Professional Documents

Culture Documents

Hazard Identification and Associated Risk Assessment

Uploaded by

Alistair Van WykOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazard Identification and Associated Risk Assessment

Uploaded by

Alistair Van WykCopyright:

Available Formats

DATE PAGE REV REF

1 of 11 Draft R/A M 02

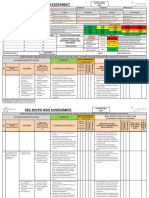

HAZARD IDENTIFICATION AND ASSOCIATED

RISK ASSESSMENT

HAZARD/TASK IDENTIFIED: A.D.T.

RISK ASSESSMENT REVISION COMMITTE

NAME DESIGNATION SIGNATURE

P Kunz PLANT MANAGER

H O’Neil PLANT SUPERINTENDENT

A van Wyk SAFETY OFFICER

D De Wet ENGINEERING FOREMAN

HEALTH AND SAFETY REPRESENTATIVE

HEALTH AND SAFETY REPRESENTATIVE

TYPES OF ASSESSMENTS

SAFETY HEALTH ENVIRONMENT

Identify potential hazards Identify potential exposure Identify potential aspects

Consider: Consider: Consider:

- Electrical - Noise Input,

- Mechanical - Vibration - Material

- Competency - Dust - Oil & Grease

- Lock outs - Ergonomics - Hazardous substances

- Tools (condition) - Cold Stress - Pollution

- Behavior - Heat Stress - Fuels

- License - Gasses Output

- Surrounding conditions - Chemicals - Releases to water, land & air

- Waste generation

- Land changes

- Visual impacts

2

3

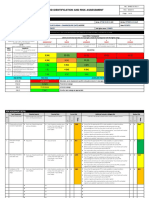

RISK RANKING MATRIX

The following “Personal Injury” matrix is used to determine the significance of the risk

More than Between 100 and Between 10 and Between 1 event Between 1 event Less than 1

Index Significance Priority 100 events 10 events per 1 event per year per year and 1 in 10 years and 1 event in 100

per year year event per 10 event in 100 years

(28 – 48) A High years years

(16 – 27) B Medium Probable Probable events Probable events Probable events Probable events Probable

(1 – 15) C Low events more between 100 and between 10 and between 1 per between 1 in 10 events less

than 100 per 10 per year 1 per year year and 1 in 10 years and 1 in than 1 in 100

year years 100 years years

FREQUENCY (Probability)

SEVERITY

(Consequence)

A B C D E F

Multiple Fatalities > 6 000 Shifts 1

Lost 48 47 45 42 38 33

1 Fatality 6 000 Shifts Lost 2

46 44 41 37 32 27

600 – 5999 Shifts Lost 3

43 40 36 31 26 21

60 – 599 Shifts Lost 4

39 35 30 25 20 15

6 – 59 Shifts Lost 5

34 29 24 19 14 10

1 – 5 Shifts Lost 6

28 23 18 13 9 6

No Time Loss 7

22 17 12 8 5 3

“Near” Miss 8

16 11 7 4 2 1

RISK RANKING MATRIX

The following “Environmental” matrix is used to determine the significance of the risk

4

More than Between 100 and Between 10 and Between 1 event Between 1 event Less than 1

Index Significance Priority 100 events 10 events per 1 event per year per year and 1 in 10 years and 1 event in 100

per year year event per 10 event in 100 years

(28 – 48) A High years years

(16 – 27) B Medium Probable Probable events Probable events Probable events Probable events Probable

(1 – 15) C Low events more between 100 and between 10 and between 1 per between 1 in 10 events less

than 100 per 10 per year 1 per year year and 1 in 10 years and 1 in than 1 in 100

year years 100 years years

FREQUENCY (Probability)

SEVERITY

(Consequence)

A B C D E F

Major Impact life of mine 1

(permanent) 48 47 45 42 38 33

Major Impact long term 2

implications (> 5 years) 46 44 41 37 32 27

Major Impact long term 3

(1 – 5 years) 43 40 36 31 26 21

Severe Impact medium term 4

implications (< 1 year) 39 35 30 25 20 15

Severe Impact medium term 5

implications (+ 6 months) 34 29 24 19 14 10

High Impact (< 6 months) 6

28 23 18 13 9 6

Slight Impact (+ 1 month) 7

22 17 12 8 5 3

No effect (< 1 day) 8

16 11 7 4 2 1

RISK RANKING MATRIX

The following “Property Damage” matrix is used to determine the significance of the risk

