Professional Documents

Culture Documents

07-Machinery Check List

07-Machinery Check List

Uploaded by

vinu0 ratings0% found this document useful (0 votes)

10 views2 pagesThis document provides a machinery preventive maintenance checklist for ANPAM Engineering. It lists 13 machinery items and the tasks to be completed on a daily, weekly, monthly, or yearly basis to maintain equipment. Checks include cleaning, oiling, electrical maintenance, and ensuring proper operation of components. The goal is to prevent breakdowns and keep all machinery running safely and efficiently through regularly scheduled inspections and servicing.

Original Description:

Original Title

07-Machinery Check list

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides a machinery preventive maintenance checklist for ANPAM Engineering. It lists 13 machinery items and the tasks to be completed on a daily, weekly, monthly, or yearly basis to maintain equipment. Checks include cleaning, oiling, electrical maintenance, and ensuring proper operation of components. The goal is to prevent breakdowns and keep all machinery running safely and efficiently through regularly scheduled inspections and servicing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views2 pages07-Machinery Check List

07-Machinery Check List

Uploaded by

vinuThis document provides a machinery preventive maintenance checklist for ANPAM Engineering. It lists 13 machinery items and the tasks to be completed on a daily, weekly, monthly, or yearly basis to maintain equipment. Checks include cleaning, oiling, electrical maintenance, and ensuring proper operation of components. The goal is to prevent breakdowns and keep all machinery running safely and efficiently through regularly scheduled inspections and servicing.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

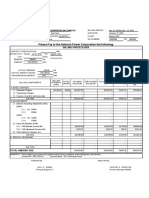

Document Code: AE/D/MTN/001

M/s. ANPAM ENGINEERING., Date of Issue: 12.10.2018

MATHUR, PUDUKKOTTAI – 622 515.

Rev No: 00

DEPT: MTN MACHINERY PREVENTIVE MAINTENANCE CHECK LIST PAGE 01 OF 02

FREQUENCY

SI .NO CHECK LIST Once in Once in Once in 6

Daily Weekly Monthly Yearly

3 days 15 days months

General

Energy meter display

Maximum Demand

Power Factor

01 Power Panel Seals -- -- -- -- -- --

Main Switches

Earthing

Fuses and Neutral Links

Surrounding

TIG / MIG –Inverter/Rectifier & Auto Welding Machine

Trans – Earthing, Termi - Tightening

02 Nozzle Checking with rail & welding Holder

-- -- --- -- --

Electrical Maintenance -- -- -- -- -- --

Cleaning -- -- -- -- --

Grinding Machine AG9&AG7&GQ5& AG4 &

Carbon Brushes -- -- --- -- --

03 Greasing -- -- -- -- ---

--

Electrical Maintenance -- -- -- ---

Cleaning -- -- ---

-- --

Pillar Drilling Machine & Magnetic Drilling Machine & Hand Drilling Machine & Die Grinder

Oiling -- -- -- -- ---

04 Greasing -- -- -- --- --

--

Electrical Maintenance -- -- -- --- --

Cleaning -- -- -- --- --

Prepared by: Manager Approved By: Proprietor

Signature: Signature:

Document Code: AE/D/MTN/001

M/s. ANPAM ENGINEERING., Date of Issue: 12.10.2018

MATHUR, PUDUKKOTTAI – 622 515.

