Professional Documents

Culture Documents

Sil-35-111 - Avox Systems, Inc.

Sil-35-111 - Avox Systems, Inc.

Uploaded by

reginaldo11Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sil-35-111 - Avox Systems, Inc.

Sil-35-111 - Avox Systems, Inc.

Uploaded by

reginaldo11Copyright:

Available Formats

SERVICE INFORMATION LETTER

AVOX Systems Inc., 225 Erie Street, Lancaster NY 14086-9502 USA

Tel: 716-683-5100 • Fax: 716-681-1089 • Vendor Code: 53655

US DOT RULE CHANGE REQUIRES REPLACEMENT OF PRESSURE RELIEF DEVICE (ALSO

REFERRED TO AS SAFETY OUTLET) ON CERTAIN P/N 801293 SERIES AND 801365 SERIES

CYLINDER AND REGULATOR ASSEMBLIES (CRA’S) IN ORDER TO SHIP BY AIR AS CARGO OR

COMPANY OWNED MATERIAL (COMAT) WHEN FILLED WITH OXYGEN.

SUMMARY

US DOT has issued a new rule governing the shipment of cylinder and regulator assemblies containing

oxygen by air as cargo or COMAT after October 1, 2008. The new rule requires a pressure relief device

(PRD) with a pressure range from 90 to 100 percent of the cylinder test pressure for cylinder type 3AA. Some

AVOX Systems CRA’s which include DOT Type 3AA steel cylinders were manufactured with a PRD that does

not conform to the new rule.

1. PLANNING INFORMATION

A. Effectivity

(1) Concerned equipment

This Service Information Letter applies to the CRA's listed in Table 1.

Table 1

End Item P/N’s of Affected P/N 801293 Series and 801365 Series CRA’s

801293-00 801365-10

801293-04 801365-11

(2) Aircraft

At the time of this Service Information Letter, 801293 Series CRA's were known to be operating

on Gulfstream and Raytheon aircraft and 801365 Series CRA's were known to be operating on

Cessna aircraft.

(3) On production line

CRA’s manufactured after January 1, 2008 will have a new safety outlet installed in the regulator.

(4) This Service Information Letter also applies to all units held in stores for service on the aircraft

listed in (2).

B. Reason

(1) The new US DOT rule (US 49 CFR 173.302(f)) changes the rating of the PRD on a charged CRA

that has a type 3AA cylinder when offered for transport aboard an aircraft as cargo or COMAT

after the time of the first hydrostatic test and requalification following October 1, 2008.

(2) This new rule does not affect CRA’s installed in aircraft as part of the required equipment for flight

unless the CRA is removed and offered for shipment as cargo or COMAT.

(3) It is recommended that the PRD be changed to comply at the next hydrostatic test, but no later

than the first hydrostatic test after October 1, 2008.

Rev: none SIL-35-111

20071112 Page 1 of 7

C. Description

(1) At the next hydrostatic test, but no later than the first hydrostatic test after October 1, 2008,

replace a non-compliant PRD with a PRD that complies with the new rule. There is one PRD on

a CRA.

(2) Install a label on the cylinder to indicate that the cylinder complies with the new rule.

D. Compliance

This Service Information Letter must be accomplished at the first scheduled hydrostatic test and

requalification after October 1, 2008 to enable the changed CRA to be transported as cargo or

COMAT aboard aircraft.

E. Manpower

(1) One Technician

(2) Estimated time: 30 minutes. (No additional manpower will be required if the unit is being

overhauled).

2. MATERIAL INFORMATION

A. Material – Availability

See Table 2

B. Industry Support Information

Not applicable.

C. Material necessary for Each Unit

Table 2 lists the parts necessary to accomplish this SIL.

(1) Material to be Purchased

One of the safety outlets in Table 2 is required for each CRA to be accomplished. Contact a

location in section 4. APPENDIX of this SIL for prices.

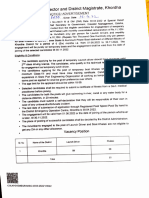

Table 2

Required Materials

Affected New Safety Label P/N Label P/N Avail.

