Professional Documents

Culture Documents

Optim

Optim

Uploaded by

Derick EnamoradoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optim

Optim

Uploaded by

Derick EnamoradoCopyright:

Available Formats

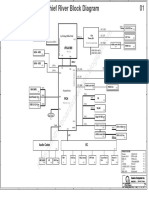

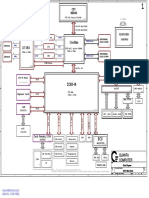

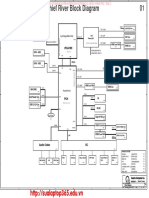

SuperServer AS-2014S-TR Quick Reference Guide

Board Layout Memory

Memory Front View & Interface Rear View

1 2 3 4 5 6 7

8

HDD2 HDD5 HDD8 HDD11

9

HDD1 HDD4 HDD7 HDD10 7 6 5 4 3 2 1

HDD0 HDD3 HDD6 HDD9

DIMM A1 DIMM E1

DIMM B1 CPU DIMM F1

1

1

DIMM C1 DIMM G1 A B C D E F G H

26

DIMM D1 DIMM H1 Item Description

25

27 Service/Asset Tag with BMC Item Description Expansion Slots

24 28 1

2 Password

23 Two 920W Redundant Power Item Description

2 Power Button A

Supply Modules*

22 3 1 PCIe 4.0 x16 (low-profile)

3 UID Button Two hot-swap 2.5” SATA drive

21 B

7 bays (optional) 2 PCIe 4.0 x 8 (low-profile)

4

8 4 Power LED C COM Port 3 PCIe 4.0 x16 (low-profile)

5

10 DIMM Module Population Sequence 6 9 5 NIC2 LED D IPMI LAN Port 4 PCIe 4.0 x 8 (low-profile)

20 5 PCIe 4.0 x16 (low-profile)

11 When installing memory, please keep the following in mind: 6 Power Fail LED E Four USB 3.0 Ports

• It is recommended that DDR4 DIMM modules of the same type, size and speed should be installed. 6 PCIe 4.0 x16 (low-profile)

19 12

• Mixed DIMM speeds can be installed. However, all DIMMs will run at the speed of the slowest DIMM. 7 HDD LED F LAN Ports 7 PCIe 4.0 x16 (low-profile)

18

• The motherboard will support odd-numbered modules (1 or 3 modules installed). However, to achieve 8 NIC1 LED G VGA Port

17 16 15 14 13 the best memory performance, a balanced memory population is recommended.

9 Information LED H UID LED

Item Description Item Description

1 JWD1 (Watch Dog Control) 15 System cooling fan headers

Processors and Their Corresponding Memory Modules

CPU Installation

2 Unit ID switch (push-button toggle switch ON/OFF) 16 Internal SATA Ports CPU# Channel

3 Back panel VGA port 17 Chassis intrusion header

Processor Installation

D1 C1 B1 A1 E1 F1 G1 H1 1. Removing the Processor Force Frame 2. Raising the Force Frame 3. Lifting the Rail Frame 4. Removing the External Cap and PnP

4 Back panel LAN1, LAN2 connectors 18 SATA DOM power connector Use a Torx T20 driver to loosen the screws holding Cover Cap

1 DIMM (supported but not recommend) down Force Frame in the sequence of 3-2-1. The

5 Back panel USB 3.0 ports 19 Internal SATA Ports screws are numbered on the Force Frame next to each

6 Dedicated IPMI LAN port 20 SATA DOM power connector CPU1 ✓ screw hole.

Rail Frame

7 Rear panel COM port #1 21 UID switch header

2 DIMMs (supported but not recommend)

8 12V 8-pin CPU core power supply connector 22 Front control panel Screw #3

CPU1 ✓ ✓ PnP Cover Cap

9 System cooling fan headers 23 Chassis overheat header

Screw #2

10 24-pin ATX power supply connector 24 Internal USB 3.0 header (USB 4/5) 4 DIMMs (condictionally recommended if 32 cores or fewer)

11 12V 8-pin CPU core power supply connector 25 4-pin BMC external IC header CPU1 ✓ ✓ ✓ ✓ Screw #1 External Cap

12 Power supply SMBus I2C header 26 Front panel external speaker header

8 DIMMs Force Frame PnP Cover Cap

13 System cooling fan headers 27 Onboard CMOS battery

14 Stand by power header 28 JNVMe0/SATA0~7 switch CPU1 ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ 5. Inserting the Carrier Frame/CPU Package 6. Lowering the Force Frame 7. Securing the Force Frame 8. The Force Frame Secured

Secure the screws in the order 1-2-3, tightening to

16.1 kgf-cm (14 lbf-in) of torque. The Force Frame

Carrier Frame/

Heatsink Installation Hard Drive Installation CPU Package

secures both the Rail Frame and CPU Package.