5

More than Between 100 Between 10 and Between 1 Between 1 Less than 1

Index Significance Priority 100 events and 10 events 1 event per year event per year event in 10 event in 100

per year per year and 1 event per years and 1 years

(28 – 48) A High 10 years event in 100

years

(16 – 27) B Medium Probable Probable events Probable events Probable events Probable events Probable

(1 – 15) C Low events more between 100 between 10 and between 1 per between 1 in 10 events less

than 100 per and 10 per year 1 per year year and 1 in 10 years and 1 in than 1 in 100

year years 100 years years

FREQUENCY (Probability)

SEVERITY

(Consequence)

A B C D E F

> R100 000 000 1

48 47 45 42 38 33

R1 000 000 – R9 999 999 2

46 44 41 37 32 27

R 100 000 – R999 999 3

43 40 36 31 26 21

R10 000 – R99 999 4

39 35 30 25 20 15

R1 000 – R9 999 5

34 29 24 19 14 10

R100 – R999 6

28 23 18 13 9 6

< R100 7

22 17 12 8 5 3

Near Loss 8

16 11 7 4 2 1

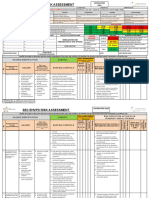

Identified Hazard/Hazard associated with the task RISK

(Safety, Health & Environmental Issues) S H E PROB. CONS. RANKING

1. PRE-USE INSPECTION:-

Struck by:-

6

- A.D.T. * E 2 32

- Moving Machinery * E 2 32

- Vehicles * E 2 32

- Engine hood * E 5 14

Missing/loose wheel stud nuts. * B 8 11

Missing wheel studs * B 8 11

Articulate locking-bar not installed. * E 2 32

Caught by moving parts. * F 3 21

Damaged/Missing:-

- Mounting steps * D 5 19

- Handrails. * D 5 19

Dirty mounting steps. * D 5 19

Tyres:-

- Under inflated * C 6 18

- Over inflated * C 6 18

- Worn * C 6 18

- Cracked sidewall * C 6 18

Burns:-

- Hot engine parts * B 6 23

- Radiator cap/water * B 6 23

Low fluid levels:-

- Diesel * B 8 11

- Water * B 8 11

- Engine oil * B 8 11

- Hydraulic oil * B 8 11

Damaged/dirty:-

- Windscreen * C 8 7

- Windows * C 8 7

- Rear view mirror. * C 8 7

Damaged/Missing load bin tipping restriction chains. * E 4 20

Moving parts not guarded. * C 8 7

7

Identified Hazard/Hazard associated RISK

with the task S H E PR CO RAN

(Safety, Health & Environmental Issues) OB. NS KIN

. G

2 OPERATIONAL PRE-USE

. INSPECTION:-

Slip and fall. * D 6 13

Strike:-

- Fellow workers * F 3 31

- Machinery/Vehicles * F 5 14

- Equipment. * E 4 20

Faulty PDS (where fitted) * E 2 32

Rev engine. * C 8 7

Leaking:-

- Pipes * C 8 7

- Hoses * C 8 7

- Fittings. * C 8 7

Faulty:-

- Wipers * C 8 7

- Head/Tailgate lights * C 8 7

- Reverse light * C 8 7

- Strobe light * C 8 7

- Reverse siren * C 8 7

- Hooter * C 8 7

- Indicators. * C 8 7

Worn wiper blades. * C 8 7

Defective foot brake. * F 2 27

Defective park brake. * F 2 27

Defective retarder. * F 2 27

‘A’ CLASS HAZARDS. * F 2 27

3 PROCEED TO WORKS AREA AND

. TRAVEL WITH LOAD:-

Fall out of cab. * F 2 27

Transport more than 1 * F 2 27

passenger.

Stall motor. * C 8 7

8

Strike:-

- Pedestrians * F 2 27

- Equipment * E 4 20

Identified Hazard/Hazard associated RISK

with the task S H E PR CO RAN

(Safety, Health & Environmental Issues) OB. NS KIN

. G

3 CONTINUED:-

.