Rev No: 00

DEPT: MTN MACHINERY PREVENTIVE MAINTENANCE CHECK LIST PAGE 02 OF 02

FREQUENCY

SI .NO CHECK LIST Once in Once in Once in

Daily Weekly Monthly Yearly

3 days 15 days 6 months

Air Compressor

05 Oil Level, Safety Valves, Cleaning -- -- -- -- --

--

Pressure Gauge -- -- -- -- --

Electrical Maintenance -- -- -- -- --

Gas Cutting Machine

07 Nasal Cleaning & Hose -- -- -- -- --

--

Regulator & Pressure Gauge Checking -- -- -- -- --

PUG Cutting Machine

08 Pipe & Nasal Cleaning -- -- --

Inside Dia frame , Pin Valve -- -- -- -- -- --

Electrical Maintenance -- --

09

Switch Boards

Plus & Sockets Cable -- -- -- -- -- --

Bench Grinding

Grinding Wheel Checking -- -- -- -- --

10

Electrical Check Up -- -- -- -- -- --

Cleaning -- -- -- -- --

Heating (Oven) / Flux Oven & Flask Oven

11. Heating Filament

Temp. Control, Door Closing, Cleaning Over all Maintenance

Electrical Check Up

12. Revit Machine

Oiling & Greasing & Cleaning Over all Maintenance

“A” Frame with Chain Pulley block

13. Oiling & Greasing, Chain Rope Movement

Over all Maintenance

Bolt & Nut Tightening

Prepared by: Manager Approved By: Proprietor

Signature: Signature:

You might also like

- 690C.D WD PDFDocument134 pages690C.D WD PDFYosmeli Zapata100% (1)

- Numeric Plasma Torch Height Controller Manual: (Type: RATE Series 1630)Document41 pagesNumeric Plasma Torch Height Controller Manual: (Type: RATE Series 1630)CiberNo ratings yet

- Equipment Calibration Record ChartDocument3 pagesEquipment Calibration Record ChartNatarajan MurugesanNo ratings yet

- Greenbook ManualDocument369 pagesGreenbook ManualbradalbiNo ratings yet

- Digital Photography GuidebookDocument58 pagesDigital Photography Guidebookmitzy01467% (3)

- Please Pay To The National Power Corporation The Following:: Billing ParticularsDocument5 pagesPlease Pay To The National Power Corporation The Following:: Billing ParticularsJaapar HassanNo ratings yet

- Daily Report 22 Juli 2022Document2 pagesDaily Report 22 Juli 2022Mobile LegendNo ratings yet

- PSM KPIsDocument2 pagesPSM KPIsHassan Rauf RaoNo ratings yet

- MTC FormatDocument1 pageMTC FormatNirmit GandhiNo ratings yet

- Atr-72 - 61 - 61-51-67-Mro-10000-001Document7 pagesAtr-72 - 61 - 61-51-67-Mro-10000-001Gino AcevedoNo ratings yet

- GR00005401 00Document32 pagesGR00005401 00TrevorNo ratings yet

- ASKO GearlessDocument20 pagesASKO GearlessRaja DuraiNo ratings yet

- 220 6720230 enUS SMDocument258 pages220 6720230 enUS SMGuillermo Guardia GuzmanNo ratings yet

- A.V.Steel Forgings PVT - LTD: Test CertificateDocument1 pageA.V.Steel Forgings PVT - LTD: Test CertificateNirmit GandhiNo ratings yet

- Purchase/ Services Requisition For International BranchesDocument1 pagePurchase/ Services Requisition For International Branchesmahmoud khtaNo ratings yet

- Form P2H Crusher & ElectrictDocument3 pagesForm P2H Crusher & ElectrictDodyElenNo ratings yet

- Total: .32,000.00Document1 pageTotal: .32,000.00fawad haiderNo ratings yet

- 2324MTC037 11361Document1 page2324MTC037 11361Shrikrushna DalviNo ratings yet

- 48K OverhaulDocument13 pages48K Overhaulscribd102No ratings yet

- DBR 2x18MWDocument107 pagesDBR 2x18MWErin WardNo ratings yet

- TM-11-5815-238-20 TT-76 SeriesDocument58 pagesTM-11-5815-238-20 TT-76 SeriesMilan StankovićNo ratings yet

- Form P2H Crusher & ElectrictDocument3 pagesForm P2H Crusher & ElectrictDodyElenNo ratings yet

- IFA - Issued For ApprovalDocument12 pagesIFA - Issued For ApprovalJHONATAN RODRIGUEZ VENTONo ratings yet

- Daily Check Sheet of All MachinesDocument4 pagesDaily Check Sheet of All Machinesrahul_2005100% (2)

