification 2. Risk Analysis 3.risk ControlDocument12 pagesActivity Title Boiler: 1. Hazard Identification 2. Risk Analysis 3.risk Controlizzah80% (5)

- HIRA (Updated)Document102 pagesHIRA (Updated)totokNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Lifting Operations RA LdwcnsDocument3 pagesLifting Operations RA LdwcnsUmair Khan100% (1)

- HIRA Electrical Works HRC 002Document7 pagesHIRA Electrical Works HRC 002syed khaja misbhuddinNo ratings yet

- Blank Risk Assessment Form SKDocument3 pagesBlank Risk Assessment Form SKAdnan Haji HarbiNo ratings yet

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- Mobilization Risk AssessmentDocument53 pagesMobilization Risk AssessmentRAMY ABOU AL DAHABNo ratings yet

- #016 Underwater OperationsDocument3 pages#016 Underwater OperationsTolias Egw100% (1)

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- 1 MobilizationDocument8 pages1 MobilizationAnthony Macatangay100% (1)

- RISK ASSESSMENT-RevantaDocument4 pagesRISK ASSESSMENT-RevantaMehboob ChoudharyNo ratings yet

- N16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSDocument5 pagesN16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSAntaryami Singh GoondiNo ratings yet

- HIRADocument6 pagesHIRAvijay kumar singhNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- Modern Steel Construction March-2022Document76 pagesModern Steel Construction March-2022jackcan501No ratings yet

- Introduction To Discourse Analysis PDFDocument20 pagesIntroduction To Discourse Analysis PDFShobade Christianah Temitope100% (1)

- Aurelia Vallier SlidesDocument42 pagesAurelia Vallier SlidesSaddy KhanNo ratings yet

- Homework 3Document4 pagesHomework 3sdphysicsNo ratings yet

- GAP Guidelines: Management Programs (Overview)Document27 pagesGAP Guidelines: Management Programs (Overview)LleiLlei100% (1)

- Ex If Tool GuiDocument2 pagesEx If Tool Guipnb55No ratings yet

- STS Module 9Document14 pagesSTS Module 9Claire Jacynth FloroNo ratings yet

- Core10 Module1Document2 pagesCore10 Module1Sagbot Nga layaNo ratings yet

- SB-165 - ASME BPVC 2021 Sección II Part BDocument6 pagesSB-165 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- Introduction To PFADocument7 pagesIntroduction To PFACHRISTINE KYLE CIPRIANONo ratings yet

- Influences of Le Corbusier and Louis I Kahn in IndiaDocument10 pagesInfluences of Le Corbusier and Louis I Kahn in IndiaRashi Chugh88% (8)

- Journal Innovation Knowledge: Indicators Used To Measure Service Innovation and Manufacturing InnovationDocument16 pagesJournal Innovation Knowledge: Indicators Used To Measure Service Innovation and Manufacturing InnovationHj SuhaimiNo ratings yet

- Fredkin Introduction To Digital PhilosophyDocument59 pagesFredkin Introduction To Digital PhilosophyEdoardo MatteiNo ratings yet

- TEST PearsonsDocument4 pagesTEST Pearsonsazertytyty000No ratings yet

- Sensair Manual 1.0 en PDFDocument104 pagesSensair Manual 1.0 en PDFPaul KinsellaNo ratings yet

- Decimal To BinaryDocument3 pagesDecimal To BinaryAngel AntonioNo ratings yet

- Long Quiz For Week 12345Document26 pagesLong Quiz For Week 12345Jerwyn Marie CayasNo ratings yet

- HYDRAULICSDocument15 pagesHYDRAULICSHoney ApariceNo ratings yet

- Micro SplatDocument17 pagesMicro SplatCarlosAndresGarnicaSalazarNo ratings yet

- Revised Research Request Form Undergrad and Masteral Back FrontDocument4 pagesRevised Research Request Form Undergrad and Masteral Back Frontmichael tampusNo ratings yet

- Practical Questions BookletDocument37 pagesPractical Questions BookletPrecious ChirangareNo ratings yet

- Geometry of Middle SurfaceDocument29 pagesGeometry of Middle SurfaceParth ShahNo ratings yet

- Manufacturing Process AssignmentDocument5 pagesManufacturing Process AssignmentPalani SuntharajanNo ratings yet

- Cambridge O Level: Art and Design 6090/01 May/June 2020Document4 pagesCambridge O Level: Art and Design 6090/01 May/June 2020Jack KowmanNo ratings yet

- Schlosser Distillation SSCHI 2011 256Document14 pagesSchlosser Distillation SSCHI 2011 256Brandon LizardoNo ratings yet

- NCh204 1977Document15 pagesNCh204 1977Cristian A. Rivera S.No ratings yet

- Sample Waste Management Tracking FormDocument3 pagesSample Waste Management Tracking FormSreekumarNo ratings yet

- Remote Sensing GeologyDocument438 pagesRemote Sensing GeologyStalin Bryan100% (2)

- Score Fusion of Finger Vein and Face For Human Recognition Based On Convolutional Neural Network ModelDocument9 pagesScore Fusion of Finger Vein and Face For Human Recognition Based On Convolutional Neural Network ModelFressy NugrohoNo ratings yet

- Military Science 2: The Home of Naval Reservists in The NorthDocument44 pagesMilitary Science 2: The Home of Naval Reservists in The NorthErwin OnatoNo ratings yet