Professional Documents

Culture Documents

SOP - BLDC CF Heating Test - Resistance Method1

SOP - BLDC CF Heating Test - Resistance Method1

Uploaded by

vijay.tambatkarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP - BLDC CF Heating Test - Resistance Method1

SOP - BLDC CF Heating Test - Resistance Method1

Uploaded by

vijay.tambatkarCopyright:

Available Formats

Department Fans Division, Vikhroli Lab

Issued by Testing Team

Crompton Greaves Consumer Electrical Limited.

Issued to Design team, Internal Quality team

Standard operating procedure – Heating Test

To streamline the procedure for testing and receiving the samples for sourced products

Purpose: To test Inhouse (R&D) and sourced final samples for to perform the product safety test

against heating.

Scope: To validate the final samples made by Crompton/ vendor.

Responsibility: Fans Design team and Quality team.

Standard: As per IS 374:2019, IS 302-1, IS 302-2-80(Clause 11).

Tolerance on ratings as per standard:

a) Limits of error of electrical Measuring instruments: Ammeter, voltmeter and watt meters used

for tests shall have accuracy of class 0.5 or better.

b) The variation in the voltage shall not exceed ±1%.

c) Power factor- tolerance minimum 0.02, Max 0.07 (requirement >0.9).

d) Fan speed ±10 percent.

e) Power Input +20 percent.

f) Temperature ratings are given in below table 3

g) The temperature rise of the body of the motor is determined instead of the temperature rise of

the windings.

h) The temperature rise of the body of the motor, where it is in contact with insulating material,

shall not exceed the values shown in Table 3 for the relevant insulating material.

Date SOP Issued Issue No 01

SOP Revision Date 00 Rev. No 00

Prepared by Vijay Tambatkar Reviewed/Approved by

Date Date:

Department Fans Division, Vikhroli Lab

Issued by Testing Team

Crompton Greaves Consumer Electrical Limited.

Issued to Design team, Internal Quality team

Standard operating procedure – Heating Test

To streamline the procedure for testing and receiving the samples for sourced products

Date SOP Issued Issue No 01

SOP Revision Date 00 Rev. No 00

Prepared by Vijay Tambatkar Reviewed/Approved by

Date Date:

Department Fans Division, Vikhroli Lab

Issued by Testing Team

Crompton Greaves Consumer Electrical Limited.

Issued to Design team, Internal Quality team

Standard operating procedure – Heating Test

To streamline the procedure for testing and receiving the samples for sourced products

Date SOP Issued Issue No 01

SOP Revision Date 00 Rev. No 00

Prepared by Vijay Tambatkar Reviewed/Approved by

Date Date:

Department Fans Division, Vikhroli Lab

Issued by Testing Team

Crompton Greaves Consumer Electrical Limited.

Issued to Design team, Internal Quality team

Standard operating procedure – Heating Test

To streamline the procedure for testing and receiving the samples for sourced products

Test Setup:

Test Corner Design:

o Dull Black painted plywood 20mm thick is used as test corner as shown below.

Thermocouple used for determining the temperature rise of the surface of the walls, ceiling

and floor of the test corner are attached to the back of the small, blackened disks of copper or

brass which is 15mm diameter and 1mm thick.

Temperature rise of the windings are determined by the resistance method. In case of any

difficulty, we can use thermocouple.

Temperature rises other than windings are determined by means of fine wire thermocouples,

positioned so that they have minimum effect on the temperature of the part under test

Thermocouple diameter is 0.3mm which is fine wire thermocouple.

Appliances normally fixed to a ceiling are fixed underneath a horizontal support.

This test corner is installed inside the enclosed room to get the temperature stability.

Date SOP Issued Issue No 01

SOP Revision Date 00 Rev. No 00

Prepared by Vijay Tambatkar Reviewed/Approved by

Date Date:

Department Fans Division, Vikhroli Lab

Issued by Testing Team

Crompton Greaves Consumer Electrical Limited.