Caution: Tightening must be executed in proper

1-2-3 sequence to avoid causing catastrophic

damage to the socket or CPU Package.

Removing a Hot-Swap Drive Carrier from the

1. Mounting the Heatsink 2. Securing the Heatsink

System

Using a diagonal pattern and a Torx T20 driver, tighten the four

heatsink screws evenly to 16.1 kgf-cm (14.0 lbf-in) torque.

Release Button 1. Press the release button on the drive carrier, which will extend

the drive carrier handle.

2. Use the drive carrier handle to pull the drive out of the chassis.

#1 Screw

Removing a Drive Carrier

Default Cable Routing Caution

#4 Screw

Installing a 3.5” Drive MB/AOC Connector BP/Riser

CN3

Drive Qty/PCIe MC Cable P/N

! SAFETY INFORMATION

IMPORTANT: See installation instructions and safety warning before

PCIE1A (NVME0/1) CBL-SAST-1297LP-85

1. Remove the dummy drive, which comes pre-installed in the drive carrier. Pull out (RSC-D2-666G4)

PCIe x16 connecting system to power supply.

the two locking clasps on the right outside of the carrier and lift out the dummy PCIE1B (NVME2/3)

CN4

CBL-SAST-1297LP-85 http://www.supermicro.com/about/policies/safety_information.cfm

(RSC-D2-666G4)

#3 Screw

drive.

CN3 ! WARNING:

2. Position the drive above the carrier with the PCB side facing down and the PCIE2A/2B (NVME4/5)

(RSC-D2R-666G4)

CBL-SAST-1296LP-85

connector end toward the rear of the carrier. PCIe x16 To reduce risk of electric shock/damage to equipment, disconnect power

CN4

3. Tilt the drive to insert it onto the two posts on the left inside of the carrier. PCIE2C/2D (NVME 6/7)

(RSC-D2R-666G4)

CBL-SAST-1296LP-85 from server by disconnecting all power cords from electrical outlets.

If any CPU socket empty, install protective plastic CPU cap.

4. Push the right side of the drive fully into the carrier and allow the two spring

CN1

SATA4-7 (NVME9) (BPN-SAS3- 4 SATA Drives CBL-SAST-1285LP-100

#2 Screw locking clasps to secure the drive. ! WARNING:

LA26A-N12)

5. Insert the drive carrier into its bay, keeping the release button on the right. When Always be sure all power supplies for this system have the same power

CN2/CN3

the carrier reaches the rear of the bay, the release handle will retract. SATA8-15 (NVME12/13) (BPN-SAS3- 8 SATA Drives CBL-SAST-1236-100

output. If mixed power supplies are installed, the system will not operate.

6. Push the handle in until it clicks into its locked position. LA26A-N12) For more information go to : http://www.supermicro.com/support

http://www.supermicro.com MNL-2411-QRG Rev. 1.0

You might also like

- SOP For Lane Cutting.Document2 pagesSOP For Lane Cutting.suvojitroy2000No ratings yet

- Ih110ms MS 7963 1.0Document43 pagesIh110ms MS 7963 1.0Alvaro Amaya PérezNo ratings yet

- Factory Acceptance Test New Sample ReportDocument13 pagesFactory Acceptance Test New Sample ReportJafarov VuqarNo ratings yet

- GALAX GTX 1050 Ti P75D Rev V10Document27 pagesGALAX GTX 1050 Ti P75D Rev V10Rafael SenaNo ratings yet

- Lenovo E531 VILE1 - VILE2 NM-A043 NM-A044 NM-A041 SchematicDocument59 pagesLenovo E531 VILE1 - VILE2 NM-A043 NM-A044 NM-A041 SchematicSaulo Dote100% (1)

- Aspire A515-54 DA0ZAWMB8C0 Quanta ZAW SchematicDocument48 pagesAspire A515-54 DA0ZAWMB8C0 Quanta ZAW SchematicRoyer ArteagaNo ratings yet

- Acer Aspire VN7-792G Newgate gddr5Document78 pagesAcer Aspire VN7-792G Newgate gddr5Josip BilicNo ratings yet