- Dtr0000014684 - A2.Catpart: Access Service ViewDocument4 pagesDtr0000014684 - A2.Catpart: Access Service ViewRubenNo ratings yet

- Weekly Report Off Season 2019Document36 pagesWeekly Report Off Season 2019Juang P SetiawanNo ratings yet

- 1s-Oo-Oo: B E E C H C R A FDocument7 pages1s-Oo-Oo: B E E C H C R A FCristian PugaNo ratings yet

- KDGC 500 Control Panel Manual o DGC-2000 DIGITAL GENSET CONTROLLERDocument92 pagesKDGC 500 Control Panel Manual o DGC-2000 DIGITAL GENSET CONTROLLERnoriegascribdNo ratings yet

- Eng-Rle: Technical Specification I-ET-5400.00-1230-300-PEI-001 Ab-Pgi / Comperj 1 of 58Document58 pagesEng-Rle: Technical Specification I-ET-5400.00-1230-300-PEI-001 Ab-Pgi / Comperj 1 of 58Allyson LisboaNo ratings yet

- Yanmar TNV Series Ecm Engine Service ManualDocument10 pagesYanmar TNV Series Ecm Engine Service ManualPeter100% (49)

- 1.5 SCH 40 (B2101104)Document1 page1.5 SCH 40 (B2101104)Mahmoud MetwallyNo ratings yet

- Daihatsu Sirion Model m300 Series Service Manual No9890 MeterDocument32 pagesDaihatsu Sirion Model m300 Series Service Manual No9890 MeterMarx RedzNo ratings yet

- Contrato Entre Gila y El Gobierno de Puerto RicoDocument122 pagesContrato Entre Gila y El Gobierno de Puerto RicoEl Nuevo DíaNo ratings yet

- Contoh Perhitungan Sheet PileDocument8 pagesContoh Perhitungan Sheet PileAnonymous iU0Vh4pNo ratings yet

- AFI 125 HCl-NaOH SystemDocument3 pagesAFI 125 HCl-NaOH Systempepenapao1217No ratings yet

- 4700Document278 pages4700Paul ByrneNo ratings yet

- Tektronix 2205 - Oscilloscope SMDocument181 pagesTektronix 2205 - Oscilloscope SMavs2773No ratings yet

- Toro Workman MD and MDXDocument238 pagesToro Workman MD and MDXATNo ratings yet

- Engine Lubrication System: SectionDocument21 pagesEngine Lubrication System: SectionDaniel Oliveira de ChavesNo ratings yet

- Siremobil Iso-C: © Si e M e Ns AG 1 9 9 8Document50 pagesSiremobil Iso-C: © Si e M e Ns AG 1 9 9 8Eduardo Saul MendozaNo ratings yet

- SC13003-C9001-Q03-0009-2 - ITP Main Cooling Water MotorDocument4 pagesSC13003-C9001-Q03-0009-2 - ITP Main Cooling Water MotorDwi Mulyanti DwimulyantishopNo ratings yet

- 369 Motor Management Relay - Instruction Manual PDFDocument262 pages369 Motor Management Relay - Instruction Manual PDFSidnei PereiraNo ratings yet

- 8900d Radar Gauge - Calibration ManualDocument18 pages8900d Radar Gauge - Calibration ManualhussamNo ratings yet

- MOM IPP 3 - PLTU Kalteng 1 - Desember 2020Document46 pagesMOM IPP 3 - PLTU Kalteng 1 - Desember 2020Rina YNo ratings yet

- 2 GP39 2Document60 pages2 GP39 2jrigorighiNo ratings yet

- Commissioning Report - HEXDocument24 pagesCommissioning Report - HEXGrace PentinioNo ratings yet

- Electronic Control Manual: YanmarDocument162 pagesElectronic Control Manual: YanmarPhan Dung100% (1)

- Yanmar Electronic Repair Manual For Hyundai MachinesDocument162 pagesYanmar Electronic Repair Manual For Hyundai MachinesHarrier Technologies100% (7)

- HSE PERFORMANCE REPORT APRIL 2021 - RedactedDocument2 pagesHSE PERFORMANCE REPORT APRIL 2021 - RedactedRizaNo ratings yet

