Professional Documents

Culture Documents

Orto Alresa - Digtor 22C Centrifuge

Uploaded by

Sergey KichenkoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Orto Alresa - Digtor 22C Centrifuge

Uploaded by

Sergey KichenkoCopyright:

Available Formats

With capacity for 4 tubes of 8”, 6”, trace and 28 “finger” tubes.

Versatile and effective, the best • Protection safety ring between the centrifugation chamber and the housing.

option out of all the centrifuges for oil applications. • Chamber of centrifugation in stainless steel (easy cleaning).

Industrial appl. centrifuges: Series Digtor 22 C

Industrial appl. centrifuges: Series Digtor 22 C

• Rotors and adapters autoclavable, easy to install by the user.

DIGTOR 22 C Features • Automatic disconnection for energy saving up to 8 h.

• Designed for oil/petrol applications according the standards: ASTM D 91, D96,

D 893, D 1796, D2273, D2709, D 2711, D 4007, D 5546, API 2542, API 2548, BS

Max. Capacity Max. Speed

4385, ISO 3734, ISO 9030, IP75, IP 359, NF M07-020, DIN 51793. Fits Babcock bottles. 4 x 100 ml (8”/6”) 2.425 xg / 3.000 RPM

• Tubes upright on rest.

Screen Type Version

• GRS: Gas release system (optional); pre-installation included. TFT Heated

TFT color touch screen, visible from more than 3 m.:

• Shows RPM and RCF, time, temperature, acceleration/deceleration values (PCBS)

EU Directives: 2011/65/EU, 2012/19/EU, 2014/30/EU, 2014/35/EU.

and unbalance location system (ULS).

Standards: EN 61010-1, EN 61010-2-020, EN 61010-2-101, EN 61326-2-6, EN 61326-1, EN

• Speed programming in 10 RPM/10 xg steps. 61010-2-010.

• Real RCF values on screen based on accessories configuration.

• Count up/down from “0” or at “set RPM/RCF” for reproducible tests. Heating

• Timer from 1 sec to 99 hours programmable in 1 sec. steps and hold position.

• PCBS: Progressive controlled acceleration and braking system up to 175 • Preheating program with rotor spinning and selectable temperature. It allows keeping the

selectable ramps that prevents sample homogenization after separation. chamber at working temperature before starting the process.

• ULS: Unbalance location system indicating on the screen the number of the • Regulation of the room temperature +5°C (41°F) to 80°C (176°F) in 1°C/1°F steps.

bucket which produces the unbalance switch off. Programmable in °C o °F.

• Temperature sensor inside the chamber. Overheating protection.

• Start delay: To program the time at which the cycle is to begin.

• Internally isolated avoiding heat loss.

• Linked program: Permits the linking of up to 8 consecutive programmes without the need of

user intervention.

Versions

• 100 programmable memories, with protection under password.

• Several acoustic and visual messages showing the situation of the device to the user. Dimensions Net Weight Voltage Frequency Consumption

(mm) (w x d x h) (Kg) (V) (Hz) (W)

Easy to use CE 238 530 640 420 77 220-230 50-60 1.260

CE 239 530 640 420 77 110-120 50-60 1.220

• Microprocessor controlled. Connectivity.

• Induction motor maintenance free (brushless).

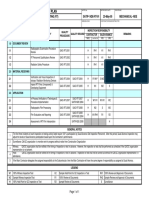

Accessories RT 293 RT 289

• Rotors and adapters list in memory.

• Noise level: below 60 dB.

• Start, stop, open lid and short spin with adjustable speed buttons.

ROTOR SWING OUT SWING OUT

• Possibility to block or modify the speed during the cycle.

• Last values remain in memory. Max. capacity 4x100 ml. (8/6”) 4x100 ml. (8”)

RPM Max. 3.000 3.000

• Automatic rotor recognition. Over-speed protection.

Radius (mm) 241 241

RCF Max. (xg) 2.425 2.425

Safety ADAPTERS ADAPTERS

SAMPLE VOLUME Dim (mm) approx.

Tubes Ref. Tubes Ref.