- JB CI 13.1 HalogenoalkanesDocument6 pagesJB CI 13.1 HalogenoalkanesOCRChemistrySaltersNo ratings yet

- Toshiba Satellite l630 l635 Bu4 Laptop Schematic PDFDocument33 pagesToshiba Satellite l630 l635 Bu4 Laptop Schematic PDFMocha ArsyaNo ratings yet

- QRG 1470Document1 pageQRG 1470ObamaNo ratings yet

- x670 Ae Gamingx Ax ManualDocument39 pagesx670 Ae Gamingx Ax ManualFovejoNo ratings yet

- GTL Termination: Micro-StarDocument30 pagesGTL Termination: Micro-StarJhinson CoyagoNo ratings yet

- IPM41 D3 090709 MoboDocument55 pagesIPM41 D3 090709 MoboLucio Oliveira67% (9)

- Toshiba L750 Quanta BLBD Schematic DiagramDocument42 pagesToshiba L750 Quanta BLBD Schematic DiagramDilum SenarathNo ratings yet

- V313 40 (00017967) DecryptDocument15 pagesV313 40 (00017967) DecryptDiego TernavasioNo ratings yet

- V313 50 (00017967) DecryptDocument15 pagesV313 50 (00017967) DecryptDiego TernavasioNo ratings yet

- Mainboard Ms - 7050 - 130Document41 pagesMainboard Ms - 7050 - 130Ho Thanh BinhNo ratings yet

- MB Circuit:6484: Power TreeDocument13 pagesMB Circuit:6484: Power TreeekinetNo ratings yet

- V313 60 (00017967) DecryptDocument15 pagesV313 60 (00017967) DecryptDiego TernavasioNo ratings yet

- NM-A451 (ThinkPad P50) BP500Document116 pagesNM-A451 (ThinkPad P50) BP500kolargol72No ratings yet

- Toshiba c840 m840 Daby3cmb8e0 SchematicDocument49 pagesToshiba c840 m840 Daby3cmb8e0 SchematicDouble HelixNo ratings yet

- Quanta tw1 R3e SchematicsDocument37 pagesQuanta tw1 R3e SchematicsOssama BohamdNo ratings yet

- Te4 - R1a 1112 Uma Toshiba L700Document37 pagesTe4 - R1a 1112 Uma Toshiba L700Mohamad YahyaNo ratings yet

- 19d46 Quanta TE4 (DAOTE4MB6D0) - Satellite L700-L740 PDFDocument37 pages19d46 Quanta TE4 (DAOTE4MB6D0) - Satellite L700-L740 PDFBee WokoNo ratings yet

- P2132-A01 NVG Gk208 Ddr3 64bit: DescriptionDocument15 pagesP2132-A01 NVG Gk208 Ddr3 64bit: DescriptionToàn ĐỗNo ratings yet

- Toshiba L700 Te5d - Intel - Discrete - 11 - 0105 - V1Document45 pagesToshiba L700 Te5d - Intel - Discrete - 11 - 0105 - V1Julio AbdalaNo ratings yet

- Toshiba Quanta BY1 INTEL - HR - UMA - C - 1109Document40 pagesToshiba Quanta BY1 INTEL - HR - UMA - C - 1109deppa lannaNo ratings yet

- WWW - Vinafix.vn: rPGA 989Document45 pagesWWW - Vinafix.vn: rPGA 989komputer caboNo ratings yet

- Quanta - Te5 - R1a Toshiba Satellite L745Document46 pagesQuanta - Te5 - R1a Toshiba Satellite L745Las DusNo ratings yet

- Gigabyte Ga-8i945aef-Ae r1.1 SchematicsDocument35 pagesGigabyte Ga-8i945aef-Ae r1.1 SchematicsAndrzej GomulaNo ratings yet

- Acer Aspire VN7-791 VN7-791G 1 Wistron Poseidon 860M - Rev1Document86 pagesAcer Aspire VN7-791 VN7-791G 1 Wistron Poseidon 860M - Rev1amir diazNo ratings yet

- Aspire A515-54 DA0ZAWMB8C0 Quanta ZAW SchematicDocument48 pagesAspire A515-54 DA0ZAWMB8C0 Quanta ZAW SchematicHomero SanzNo ratings yet

- Schematic Zeroboard UnoDocument1 pageSchematic Zeroboard UnoKutu BusuxNo ratings yet