- Machinery/Vehicles. * F 5 14

Exceed Mine road speed limit. * C 8 7

Engine overheating * E 4 20

Whilst operational:-

- Talk on cell phone * C 8 7

- Headlights not switched on. * C 8 7

Approach speed. * C 5 24

Struck by – Machinery. * F 6 6

Incorrect product. * F 6 6

Unlevel loading area. * E 2 32

Negotiating inclines/declines * F 2

2

7

Driving on ramps:-

- Embankment breakaway * F 2

27

- Collide with Vehicle/Machinery *

F 2 27

Speed not reduced in pit area. * E 2 32

Wet weather:-

- Slippery conditions * F 2 27

- Cambered areas * F 2 27

Reversing up an embankment at * E 2 32

an angle.

Lights on bright – approaching * F 2 27

9

vehicle.

4 LOADING:-

.

Struck by – F.E.L./Excavator * E 2 32

Insufficient F.E.L./Excavator * C 8 7

reach.

Contamination of product. * C 8 7

Overloading. * C 8 11

Uneven distribution of the load. * C 7 12

Unlevel loading area. * C 8 7

Identified Hazard/Hazard associated RISK

with the task S H E PR CO RAN

OB. NS KIN

(Safety, Health & Environmental Issues) . G

4 CONTINUED:

.

Dumper articulation not aligned. * C 8 7

5 TIPPING:-

.

Approach speed. * B 8 11

Incorrect product. * B 8 11

Overhead power lines. * D 6 13

Strike personnel. * D 6 13

A.D.T. articulation not aligned. * E 2 32

Unlevel tipping area. * C 8 7

Excessive windy conditions. * D 8 4

Travel with raised load bin. * C 4 30

Dumper articulation not aligned. * C 8 7

6 BREAKDOWN AND MAINTENANCE

. PROCEDURE:

Caught by:-

- Articulation * E 2 32

- Moving parts. * E 2 32

Struck by moving:-

- Machinery * F 2 27

10

- Vehicles/Haulers. * F 2 27

Burns:-

- Hot engine parts * D 5 19

- Radiator cap/water. * D 5 19

Raised load bin. * F 2 27

Jacked – Dumper. * F 2 27

Jump starting;-

- Incapacity of helper battery * C 7 12

- Machine/Vehicle housing helper * C 7 12

battery not isolated

- Incapacity of jumper cable. * C 7 12

- Substandard jumper cable * C 7 12

clamps.

- Electrocution * D 6 13

- Incorrect polarity * C 7 12

Identified Hazard/Hazard associated RISK

with the task S H E PR CO RAN

OB NS KIN

(Safety, Health & Environmental Issues) . . G

6 CONTINUED:

.

- Dumper battery not allowed to * C 7 12

charge.

Drain oil – contamination. * D 6 13

Refuel – explosion. * F 2 27

Inflating a tyre – struck by wheel * D 2 37

lock ring.

Brakes adjustment – brake test * E 2 32

not carried out.

7 JACKING/CHANGING A WHEEL:

.

Substandard jack. * E 2 32

Jack lifting piece not fully * E 2 32

inserted.

Substandard activating * C 8 7

lever/crank.

11

Hand injuries. * D 5 19

Injury to fellow workers. * D 5 19

Struck by Vehicles/Machines. * E 2 32

Incorrect sequence of loosening * C 8 7

of wheel nuts.

Incorrect tensioning sequence of * E 2 32

wheel nuts.

8 PARKING AN A.D.T:

.

Unauthorized use. * E 2 32

Struck by moving:-

- Machinery * F 4 15

- Vehicles/Machines. * F 4 15

Failure to install stop blocks – * D 4 25

runaway A.D.T.

The contents of this document supersede all previous documentation relating to Ref. No. R/A M 02

WHO SHOULD BE TRAINED IN THE RECOMMENDED ELIMINATION, CONTROL &

MINIMISATION METHODS

12

RESPONSIBILITY

HEALTH AND SAFETY COMMITTEE

NAME DESIGNATION SIGNATURE

13

RISK ASSESSMENT STATUS

REVISION DESCRIPTION OF REVISION PAGE EFFECTIVE

NO. NO. DATE

00 Draft

You might also like

- 02-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument5 pages02-F02 HIRA-Hazard ID and Risk Assessment Form and Registershaibaz chafekarNo ratings yet

