Professional Documents

Culture Documents

Pages From SM - 3000 4

Pages From SM - 3000 4

Uploaded by

afadfafa0 ratings0% found this document useful (0 votes)

9 views1 pageOriginal Title

Pages from SM_3000 4

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pagePages From SM - 3000 4

Pages From SM - 3000 4

Uploaded by

afadfafaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

3000 PRODUCT FAMILIES SERVICE MANUAL—ALLISON 4 th GENERATION

The allowable end play is 0.025–0.127 mm

NOTE: (0.001–0.005 inch).

Both idler covers must be installed and tightened to 54. When preload is within the specified limits, re-

establish the idler gear position before bearing pre- move the special tools.

load is checked.

55. Install guide pins to ease installation of the

front idler cover.

35. Install guide pins in two rear idler cover bolt

56. Install a new gasket 28 over the guide pins, and

holes.

onto the transfer case.

36. Install new gasket 47 (Foldout 14) over guide

57. Install shims 25, 26, and 27 (shim pack B).

pins. Install new O-ring 48 on rear idler

cover 49. 58. Install a new idler cover O-ring 24.

37. Lube O-ring and install cover 49 over guide 59. Lube the O-ring.

pins. Install five bolts 50 and tighten them to 60. Install idler cover 23, and tap it lightly for in-

60–75 N·m (44–55 lb ft). Two bolts replace the stallation.

guide pins.

61. Install five bolts 22 and tighten them to 60–75 N·m

38. Rotate the transfer case assembly so that the (44–55 lb ft). Two bolts replace the guide pins.

front side is up.

62. Install a new O-ring on main wiring harness

39. Install guide pins to ease installation of the connector 31.

front idler cover.

63. Install harness connector assembly 31 on connec-

40. Install a new gasket 28 (Foldout 13) over the tor plate 29 and tighten nut 88 to 2.73–4.09 N·m

guide pins and onto the transfer case. (24–36 lb in.).

41. Install shims 25, 26, and 27 (shim pack B) over 64. Place a new gasket 30 on the connector plate,

the guide pins. carefully rotating wiring harness through the

42. Install a new O-ring 24 on cover 23. gasket.

43. Lube the O-ring. 65. Position the harness connector through the

44. Install idler cover 23 and tap it lightly with a transfer case, and the connector plate.

soft-faced mallet to seat it in position. 66. Install four bolts 32 and tighten them to 5–8 N·m

45. Install five bolts 22 and tighten them to 60–75 N·m (4–6 lb ft).

(44–55 lb ft). Two bolts replace the guide pins. 67. Install a new O-ring 5 on suction hose fitting 2.

46. Remove front idler cover bolts 22, cover 23, Lube the O-ring (Figure 5–22).

shim pack B, and gasket 28 to start the idler

68. Lube the metal boss of filter screen 6 and posi-

gear bearing preload check.

tion it in fitting 2.

47. Install the handle of tool J 39623 into the

threaded hole of idler gear 39. 69. Carefully thread the fitting into the transfer

case.

48. Mount the dial indicator.

49. Bottom the idler gear assembly by slightly ro- 70. Tighten the jam nut on fitting 2 to 100–120 N·m

tating tool J 39623 while applying downward (74–89 lb ft).

force. 71. Install C7 clutch assembly 58 (Foldout 13) into

50. Zero the dial indicator. the transfer case.

51. Use a chain hoist and apply 734–778 N 72. Install guide pins in two front output housing

(165–175 lbs) of upward force. bolt holes.

52. Read dial indicator to determine bearing pre-

load. 73. Install a new output housing gasket 50.

53. If preload is not within the specified limits, add 74. Position front output housing 49 on the transfer

or remove shims and repeat Steps (41)–(53). case.

5–36 Copyright © 2005 General Motors Corp.

