Professional Documents

Culture Documents

ProblemSheet - Unit 1

Uploaded by

Vishal VaziraniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ProblemSheet - Unit 1

Uploaded by

Vishal VaziraniCopyright:

Available Formats

DEI-FOE MEM-103 Problem Sheet: Mechanical Properties of Materials

1. A steel rod 6 mm in diameter is under the action of a tensile force of 800 Newtons. Calculate the tensile stress in the bar.

2. A 30-mm gauge length is marked on an aluminium test piece. The test piece is strained in tension so that the gauge length becomes

32.3 mm. Calculate the strain.

3. A steel wire, 0.5 mm2 in cross-sectional area, and 10m long is extended elastically 1.68 mm by a force of 18 N. Calculate the modulus

of elasticity for the steel.

4. A 200-mm-long strip of metal is stretched in two steps, first to 300 mm and then to 400 mm. Show that the total true strain is the sum

of the true strains in each step; in other words, the true strains are additive. Show that, in the case of engineering strains, the strains

cannot be added to obtain the total strain.

5. A paper clip is made of wire 0.7 mm in diameter. If the original material from which the wire is made is a rod 25 mm in diameter,

calculate the longitudinal engineering and true strains that the wire has undergone during processing.

6. A steel rod having 0.1 mm diameter and 1.5 m length is subjected to an axial pull of 1 kN. Find (a) stress (b) strain and (c) elongation.

Assume modulus of elasticity E = 205 × 106 kN/m2.

The following data were obtained during the tensile test of a steel specimen having 30 mm diameter and 200 mm length.

Extension at a load of 50 kN = 0.1 mm

Load at elastic limit = 230 kN

Maximum load = 300 kN

Total extension = 50 mm, Diameter of rod at failure = 20 mm

Calculate (a) Young’s modulus (b) percentage elongation (c) percentage decrease in area.

7. A short timber post of rectangular cross section has one side of section twice the other. When the timber post is subjected to compressive

load of 10 kN it contracts by 0.0521 mm for 1 m length. If the modulus of elasticity of timber is 12 GPa, calculate the dimensions of

the post.

8. A tensile test uses a test specimen that has a gage length of 50 mm and an area = 200 mm2. During the test the specimen yields under a

load of 98,000 N. The corresponding gage length = 50.23 mm. This is the 0.2 percent yield point. The maximum load = 168,000 N is

reached at a gage length = 64.2 mm. Determine: (a) yield strength Y, (b) modulus of elasticity E, and (c) tensile strength TS.

9. A copper wire of diameter 0.80 mm fails at an engineering stress = 248.2 MPa. Its ductility is measured as 75% reduction of area.

Determine the true stress and true strain at failure.

10. List and explain the desirable mechanical properties of :

(a) an elevator cable,

(b) a paper clip,

(c) a leaf spring for a truck,

(d) a bracket for a bookshelf,

(e) piano wire,

(f) a wire coat hanger, (g) the clip for a pen, and (h) a staple.

You might also like

- Babu Banarasi Das: Practice QuestionsDocument7 pagesBabu Banarasi Das: Practice QuestionsNeeraj KshatriyaNo ratings yet

- CE6306 SOM Important QuestionsDocument4 pagesCE6306 SOM Important QuestionsUTHIRANo ratings yet

- Metal Casting Lectures NotesDocument125 pagesMetal Casting Lectures NotesSabir AliNo ratings yet

- BOQ 2 Mugema RoadDocument6 pagesBOQ 2 Mugema RoadBAMS100% (1)

- The Modern Field Development ApproachDocument9 pagesThe Modern Field Development ApproachEyoma Etim100% (2)

- Vernacular Architecture of Jammu & KashmirDocument51 pagesVernacular Architecture of Jammu & KashmirMeenu50% (4)