- 31.0.12 ALR - Traffic Control by FlagmanDocument3 pages31.0.12 ALR - Traffic Control by FlagmanGerrit100% (1)

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- RA For Summer Heat Stress Management A71Document4 pagesRA For Summer Heat Stress Management A71Sajid Shah100% (1)

- 2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Document9 pages2.8c Risk Assessment - 023 Scaffolding Erection, Dismantling, Modification Rev. July 2019Shah MuzzamilNo ratings yet

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- 31.0.9 ALR - Loading & Off-Loading TruckDocument5 pages31.0.9 ALR - Loading & Off-Loading TruckGerrit100% (1)

- UG RA 008 - Asphalt Cutting by Using Concrete BreakingDocument5 pagesUG RA 008 - Asphalt Cutting by Using Concrete BreakingshamshuddinNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- UG RA 007 - Asphalt Cutting Using Roto MillDocument5 pagesUG RA 007 - Asphalt Cutting Using Roto MillshamshuddinNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- Shutdown - Ra - RiyadhDocument4 pagesShutdown - Ra - RiyadhRais BurondkarNo ratings yet

- UG RA 006 - Installation of Road BarricadesDocument4 pagesUG RA 006 - Installation of Road BarricadesshamshuddinNo ratings yet

- UG RA 004 - Test Pit Manual ExcavationDocument5 pagesUG RA 004 - Test Pit Manual ExcavationshamshuddinNo ratings yet

- UG RA 003 - Test Pit Markings and Asphalt CuttingDocument6 pagesUG RA 003 - Test Pit Markings and Asphalt CuttingshamshuddinNo ratings yet

- Equipment Risk and Equipment ReliabilityDocument28 pagesEquipment Risk and Equipment ReliabilityMohammed AbdallaNo ratings yet

- OHS-PR-09-03-F02 (A) HIRA-Hazard ID and Risk Assessment Form and RegisterDocument8 pagesOHS-PR-09-03-F02 (A) HIRA-Hazard ID and Risk Assessment Form and RegisterShafie ZubierNo ratings yet

- UG RA 005 - Thermal Integrity and Resistivity TestingDocument6 pagesUG RA 005 - Thermal Integrity and Resistivity TestingshamshuddinNo ratings yet

- Risk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Document6 pagesRisk Assessment For CONCRETE WORKS - SUBSTRUCTURE - 01Bulent AkNo ratings yet

- UG RA 002 - Route SurveyingDocument4 pagesUG RA 002 - Route SurveyingshamshuddinNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- UG RA 001 - Mobilization and Preparation of Site OfficesDocument5 pagesUG RA 001 - Mobilization and Preparation of Site Officesshamshuddin100% (1)

- Risk Assessment Water Tank Cleaning 2023Document3 pagesRisk Assessment Water Tank Cleaning 2023Karan SuleNo ratings yet

- Landscape Urbanism: Mumbai - An Ecologically Unique CityDocument7 pagesLandscape Urbanism: Mumbai - An Ecologically Unique CityShirley BallaneyNo ratings yet

- Radar Target Detection: Handbook of Theory and PracticeFrom EverandRadar Target Detection: Handbook of Theory and PracticeRating: 5 out of 5 stars5/5 (1)

- Probability in Pipeline Risk AssessmentDocument27 pagesProbability in Pipeline Risk Assessmentnitish100% (1)

- Urban Transportation Planning..Document12 pagesUrban Transportation Planning..priyaranjan naskarNo ratings yet

- Equipment - Risk and ReliabilityDocument28 pagesEquipment - Risk and ReliabilityAkshay SetlurNo ratings yet

- Risk Acceptance CriteriaDocument27 pagesRisk Acceptance CriteriaJOSE LUIS GUTIERREZ GARCIANo ratings yet

- Effective Risk AssessmentDocument17 pagesEffective Risk Assessmentali_1987No ratings yet

- Data Base - CriticalPoints - Exposureto HazardDocument58 pagesData Base - CriticalPoints - Exposureto HazardWendel AbejoNo ratings yet

- Project Risk Management: Dushyant MahadikDocument18 pagesProject Risk Management: Dushyant MahadikAkb BhanuNo ratings yet

- Lifeline Facilities (Flood, SS, Landslide)Document1,869 pagesLifeline Facilities (Flood, SS, Landslide)Wendel AbejoNo ratings yet