You might also like

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- 6WG1 Engine Cntrol Training Ver.2.2Document74 pages6WG1 Engine Cntrol Training Ver.2.2Miguel Cevallos100% (14)

- Assembly Transmission Volvo A40GDocument52 pagesAssembly Transmission Volvo A40GNanang Setiawan100% (1)

- T 176Document9 pagesT 176ashkansoheylNo ratings yet

- Transmission Service Manual PDFDocument42 pagesTransmission Service Manual PDFsoelist teoNo ratings yet

- Replace Timing Belt / Water Pump Honda Accord 1990-1995 4 CylinderDocument7 pagesReplace Timing Belt / Water Pump Honda Accord 1990-1995 4 Cylinderkararoy100% (5)

- HFE M2 Operator's Manual (X41176B)Document350 pagesHFE M2 Operator's Manual (X41176B)ΕΛΙΣΣΑΙΟΣ ΑΝΕΝΟΓΛΟΥ78% (9)

- Ignition - Wiring Basic Wiring Diagram BRIGGS & STRATTONDocument1 pageIgnition - Wiring Basic Wiring Diagram BRIGGS & STRATTONvulpinor58% (12)

- Thermolator Conair ManualDocument115 pagesThermolator Conair ManualLuiz RegaladoNo ratings yet

- Aircraft Design QuestionsDocument2 pagesAircraft Design QuestionsVijay Gorfad100% (2)

- PFD Nitric Acid Dan Pid PDFDocument9 pagesPFD Nitric Acid Dan Pid PDFasriNo ratings yet

- 2007 AcertDocument134 pages2007 Acertbanglacat100% (5)

- Structural Analysis of Crane HookDocument5 pagesStructural Analysis of Crane HookAkesh KakarlaNo ratings yet

- Ford 1.6 Cam TimingDocument3 pagesFord 1.6 Cam TimingAlexis martin Hernández SilvaNo ratings yet

- Curso Cat 428B Sist Hidraulico Desarmado - Armado Bomba HidraulicaDocument31 pagesCurso Cat 428B Sist Hidraulico Desarmado - Armado Bomba HidraulicaSilas F Pimenta83% (6)

- Turbomachinery Handbook - Hydrocarbon Processing-1974Document117 pagesTurbomachinery Handbook - Hydrocarbon Processing-1974VS2712100% (6)

- JLG E450AJ M450AJ Service Manual PDFDocument256 pagesJLG E450AJ M450AJ Service Manual PDFConstantino Sanchez L100% (1)

- Land Rover SU Carb OverhaulDocument10 pagesLand Rover SU Carb OverhaulAdamCzulewiczNo ratings yet

- Assembly Transmission 777DDocument62 pagesAssembly Transmission 777DKeron TrotzNo ratings yet

- Norriseal 1001A ControllerDocument21 pagesNorriseal 1001A Controllergiovanny silvaNo ratings yet

- Pages From SM - 3000 5Document1 pagePages From SM - 3000 5afadfafaNo ratings yet

- Pages From SM - 3000 3Document1 pagePages From SM - 3000 3afadfafaNo ratings yet

- 06.rear Axle 3 PDFDocument22 pages06.rear Axle 3 PDFFrezgi BirhanuNo ratings yet

- 761-639 - Arrow Iii - Turbo Arrow Iii Service Manual - Pa-28r-201 - 201TDocument9 pages761-639 - Arrow Iii - Turbo Arrow Iii Service Manual - Pa-28r-201 - 201TAndres Santiago RestrepoNo ratings yet

- Pages From SM - 3000 2Document1 pagePages From SM - 3000 2afadfafaNo ratings yet

- Sis 2.0Document16 pagesSis 2.0Ilham BoysNo ratings yet

- Section Vii Assembly of SubassembliesDocument8 pagesSection Vii Assembly of SubassembliesMaximo gabriel MaranoNo ratings yet

- 23gearboxDocument56 pages23gearboxcarzclassixNo ratings yet

- Main Hydraulic Pump PDFDocument12 pagesMain Hydraulic Pump PDFalsief1951No ratings yet

- Convertidor de Torque D5BDocument13 pagesConvertidor de Torque D5BDeyner PerezNo ratings yet

- Olympia Seal Installation m211-2Document5 pagesOlympia Seal Installation m211-2Pedro SanchezNo ratings yet

- JLG 1250AJP Service Manual-2Document90 pagesJLG 1250AJP Service Manual-2abdallah gomaaNo ratings yet

- Eng 5.4-97Document25 pagesEng 5.4-97Alexey KolmakovNo ratings yet

- Transmission - Assemble.Document20 pagesTransmission - Assemble.David MercadoNo ratings yet

- Assembly Transmission 777GDocument61 pagesAssembly Transmission 777GKeron TrotzNo ratings yet

- 270 Outdrive Service Manual (22 44)Document23 pages270 Outdrive Service Manual (22 44)Federico De FilippiNo ratings yet

- Desarmado y Armado Trans D8RDocument27 pagesDesarmado y Armado Trans D8RCristian EduardoNo ratings yet

