Professional Documents

Culture Documents

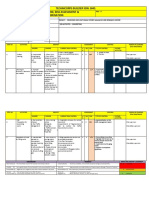

Job Safety Analysis For Highmast Erection

Uploaded by

Saleh AbusalehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis For Highmast Erection

Uploaded by

Saleh AbusalehCopyright:

Available Formats

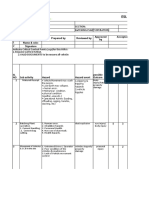

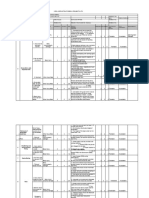

HAZARD IDENTIFICATION &

RISK

Process & Erection,testing and comisssioning of

Location: High mast lighting tower

Risk Assessment Team: Assessment Date:

Leader: Mr.A.K.Maurya Last review date:

Member 1 Mr.Balasubramanian Next review date:

Member 2 Mr.A.Amalraj Approved By : Mr. Sandipan Ghosh

Signature

HAZARD IDENTIFICATION

Consequence

Work Activity

(Possible Risk Level (Low- L;

S.N. (Job steps in Hazards

injury/Ill- Medium- M; High- H)

sequence)

Health/ Persons-at-Risk

& Environmental)

1. Person trap inside the pit

1.Electricution

Excavation by mechanical

1

equipment

2. Body parts burns H

2.cabin 3. serious body part

3. Trap between two objects injury

Preparation of 1.Body parts injury

1.serious injury

2 reinforcement and fixing

2.Amputation H

of foundation bolts.

Concrete casting (PCC &

3

RCC)

1.Dermitices 1.Skin deases M

1. Trap with moving vehicles

Transporatation of High 2. Falling of

4

mast. material 3.slip,trip,toppling

1.Serious body part damage H

4.Hit by object

1.Chain pulley block chain give

5 Asembly of High mast

away 2.Hit by object

Body Injury H

1. Falling Hazard

1.Serious body part injury 2.Property

6 Erection of High mast 2. Lift gear give away. 3.Hydra

damage H

topple 4.Amputation

Installation of illumination 1.Falling of object 2.Person hit by

1.Body part burnt . 2.Serious body part

7 system and hoisting to the object 3.Failure of hoisting

injury H

proper position. mechanism 4.electricution

Check and

1.Serious body part burnt. 2.property

8 commissioning of the 1.Electricution. 2.Short circuit

damage H

illumination system.

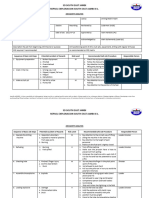

Rev. No.: 0

ASSESSMENT (HIRA)/JSA Ref. No. : BGR/PPD/0208/GN/PRO/ -Rev 00

GENERAL NOTES:

1- All necessary permits to be obtained from BGRE/OPGC.

2-All persons must be Safety Inducted.

3- Mandatory PPEs are Safety helmet, Hard toe safety shoes/Gum Boot, Safety glasses, Reflective vest,

Full/half sleeve (at least 4 inch long) shirt ,Full length pant/trousers

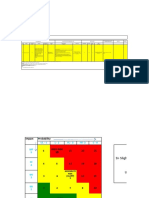

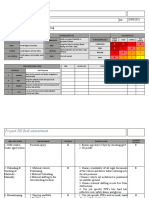

4- Probability, Severity & risk Table is attached for reference

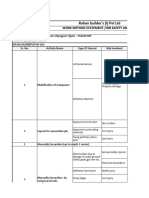

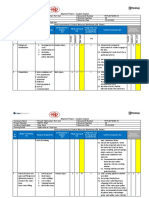

RISK EVALUATION RISK CONTROL

Residual Risk

(Low- L;

Present Control Measures Person responsible

Medium- M;

High- H)

ground utility identification need to be done.

3. Competent excavator operator need to

be deployed. 4.Backs man need to be deployed to control the excavation

activity.