- Sensors and Actuators (FinalDocument66 pagesSensors and Actuators (Finalfarid salmaniNo ratings yet

- Monthly Maintenance - FEB 2020Document2 pagesMonthly Maintenance - FEB 2020babul_jalajNo ratings yet

- 220 3DR E12 00001Document39 pages220 3DR E12 00001PabloNo ratings yet

- Ct2ea LCD With Rs 485Document10 pagesCt2ea LCD With Rs 485Prabhu Natarajan0% (1)

- 2006 Toyota VEHICLE DIAGNOSTIC REPORT - 4T1BE32K36U139465 - 20230210115953Document1 page2006 Toyota VEHICLE DIAGNOSTIC REPORT - 4T1BE32K36U139465 - 20230210115953eduardo maciasNo ratings yet

- Manual Ascon - 2Document62 pagesManual Ascon - 2Sadikul FuadNo ratings yet

- Segeg Tech SpecDocument44 pagesSegeg Tech SpecMaulid100% (1)

- vt651 mk2 Maintenance ManualDocument210 pagesvt651 mk2 Maintenance ManualDaniel Amanor100% (2)

- August MAYNILAD BILLDocument1 pageAugust MAYNILAD BILLJIRA JINN GONZALESNo ratings yet

- Jet 16 CH2 Maintenance Manual - 0208228763025Document40 pagesJet 16 CH2 Maintenance Manual - 0208228763025GSE CNF RealaviationNo ratings yet

- Driver Information System: SectionDocument42 pagesDriver Information System: SectionJarden VegaNo ratings yet

- 3 U 141 SogDocument228 pages3 U 141 SogGAS PLANTNo ratings yet

- LG Microwave PDFDocument35 pagesLG Microwave PDFReynaldo FloresNo ratings yet

- WPS 006Document2 pagesWPS 006vinuNo ratings yet

- XL - ReportDocument1 pageXL - ReportvinuNo ratings yet

- RT - ReportDocument1 pageRT - ReportvinuNo ratings yet

- Supplier Introduction FormDocument2 pagesSupplier Introduction FormvinuNo ratings yet

- 074 - ANPAM EnggDocument1 page074 - ANPAM EnggvinuNo ratings yet

- 12.co2 100V 112 - 2ND MeterDocument1 page12.co2 100V 112 - 2ND MetervinuNo ratings yet

- 6.400a 106Document1 page6.400a 106vinuNo ratings yet

- 9.200a 109Document1 page9.200a 109vinuNo ratings yet

- 11.co2 400a 111 - 1meterDocument1 page11.co2 400a 111 - 1metervinuNo ratings yet

- 10.200a 110Document1 page10.200a 110vinuNo ratings yet

- 2.P Gauge 102Document1 page2.P Gauge 102vinuNo ratings yet

- 4.400a 104Document1 page4.400a 104vinuNo ratings yet

- 02-Job Card - AEDocument2 pages02-Job Card - AEvinuNo ratings yet

- 1.oven 101Document1 page1.oven 101vinuNo ratings yet

- 1-Docs Distribution PlanDocument1 page1-Docs Distribution PlanvinuNo ratings yet

- 0.MVR 2020 030Document4 pages0.MVR 2020 030vinuNo ratings yet

- 5-Master List of RecordsDocument2 pages5-Master List of RecordsvinuNo ratings yet

- 2 - Daily PlanDocument1 page2 - Daily PlanvinuNo ratings yet

- 2 - Daily PlanDocument2 pages2 - Daily PlanvinuNo ratings yet

- 1.2020-030-Valve and Fittings TracDocument1 page1.2020-030-Valve and Fittings TracvinuNo ratings yet

- Atms Display On WebsiteDocument117 pagesAtms Display On Websitevinu100% (1)

- ATM Dos DontsDocument2 pagesATM Dos DontsvinuNo ratings yet

- 22 03 2018 HVAC Rev-2A Final DWGDocument22 pages22 03 2018 HVAC Rev-2A Final DWGSaleh El-hawaryNo ratings yet