• Lid provided with security systems: ASTM cone shape 6” Ø 44-46x162-167 4 RE 475 - -

- Automatic lid lock system, motorized with double lock. ASTM pear shape Ø 58-59x157-160 4 RE 477 - -

- Emergency lid-lock release. ASTM trace/cone 8” Ø 36-38x195-203 4 RE 476 4 -

- Locking and protection against opening along the run. API finger 12,5 ml Ø 16x105 28 RE 456 4 RE 455

API finger 12,5 ml Ø 16x105 - - 16 RE 454

- Lid dropping protection.

2 3

- Port in the lid for calibration and operation checking. Available tubes, check tube features at pag. 22 of the general catalogue.

• Unbalance detection and switch off. Check the max. RCF allowed for your ASTM tubes. Max. RCF supported by our ASTM tubes 850 xg.

Safety

Accessories for centrifuges: Gas Release System

Accessories for centrifuges: Rolling table

GAS RELEASE SYSTEM • Hazardous gases input is not required.

ROLLING TABLE

Accessories for centrifuge series Digtor 22 C • Low noise level <40 dB. Accessories for centrifuge series Digtor 22 C

• Powered only by rotor in motion and lid blocked.

• Low power consumption.

The petroleum testing laboratories environment presents a number of risks inherent to the type

EU Directives: 2011/65/EU, 2012/19/EU, 2014/30/EU, 2014/35/EU.

of sample. The devices used for the analysis of samples should ensure minimal risk conditions With the aim of offering an alternative to those laboratories that need to increase their equipment,

Standards: EN 61010-1, EN 61010-2-020, EN 61326-1,EN 61010-2-010.

in the work environment, a critical premise in the development of devices for this application at but do not have enough space, we have designed these rolling tables for our centrifuges.

Ortoalresa.

Versions This accessory allows the equipment to be positioned and moved easily thanks to its four 360º

Centrifugation processes for the determination of water and sediment in petroleum, require Dimensions Net Weight Voltage Frequency Consumption rotating wheels. Once the rolling table is located, and before starting to work with the centrifuge,

an organic solvent which, reacting with the sample and the caloric intake of the equipment, (mm) (w x d x h) (Kg) (V) (Hz) (W) the wheels can be fixed with the brake system that will prevent involuntary displacement during

generates aerosols. In order to remove this gas from the centrifuge and take it to a safe area, the centrifugation process. The robust design supports the weight of the equipment and prevents

CP 001 140 220 120 2 220-240 50-60 20

Ortoalresa has designed the GRS (Gas Release System) as an accessory for all of the Digtor 22 CP 004 140 220 120 2 110-120 50-60 20 vibration transfer.

C series centrifuges. This accessory creates low pressure intake or vacuum suction, inside the

centrifuge chamber, concretely on its top, when locked, that allows the suction of the atmosphere We offfer two types of tables, one with height to locate the equipment at the same height as if they

high in aerosols. This atmosphere is piped through the GRS up to its exit, where it can be treated were on the laboratory table and another, that enables you to place your centrifuge under the table

in isolation. The whole circuit is continuously monitored by the equipment, that will manage the of your laboratory, saving even more space.

right moment to operate the system. Moreover, it only requires the presence of a compressed air

supply of 2 bar pressure, in order to create a 10l/min suction, sufficient to perform the suction A solution for each type of need.

of the centrifuge inside chamber volume every 5 min.

GRS main functions are:

• Decreasing gas concentration during operation, and therefore the risk of explosion.

• Eliminating the user’s health risk by inhalation of produced vapors

• Avoiding gas dispersion into laboratory environment.

References

Easy to use

Dimensions Net weight (kg) Centrífuge model

(mm) (w x d x h)

• It only requires a compressed air supply.

CP 007 560 590 580 65 Series Digtor 22 C

• It has 4 connections: A compressed air inlet, an air inlet for air removed from the equipment,

an atmosphere outlet to a safe area, and the control input from the equipment.

• Operation pilot light.

• Air inlet pressure regulator.

• Inlet pressure gauge.

• Operation controlled by core equipment.

Features

• Setting up at a 2 bar pressure, creates a 10 l/min suction.

• 0.2 bar gauge accuracy.

• Max 8 bar inlet pressure.

• Fast inlet and outlet connections.