- MEM103 - Problems Sheet - Mechanical Properties of Materials - Problems Sheet - Mechanical Properties of MaterialsDocument2 pagesMEM103 - Problems Sheet - Mechanical Properties of Materials - Problems Sheet - Mechanical Properties of MaterialsEashurock KnigamNo ratings yet

- Home Work 1 2015Document2 pagesHome Work 1 2015Misbah NiamatNo ratings yet

- Applied Mechanics (ME 14.101) Tutorial Sheet-6: (Tension, Compression & Shear)Document1 pageApplied Mechanics (ME 14.101) Tutorial Sheet-6: (Tension, Compression & Shear)atulkumargaur26No ratings yet

- Amd Tutorial Me Cadcam 2017Document5 pagesAmd Tutorial Me Cadcam 2017rip111176No ratings yet

- SOM Assignment QuestionsDocument6 pagesSOM Assignment QuestionsPrajwal RpNo ratings yet

- AMD Tutorial ME CADCAM 2022-23Document6 pagesAMD Tutorial ME CADCAM 2022-23rip111176No ratings yet

- Assignment 3Document3 pagesAssignment 3Hasan AliNo ratings yet

- ProblemsDocument8 pagesProblemskishoreNo ratings yet

- Exercise 1Document1 pageExercise 1Aa AnimationsNo ratings yet

- Tutorial 2 Chapter 3 - Mechanical, Electrical and Thermal PropertiesDocument2 pagesTutorial 2 Chapter 3 - Mechanical, Electrical and Thermal PropertiesHafizatul AqmarNo ratings yet

- QbankDocument8 pagesQbanknkchandruNo ratings yet

- Sterngth of MaterialsDocument2 pagesSterngth of Materialschandru civilNo ratings yet

- Tutorial 2 AnswerDocument8 pagesTutorial 2 AnswerservetNo ratings yet

- Assignment No 1 MD-1..Document3 pagesAssignment No 1 MD-1..Yadnyesh TaNo ratings yet

- Problems in I UnitDocument6 pagesProblems in I UnitjeroldscdNo ratings yet

- Bending AssignmentDocument1 pageBending AssignmentGhanvir SinghNo ratings yet

- Met201 Tutorial 3Document3 pagesMet201 Tutorial 3SijuKalladaNo ratings yet

- Worked Solution To Various QuestionsDocument29 pagesWorked Solution To Various QuestionsJohn MutumaNo ratings yet

- CH6 AssignmetDocument11 pagesCH6 AssignmetHasan AhmedNo ratings yet

- Strength WorksheetDocument9 pagesStrength WorksheetHabtamu GetaNo ratings yet

- Mom AssignmentDocument8 pagesMom AssignmentfrogNo ratings yet

- Me2254 SM QBDocument15 pagesMe2254 SM QBhodvmkvecautoNo ratings yet

- Tutorial 3Document3 pagesTutorial 3Sothea ChimNo ratings yet

- ProblemSession1 2024Document2 pagesProblemSession1 2024s2038163No ratings yet

- Test On Strength of MaterialDocument9 pagesTest On Strength of MaterialJonathan Green100% (1)

- Mechanical ScienceDocument12 pagesMechanical ScienceFernando EyzaguirreNo ratings yet

- Me2254 QBDocument18 pagesMe2254 QBAinnar Kesavan0% (1)

- G For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of TheDocument6 pagesG For The Material Is 82 GN/m2. If The I-Section Is Replaced by A T-Section Made of Theክበር ተመስጌንNo ratings yet

- Sheet Metal Working& Powder MetallurgyDocument13 pagesSheet Metal Working& Powder Metallurgyanant709skNo ratings yet

- Simple Stresses and Strains ExerciseDocument3 pagesSimple Stresses and Strains ExercisechegedennNo ratings yet

- PSC TutorialDocument2 pagesPSC TutorialRevaNo ratings yet

- SOM Question Bank For RevisionDocument11 pagesSOM Question Bank For RevisiongoldencometNo ratings yet