Issued to Design team, Internal Quality team

Standard operating procedure – Heating Test

To streamline the procedure for testing and receiving the samples for sourced products

Test procedure as applicable

Step 1:

Attach the thermocouple to measure the temperature rise at places of insulation where failure could

cause.

Step 2:

After mounting ceiling fan, at the beginning of the test, the temperature of all the measurement parts

are maintained at ambient temperature of 27 ±5°C.

After that set the ambient test temperature(t1) 40°C (+3°C tolerance)

Step 3:

Once temperature gets stabilize measure the resistance(R1) of windings (U-V, V-W, U-W) and take

average of it before the test.

Note: Make sure that rotor is steady while measuring the resistance.

Step 4:

Supply input voltage to fan with most unfavorable i.e. 1.06 times the rated voltage.

Step 4:

Duration of test is most unfavorable conditions of normal use i.e 2 Hours.

Step 5:

During test, temperatures of all parts are monitored continuously, and it should not cross the limit

mentioned in table 3.

Step 6:

After completion of the test take windings resistance (U-V, V-W, U-W) and take average of it(R2).

Measure the winding resistance at short interval after mains switching off.

Also note down the ambient temperature(t2) after the test.

Step 6:

Calculate the temperature rise of winding as follows:

Date SOP Issued Issue No 01

SOP Revision Date 00 Rev. No 00

Prepared by Vijay Tambatkar Reviewed/Approved by

Date Date:

Department Fans Division, Vikhroli Lab

Issued by Testing Team

Crompton Greaves Consumer Electrical Limited.

Issued to Design team, Internal Quality team

Standard operating procedure – Heating Test

To streamline the procedure for testing and receiving the samples for sourced products

Note:

Motor Operated at Normal Operation.

Supplied with most unfavorable voltage between 0.94 times and 1.06 times the rated

voltage.

Duration of test is most unfavorable conditions of normal use.

The protective device shall not operate during except protective electronic circuits are

allowed to operate provided they are tested for following number of cycle of operations:

Reference Drawing of BLDC Fan Connections.

Date SOP Issued Issue No 01

SOP Revision Date 00 Rev. No 00

Prepared by Vijay Tambatkar Reviewed/Approved by

Date Date:

You might also like

- Luminaires Part 2: Particular Requirements Section 5: FloodlightsDocument58 pagesLuminaires Part 2: Particular Requirements Section 5: FloodlightsKevin Eduardo Palpa MedranoNo ratings yet

- Operational Qualification Protocol OF Vacuum Tray DryerDocument9 pagesOperational Qualification Protocol OF Vacuum Tray DryerNishit SuvaNo ratings yet

- Series Resonance Circuits PDFDocument16 pagesSeries Resonance Circuits PDFnpavankNo ratings yet

- Physics Investigatory ProjectDocument17 pagesPhysics Investigatory ProjectSubhasish BeheraNo ratings yet

- 6 PreheatingDocument63 pages6 PreheatingvgNo ratings yet

- Slump Cone and Rod - CalibrationDocument1 pageSlump Cone and Rod - CalibrationKannan MurugesanNo ratings yet

- Aging Test Report (3000hours) LM84Document9 pagesAging Test Report (3000hours) LM84Anouer Belkadi100% (1)

- 4.25.11.WPE - Lab. Personal Power Stairs LabDocument4 pages4.25.11.WPE - Lab. Personal Power Stairs LabArra VillanuevaNo ratings yet

- ASME Impact Test RequirementDocument15 pagesASME Impact Test Requirementumar_hazrad8219No ratings yet

- VINDAIR SOP.01 Duct Pressure TestDocument3 pagesVINDAIR SOP.01 Duct Pressure TestRamakrishna Agumbe100% (2)

- IRT Report FormatDocument7 pagesIRT Report Formatshahbaz akramNo ratings yet

- Test Report For Lab Iso 17025Document6 pagesTest Report For Lab Iso 17025vines7831No ratings yet

- Ipp 260 EcoDocument25 pagesIpp 260 EcoYoosu NguyenNo ratings yet

- QC - 08 PTCDocument5 pagesQC - 08 PTCmahendraNo ratings yet

- Induction Motor Testing at FactoryDocument7 pagesInduction Motor Testing at FactorysrinivasgillalaNo ratings yet