CRA P/N Outlet P/N Qty (min qty=10) Qty (min qty=10) Qty (days)

801293-00 800659-06 1 10014464 1 2824-00 1 90

801293-04 800659-06 1 10014464 1 2824-00 1 90

801365-10 800659-01 1 10014464 1 2824-00 1 90

801365-11 800659-01 1 10014464 1 2824-00 1 90

D. Re-identified Parts

The regulator will be re-identified by stamping the new P/N on the replacement identification label P/N

2824-00 (see Table 3 and Figure 2) with a steel stamp of approximately 1/8 inch (3 mm) character

size.

Rev: none SIL-35-111

20071112 Page 2 of 7

Table 3

Conversion of Regulator and Safety Outlet Part Numbers

Old Revised

Affected Regulator Regulator Old Safety New Safety

CRA P/N P/N P/N Outlet P/N Outlet P/N

801293-00 801292-00 801292-05 800659-05 800659-06

801293-04 801292-01 801292-06 800659-05 800659-06

801365-10 801366-11 801366-15 800659-03 800659-01

801365-11 801366-10 801366-14 800659-03 800659-01

3. ACCOMPLISHMENT INSTRUCTIONS

WARNING: FAILURE TO FOLLOW THE PROCEDURES IN THIS SERVICE INFORMATION LETTER,

INCLUDING BUT NOT LIMITED TO FAILURE TO READ AND HEED THE WARNINGS IN

THIS SERVICE INFORMATION LETTER, OR ATTEMPTING TO PERFORM ANY OF THE

PROCEDURES IN THIS SERVICE INFORMATION LETTER UNLESS TRAINED IN THE

PROPER USE AND MAINTENANCE OF AVIATION OXYGEN EQUIPMENT, MAY

RESULT IN AN EXPLOSION, ILLNESS, SERIOUS PERSONAL INJURY, OR DEATH.

A. Read and understand all the information in this Service Information Letter before performing any

procedures on the CRA. Perform all procedures in the sequence of operations given. Do not attempt

to perform any of the procedures in this Service Information Letter unless you are trained and

qualified in the proper use and maintenance of aviation oxygen equipment. Maintenance personnel

must know how to avoid the hazards of maintaining aviation oxygen equipment and must comply with

all applicable government regulations.

WARNING: FAILURE TO CONTROL HIGH PRESSURE GASEOUS OXYGEN MAY RESULT IN

SERIOUS PERSONAL INJURY OR DEATH.

B. High pressure oxygen is a hazardous material. When pressurized oxygen is discharged intentionally

or due to equipment failure, the released energy can be highly destructive if not properly controlled.

Do not perform any procedure on an unsecured, charged, cylinder assembly. Also, while oxygen is

not a flammable material, it will accelerate combustion and must be considered a fire hazard. Refer to

paragraph 3.C. below.

WARNING: CONTAMINATION OF OXYGEN EQUIPMENT BY FAILING TO HANDLE OXYGEN

EQUIPMENT IN AN AREA CLEAN OF OIL, GREASE, FLAMMABLE SOLVENTS, OR

OTHER COMBUSTIBLE MATERIALS INCLUDING DUST, LINT, AND FINE METAL

PARTICLES; CONTAMINATION FROM FAILING TO USE CLEAN HANDS, GLOVES,

TOOLS; OR CONTAMINATION BY ANY OTHER MEANS, WHEN HANDLING OXYGEN

EQUIPMENT, MAY RESULT IN FIRE OR EXPLOSION THAT MAY CAUSE SERIOUS

PERSONAL INJURY OR DEATH.

C. If oxygen equipment becomes contaminated with oil, grease, flammable solvents, or other

combustible materials, fire and explosion may occur. Also, many substances and materials that do

not normally burn in air, including dust, lint, and fine metal particles can ignite in the presence of

oxygen. Handle oxygen equipment only in a clean area and with clean hands, gloves, and tools.