- Machine Desig1Document1 pageMachine Desig1Francis John S. TanarteNo ratings yet

- Bai Tap - Vat Lieu Hoc - Phan Tinh Chat - NTS - v1Document26 pagesBai Tap - Vat Lieu Hoc - Phan Tinh Chat - NTS - v1Hoàng BeeNo ratings yet

- Assignment No. 2 Mechanics of Solids (NME-302)Document2 pagesAssignment No. 2 Mechanics of Solids (NME-302)nitin_johriNo ratings yet

- SM Model Exam QuestionDocument5 pagesSM Model Exam QuestionAravind PhoenixNo ratings yet

- Answer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameDocument10 pagesAnswer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NamegalehNo ratings yet

- SM Coaching QuestionDocument3 pagesSM Coaching QuestionSelvaraj GNo ratings yet

- Ce 6306 Som QBDocument11 pagesCe 6306 Som QBHODMECHANICAL AKTMCETNo ratings yet

- مسائل الخواص الميكانيكيةDocument2 pagesمسائل الخواص الميكانيكيةا.م معتز باللهNo ratings yet

- MOS Assignment II Autumn 2022-23Document6 pagesMOS Assignment II Autumn 2022-23PankajNo ratings yet

- DME Assignment 1Document2 pagesDME Assignment 1sumikannuNo ratings yet

- Mehcanics of Solids May2004 RR 220304Document8 pagesMehcanics of Solids May2004 RR 220304Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Answers 1Document4 pagesAnswers 1AhmedAhmedNo ratings yet

- Bulk Problems PDFDocument5 pagesBulk Problems PDFSatyasankar LgNo ratings yet

- Som TutorialsDocument22 pagesSom TutorialsbaizubirajiNo ratings yet

- 18ME404 Assignment 1Document2 pages18ME404 Assignment 1BharanitharanNo ratings yet

- 9A01302 Strength of Materials - IDocument8 pages9A01302 Strength of Materials - IsivabharathamurthyNo ratings yet

- Queastion Bank MOM 22 26Document5 pagesQueastion Bank MOM 22 26karvaminNo ratings yet

- 9A01401 Strength of Materials - IIDocument4 pages9A01401 Strength of Materials - IIsivabharathamurthyNo ratings yet

- Home Assignment 5Document2 pagesHome Assignment 5SantoshNo ratings yet

- Mechanics of Solids Nov2003 or 210851Document2 pagesMechanics of Solids Nov2003 or 210851Nizam Institute of Engineering and Technology LibraryNo ratings yet

- Assignment ProblemsDocument3 pagesAssignment ProblemsKaushik SreenivasNo ratings yet

- Unit 1 RamDocument3 pagesUnit 1 RamVENKATESHNo ratings yet

- SM Assignment 1Document1 pageSM Assignment 1vikram eedaNo ratings yet

- Answer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameDocument2 pagesAnswer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameavinashNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

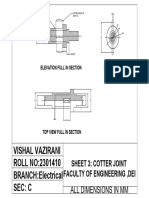

- VivankDocument3 pagesVivankVishal VaziraniNo ratings yet

- VISHAL @2301410-Sheet3lDocument1 pageVISHAL @2301410-Sheet3lVishal VaziraniNo ratings yet

- Ilovepdf Merged RemovedDocument2 pagesIlovepdf Merged RemovedVishal VaziraniNo ratings yet

- Unsatisfactory & Consolidated Chart B.SC Hons 1st, 3rd & 5th SemDocument50 pagesUnsatisfactory & Consolidated Chart B.SC Hons 1st, 3rd & 5th SemVishal VaziraniNo ratings yet

- BT Electrical 8sem Consolidated ChartDocument3 pagesBT Electrical 8sem Consolidated ChartVishal VaziraniNo ratings yet