- DAOTE5MB6FO L700-L745 Toshiba PDFDocument45 pagesDAOTE5MB6FO L700-L745 Toshiba PDFJhonCardenasNo ratings yet

- Z8E AMD A3 Platform Block Diagram: Power SolutionDocument44 pagesZ8E AMD A3 Platform Block Diagram: Power Solutionjulio cesar mina100% (2)

- Quanta ZAUI - MB - SCHDocument47 pagesQuanta ZAUI - MB - SCHjokerNo ratings yet

- Toshiba Satellite T110 - Quanta - BU3 - Laptop - SchematicsDocument34 pagesToshiba Satellite T110 - Quanta - BU3 - Laptop - SchematicsTsukamoto TsukushiNo ratings yet

- 4PMMNL Abridged User GuideDocument4 pages4PMMNL Abridged User Guidew_muangphuanNo ratings yet

- MB - Manual - B650 AORUS ELITE AX V2 ICE - 1002 - eDocument38 pagesMB - Manual - B650 AORUS ELITE AX V2 ICE - 1002 - ealejossNo ratings yet

- GD1B Block Diagram: Crestline Ati M64Document35 pagesGD1B Block Diagram: Crestline Ati M64Paulo chagas paulo ratoNo ratings yet

- Sony VGN-CR Series MBX-177A QUANTA GD1A Schematic Diagram PDFDocument35 pagesSony VGN-CR Series MBX-177A QUANTA GD1A Schematic Diagram PDFwelltonarrudaNo ratings yet

- Toshiba Satellite L700 Quanta TE5 Rev1ADocument45 pagesToshiba Satellite L700 Quanta TE5 Rev1Aramesh reddyNo ratings yet

- Toshiba Satellite l655 700Document36 pagesToshiba Satellite l655 700Eduardo LiberatoNo ratings yet

- Toshiba C800 Quanta Daby3cmb8e0Document49 pagesToshiba C800 Quanta Daby3cmb8e0LEONNo ratings yet

- System Block:: Leaving Blank .....Document2 pagesSystem Block:: Leaving Blank .....Yurii VovchenkoNo ratings yet

- MB Manual Z790-Aero-G 1001 eDocument41 pagesMB Manual Z790-Aero-G 1001 egopikiran6No ratings yet

- SONY - PCG-diagrama MainDocument35 pagesSONY - PCG-diagrama MainAndres Felipe Garcia PinedaNo ratings yet

- Biostar A78dg-A2t Rev 6.0 SCHDocument46 pagesBiostar A78dg-A2t Rev 6.0 SCHИван ИвановNo ratings yet

- Wistron - Mockingbird - N - V - 14 - 15 - TGL - & - Hellcat - 14 - 15 - 17 - TGL - 19861 - 19862 1986-1 Dell Inspiron 5402Document105 pagesWistron - Mockingbird - N - V - 14 - 15 - TGL - & - Hellcat - 14 - 15 - 17 - TGL - 19861 - 19862 1986-1 Dell Inspiron 5402German ValenciaNo ratings yet

- P2131 - A00 GK208 GDDR5 X16 64BIT: DescriptionDocument16 pagesP2131 - A00 GK208 GDDR5 X16 64BIT: DescriptionCarlosBayonaMontenegroNo ratings yet

- P38G001 (Nottec)Document66 pagesP38G001 (Nottec)Darcio TolottiNo ratings yet

- Lenovo ThinkPad P51X LCFC Walter2-Note NM-B041 Rev 0.1-1Document119 pagesLenovo ThinkPad P51X LCFC Walter2-Note NM-B041 Rev 0.1-1Michal MíkaNo ratings yet

- Toshiba Satellite Pro C70 QuantaDocument50 pagesToshiba Satellite Pro C70 QuantaSabelli CameliaNo ratings yet

- RSAG7.820.6487 EsquemaDocument14 pagesRSAG7.820.6487 EsquemaJose LuisNo ratings yet

- Quanta bd3g R2a Schematics PDFDocument43 pagesQuanta bd3g R2a Schematics PDFsaom09No ratings yet

- P2131 - A00 GK208 GDDR5 256X32Bit: DescriptionDocument16 pagesP2131 - A00 GK208 GDDR5 256X32Bit: DescriptionCarlosBayonaMontenegroNo ratings yet

- .Te7 Ramp Rb2a 1215 FinalDocument35 pages.Te7 Ramp Rb2a 1215 Finalmbah bejoNo ratings yet