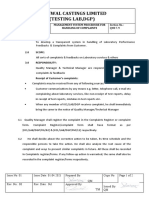

- Kejriwal Castings Limited (Testing Lab, DGP) : 1.0 PurposeDocument2 pagesKejriwal Castings Limited (Testing Lab, DGP) : 1.0 PurposeAniruddha ChatterjeeNo ratings yet

- Testing & Commissioning Certificate For SPRKDocument2 pagesTesting & Commissioning Certificate For SPRKgururaj100% (3)

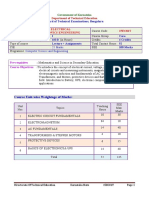

- Daily Lesson Log: (1st Quarter)Document11 pagesDaily Lesson Log: (1st Quarter)Marissa FontanilNo ratings yet

- Full Download Solution Manual For Electrical Engineering Concepts and Applications S A Reza Zekavat PDF Full ChapterDocument36 pagesFull Download Solution Manual For Electrical Engineering Concepts and Applications S A Reza Zekavat PDF Full Chaptersizerarresteed2ygt100% (19)

- SOP - BLDC - CF - 004 - Interchangeability TestDocument1 pageSOP - BLDC - CF - 004 - Interchangeability Testvijay.tambatkarNo ratings yet

- SOP - BLDC CF - Starting TestDocument1 pageSOP - BLDC CF - Starting Testvijay.tambatkarNo ratings yet

- تقرير هئيه الطاقه الجديده والمتجددهDocument11 pagesتقرير هئيه الطاقه الجديده والمتجددهInter Solar EgyptNo ratings yet

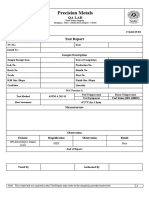

- Precision Metals: Qa LabDocument1 pagePrecision Metals: Qa Labpm metlabNo ratings yet

- SOP Name SOP For Aluminum Tube Heater Quality Test (Refrigerator) DATE ISSUED 07.07.2020Document7 pagesSOP Name SOP For Aluminum Tube Heater Quality Test (Refrigerator) DATE ISSUED 07.07.2020swapon kumar shillNo ratings yet

- Certificate of Quality: MOGAS-95Document1 pageCertificate of Quality: MOGAS-95Basant Kumar SaxenaNo ratings yet

- SOP Name SOP For Aluminum Foil Heater Quality Test (Refrigerator) DATE ISSUED 07.07.2020Document7 pagesSOP Name SOP For Aluminum Foil Heater Quality Test (Refrigerator) DATE ISSUED 07.07.2020swapon kumar shillNo ratings yet

- Unique Group ResearchDocument2 pagesUnique Group ResearchUNIQUE CALIBRATION SOLUTIONSNo ratings yet

- Vega Plast E84 3167672.nov 27-08-1Document12 pagesVega Plast E84 3167672.nov 27-08-1DecorPlastics.com100% (2)

- SQ1 Mogas95Document1 pageSQ1 Mogas95Basant Kumar SaxenaNo ratings yet

- Control Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Document4 pagesControl Plan - Tie Rod 1.375'-12-2A UNFX12.78, 84B515663ADP1.Himanshu MishraNo ratings yet

- CAPA Escort (08.08.2023)Document1 pageCAPA Escort (08.08.2023)HOD QUALITYNo ratings yet

- M38T0004 (Corrosion Test Method 1)Document14 pagesM38T0004 (Corrosion Test Method 1)Carlos MENEZESNo ratings yet

- YesDocument3 pagesYesmahmoodreza.shadfarNo ratings yet

- Non Electrical Test Lab. PresentationDocument121 pagesNon Electrical Test Lab. PresentationYomna SamiNo ratings yet

- Crs 000007Document2 pagesCrs 000007ahetesham marufNo ratings yet

- WC059 AMG Metal Non Drainable Louver Test - MSRKDocument9 pagesWC059 AMG Metal Non Drainable Louver Test - MSRKAMG Co.No ratings yet