5. Excavated soil need to be dumped two mtr away

from the pit.

6. Dewatering pump need to be arranged . L Site Head (RCM) / Package In charge

1.ELCB and earthing of the machine need to be checked. 2.cutting machine

(rotating part) need to be covered with guard. L Site Head (RCM) / Package In charge

1. Area need to be barricated.

2. Proper approach to be made for movement of concrete vehicles and worksmen.

L Site Head (RCM) / Package In charge

1.Autherised trailor driver need to be deployed for transportion. 2.Speed limit need to be

followed. 3.While loading in hydra

authorised operator need to be deployed.

4.Experince ragging and signal man to be deployed. 5.During

loading of highmast protroding beyond the trailor is not advisable.

6.Loaded L Site Head (RCM) / Package In charge

mast need to be secured to prevent sliding and rolling hazards.

7.During

placing tagline to be used. 8.Unloading

need to be done in a designated mass assemble area.

1.Certified chain pulley blocks need to be used. 2.Hazzard

briefing to be carried out before operation. 3.Mark the lapping/ bearing

length 4.Secure chain pulley block as L Site Head (RCM) / Package In charge

per the engineer instruction 5. Dragging of top mast towards close to

bottom at top most. 6.Ensure lapping/bearing according to the mast design.

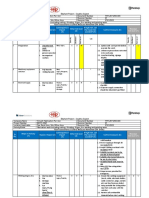

1.Autherised hydra operator need to be deployed. 2.JSA

briefing need to be carried out. 3.Certified

lifting gears need to be used for lifting purpose. 4.Lifting points need to be decided

according to the height and weight of the mast.

5.During lifting dragging is not advisable. 6.Tag

name need to be used to control the mast. L Site Head (RCM) / Package In charge

7.During hoisting bring the mast to a vertical position and place the

bottom of the mast above the mast foundation. 8.Tightening the mast

by tightening the nuts using right tools. 9.During tightening mast

verticality need to be checked.

1.Experience electrician need to be deployed. 2.Hazard briefing

need to explained .3.Illumination fitting need to

be assembled and fixing as per vendor manual.

4.Recommeded electrical wire need

to be used 5.The entire electrical wiring system need to

be connect with DB box with proper earthing system. L Site Head (RCM) / Package In charge

6.During hoisting ensure all the illumination fitting need to be in a tight

position along with the mast illumination ring frame. 7. For hoisting

rotate the handle in a clockwise manner with stead and smooth rotation.

8.Ensure the illumiation

system has been reached at the top and the hoisting mechanism has been locked.

1.Appropriate approved electrical PPE need to be used. 2.JSA briefing

need to be carried out.

3. Experienced electrician need to be deployed for this activity. 4.BGRE Electrical

engineer need to be declair with the execution team for shut down for connecting new

illumiation system. 5.Before charging BGRE electrical engineer need to inform to the L Site Head (RCM) / Package In charge

execution team for charging system.

6. Activate MCB to energies the illumination system.

7. Check and ensure the illuminated area which has been covered.

You might also like

- RA-22 For Grating Floorplate Installation ModificationDocument12 pagesRA-22 For Grating Floorplate Installation Modificationalla malikNo ratings yet

- Hira Arvos SiteDocument7 pagesHira Arvos SiteR. Ayyanuperumal AyyanuperumalNo ratings yet

- HIRA Batching PlanDocument9 pagesHIRA Batching Plannitish tiwariNo ratings yet

- HiraDocument30 pagesHiravijay kumar singhNo ratings yet

- Sener/Sepcoiii Consortium Noor Iii Project: Risk AssessmentDocument7 pagesSener/Sepcoiii Consortium Noor Iii Project: Risk AssessmentmessaoudiNo ratings yet