- Hanford Risk Assessment For Glass PartitionDocument5 pagesHanford Risk Assessment For Glass PartitionAbiama FrankNo ratings yet

- Data Base Lifeline Exposureto HazardDocument104 pagesData Base Lifeline Exposureto HazardWendel AbejoNo ratings yet

- Developing A Facility Hazard and Vulnerability Analysis (HVA)Document27 pagesDeveloping A Facility Hazard and Vulnerability Analysis (HVA)Jair Acasiete LozaNo ratings yet

- Perlin IDocument544 pagesPerlin IbalasubramaniamNo ratings yet

- 2500 Metrohealth Drive Cleveland Ohio 44109Document31 pages2500 Metrohealth Drive Cleveland Ohio 44109vic196No ratings yet

- Hazard AnalysisDocument15 pagesHazard AnalysisAthil ShipateNo ratings yet

- IC Simple Safety Risk Register 11044Document4 pagesIC Simple Safety Risk Register 11044MAHESH SHAWNo ratings yet

- 4.1.2 Covid-19 Risk AssessmentDocument41 pages4.1.2 Covid-19 Risk AssessmentaceNo ratings yet

- Concreting With Concrete BucketDocument3 pagesConcreting With Concrete Bucketkwame fosterNo ratings yet

- Chapter 13Document39 pagesChapter 13Mr. BossNo ratings yet

- Rumaila Project: Document NumberDocument33 pagesRumaila Project: Document NumberMustafaAdnanNo ratings yet

- Chapter 13Document39 pagesChapter 13Musabbir Al NiajNo ratings yet

- 231el RamlyDocument9 pages231el Ramlye244064No ratings yet

- Block WorksDocument4 pagesBlock Workskwame fosterNo ratings yet

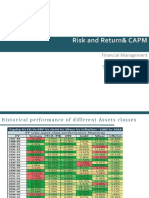

- Risk and Return TheoryDocument45 pagesRisk and Return Theoryanshika rathoreNo ratings yet

- HVA - Group 2 NBDocument12 pagesHVA - Group 2 NBBrandy JaffarNo ratings yet

- GC RiskDocument12 pagesGC RiskC LangiNo ratings yet

- 2.16 PPE Risk Assessment - Eye & Face ProtectionDocument5 pages2.16 PPE Risk Assessment - Eye & Face ProtectionAsif HussainNo ratings yet

- IC Risk and Opportunity Register 11805 WORDDocument3 pagesIC Risk and Opportunity Register 11805 WORDKoshalNo ratings yet

- Risk Management ProcedureDocument10 pagesRisk Management ProcedurehapisstendeNo ratings yet

- JWCh06 PDFDocument23 pagesJWCh06 PDF007featherNo ratings yet

- Effective Risk AssessmentDocument17 pagesEffective Risk Assessmentali_1987No ratings yet

- IC Corporate Risk Register 9419Document3 pagesIC Corporate Risk Register 9419Sathappan KasiNo ratings yet

- 2.8c Risk Assessment - 003 Temporary Perimeter Fencing Rev. July 2019Document6 pages2.8c Risk Assessment - 003 Temporary Perimeter Fencing Rev. July 2019Shah MuzzamilNo ratings yet

- 03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterDocument8 pages03-F02 HIRA-Hazard ID and Risk Assessment Form and RegisterSn AhsanNo ratings yet

- 2.12 00766 Risk Register Final 082212 RiskdistrutionDocument8 pages2.12 00766 Risk Register Final 082212 RiskdistrutionravindraNo ratings yet

- Darwin CollegeDocument11 pagesDarwin CollegeMrWaratahsNo ratings yet

- Specsem Erm 2001 Handouts Dickson1Document20 pagesSpecsem Erm 2001 Handouts Dickson1Ayid AlmgatiNo ratings yet

- Measuring Risk: Risk Management For Enterprises and IndividualsDocument50 pagesMeasuring Risk: Risk Management For Enterprises and IndividualsAhmad RazaNo ratings yet

- MS 20 Use of GeoTubes in IndiaDocument6 pagesMS 20 Use of GeoTubes in IndiaQuoc Le NamNo ratings yet

- Lesson Reviewer - Indigenous Peoples of The Philippines and Dimensions of PovertyDocument3 pagesLesson Reviewer - Indigenous Peoples of The Philippines and Dimensions of Povertyariansofia1031No ratings yet