Rev: none SIL-35-111

20071112 Page 3 of 7

WARNING: FAILURE TO USE ONLY OXYGEN COMPATIBLE PRODUCTS, EQUIPMENT, AND

MATERIALS WHEN CARRYING OUT THE PROCEDURES IN THIS SIL, CAN BRING

ABOUT A VIOLENT REACTION RESULTING IN FIRE OR EXPLOSION THAT MAY

CAUSE SERIOUS PERSONAL INJURY OR DEATH.

D. Many commonly used materials may react violently in the presence of high pressure oxygen. Only

equipment and materials known to be compatible with oxygen should be used. Do not substitute

other equipment or materials such as elastomeric o-rings, gaskets, seals, and metal components,

even if they look the same.

WARNING: FAILURE TO USE EYE PROTECTION AT ALL TIMES DURING SERVICE OR

OVERHAUL PROCEDURES DESCRIBED IN THIS MANUAL MAY CAUSE INJURY TO

THE EYES.

E. Use eye protection at all times during all service or overhaul procedures.

WARNING: FAILURE TO FULLY DISCHARGE THE OXYGEN FROM THE CRA, COMPONENT

PARTS, OR TEST SETUP PRIOR TO DISASSEMBLY OF ANY PART MAY CAUSE

SERIOUS PERSONAL INJURY OR DEATH.

F. High pressure oxygen is a hazardous material. When pressurized oxygen is discharged intentionally

or due to equipment failure, the released energy can be highly destructive if not properly controlled.

Fully discharge the oxygen from the CRA, component parts, and test setup prior to disassembly of

any part.

NOTE: This SIL is to be accomplished off-wing. Do not use the Overhaul Manual H-173 to

accomplish this SIL. Follow the steps below which apply during a hydrostatic test, an

overhaul, a repair or strictly for the replacement of the safety outlet.

G. In a clean, grease-free area, bleed the oxygen from the cylinder.

H. Remove the regulator from the cylinder.

I. Remove and discard the safety outlet assembly (P/Ns 800659-03 or 800659-05) from the regulator.

J. Apply a light film of oxygen compatible lubricant to the exposed surface of the gasket in the safety

adapter (P/N 10001420) of the new safety outlet assembly (P/Ns 800659-01 or 800659-06). Refer to

Figure 1.

K. Thread the safety adapter (P/N 10001420) into the regulator outlet and torque to 325 inylbs

(36.7 Nym). Refer to Figure 1.

L. Hold the safety adapter with a wrench and torque the safety outlet nut (P/Ns 10723-00 or 22605-03)

to 300 inylbs (33.9 Nym) into the safety adapter (P/N 10001420).

M. Re-identify the regulator.

(1) Stamp the S/N from the current identification label onto the replacement identification label P/N

2824-00 (see Figure 2).

(2) Stamp the revised P/N from Table 3 onto the replacement identification label P/N 2824-00 (see

Figure 2).

(3) Remove the current identification label from the regulator.

(4) Attach the replacement identification label P/N 2824-00 to the regulator in place of the label that

was removed.

Rev: none SIL-35-111

20071112 Page 4 of 7

N. Use the appropriate technical documents to complete the hydrostatic test, overhaul, or repair if

required or do a leak test.

O. After the service has been completed, attach the P/N 10014464 Label (Figure 3) to the cylinder in the

location shown in Figure 4.

NOTE: On smaller cylinders the label can be placed in a location just below the identification label.

NOTE: Locate the label P/N 10014464 so that it will not be covered by the mounting band that will

hold the cylinder after installation.

P. Affected units listed in Table 1 can be shipped in an empty condition to an authorized repair facility

listed in paragraph 4. Appendix to have the SIL accomplished.