8 • Suction capacity: minimum twice total chamber volume in 10 min. 9

You might also like

- Centrifuge Digtor22CDocument9 pagesCentrifuge Digtor22Cbilal khan0% (1)

- Termo Wasaga PDFDocument28 pagesTermo Wasaga PDFMaximNo ratings yet

- Explosion Proof PTZ CameraDocument6 pagesExplosion Proof PTZ Camerasalic2013No ratings yet

- Honeywell T8024Document12 pagesHoneywell T8024d.c.delatorre2200No ratings yet

- Visionpro™ 8000 Touchscreen Programmable Thermostat: FeaturesDocument40 pagesVisionpro™ 8000 Touchscreen Programmable Thermostat: Featurespctyson100% (1)

- Bhhs Melter Xmelt ENDocument4 pagesBhhs Melter Xmelt ENarsya_agasNo ratings yet

- Brochure TP-Guide enDocument8 pagesBrochure TP-Guide enМихаил УльяновNo ratings yet

- ES30C/ES31C Series Positioning System: Product SpecificationDocument4 pagesES30C/ES31C Series Positioning System: Product SpecificationdenfertNo ratings yet

- Zio Lite Wall Modules: Tr40 and Tr42 Models With SylkDocument2 pagesZio Lite Wall Modules: Tr40 and Tr42 Models With SylkUsman Azeem0% (1)

- Solderstar Reflow SolutionsDocument2 pagesSolderstar Reflow SolutionsismailNo ratings yet

- Owner's Manual: Self-Contained Air Conditioning UnitDocument32 pagesOwner's Manual: Self-Contained Air Conditioning UnittienNo ratings yet

- Electrolux 727674 DatasheetDocument3 pagesElectrolux 727674 DatasheetJose FranciscoNo ratings yet

- GC Crystal 9000 - Datasheet - 2021Document7 pagesGC Crystal 9000 - Datasheet - 2021EvgenyNo ratings yet

- S Inertgasgenerator DatasheetDocument4 pagesS Inertgasgenerator DatasheetVikram SinghNo ratings yet

- Versatile Hospital SterilizerDocument8 pagesVersatile Hospital Sterilizermohd shuib abd rahmanNo ratings yet

- TSX ULT Freezers - NorthAmerica - 0719 v2 PDFDocument9 pagesTSX ULT Freezers - NorthAmerica - 0719 v2 PDFambitiousamit1No ratings yet

- Avanti J25 Brochure PDFDocument2 pagesAvanti J25 Brochure PDFPedro BrachoNo ratings yet

- TF Series: Panametrics Aluminum Oxide Moisture ProbeDocument4 pagesTF Series: Panametrics Aluminum Oxide Moisture ProbejhonaNo ratings yet

- HX316C10FBK2/16: 16GB (8GB 1G X 64-Bit X 2 PCS.) DDR3-1600 CL10 240-Pin DIMM KitDocument2 pagesHX316C10FBK2/16: 16GB (8GB 1G X 64-Bit X 2 PCS.) DDR3-1600 CL10 240-Pin DIMM KitinformagicNo ratings yet

- Proven Performance: A World of Soldering SolutionsDocument2 pagesProven Performance: A World of Soldering SolutionsHoussem GhzelNo ratings yet

- AdvantageDocument6 pagesAdvantageDavid_Allen_007No ratings yet

- Catalogue Series Digicen 22 ENGDocument14 pagesCatalogue Series Digicen 22 ENGinna husnaNo ratings yet

- Elster EK205: I Connected IndustrialDocument2 pagesElster EK205: I Connected IndustrialmohamedwalyNo ratings yet

- hx318c10fb 4 PDFDocument2 pageshx318c10fb 4 PDFjafobr4152No ratings yet

- Brochure - Phase Transition AnalyzerDocument2 pagesBrochure - Phase Transition Analyzersarah ahmedNo ratings yet

- BU - GC1000 MarkII - 11B03A03-01EDocument10 pagesBU - GC1000 MarkII - 11B03A03-01EhajduzoliNo ratings yet

- Hurricane Boosters: Air or NitrogenDocument2 pagesHurricane Boosters: Air or NitrogenRas-Sherwin A. JalaniNo ratings yet

- Marine Generator SetsDocument8 pagesMarine Generator SetsmouradNo ratings yet

- Newton Manikin Spec Sheet.R1Document2 pagesNewton Manikin Spec Sheet.R1aqsa imranNo ratings yet

- SB-1500 Slickline Electronic Perforating Tool AdvantagesDocument1 pageSB-1500 Slickline Electronic Perforating Tool AdvantagesSusin LimNo ratings yet