- Fuel NozzleDocument27 pagesFuel NozzleJean P. MuñozNo ratings yet

- 360 BP'MCV, AssDocument6 pages360 BP'MCV, AssAimHighNo ratings yet

- Drill Press Is Required Hand Drilling Is Prohibited.: CautionDocument2 pagesDrill Press Is Required Hand Drilling Is Prohibited.: CautionNickNo ratings yet

- 21 30 DM45spurhd Rev001Document10 pages21 30 DM45spurhd Rev001whmidi7331100% (1)

- Bearing Mounting - SKF Drive Up MethodDocument5 pagesBearing Mounting - SKF Drive Up Methodkuruvillaj2217No ratings yet

- HD785-7 SEN01274-15 Shop Manual-1608-1821Document214 pagesHD785-7 SEN01274-15 Shop Manual-1608-1821Muhammad RizqiNo ratings yet

- Toyota Truck Highlander 2WD L4-2.4L (2AZ-FE) 2002: Timing Chain: Service and RepairDocument14 pagesToyota Truck Highlander 2WD L4-2.4L (2AZ-FE) 2002: Timing Chain: Service and RepairOscar jhonyffer Pereda RiscoNo ratings yet

- Z Main Bearing RemovalDocument2 pagesZ Main Bearing RemovalTVK TVKNo ratings yet

- SEN00322-04 50 Disassembly and AssemblyDocument10 pagesSEN00322-04 50 Disassembly and AssemblyЕгорNo ratings yet

- MotorDocument9 pagesMotorjaimes.najithNo ratings yet

- Air StarterDocument44 pagesAir StarterShakti NaikNo ratings yet

- Caja Direccion 2007 Dodge RamDocument19 pagesCaja Direccion 2007 Dodge RamBSVolcanNo ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K02679 and Up)Document23 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K02679 and Up)rpoy9396615No ratings yet

- Pfaff Coverlock 4772 Sewing Machine Service ManualDocument70 pagesPfaff Coverlock 4772 Sewing Machine Service ManualiliiexpugnansNo ratings yet

- Carter WCD ManualDocument35 pagesCarter WCD ManualsvanellaautosNo ratings yet

- Flow Doc 2 PDFDocument18 pagesFlow Doc 2 PDFJozefNo ratings yet

- Electric Lost Motion Actuator Instructions For Conversion From 115V, 60 HZ To 220V, 50 HZDocument3 pagesElectric Lost Motion Actuator Instructions For Conversion From 115V, 60 HZ To 220V, 50 HZAlexis SánchezNo ratings yet

- Main Bearing Removal ProcedureDocument2 pagesMain Bearing Removal ProcedureShamsher SinghNo ratings yet

- 81463015accumulator Charging ValveDocument3 pages81463015accumulator Charging ValveЯрослав ВалькоNo ratings yet

- Desarmado y Armado Bomba ImplementosDocument13 pagesDesarmado y Armado Bomba ImplementosRafael RodriguezNo ratings yet

- 07 - Power DrivetrainDocument20 pages07 - Power DrivetrainVictor RamirezNo ratings yet

- 336D Cat Mando Final EnsambleDocument16 pages336D Cat Mando Final EnsambleAlicia Serje100% (1)

- 8-54 Lower U N It: AdjustmentDocument1 page8-54 Lower U N It: AdjustmentBranko FerenčakNo ratings yet

- SU Carburatores - LandRoverDocument24 pagesSU Carburatores - LandRoverChevronelleNo ratings yet

- Caterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K01301-02678)Document22 pagesCaterpillar Cat 235 EXCAVATOR (Prefix 32K) Service Repair Manual (32K01301-02678)rpoy9396615No ratings yet

- Automatic TransmissionDocument18 pagesAutomatic TransmissionWoong-Sub LeeNo ratings yet

- 50SWP26 Rev-FDocument16 pages50SWP26 Rev-FManar MahmoudNo ratings yet

- TM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 3Document130 pagesTM 9-2330-397-14P M1112 Trailer, Tank, Water 400 Gallon Part 3AdvocateNo ratings yet

- Balance Disk Replacement PDFDocument8 pagesBalance Disk Replacement PDFOscar Araya RojasNo ratings yet

- Ï Partial Engine Assy (1Cd ïFTV) (From September, 2003)Document3 pagesÏ Partial Engine Assy (1Cd ïFTV) (From September, 2003)victorjoseteixeiraNo ratings yet