Safety Outlet Installation

Figure 1

Replacement Identification Label P/N 2824-00

Figure 2

Rev: none SIL-35-111

20071112 Page 5 of 7

US DOT Compliance Label P/N 10014464

Figure 3

Location of the Compliance Label on the Cylinder

Figure 4

Rev: none SIL-35-111

20071112 Page 6 of 7

4. APPENDIX

Contact Information:

AVOX Services Inc. IN-Services Europe

225 Erie Street 7, Avenue du Parana

Lancaster, NY 14086-9502 USA B.P. 303

91958 Courtaboeuf Cedex

Tel: 716-683-5100

France

Fax: 716-686-1751

Customer Services

Celine Robitaille

IN-Services Asia

Phone: 33 1 64 86 69 19

80 Chun Choi Street

Email: crobitaille@intertechnique.zodiac.com

Tseung Kwan O Industrial Estate

New Territories

Hong Kong, China IN-Services (Middle East)

Abu Dhabi International Airport

General Manager

P.O. Box 106675

Sebastien WEBER

Cargo Village Area

Email: weber.inasia@haeco.com

Abu Dhabi, U.A.E.

Customer Support Administration-

Shirley Huen GM and Sales Manager

Email: huen.inasia@haeco.com Boulouafi Bouach

Phone: (852) 2260 4050 Phone: (971) 2 672 5257

Fax: (852) 2260 4052 Email: bbouach@inservices-alrumaithy.com

AVOX-EROS Services

6734 Valjean Ave

Van Nuys, CA 91406

Phone: 818-787-3852

Fax: 818-435-0992

Jean-Marc LeMaitre

Director of Marketing & Customer

Relations

Email: ptaylor@avox-eros.zodiac.com

818-435-0911

Rev: none SIL-35-111

20071112 Page 7 of 7

You might also like

- Century IservicemanualDocument25 pagesCentury IservicemanualJessica Stanton Aahcc0% (2)

- Collins WXR-840 Advanced Weather Radar System: Installation ManualDocument135 pagesCollins WXR-840 Advanced Weather Radar System: Installation ManualEric Houvenaghel0% (1)

- SS9208 Rev 48 (Production Acceptance Criteria)Document64 pagesSS9208 Rev 48 (Production Acceptance Criteria)mtcengineering100% (1)

- AIR CRUISERS 004-25-87 R3 Dt. 07.02.20Document10 pagesAIR CRUISERS 004-25-87 R3 Dt. 07.02.20Pradeep K s100% (1)

- Dental Case Sheet Corrcted / Orthodontic Courses by Indian Dental AcademyDocument8 pagesDental Case Sheet Corrcted / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- APS-85 (Autopilot System: RockwellDocument262 pagesAPS-85 (Autopilot System: Rockwellnixon_b_2000100% (1)

- Airbus A320 Eng Starter SRVDocument8 pagesAirbus A320 Eng Starter SRVPanagiotis Diakidis100% (1)

- Technical Catalogue-RUA-4AT3S To RUA10AT3SDocument24 pagesTechnical Catalogue-RUA-4AT3S To RUA10AT3Smvenkatkumar100% (2)

- 61 20Document12 pages61 20Miguel Condor100% (1)

- InsulationDocument63 pagesInsulationSH1961No ratings yet

- Hitachi RAS-10KH2 - Manual Service - Lb. Engleza PDFDocument68 pagesHitachi RAS-10KH2 - Manual Service - Lb. Engleza PDFnoidforall100% (2)

- As 3007.2 - Electrical InstallationsDocument43 pagesAs 3007.2 - Electrical Installationsduckman2009No ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- All You Need To Know About Clips: AckermannDocument9 pagesAll You Need To Know About Clips: AckermannjulzcatNo ratings yet

- Mil A 83039b Am3MIL-A-83039B AM32C-10A AIRCYCLE AIRCONDITIONER2c 10a Aircycle AirconditionerDocument29 pagesMil A 83039b Am3MIL-A-83039B AM32C-10A AIRCYCLE AIRCONDITIONER2c 10a Aircycle Airconditionerjohn_gouveia_8No ratings yet

- Mil DTL 7990cDocument10 pagesMil DTL 7990cDavid Esteban Pinzon GiraldoNo ratings yet

- TM-10-6640-229-13-and-P Servicio Baño Maria Precision ScientificDocument32 pagesTM-10-6640-229-13-and-P Servicio Baño Maria Precision ScientificAlejandro LiNo ratings yet

- TM 1-1500-204-23-8 Machine & Welding Shop PracticesDocument55 pagesTM 1-1500-204-23-8 Machine & Welding Shop PracticesokamoNo ratings yet

- Manual Soplador 3003 TuthillDocument44 pagesManual Soplador 3003 TuthillIgnacio León CornejoNo ratings yet

- Installation, Operation and Maintenance Manual For at Series Air Conditioning UnitsDocument32 pagesInstallation, Operation and Maintenance Manual For at Series Air Conditioning UnitsEchebiri CollinsNo ratings yet

- 6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValveDocument20 pages6" 6" 6" 6" WRDP WRDP WRDP WRDP - 2MP 2MP 2MP 2MP - NS Safety Valve NS Safety Valve NS Safety Valve NS Safety ValvePilar HernandezNo ratings yet

- Sil 26-0233eDocument13 pagesSil 26-0233eKhaled ElmabroukNo ratings yet

- Tuthill - Manual de Mantenimiento Linea Equalizer (4000-6000)Document44 pagesTuthill - Manual de Mantenimiento Linea Equalizer (4000-6000)Pedro FernandezNo ratings yet

- Accelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Document3 pagesAccelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Satya kaliprasad vangaraNo ratings yet

- Carrier 2trDocument15 pagesCarrier 2trfernandoreyes893No ratings yet

- Instruction Manual For Fuel Gas FilterDocument20 pagesInstruction Manual For Fuel Gas Filterroronoa_zorro11100% (2)

- 15 Saip 50Document5 pages15 Saip 50malika_00No ratings yet

- MIL-PRF-907f Performance Specification Anti-Sieze CompoundDocument9 pagesMIL-PRF-907f Performance Specification Anti-Sieze CompoundGarthSandersNo ratings yet

- Alert Service Bulletin: ASB221EDocument20 pagesAlert Service Bulletin: ASB221ENathaniel LuraNo ratings yet

- 221EDocument19 pages221EAnonymous RTGzZGtINo ratings yet

- Operating and Maintenance Norms For Cylinders and ServocylindersDocument5 pagesOperating and Maintenance Norms For Cylinders and ServocylindersJesus N RodriguezNo ratings yet

- Centa Operators ManualDocument25 pagesCenta Operators Manualm_najmanNo ratings yet

- Australian Standard: Extruded Rod and TubeDocument14 pagesAustralian Standard: Extruded Rod and TubeWidodo MuisNo ratings yet

- Mil STD 870cDocument13 pagesMil STD 870cKrishnan DandapaniNo ratings yet

- Stators and Mud EvaluationDocument7 pagesStators and Mud EvaluationSanjenbam SumitNo ratings yet

- Crane 1 2 HH400-1518-4Document244 pagesCrane 1 2 HH400-1518-4cengiz kutukcu100% (1)

- Crane 3 GP160-0516-2Document222 pagesCrane 3 GP160-0516-2cengiz kutukcuNo ratings yet

- TM 5-3810-300-24&P3Document736 pagesTM 5-3810-300-24&P3svaasandNo ratings yet

- Trace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFDocument22 pagesTrace Analytics AirCheck Kit K8573NB Sampling Instructions V8 PDFHassan Houdoud100% (1)

- f1273 Flame ArresterDocument5 pagesf1273 Flame ArresterIndil Veha100% (1)

- TB 1-1670-260-20-1Document24 pagesTB 1-1670-260-20-1"Rufus"No ratings yet

- Slaughter 2550 PDFDocument47 pagesSlaughter 2550 PDFequiposNo ratings yet

- Mil DTL 5886HDocument21 pagesMil DTL 5886HjohnneracalNo ratings yet

- Cah-Cel Iom Manual 8 5x11 Rev Dec 2014 WebDocument20 pagesCah-Cel Iom Manual 8 5x11 Rev Dec 2014 Webapi-252481722No ratings yet

- Hipot 1305Document47 pagesHipot 1305Raul TovarNo ratings yet

- Overhaul DC Generators & Motors: 1. ScopeDocument33 pagesOverhaul DC Generators & Motors: 1. Scopea s m firoz PrinceNo ratings yet

- Cherry Burrell Processor ManualDocument48 pagesCherry Burrell Processor ManualMadan YadavNo ratings yet

- TM 10 6630 233 13 and P PDFDocument39 pagesTM 10 6630 233 13 and P PDFJulio Cesar RoaNo ratings yet

- Split System Air Conditioners ManualDocument20 pagesSplit System Air Conditioners ManualGiuseppe MaioranaNo ratings yet

- MMM Actregdreengrev2Document22 pagesMMM Actregdreengrev2alexmuchmure2158No ratings yet

- AICIP ExamDocument8 pagesAICIP Examcybercreed2002_11486100% (1)

- 87 122000 001 - PrintDocument292 pages87 122000 001 - Printmax_power100% (3)

- Installation and Operation Manual of Air Conditioning UnitDocument31 pagesInstallation and Operation Manual of Air Conditioning Unitசர்வமும் சிவமயம்No ratings yet

- TM 10 4320 307 10Document128 pagesTM 10 4320 307 10maria_bustelo_2No ratings yet

- As 3007.1 - Electrical InstallationsDocument12 pagesAs 3007.1 - Electrical Installationsduckman2009No ratings yet

- Service Manual: Room Air ConditionerDocument68 pagesService Manual: Room Air ConditionerarteorNo ratings yet

- TCS K 10001 R0Document38 pagesTCS K 10001 R0Tori SmallNo ratings yet

- TFP330 10 2013Document4 pagesTFP330 10 2013Mihai CatalinNo ratings yet

- Mil PRF 27260Document11 pagesMil PRF 27260Mervyn EatonNo ratings yet

- Is 15652Document14 pagesIs 15652girish19100% (1)

- Rotork - CP - Manual OyM Pub013-003!00!0308Document10 pagesRotork - CP - Manual OyM Pub013-003!00!0308Richard VizcarraNo ratings yet

- Chapter 57 - WingsDocument64 pagesChapter 57 - Wingsreginaldo11No ratings yet

- Chapter 76 - Engine ControlsDocument40 pagesChapter 76 - Engine Controlsreginaldo11No ratings yet

- Chapter 55 - StabilizersDocument72 pagesChapter 55 - Stabilizersreginaldo11No ratings yet

- Chapter 52 - DoorsDocument104 pagesChapter 52 - Doorsreginaldo11No ratings yet

- Chapter 53 - FuselageDocument66 pagesChapter 53 - Fuselagereginaldo11No ratings yet

- Phenom Wheel Log CardDocument2 pagesPhenom Wheel Log Cardreginaldo11No ratings yet

- Chapter 77 - Engine IndicatingDocument38 pagesChapter 77 - Engine Indicatingreginaldo11No ratings yet

- SB 181 Assembly InstructionsDocument1 pageSB 181 Assembly Instructionsreginaldo11No ratings yet

- At 19 Mantanince Manual 1Document128 pagesAt 19 Mantanince Manual 1reginaldo11No ratings yet

- Ap 2144Document160 pagesAp 2144reginaldo11100% (1)

- G18S 6Document6 pagesG18S 6reginaldo11No ratings yet

- 2023-10-02 Paragraph IDocument1 page2023-10-02 Paragraph Ireginaldo11No ratings yet

- Chapter 12 - Servicing (Lubrications)Document148 pagesChapter 12 - Servicing (Lubrications)reginaldo11No ratings yet

- MM Phenom 300 - ENGINE - Chapter 04 e 05 - DWNLD 24mar22Document22 pagesMM Phenom 300 - ENGINE - Chapter 04 e 05 - DWNLD 24mar22reginaldo11No ratings yet

- 2021 A Hierarchical Porous Aerogel Nanocomposite of GrapheneNiCo2S4 As An Activ Pre-Proof JoSAMDDocument29 pages2021 A Hierarchical Porous Aerogel Nanocomposite of GrapheneNiCo2S4 As An Activ Pre-Proof JoSAMDHeri RustamajiNo ratings yet

- "The Social Contract Is Broken": Why Millennials Who Lack Rich Parents Feel Increasingly HopelessDocument5 pages"The Social Contract Is Broken": Why Millennials Who Lack Rich Parents Feel Increasingly HopelessviniciuscastanheiraNo ratings yet

- PTERYGIUMDocument33 pagesPTERYGIUMdiana0% (1)

- Swim School Brochure For WebDocument2 pagesSwim School Brochure For WebSudhakar GanjikuntaNo ratings yet

- Chapter 11 - Access Control FundamentalsDocument60 pagesChapter 11 - Access Control FundamentalsmaryaNo ratings yet

- OMNI S Service Manual - Rev4 - Grips (Manual de Servicio RevisiDocument274 pagesOMNI S Service Manual - Rev4 - Grips (Manual de Servicio RevisiDario Briceño100% (1)

- Manual de Serviço Injeção EletrônicaDocument87 pagesManual de Serviço Injeção EletrônicaMarcos MedradoNo ratings yet

- Homogeneous Photocatalysis: FentonDocument3 pagesHomogeneous Photocatalysis: FentonsyatipNo ratings yet

- Methyl Propyl Ketone (MPK)Document11 pagesMethyl Propyl Ketone (MPK)anselmo sanchezNo ratings yet

- Announcement 01 Oct PDFDocument2 pagesAnnouncement 01 Oct PDFgaurav chauhanNo ratings yet

- 2021 11 26 470145 FullDocument41 pages2021 11 26 470145 FulluttamNo ratings yet

- Overflow With Hope - Joel OsteenDocument7 pagesOverflow With Hope - Joel OsteenJHON RAY OTAÑESNo ratings yet

- Triogen UV Integra EN V0Document2 pagesTriogen UV Integra EN V0Clark MansionNo ratings yet

- JMP Stat Graph GuideDocument1,076 pagesJMP Stat Graph Guidevemuriraja100% (1)

- Latihan Passive VoiceDocument9 pagesLatihan Passive VoiceAlby MaulanaNo ratings yet

- Formulation and Evaluation of Moxifloxacin Loaded Alginate Chitosan NanoparticlesDocument5 pagesFormulation and Evaluation of Moxifloxacin Loaded Alginate Chitosan NanoparticlesSriram NagarajanNo ratings yet

- LM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 DescriptionDocument42 pagesLM2907 and LM2917 Frequency To Voltage Converter: 1 Features 3 Descriptioncontrol tejidoNo ratings yet

- Chapter 16 - The SelfDocument4 pagesChapter 16 - The SelfM WNo ratings yet

- ReadDocument40 pagesReadManiNo ratings yet

- CV, TabrezDocument3 pagesCV, TabrezShams TabrezNo ratings yet

- Biomarkers of Fruit and Vegetable Intake in HumanDocument22 pagesBiomarkers of Fruit and Vegetable Intake in HumanSie ningsihNo ratings yet

- Apocalypse by Junot DíazDocument6 pagesApocalypse by Junot DíazClyde PasagueNo ratings yet

- Impacts of Biodiversity Loss 2Document5 pagesImpacts of Biodiversity Loss 2Sanu Raja MaharjanNo ratings yet

- Iq3500 Owner S ManualDocument60 pagesIq3500 Owner S ManualDanielRamirezVieraNo ratings yet

- 16 Launch Driver Boat Khalasi Posts Advt Details Collector Office OdishaDocument2 pages16 Launch Driver Boat Khalasi Posts Advt Details Collector Office OdishaGudu PandaNo ratings yet

- Ficha Personal Del Estudiante 2020 HBDocument82 pagesFicha Personal Del Estudiante 2020 HBerika garciaNo ratings yet

- Barfoed Reagent: Material Safety Data SheetDocument4 pagesBarfoed Reagent: Material Safety Data SheetEkaTiyasAnggraeniNo ratings yet

- Comprehensive of Combined BA and BS-MD Medical ProgramsDocument15 pagesComprehensive of Combined BA and BS-MD Medical Programssonnynguyen208682100% (1)