- HX316C10FDocument2 pagesHX316C10FRuben CarlosNo ratings yet

- DC200 Equipment ManualDocument3 pagesDC200 Equipment ManualAdrian S. QuirosNo ratings yet

- Atlas Copco Leaflet Portable Zone2 R3Document2 pagesAtlas Copco Leaflet Portable Zone2 R3KunalanNo ratings yet

- Testo 350 XL Portable Emissions Analyser PDFDocument2 pagesTesto 350 XL Portable Emissions Analyser PDF201102262No ratings yet

- 3 CentrifugeDocument1 page3 CentrifugeFlor FloresNo ratings yet

- CM907 Product SpecificationDocument7 pagesCM907 Product SpecificationklematronicNo ratings yet

- HX316C10FB/8 8GB DDR3-1600 Memory ModuleDocument2 pagesHX316C10FB/8 8GB DDR3-1600 Memory Moduleelegido911No ratings yet

- TI-4GS Carbon Dioxide Sensor Provides Easy Setup and Low CostsDocument2 pagesTI-4GS Carbon Dioxide Sensor Provides Easy Setup and Low CostsJose MhNo ratings yet

- Ethylene Oxide Gas (Eto) Sterilizers: DE LAMA Holds The Quality System Certificates ISO 9001 and EN 46001Document6 pagesEthylene Oxide Gas (Eto) Sterilizers: DE LAMA Holds The Quality System Certificates ISO 9001 and EN 46001soajaniiNo ratings yet

- How To Increase Crude Throughput in Desalter ApplicationsDocument28 pagesHow To Increase Crude Throughput in Desalter ApplicationsAnonymous bHh1L1No ratings yet

- Automatic Tank Gauging System PDFDocument2 pagesAutomatic Tank Gauging System PDFRahul DivakaranNo ratings yet

- Pelco Esprit ES31PC PTZ CameraDocument4 pagesPelco Esprit ES31PC PTZ Camerabuzz2010buzzNo ratings yet

- Inverter Technology in Refrigeration and HVAC Applications Inverter-DriverDocument14 pagesInverter Technology in Refrigeration and HVAC Applications Inverter-Driver123wonbidNo ratings yet

- Sensor de Ruido Espectral: GEO-SNM (Self-Contained Sound Noise Level Meter) PurposeDocument4 pagesSensor de Ruido Espectral: GEO-SNM (Self-Contained Sound Noise Level Meter) Purposecarlos schoepsNo ratings yet

- HW Rm7840l1075control Bro 63-9505Document4 pagesHW Rm7840l1075control Bro 63-9505alfredomamutNo ratings yet

- Leaflet NCP Tech enDocument4 pagesLeaflet NCP Tech enmiles100% (1)

- ARP 95 Ammann Tandem Vibrating Rollers ARP T4i en 2Document8 pagesARP 95 Ammann Tandem Vibrating Rollers ARP T4i en 2MuhaiminNo ratings yet

- GasAlertMaxXTII DatasheetDocument2 pagesGasAlertMaxXTII DatasheetAnil yucebasNo ratings yet

- Kidde Fire Systems Natura™ Inert Gas Fire Suppression SystemDocument12 pagesKidde Fire Systems Natura™ Inert Gas Fire Suppression SystemPrajwal shettyNo ratings yet

- The Density Transducer: CatalogueDocument8 pagesThe Density Transducer: CataloguecescNo ratings yet

- CM20200320 39552 31fa9Document4 pagesCM20200320 39552 31fa9johnward19951995No ratings yet

- CEMDT8880 Hot WireDocument3 pagesCEMDT8880 Hot WireCristhian Camilo Avila CertucheNo ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 2018-02-Halliburton-slidesDocument14 pages2018-02-Halliburton-slidesSergey KichenkoNo ratings yet

- Brady Catalogue enDocument92 pagesBrady Catalogue enAde SetiawanNo ratings yet

- QA/QC ManualDocument42 pagesQA/QC ManualGuilherme Dos Santos Moreira100% (1)

- InnerVue Diagnostics ServicesDocument1 pageInnerVue Diagnostics ServicesSergey KichenkoNo ratings yet

- Protecting plant piping from CUI with water repellencyDocument2 pagesProtecting plant piping from CUI with water repellencySergey KichenkoNo ratings yet