- Iso/Iec 17025:2005, Accredited by Nabl, Constituent Board of Quality Council of India in The Field of Chemical and Mechanical TestingDocument6 pagesIso/Iec 17025:2005, Accredited by Nabl, Constituent Board of Quality Council of India in The Field of Chemical and Mechanical Testingpuri16No ratings yet

- Penetration of Bituminous Material - Method ASTM D5/D5M-19a: Sample Identification Water Bath Temperature 2 3 1Document1 pagePenetration of Bituminous Material - Method ASTM D5/D5M-19a: Sample Identification Water Bath Temperature 2 3 1jerin sam kurianNo ratings yet

- Test ReportDocument9 pagesTest ReportAlberto Aleman AquinoNo ratings yet

- Gridmesh Anchor Test Report ANSI Z359.18Document14 pagesGridmesh Anchor Test Report ANSI Z359.18IMIXCINo ratings yet

- M38T0005 (Corrosion Test Method 4)Document11 pagesM38T0005 (Corrosion Test Method 4)Carlos MENEZESNo ratings yet

- 03 Initial and Final SettingDocument1 page03 Initial and Final SettingjitendraNo ratings yet

- Astm D8047 - 19Document43 pagesAstm D8047 - 19mancjaNo ratings yet

- Test Report For APP Water Proofing Membrane: Sample InformationDocument1 pageTest Report For APP Water Proofing Membrane: Sample InformationcivillabNo ratings yet

- GBDFFDocument1 pageGBDFFESHWAR CHARYNo ratings yet

- Continental Collection EN1021-1 CertificateDocument3 pagesContinental Collection EN1021-1 CertificateLilian IbimarNo ratings yet

- 10 Multiple Choice QuestionsDocument3 pages10 Multiple Choice QuestionsArchaios DrakosNo ratings yet

- Attock Refinery Limited: Quality Control LaboratoryDocument1 pageAttock Refinery Limited: Quality Control Laboratoryrafaqat hussainNo ratings yet

- L22-626 Metrological COM Testing FinalDocument2 pagesL22-626 Metrological COM Testing FinalVERONICANo ratings yet

- Certificate of Analysis: National Plastic Factory L.L.C Date SupplierDocument1 pageCertificate of Analysis: National Plastic Factory L.L.C Date SupplierSunny SelvarajNo ratings yet

- Test CertificateDocument3 pagesTest CertificateMata Gyan Devi Endocrine CentreNo ratings yet

- 75 kVA Single Phase Distribution Transformer Test ResultDocument9 pages75 kVA Single Phase Distribution Transformer Test ResultCarlNo ratings yet

- 80mm Zigzag MTCDocument1 page80mm Zigzag MTCQAQC ZFNo ratings yet

- ASTM D6794 (2019) - Engine Filter AbilityDocument7 pagesASTM D6794 (2019) - Engine Filter Abilityرضا ساریخانیNo ratings yet

- Test and Software Calibration Procedures.: Geniusmt / JokermtDocument6 pagesTest and Software Calibration Procedures.: Geniusmt / JokermtДрагомир ВеликовNo ratings yet

- COA - Intergard 821 ADocument1 pageCOA - Intergard 821 AZarni KyawNo ratings yet

- Crs 000008Document2 pagesCrs 000008ahetesham marufNo ratings yet

- Test Certificate: of Special TestsDocument5 pagesTest Certificate: of Special TestsCristhian Sleiter Copa ZevallosNo ratings yet

- Kejriwal Castings Limited (Testing Lab, DGP) : 1.0 PurposeDocument3 pagesKejriwal Castings Limited (Testing Lab, DGP) : 1.0 PurposeAniruddha ChatterjeeNo ratings yet

- Ies-Industrial Engineering Services: Hydraulic Test ReportDocument7 pagesIes-Industrial Engineering Services: Hydraulic Test ReportMD Shadikul Huq ShezanNo ratings yet

- Westmoreland Mechanical Testing and Research, Inc.: 14 Bayhill DriveDocument4 pagesWestmoreland Mechanical Testing and Research, Inc.: 14 Bayhill Driveamirkhakzad498No ratings yet