- Strowger Switch - PPSXDocument22 pagesStrowger Switch - PPSXCharles Kenn MantillaNo ratings yet

- 03 - Weekly Report W1 With LBD 01 - 10 November 2022Document23 pages03 - Weekly Report W1 With LBD 01 - 10 November 2022kkmechNo ratings yet

- Hydraulic Drive Head Motor: The Sensible ChoiceDocument2 pagesHydraulic Drive Head Motor: The Sensible Choicechaky212No ratings yet

- AAiT Introduction To Electro-PneumaticsDocument71 pagesAAiT Introduction To Electro-PneumaticsSamuel WozabNo ratings yet

- Fotometrijski ProračunDocument16 pagesFotometrijski ProračundannniiillloooNo ratings yet

- FC1500 User ManualDocument15 pagesFC1500 User ManualAndre GalarzaNo ratings yet

- Material List: Saudi Arabian Oil CompanyDocument1 pageMaterial List: Saudi Arabian Oil CompanybalajiNo ratings yet

- PTSC1 ManualDocument2 pagesPTSC1 ManualNguyen Tran Duc ThinhNo ratings yet

- Manual de Utilizare Fotocelule MF30 11Document1 pageManual de Utilizare Fotocelule MF30 11Pintea Ioan DanutNo ratings yet

- Centrfugos ECDocument52 pagesCentrfugos ECAdil BorjaNo ratings yet

- L&T Panel Accessories Price List 01JUL2017Document44 pagesL&T Panel Accessories Price List 01JUL2017TarunPatraNo ratings yet

- THHN TC FuerzaDocument2 pagesTHHN TC Fuerzajuan pablo castro gallegoNo ratings yet

- Galli Freddo Broch.3anteDocument2 pagesGalli Freddo Broch.3anteRenato MrCoachNo ratings yet

- UHP Water Jetting Unit: Ultrabar 10 ECDocument1 pageUHP Water Jetting Unit: Ultrabar 10 ECFrederik CañabiNo ratings yet

- Shear Release Disconnect Sub (Torque Thro') Hydraulic Disconnect Sub (Torque Thro') Burst Disc Circulating Sub Dual Function Circulating SubDocument6 pagesShear Release Disconnect Sub (Torque Thro') Hydraulic Disconnect Sub (Torque Thro') Burst Disc Circulating Sub Dual Function Circulating SubJones LakerNo ratings yet

- KPT Electrical Portable Power Tools Price List May 2012 PDFDocument4 pagesKPT Electrical Portable Power Tools Price List May 2012 PDFsekhargm0% (1)

- Solar PV Installer - ElectricalDocument7 pagesSolar PV Installer - Electricaljaveeed0401100% (2)

- Monark 915 Exploded DiagramDocument2 pagesMonark 915 Exploded Diagramحسين الزينNo ratings yet

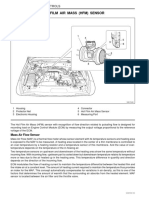

- Hot Film Air Mass (HFM) Sensor: 1F1-50 M162 Engine ControlsDocument4 pagesHot Film Air Mass (HFM) Sensor: 1F1-50 M162 Engine Controlskrishna prakashNo ratings yet

- ValvesDocument108 pagesValvesShakerMahmood100% (1)

- Pigtail and Patch Cord: AppearanceDocument2 pagesPigtail and Patch Cord: AppearanceСергей МирошниченкоNo ratings yet

- Vit Series: Inlinecentrifugal Duct FanDocument3 pagesVit Series: Inlinecentrifugal Duct FanTedi A MaulanaNo ratings yet

- XG110 160kWAVDocument26 pagesXG110 160kWAVAgeng A. PooNo ratings yet

- UENR76350001 Interactivo 994K Sistema EléctricoDocument43 pagesUENR76350001 Interactivo 994K Sistema EléctricoWaldo HuanchicayNo ratings yet

- 2021 Air Conditioners CatalogueDocument20 pages2021 Air Conditioners CatalogueSan DeepNo ratings yet