- WMME 57 Vac Pump Procedure Revised October 2008Document15 pagesWMME 57 Vac Pump Procedure Revised October 2008Sandison stlNo ratings yet

- STEERING SYSTEM Volvo 940Document16 pagesSTEERING SYSTEM Volvo 940JaNo ratings yet

- Engine - Mechanical 1Document4 pagesEngine - Mechanical 1Fabricio Vilela100% (1)

- Pages From SM - 3000 3Document1 pagePages From SM - 3000 3afadfafaNo ratings yet

- Pages From SM - 3000 5Document1 pagePages From SM - 3000 5afadfafaNo ratings yet

- Pages From SM - 3000 8Document1 pagePages From SM - 3000 8afadfafaNo ratings yet

- Pages From SM - 3000 7Document1 pagePages From SM - 3000 7afadfafaNo ratings yet

- Pages From SM - 3000 2Document1 pagePages From SM - 3000 2afadfafaNo ratings yet

- 86575157-No Passpdf 323Document1 page86575157-No Passpdf 323afadfafaNo ratings yet

- 86575157-No Passpdf 317Document1 page86575157-No Passpdf 317afadfafaNo ratings yet

- 86575157-No Passpdf 319Document1 page86575157-No Passpdf 319afadfafaNo ratings yet

- 86575157-No PasspdfDocument673 pages86575157-No PasspdfafadfafaNo ratings yet

- Powrtwin 6900 Di: Owner'S ManualDocument32 pagesPowrtwin 6900 Di: Owner'S ManualCarlos Eduardo Cardenas SochaNo ratings yet

- FB Chart: Check Whether It Is Laterally Supported or Unsupported Use Whichever Is Greater Of: ButDocument2 pagesFB Chart: Check Whether It Is Laterally Supported or Unsupported Use Whichever Is Greater Of: ButMugiwara SparrowNo ratings yet

- HW4Document23 pagesHW4AliceAlormenu0% (1)

- Datasheet MRS SeriesDocument6 pagesDatasheet MRS SeriesSantiago OspinaNo ratings yet

- MX Pressure Booster Maximat MX1 PDFDocument2 pagesMX Pressure Booster Maximat MX1 PDFNarendra Reddy BhumaNo ratings yet

- Air Pressure Process Control Lab ManualDocument11 pagesAir Pressure Process Control Lab ManualFaris Putera100% (1)

- EEM343-Robotics Week1 1 PDFDocument33 pagesEEM343-Robotics Week1 1 PDFShobanraj LetchumananNo ratings yet

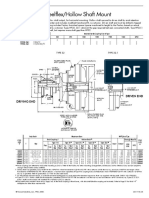

- HF32, 32-1 Steelflex/Hollow Shaft Mount: Driven End Driving EndDocument1 pageHF32, 32-1 Steelflex/Hollow Shaft Mount: Driven End Driving EndThylaneNo ratings yet

- Perbandingan Produk Car Lift PD Sarana Jaya 2018Document1 pagePerbandingan Produk Car Lift PD Sarana Jaya 2018Syaifudin IsharNo ratings yet

- Brake System: SectionDocument36 pagesBrake System: SectionOscar Jhonyffer Pereda RiscoNo ratings yet

- Extraction Condensing Turbine PDFDocument2 pagesExtraction Condensing Turbine PDFAndresNo ratings yet

- Jumbo MDocument5 pagesJumbo MholkeirNo ratings yet

- History of HeatDocument31 pagesHistory of Heatkarlo marko sta. rosaNo ratings yet

- Tarea 9 - Modelado y Experimentación 2007-01-3546 Development and Application of Buckling Estimation Method in Engine Connecting RodDocument7 pagesTarea 9 - Modelado y Experimentación 2007-01-3546 Development and Application of Buckling Estimation Method in Engine Connecting RodSantiago Sánchez MaldonadoNo ratings yet

- VW Fluid Capacity Chart 2003Document5 pagesVW Fluid Capacity Chart 2003Lalo Barajas GarciaNo ratings yet

- IPS Past Question 2004Document105 pagesIPS Past Question 2004Sean Kalu Onuoha100% (1)

- Frog Leg WindingDocument9 pagesFrog Leg WindingAbhijeet RedekarNo ratings yet

- Astm F984Document9 pagesAstm F984ashu23283No ratings yet

- ASEE Paper 1048 Ali EydgahiDocument15 pagesASEE Paper 1048 Ali EydgahiNguyễn Hoài NamNo ratings yet