- Salt in Crude Analyser ApparatusDocument2 pagesSalt in Crude Analyser ApparatusDAVID JUMANo ratings yet

- Training Manual (GET Process) 1Document34 pagesTraining Manual (GET Process) 1Steve Wan100% (2)

- Corrosion Monitoring Methods (Chevron)Document65 pagesCorrosion Monitoring Methods (Chevron)Sergey KichenkoNo ratings yet

- SP-2275, Rev1Document48 pagesSP-2275, Rev1Moetaz Mohamed0% (1)

- The Three P's of High Temperature Plastic PipeDocument70 pagesThe Three P's of High Temperature Plastic PipeSergey KichenkoNo ratings yet

- Analytical Systems Keco - 205L Laboratory H2S Analyzer in Crude OilDocument2 pagesAnalytical Systems Keco - 205L Laboratory H2S Analyzer in Crude OilSergey KichenkoNo ratings yet

- Vapor Pressure Testing at Its Best: EravapDocument6 pagesVapor Pressure Testing at Its Best: EravapAdikoDenzeyAnonhNo ratings yet

- SAIC-RT-2004 Verify RT EquipmtDocument3 pagesSAIC-RT-2004 Verify RT EquipmtKirubhakarPooranamNo ratings yet

- ASTM D4929-19 Determination of Organic Chloride Content in Crude OilDocument10 pagesASTM D4929-19 Determination of Organic Chloride Content in Crude OilSergey KichenkoNo ratings yet

- Operator Manual Dakota UT MVXDocument120 pagesOperator Manual Dakota UT MVXRoyce BergNo ratings yet

- Corrosion Detection and ControlDocument47 pagesCorrosion Detection and ControlMassimo FumarolaNo ratings yet

- Comparison Corrosion Mapping Solutions Using PDFDocument10 pagesComparison Corrosion Mapping Solutions Using PDFfabian barraganNo ratings yet

- SAIC-RT-2002 Revw RT Person QualificationDocument1 pageSAIC-RT-2002 Revw RT Person QualificationKirubhakarPooranamNo ratings yet

- SAIC-RT-2005 Mat Insp-Fils Nad DevelopingDocument3 pagesSAIC-RT-2005 Mat Insp-Fils Nad DevelopingKirubhakarPooranamNo ratings yet

- SAIC-RT-2003 Radiation Safety Procedure ReviewDocument1 pageSAIC-RT-2003 Radiation Safety Procedure ReviewKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection Checklist: Radiographic Film Evaluation and Reporting SAIC-RT-2009 25-May-05 NdeDocument6 pagesSaudi Aramco Inspection Checklist: Radiographic Film Evaluation and Reporting SAIC-RT-2009 25-May-05 NdeSergey KichenkoNo ratings yet

- XXX RadiographsDocument48 pagesXXX RadiographsJoseph MidouNo ratings yet

- SAIC-RT-2007 In-Process For RT ImplementationDocument7 pagesSAIC-RT-2007 In-Process For RT ImplementationSergey KichenkoNo ratings yet

- EN 16407 HOIS PresentationDocument26 pagesEN 16407 HOIS PresentationEsin DenizNo ratings yet

- SAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTION PLANDocument1 pageSAUDI ARAMCO RADIOGRAPHIC TESTING INSPECTION PLANKirubhakarPooranamNo ratings yet

- Saic K 4039Document1 pageSaic K 4039dilshadmit1280No ratings yet

- Measure Pipe Wall Thickness Using Tangential RadiographyDocument7 pagesMeasure Pipe Wall Thickness Using Tangential Radiographykirubha_karan2000No ratings yet

- Iaea Tecdoc 1445Document114 pagesIaea Tecdoc 1445avazcNo ratings yet

- Radiographic Inspection of Corrosion and Deposits in Pipes by X - and Gamma Rays Tangential Radiographic Inspection Technique (ISO 20769)Document16 pagesRadiographic Inspection of Corrosion and Deposits in Pipes by X - and Gamma Rays Tangential Radiographic Inspection Technique (ISO 20769)Sergey KichenkoNo ratings yet

- Pipe Wall Thickness and Corrosion AssessmentDocument13 pagesPipe Wall Thickness and Corrosion AssessmentSantosh mishraNo ratings yet