- Test Report: Terms & ConditionsDocument1 pageTest Report: Terms & Conditionschetan selokarNo ratings yet

- Test ReportDocument7 pagesTest ReportJob TiruNo ratings yet

- PT - Turbo Daya Mekanika: Instrument File ReportDocument26 pagesPT - Turbo Daya Mekanika: Instrument File ReportandriNo ratings yet

- TRX - Vertical Multistage Inline - 2019-16Document1 pageTRX - Vertical Multistage Inline - 2019-16Jason Wei Han LeeNo ratings yet

- Science-9 WLP Week 2Document9 pagesScience-9 WLP Week 2VERNA NGONo ratings yet

- WaveDocument5 pagesWaveArijitSherlockMudiNo ratings yet

- General Chemistry Module 1: Chapter 1: Kinetic Particle TheoryDocument5 pagesGeneral Chemistry Module 1: Chapter 1: Kinetic Particle TheoryKeano GelmoNo ratings yet

- Topic: Measuring Instrument Analogue InstrumentsDocument6 pagesTopic: Measuring Instrument Analogue InstrumentsParmanand AlvinNo ratings yet

- QuizDocument2 pagesQuizItsMeRyanCNo ratings yet

- Heat Eachner DesignDocument32 pagesHeat Eachner DesignCH1253No ratings yet

- INTRODocument2 pagesINTROPrincess kc DocotNo ratings yet

- Eddy Current Acknowledgement PDFDocument22 pagesEddy Current Acknowledgement PDFShanmuga PriyanNo ratings yet

- Parameters of A Transmission LinesDocument26 pagesParameters of A Transmission LinesFrancis IlardeNo ratings yet

- Unit 2 - DC Generators - 6/8/10 Marks Questions: Msec/Eee Dr.B.BalaganeshDocument2 pagesUnit 2 - DC Generators - 6/8/10 Marks Questions: Msec/Eee Dr.B.BalaganeshNaveen Raj ENo ratings yet

- 1 TEDC 2105 Electrical Energy Generation and UtilizationDocument35 pages1 TEDC 2105 Electrical Energy Generation and UtilizationKusiimaNo ratings yet

- Fizik K1 2022 Penggal 1Document13 pagesFizik K1 2022 Penggal 1AHMAD SUHAIMI HalimNo ratings yet

- PHY 221 Long Quiz #3 - MagnetismDocument1 pagePHY 221 Long Quiz #3 - MagnetismCatherine Shaina O. PasionNo ratings yet

- AC Transmission Line LossesDocument8 pagesAC Transmission Line LossesThakur YogendraNo ratings yet

- Transformer Design: Sylhet Engineering CollegeDocument23 pagesTransformer Design: Sylhet Engineering CollegeMohiuddin A SiddikNo ratings yet

- Week 2.apsychrometry-Air ConditioningdocxDocument20 pagesWeek 2.apsychrometry-Air ConditioningdocxMariel MirafloresNo ratings yet

- ISV SM Ch32Document35 pagesISV SM Ch32손은결No ratings yet

- Conversion Factor ProblemsDocument2 pagesConversion Factor ProblemsBeauMattyNo ratings yet

- 3.1 PressureDocument5 pages3.1 PressureFlorian_AngererNo ratings yet

- Thermofluid Practical 2.0Document37 pagesThermofluid Practical 2.0Tshawe IsaacNo ratings yet

- Motion NCert SolutionDocument23 pagesMotion NCert SolutionRamKumarSharmaNo ratings yet

- Lab 3 - Ohms Law and Series CircuitDocument5 pagesLab 3 - Ohms Law and Series CircuitHenry GallagherNo ratings yet

- 3.concepts of Electrical & Electronics EnggDocument15 pages3.concepts of Electrical & Electronics Enggakangadi09No ratings yet

- Mole and Molar Mass of Elements and Compounds - ReportDocument12 pagesMole and Molar Mass of Elements and Compounds - ReportIngrid KimNo ratings yet