- PEE Activities SummaryDocument4 pagesPEE Activities SummaryShaina Montero0% (1)

- Designing A Solar-Powered Trash Compactor With Built-In Disinfectant SprayerDocument6 pagesDesigning A Solar-Powered Trash Compactor With Built-In Disinfectant SprayerHoney Rose GamboaNo ratings yet

- What Makes A Planet Habitable?Document3 pagesWhat Makes A Planet Habitable?Willie WilliowNo ratings yet

- E30070 V 20 EA0 P10 Hawassa 0 ESIA0 P129174Document120 pagesE30070 V 20 EA0 P10 Hawassa 0 ESIA0 P129174Biniyam BekeleNo ratings yet

- IWRP&M Assignment No.8.Document7 pagesIWRP&M Assignment No.8.Prathamesh PatilNo ratings yet

- Ecology and Evolution of Plant-Pollinator InteractionsDocument9 pagesEcology and Evolution of Plant-Pollinator Interactionsnebiyu tarikuNo ratings yet

- International Journal of Sustainable Building Technology and Urban DevelopmentDocument8 pagesInternational Journal of Sustainable Building Technology and Urban DevelopmentsimoneweilNo ratings yet

- Environmental-Science-And-Ecology Solved MCQs (Set-6)Document7 pagesEnvironmental-Science-And-Ecology Solved MCQs (Set-6)Muhammad SaimNo ratings yet

- Green Star Buildings-Guidance On Credit Substitution r1Document10 pagesGreen Star Buildings-Guidance On Credit Substitution r1Chetan SakharkarNo ratings yet

- 500 Word EssayDocument3 pages500 Word EssayJasper Rei LopenaNo ratings yet

- Stream-Gaging Procedure: A Manual Describing Methods and Practices of The Geological SurveyDocument298 pagesStream-Gaging Procedure: A Manual Describing Methods and Practices of The Geological SurveyEinstein DamilolaNo ratings yet

- An Integrated Strategic Framework For The Urban Development of Favela Dique Da Vila Gilda in Santos, BrazilDocument232 pagesAn Integrated Strategic Framework For The Urban Development of Favela Dique Da Vila Gilda in Santos, Braziljéssica franco böhmerNo ratings yet

- Abdullah Tamim ArticleDocument12 pagesAbdullah Tamim ArticleAbdullah TamimNo ratings yet

- 7 Ways To Reduce Ocean Plastic Pollution Today - Oceanic SocietyDocument12 pages7 Ways To Reduce Ocean Plastic Pollution Today - Oceanic SocietyHanani HelmiNo ratings yet

- Urban Forestry ThesisDocument8 pagesUrban Forestry Thesisafcnyiatk100% (2)

- (Sustainable Mountaineering) : Project 1Document10 pages(Sustainable Mountaineering) : Project 1Pavithra N MaaneyNo ratings yet

- Factor Trait Report - Noah SmithDocument4 pagesFactor Trait Report - Noah SmithstanleyNo ratings yet

- The Bartlett Digital Case StudyDocument4 pagesThe Bartlett Digital Case StudyHari VenkatNo ratings yet

- Science and The EnvironmentDocument6 pagesScience and The EnvironmentJohn Michael SorianoNo ratings yet

- Introduction - Environmental StudiesDocument26 pagesIntroduction - Environmental StudiesPulkit JainNo ratings yet

- Industrial Town Planning: ConceptDocument1 pageIndustrial Town Planning: ConceptAshish BunglaNo ratings yet

- Land DevelopmentDocument8 pagesLand DevelopmentAshley Nicole AsuncionNo ratings yet

- Fluid Thinking, Smart Solutions: Independent Research and Consultancy in Civil Engineering and Environmental HydraulicsDocument16 pagesFluid Thinking, Smart Solutions: Independent Research and Consultancy in Civil Engineering and Environmental HydraulicsAsjsjsjsNo ratings yet

- Urban EcologyDocument4 pagesUrban Ecologyshahriar sNo ratings yet

- TDS OF H-408 Silicone Adjuvant For AgricultureDocument2 pagesTDS OF H-408 Silicone Adjuvant For AgricultureAda FuNo ratings yet

- Queensferry Crossing Presentation by DawidDocument11 pagesQueensferry Crossing Presentation by Dawidmlynarczykdawid0No ratings yet