- Ilovepdf Merged RemovedDocument2 pagesIlovepdf Merged RemovedVishal VaziraniNo ratings yet

- BTECH (ELECTRICAL) - 1-Consolidated ChartDocument7 pagesBTECH (ELECTRICAL) - 1-Consolidated ChartVishal VaziraniNo ratings yet

- Build A Basement Root CellarDocument3 pagesBuild A Basement Root Cellarjonjeys100% (1)

- Design Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550Document8 pagesDesign Recommendations For Precast Concrete Structures: Reported by ACI-ASCE Committee 550nathanNo ratings yet

- Detalji Krovova - OluciDocument31 pagesDetalji Krovova - OluciSamirNo ratings yet

- Criterios de Falla Vesic (1975)Document13 pagesCriterios de Falla Vesic (1975)ira0218No ratings yet

- Tablas CM y CV - Asce 7-10Document9 pagesTablas CM y CV - Asce 7-10Josep R HerreraNo ratings yet

- Lesson Plan:: Unit SyllabusDocument6 pagesLesson Plan:: Unit SyllabusSurjit Kumar GandhiNo ratings yet

- Suncrest BrochureDocument46 pagesSuncrest BrochureS M SHEKAR AND CONo ratings yet

- KEI-PL-2102T 0 - Flowline Carbon Steel SpecDocument41 pagesKEI-PL-2102T 0 - Flowline Carbon Steel Specajaykg100% (1)

- Comparative Study On Dynamic Analysis of Composite, RCC & Steel StructureDocument8 pagesComparative Study On Dynamic Analysis of Composite, RCC & Steel StructureRajalakshmi JothivelNo ratings yet

- VIBROFLOTATIONDocument39 pagesVIBROFLOTATIONSOLOMON T. OMITOGUNNo ratings yet

- A Case History On Design, Construction, and Performance of Stone Column ...Document10 pagesA Case History On Design, Construction, and Performance of Stone Column ...Suthan PooranampillaiNo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Document11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Ono SoeratnoNo ratings yet

- Les EspacesDocument28 pagesLes EspacesSejal MengajiNo ratings yet

- KU SparePartDocument17 pagesKU SparePartPolycarp DansonNo ratings yet

- Local Flange Bending and Local Web Yielding Limit States in Steel Moment-Resisting ConnectionsDocument11 pagesLocal Flange Bending and Local Web Yielding Limit States in Steel Moment-Resisting ConnectionsMuhammad irfan javaidNo ratings yet

- Civil PDFDocument471 pagesCivil PDFankitNo ratings yet

- LED LINEAR PROFILE LIGHTING CATALOGUE 18 19 Edited EditedDocument42 pagesLED LINEAR PROFILE LIGHTING CATALOGUE 18 19 Edited EditedKeshav SinghNo ratings yet

- Pile Foundation: Typical Pile and Beam SectionDocument1 pagePile Foundation: Typical Pile and Beam SectionDhananjay KadamNo ratings yet

- Hydro-Mechanical Verification ReportDocument11 pagesHydro-Mechanical Verification ReportAnkit GautamNo ratings yet

- 3 EVER Panelboard PDFDocument1 page3 EVER Panelboard PDFGLITZ ELEKTRO BUILDERS CDO BRANCHNo ratings yet

- DUROFLEX2020 LimpiadorDocument8 pagesDUROFLEX2020 LimpiadorSolid works ArgentinaNo ratings yet

- Origin and Evolution of Brasilia: Seminar ReportDocument10 pagesOrigin and Evolution of Brasilia: Seminar Reporttintu cleetusNo ratings yet

- Leak Off TestDocument80 pagesLeak Off Testb4rfNo ratings yet

- Non-Linear Time History Analysis of Cable Stayed BridgesDocument56 pagesNon-Linear Time History Analysis of Cable Stayed Bridgespraxie100% (4)

- Vitra WCDocument160 pagesVitra WCcothacoNo ratings yet

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet