Professional Documents

Culture Documents

Nr3036451-Cert Y8 - 2302852

Uploaded by

Manuel CardosoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nr3036451-Cert Y8 - 2302852

Uploaded by

Manuel CardosoCopyright:

Available Formats

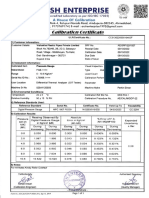

INSPECTION CERTIFICATE - REVISION 0.

0 CAST NO : 2302852

This document complies to BS EN 10204 3.1 ORDER NO / CERT NO: 18NR WZA3036451

NAME AND ADDRESS OF SENDER CUSTOMER ORD NO : MAP-06-02-23-VA

ArcelorMittal South Africa Limited 1989/002164/06 CUSTOMER NO : 62389

Long Steel Products SHIP :

Newcastle Works Iscor Road, Newcastle, 2940, South Africa SAP ORD NO : 4500069462

CUSTOMER NAME AND ADDRESS OF CONSIGNEE DESCRIPTION OF GOODS

FERPINTA MOCAMBIQUE S.A.R.L. FERPINTA MOCAMBIQUE # Profile: Rebar Lengths : 8mm

# Specification:BS 4449/2005 Gr B500B

P.O.Box 251 E.N. n?1 KM 14 MAPUTO .

BEIRA MAPUTO-MOZAMBIQUE

Ord Mass : 60000

Mozambique # LENGTH: 12000.0 mm # CONDITION: AS ROLLED

# TOLERANCE : SPE 235 # NO OF TESTS: 3

CHEMICAL ANALYSIS

C Si Mn S P Cr Ni Mo Cu V Al Ti Sn Nb N B Ca As Sb Pb CEV# Kg/m Theoretical Actual

% % % % % % % % % % % % % % % % % % % % Mass (kg) Mass (kg)

Actual 0.23 0.37 1.43 0.006 0.014 0.040 0.017 0.002 0.011 0.004 0.002 0.002 0.003 0.022 0.004 0.0003 0.000 0.005 0.002 0.002 0.48 0.395 1996 1885

Minimum 0.010

Maximum 0.25 0.40 1.60 0.050 0.050 0.200 0.250 0.070 0.350 0.080 0.010 0.020 0.020 0.050 0.010 0.0007 0.030 0.010 0.010 0.010

Temp Dimensions mm IT1 (Joules) IT2 (Joules) IT3 (Joules) IT4 (Joules) IT5 (Joules) Lateral

Direction o Ave

C Height Width 1 2 3 1 2 3 1 2 3 1 2 3 1 2 3 Exp(mm)

MECHANICAL PROPERTIES

Yield Strength MPa Tensile Strength MPa Cross-sectional Area mm2 Elongation % Elong at max force % Rebend

1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

Actual 633.4 559.9 573.0 779.3 732.7 734.4 50.3 50.3 50.3 27.0 26.3 26.8 9.1 12.2 11.3 Pass Pass Pass

Minimum

Maximum

MECHANICAL PROPERTIES and METALLURGICAL RESULTS

Test Test Gross- Hardness Grain Decarburization

Piece Temp man Size Partial Complete

Direction oC Factor# 1 2 3 4 5 Ave (mm) Ave (%) Max (mm) Max (%) Max (mm) Max (%)

Actual L 22.00

Minimum

Maximum

Elongation = 5.65*sqrt(So) HRB: Rockwell hardness B scale HRC: Rockwell hardness C scale HBW: Brinell Hardness 10/3000 scale CEV: Carbon Equivalent Value R11 = Cu + 10Sn

STANDARD REMARKS :

N MATHE

PRODUCT CERTIFICATION

Issue Date: 2023-05-30

ISO 9001:2015 CERTIFICATION (DQS CERTIFICATION SYSTEM): THE MATERIAL HEREIN HAS BEEN MADE USING THE BASIC OXYGEN PROCESS AND CONTINUOUSLY CAST. SAMPLING IS EXECUTED BY THE PLANT ACCORDING TO THE SPECIFICATION REQUIREMENTS.TESTING IS CONDUCTED

ON THE SAMPLES SUPPLIED. INSPECTION AND TESTING COMPLIES WITH THE SPECIFICATION REQUIREMENTS AND ADDITIONAL CUSTOMER REQUIREMENTS FOR THE MATERIAL. A COPY OF THE DQS CERTIFICATE IS AVAILABLE UPON REQUEST.(NOT ACCREDITED BY SANAS).

ISO 17025:2017 ACCREDITATION: TESTING IS PERFORMED ACCORDING TO THE FOLLOWING SANAS ACCREDITED PROCEDURES. Viz - ASTM E-415, ASTM E-1019, ASTM E 112, ASTM E 1077, ASTM E 45, DIN 50 602, ISO 6892-1:2009 B, E 10, ASTM E18, ISO 15630-1,

BS EN ISO 148-1 AND ISO 642 AND ISO 10 606. UNCERTAINTY IS NOT INCLUDED ON THE REPORT; THE VALUES ARE AVALIABLE ON REQUEST.

This certificate shall not be reproduced except in full without approval of the laboratory to provide assurance that parts of a report are not taken out of context.

End of Report

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 1.5MM 304Document1 page1.5MM 304pankaj kumarNo ratings yet

- Electric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesFrom EverandElectric Arc Welding and Related Studies: Electric Arc Welding & Related StudiesNo ratings yet

- Ab 2501 24 MTCDocument3 pagesAb 2501 24 MTCVISHNU KKNo ratings yet

- 304 1.5MM PCDocument1 page304 1.5MM PCsabir hussain100% (1)

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOshekarNo ratings yet

- AB Enq. 1590-24 - Revised Sample MTCDocument5 pagesAB Enq. 1590-24 - Revised Sample MTCMajDiM.AlkHatibNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOParesh Mehta100% (1)

- Quantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Document1 pageQuantity and Quality Certificate (EN 10204/3.1) : PAGE:1/7Nilton Santillan OrtegaNo ratings yet

- 1.14.1 MTC-11372 - Tube - 1 TUBINGDocument1 page1.14.1 MTC-11372 - Tube - 1 TUBINGgroupj.sr.servicesNo ratings yet

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Cargo Plan - VPF-1020 (Load)Document36 pagesCargo Plan - VPF-1020 (Load)Hồ Đăng An BìnhNo ratings yet

- Dossier Merla - ODB 4604279Document33 pagesDossier Merla - ODB 4604279Indira briceñoNo ratings yet

- Img 0001Document1 pageImg 0001Harish RanaNo ratings yet

- C10-Capacity Closely Space Check-ReportDocument1 pageC10-Capacity Closely Space Check-Reportchirathip vasuvattakulNo ratings yet

- C60 68719 - 25 QtyDocument1 pageC60 68719 - 25 QtyMohammad Shanawaz MNo ratings yet

- Wac - Test Certificate 7313Document1 pageWac - Test Certificate 7313dian priyantoNo ratings yet

- 54-Pressure Gauge OIT Calibration CartificateDocument1 page54-Pressure Gauge OIT Calibration CartificateCustomer Support100% (1)

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOMANIMARAN QC100% (1)

- Test Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞDocument3 pagesTest Sertifikasi: Kiraç Galvaniz Telekom Metal Mak - İnş.El - San.Ve Tic.A.ŞBeytullah KurnalıNo ratings yet

- Sertifikat Produksi Caa-2212-00097Document1 pageSertifikat Produksi Caa-2212-00097figo zaliNo ratings yet

- Erp-Reinf Shearwall R1Document6 pagesErp-Reinf Shearwall R1Gunawan Prc2020No ratings yet

- Int'L NDT Services: Magnetic Particle Examination ReportDocument3 pagesInt'L NDT Services: Magnetic Particle Examination Reportsarsan nedumkuzhiNo ratings yet

- Customer Specification Shipment/Delivery No.: GL 5.65 SODocument1 pageCustomer Specification Shipment/Delivery No.: GL 5.65 SOBilal Luhar100% (1)

- Jyoti Engineering Works: Chemical AnalysisDocument8 pagesJyoti Engineering Works: Chemical AnalysisKristin CrawfordNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Inspection Certificate: Customer: CommodityDocument1 pageInspection Certificate: Customer: CommodityGisella Mariel Rubilar100% (1)

- UTG - LPG - Tank (12) (Updated)Document1 pageUTG - LPG - Tank (12) (Updated)Ali TahirNo ratings yet

- AcerinoxDocument1 pageAcerinoxOmkar PrindavankarNo ratings yet

- De Test Reports 2023Document117 pagesDe Test Reports 2023ADEPU RAKESHNo ratings yet

- E6013 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE6013 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Inspection Report: V'Groove DetailsDocument4 pagesInspection Report: V'Groove DetailsVijay Makwana VishwakarmaNo ratings yet

- Mir 001Document2 pagesMir 001MCCIN L&WNo ratings yet

- 3.1digital Vernier Caliper Calibration CertificateDocument1 page3.1digital Vernier Caliper Calibration CertificateGolden RosesNo ratings yet

- E7014 Data Sheet: ISO 9001:2015 REGISTEREDDocument3 pagesE7014 Data Sheet: ISO 9001:2015 REGISTEREDThomas MacDonaldNo ratings yet

- Board Line: - 022 66595154: As Per Iso 2341Document1 pageBoard Line: - 022 66595154: As Per Iso 2341BARKAT ALINo ratings yet

- E/Aod: According To en 10204Document1 pageE/Aod: According To en 10204agungNo ratings yet

- VTB-600-2 A105n W1834221,235,230.QR PDFDocument1 pageVTB-600-2 A105n W1834221,235,230.QR PDFJoe KylaNo ratings yet

- Certificats BackupDocument17 pagesCertificats BackupS. KaciouiNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- Sertifikat Produksi Caa-2211-00021Document1 pageSertifikat Produksi Caa-2211-00021figo zaliNo ratings yet

- SWG 31 WDocument1 pageSWG 31 WRajesh RoyNo ratings yet

- Esab, Ok 309L (29.12.16)Document1 pageEsab, Ok 309L (29.12.16)RodrigoNo ratings yet

- MTC Pipa Kotak 60x2, 50x2Document1 pageMTC Pipa Kotak 60x2, 50x2Pahala LumbantoruanNo ratings yet

- Cert ACERO INOX 316L PDFDocument1 pageCert ACERO INOX 316L PDFCarlos RomeroNo ratings yet

- TM 215461 SRTDocument3 pagesTM 215461 SRTömer cılızNo ratings yet

- Sample MTC: Material Test CertificateDocument2 pagesSample MTC: Material Test CertificateSameer KmNo ratings yet

- Qte 6708582Document2 pagesQte 6708582cruz.gibagoNo ratings yet

- Cold Test Report 3Document1 pageCold Test Report 3Venkitesh PG100% (1)

- Digital Readout Unit Settings: KN MM KN % Mm/dak KN % Mm/dak MM MM KN KNDocument2 pagesDigital Readout Unit Settings: KN MM KN % Mm/dak KN % Mm/dak MM MM KN KNOpu DebnathNo ratings yet

- UntitledDocument1 pageUntitledpadutamasiteNo ratings yet

- 1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataDocument24 pages1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataNADEEM AHMEDNo ratings yet

- 2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP UttmDocument3 pages2024 1 U11 Ta24 Pip 064 4 P11806 Ad1 PP Uttminjoker fxNo ratings yet

- Ribo TC 324 (00000003)Document1 pageRibo TC 324 (00000003)Vinay YadavNo ratings yet

- Calculation Test PBAS FT 110 - 1Document1 pageCalculation Test PBAS FT 110 - 1padutamasiteNo ratings yet

- ANGULO 3 X 3 X 0.1875Document1 pageANGULO 3 X 3 X 0.1875edson.ortegaNo ratings yet

- 1299 - Ec0176Document4 pages1299 - Ec0176Deipak HoleNo ratings yet

- Sample Test Cert. 07.09.2011 - 02Document1 pageSample Test Cert. 07.09.2011 - 02Vipul PanchalNo ratings yet

- Diesel Fuel MSDS PDFDocument7 pagesDiesel Fuel MSDS PDFgeverett2765No ratings yet

- Flyash MSDSDocument6 pagesFlyash MSDSManuel CardosoNo ratings yet

- Thinners MSDSDocument7 pagesThinners MSDSManuel CardosoNo ratings yet

- Sabs Sans920Document1 pageSabs Sans920Manuel CardosoNo ratings yet

- Sikagrout 350Document3 pagesSikagrout 350Manuel CardosoNo ratings yet

- Sikagrout - 528 SFDocument4 pagesSikagrout - 528 SFManuel CardosoNo ratings yet

- Chemistry For Engineers Set ADocument5 pagesChemistry For Engineers Set AMark Jecel RapirNo ratings yet

- Robotics: EverythingDocument11 pagesRobotics: Everythingabu saidNo ratings yet

- Compress 5800i AW Heat Pump Outdoor Unit Installation ManualDocument36 pagesCompress 5800i AW Heat Pump Outdoor Unit Installation ManualGeorge PopaNo ratings yet

- D 5088 - 90 - RduwodgtotaDocument3 pagesD 5088 - 90 - RduwodgtotaPrakash MakadiaNo ratings yet

- 2 bài đọc hiểuDocument5 pages2 bài đọc hiểutrtlinh08No ratings yet

- Nitrogen PSA Brochure US - tcm136-454333Document12 pagesNitrogen PSA Brochure US - tcm136-454333barun1977No ratings yet

- Bylkas 1997Document5 pagesBylkas 1997Catarina SabinoNo ratings yet

- Fluid Mechanic, Cengel - Chapter 01Document17 pagesFluid Mechanic, Cengel - Chapter 01Zandrik ArismendiNo ratings yet

- 2015 Design SrinivasDocument71 pages2015 Design SrinivasEdinson LoayzaNo ratings yet

- 9800 XRF XRD - ArtigoDocument8 pages9800 XRF XRD - Artigocelestino biasottoNo ratings yet

- Cyanobacteria: A Precious Bio-Resource in Agriculture, Ecosystem, and Environmental SustainabilityDocument6 pagesCyanobacteria: A Precious Bio-Resource in Agriculture, Ecosystem, and Environmental SustainabilityJoshua De LeonNo ratings yet

- Example 4.10-1. Radiation To A Metal TubeDocument7 pagesExample 4.10-1. Radiation To A Metal TubeShane Patulot0% (2)

- Translational EquilibriumDocument2 pagesTranslational EquilibriumJossie Razil TolibasNo ratings yet

- 3.05 Ionic Bonding and Ionic CompoundsDocument3 pages3.05 Ionic Bonding and Ionic CompoundsIBRAHIM ABOU EL NAAJNo ratings yet

- SJPO 2017 General Round - Answer GuideDocument16 pagesSJPO 2017 General Round - Answer GuideDivyaNo ratings yet

- Nisad Avdic: ContactDocument2 pagesNisad Avdic: ContactnasoonyNo ratings yet

- JEE Main 2019 Question Paper 12th Jan Evening PDFDocument22 pagesJEE Main 2019 Question Paper 12th Jan Evening PDFDebi prasad jenaNo ratings yet

- Adt-03 Engine 3112 Ob1922568Document1 pageAdt-03 Engine 3112 Ob1922568abdul rahmatNo ratings yet

- Medicel® Oxygen (O2) Gas SensorDocument5 pagesMedicel® Oxygen (O2) Gas SensorShtomaNo ratings yet

- ChE 311 Problem Set With Answer KeyDocument5 pagesChE 311 Problem Set With Answer KeyGian BanaresNo ratings yet

- JEE Main Nurture Main Nurture Lite Phase I II MT6 106816 TEST PDF xU2Qu7XSBpDocument20 pagesJEE Main Nurture Main Nurture Lite Phase I II MT6 106816 TEST PDF xU2Qu7XSBpganeshay117No ratings yet

- SAF 2205 DatasheetDocument11 pagesSAF 2205 DatasheetNitinNo ratings yet

- I. Development of The Virial TheoremDocument14 pagesI. Development of The Virial Theoremjohnsmith37758No ratings yet

- Applied Sciences: Immobilized Tio - Polyethylene Glycol: Effects of Aeration and PH of Methylene Blue DyeDocument1 pageApplied Sciences: Immobilized Tio - Polyethylene Glycol: Effects of Aeration and PH of Methylene Blue DyeKuna JackNo ratings yet

- Effects of Solidification Rate and Heat Treatment On Microstructure Characterization and Hot Tensile Strength of Single Crystal CMSX-4 SuperalloyDocument11 pagesEffects of Solidification Rate and Heat Treatment On Microstructure Characterization and Hot Tensile Strength of Single Crystal CMSX-4 Superalloykianrob123100% (1)

- B.T. Kumaon Institute of Technology, Dwarahat End Semester (Back) Examination, 2020-2021Document2 pagesB.T. Kumaon Institute of Technology, Dwarahat End Semester (Back) Examination, 2020-2021verma.ashok031No ratings yet

- Theoretical Problems 50 IChO - Final - Sol PDFDocument63 pagesTheoretical Problems 50 IChO - Final - Sol PDFnam nam100% (1)

- P Science 6 Diagnostic Earth and SpaceDocument5 pagesP Science 6 Diagnostic Earth and SpaceLyaz AntonyNo ratings yet

- BESCK204ADocument4 pagesBESCK204Asuhasg027No ratings yet

- Aucr 2021Document114 pagesAucr 2021mnagaarjun323No ratings yet