- BU8 Block Diagram: Sata - HDDDocument43 pagesBU8 Block Diagram: Sata - HDDwen_sifuNo ratings yet

- Lenovo ThinkPad E465 LCFC BE465 NM-A621 Rev 1 0 Схема SCHDocument5 pagesLenovo ThinkPad E465 LCFC BE465 NM-A621 Rev 1 0 Схема SCHemail2 meNo ratings yet

- Msi ms-7168 Rev 200 SCHDocument32 pagesMsi ms-7168 Rev 200 SCHQuiteNo ratings yet

- Toshiba c800Document49 pagesToshiba c800Gie AvNo ratings yet

- DVD Studio Pro 4: The Complete Guide to DVD Authoring with MacintoshFrom EverandDVD Studio Pro 4: The Complete Guide to DVD Authoring with MacintoshNo ratings yet

- Commercial Lease Contract DrafrDocument3 pagesCommercial Lease Contract Drafraprille anneNo ratings yet

- Triogen UV Integra EN V0Document2 pagesTriogen UV Integra EN V0Clark MansionNo ratings yet

- Sahs OpcrfDocument8 pagesSahs OpcrfErnesto Mayo FogataNo ratings yet

- APOMDocument1 pageAPOMKishan Ramtohul0% (2)

- A380 - US Vrs - C5-37A - June 2006-2Document12 pagesA380 - US Vrs - C5-37A - June 2006-2Christian ORNo ratings yet

- PROFITABILITY ANALYSIS at ASIAN PAINTSDocument62 pagesPROFITABILITY ANALYSIS at ASIAN PAINTSRajesh BathulaNo ratings yet

- BIR Form 2551 - PDFDocument1 pageBIR Form 2551 - PDFMichael LaquianNo ratings yet

- Module 2 SolutionDocument2 pagesModule 2 SolutionLJ Valdez100% (1)

- ReadDocument40 pagesReadManiNo ratings yet

- Speciality FibresDocument38 pagesSpeciality Fibresnitishkohli100% (6)

- Adorable Pet PhotographyDocument24 pagesAdorable Pet PhotographyMario ObadNo ratings yet

- SHEBA - XYZ - hrm360Document10 pagesSHEBA - XYZ - hrm360Shuvo DattaNo ratings yet

- Comprehensive of Combined BA and BS-MD Medical ProgramsDocument15 pagesComprehensive of Combined BA and BS-MD Medical Programssonnynguyen208682100% (1)

- 12 Chemistry Ncert Ch10 Haloalkanes and HaloarenesDocument48 pages12 Chemistry Ncert Ch10 Haloalkanes and HaloarenesJithenthiriya Jithu100% (1)

- Animal RightsDocument12 pagesAnimal RightsAmeer HamzaNo ratings yet

- Aldosterone Renin RatioDocument2 pagesAldosterone Renin RatioPoon CaniceNo ratings yet

- Research 'Document191 pagesResearch 'Quentin AsparriaNo ratings yet

- Current Waste Management Methods in Ready Mix ConcreteDocument3 pagesCurrent Waste Management Methods in Ready Mix ConcreteGagan ShrivastavaNo ratings yet

- Renovation Quotation Template inDocument3 pagesRenovation Quotation Template indipak kamble100% (1)

- Journal of Surgery April2014Document62 pagesJournal of Surgery April2014petrarizkyNo ratings yet

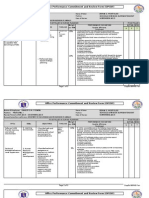

- Compendium As of September 2018 From CODocument120 pagesCompendium As of September 2018 From CODominique Larah EstrellaNo ratings yet

- Kanwrite Catalog NewDocument21 pagesKanwrite Catalog NewAlokNo ratings yet

- Economic Growth and Environmental Sustainability: The PhilippinesDocument27 pagesEconomic Growth and Environmental Sustainability: The PhilippinesMuhammad Tabish HafeezNo ratings yet

- TG 9780190700140 5Document124 pagesTG 9780190700140 5ayesha shafiqueNo ratings yet

- Aggression PDFDocument2 pagesAggression PDFAhmed BaigNo ratings yet

- Arla Foods Is A SwedishDocument2 pagesArla Foods Is A SwedishHimanshu MadaanNo ratings yet

- Test Bank For Investment Analysis and Portfolio Management 11th by ReillyDocument36 pagesTest Bank For Investment Analysis and Portfolio Management 11th by Reillyrestatevinery.nt5ykp100% (42)