- Xitron Plugin For TrendsetterDocument16 pagesXitron Plugin For TrendsetterRogerio FerracinNo ratings yet

- Singh 2017Document22 pagesSingh 2017PutriMutiaRizkiNo ratings yet

- MCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 700 EDocument3 pagesMCGB - Data Sheet For Suppliers Old MAT Nos.: Weldox 700 Ebaskaran ayyapparajNo ratings yet

- XML Quiz with AnswersDocument17 pagesXML Quiz with AnswersManoj GuptaNo ratings yet

- General Purpose & Power Relays GuideDocument20 pagesGeneral Purpose & Power Relays GuideMahesh KumbharNo ratings yet

- Shop Inspection and Test Plan for FRP Water TroughDocument29 pagesShop Inspection and Test Plan for FRP Water TroughEljo AndsNo ratings yet

- Genelec 8020A Active Monitoring System Operating ManualDocument8 pagesGenelec 8020A Active Monitoring System Operating ManualavkoemanNo ratings yet

- Biological Buffer SystemDocument4 pagesBiological Buffer SystemSharm Jarin-AlonzoNo ratings yet

- Lime Soda Ash Softening Calculations PDFDocument34 pagesLime Soda Ash Softening Calculations PDFDaniel Ortiz100% (1)

- Introduction To Tel-X-Ometer Equipment-Manual ProcedureDocument7 pagesIntroduction To Tel-X-Ometer Equipment-Manual ProcedurehannaNo ratings yet

- BROADLEAF 6 ManualDocument109 pagesBROADLEAF 6 ManualBaseCubica ArquitectosNo ratings yet

- Distrib: Probability Distribution AnalysisDocument17 pagesDistrib: Probability Distribution AnalysisLiz castillo castilloNo ratings yet

- Display, Operate, Switch, Control, Regulate and Communicate: For Sales and SupportDocument24 pagesDisplay, Operate, Switch, Control, Regulate and Communicate: For Sales and SupportVictor Rolando Tarifa BlancoNo ratings yet

- Lecture NotesDocument41 pagesLecture NotesAkeem Emmanuel Uy Feria100% (1)

- Datum Transformation PDFDocument165 pagesDatum Transformation PDFfreddy ramdinNo ratings yet

- Saas 1000Document69 pagesSaas 1000rjnemoNo ratings yet

- Chemistry Investigatory Project: Name: Mengulhounuo Keretsu Class: 12 (Science) School: Maple Tree SchoolDocument23 pagesChemistry Investigatory Project: Name: Mengulhounuo Keretsu Class: 12 (Science) School: Maple Tree SchoolmengulhounuoNo ratings yet

- Erickson Power Electronics PDFDocument2 pagesErickson Power Electronics PDFStephanie0% (2)

- Horizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewDocument18 pagesHorizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewHavaldar, SanjayNo ratings yet

- What Makes A Planet Habitable?Document3 pagesWhat Makes A Planet Habitable?Willie WilliowNo ratings yet

- Garnet PDFDocument2 pagesGarnet PDFMarco VillanuevaNo ratings yet

- Schott Ky DiodesDocument3 pagesSchott Ky DiodesAmarnath M DamodaranNo ratings yet

- Video Surveillance 2012 MailDocument76 pagesVideo Surveillance 2012 MailcoreloneNo ratings yet

- 181 120 101Document5 pages181 120 101Md Rafiqul Islam ManikNo ratings yet

- Circle Theorem June/July 2021Document4 pagesCircle Theorem June/July 2021Sachin MangarNo ratings yet

- Instrument Note RangesDocument11 pagesInstrument Note RangesWalter Macasiano GravadorNo ratings yet

- Openmusic: Design and Implementation Aspects of A Visual Programming LanguageDocument8 pagesOpenmusic: Design and Implementation Aspects of A Visual Programming LanguageGheorghe IonicaNo ratings yet

- Advanced Aspects SpectrosDocument548 pagesAdvanced Aspects SpectrosPraveen Mishra100% (3)

- Solutions to Mandatory Exercises and Unit Test for Sets, Relations and FunctionsDocument34 pagesSolutions to Mandatory Exercises and Unit Test for Sets, Relations and FunctionsShashankAnilNo ratings yet

- 23 Samss 060Document14 pages23 Samss 060Cherukunnon JubuNo ratings yet