- Risk AssDocument1 pageRisk AssViorel R.No ratings yet

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTNo ratings yet

- AHA - Earthworks (Excavation, Compaction, Backfilling and Filling) - REV-1 (3-9-2019)Document8 pagesAHA - Earthworks (Excavation, Compaction, Backfilling and Filling) - REV-1 (3-9-2019)Eyal BabuNo ratings yet

- HIRA Format (2) Structural WorkDocument9 pagesHIRA Format (2) Structural WorkR. Ayyanuperumal AyyanuperumalNo ratings yet

- TRA 02 Lifting of Skid Units During Rig MovesDocument3 pagesTRA 02 Lifting of Skid Units During Rig MovesPirlo PoloNo ratings yet

- Electrical, Rev 01Document235 pagesElectrical, Rev 01Samy KsNo ratings yet

- Neral Cleaning of EclDocument4 pagesNeral Cleaning of EclHari NairNo ratings yet

- HIRA - ColumnDocument8 pagesHIRA - ColumnSandy MNo ratings yet

- AHA - Asbestos Abatement-11-11-2019Document7 pagesAHA - Asbestos Abatement-11-11-2019Eyal BabuNo ratings yet

- Apprvd. Movilazation of Temporary Site OfficeDocument6 pagesApprvd. Movilazation of Temporary Site OfficeFaisal RazaNo ratings yet

- Hira (Structural Work)Document19 pagesHira (Structural Work)Dhirendra TiwariNo ratings yet

- Activity Hazard Analysis For Erection and Dismantling of ScaffoldDocument2 pagesActivity Hazard Analysis For Erection and Dismantling of ScaffoldCherrycherry Betonio0% (1)

- Mobilization of CabinDocument1 pageMobilization of CabinRashidi RahmanNo ratings yet

- HIRA - Hydro TestDocument3 pagesHIRA - Hydro TestHiralal PattanayakNo ratings yet

- RA For HydrotestDocument26 pagesRA For HydrotestSandeep kumarNo ratings yet

- Hira - 01Document3 pagesHira - 01Angw BasumataryNo ratings yet

- Risk Assessment Form 2Document13 pagesRisk Assessment Form 2Selva SoniyaNo ratings yet

- Pit Cleaning HSE ProfessionalsDocument1 pagePit Cleaning HSE ProfessionalsSamadov 13No ratings yet

- Excavation JSADocument9 pagesExcavation JSASuvarnrajNo ratings yet

- Task Risk Assessment Tra Number: JOB DESCRIPTON: HLP #60 CNV Work at Shutdown HazardDocument8 pagesTask Risk Assessment Tra Number: JOB DESCRIPTON: HLP #60 CNV Work at Shutdown HazardCartila MawratiNo ratings yet

- Hira For Pipe Coating Monsher Fire Protectioin System P. L.Document31 pagesHira For Pipe Coating Monsher Fire Protectioin System P. L.Nikhil ManjrekarNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- 007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationDocument5 pages007 Risk Assessment For Precast Construction & Installation of Street Lighting FoundationJahan Zaib50% (2)

- 2.preheater Building HiraDocument2 pages2.preheater Building HirasgcworkjpflNo ratings yet

- OHS - R - 4.3.1 / 01 Hazard Identification & Risk AssessmentDocument2 pagesOHS - R - 4.3.1 / 01 Hazard Identification & Risk AssessmentDevend HarinkhedeNo ratings yet

- Material Loading Unloading and Shifting JSA HSE ProfessionalsDocument1 pageMaterial Loading Unloading and Shifting JSA HSE ProfessionalsSamadov 13No ratings yet

- OSHE-F - 08 Excavation PTW R 1Document3 pagesOSHE-F - 08 Excavation PTW R 1Ibrahim EsmatNo ratings yet

- 13 Mobile Tower Crane OperationDocument2 pages13 Mobile Tower Crane Operationshamshad ahamedNo ratings yet

- Hira BCN 22aDocument33 pagesHira BCN 22aDhaneswar SwainNo ratings yet

- AHA - Electric Switchboard Installation - 19-3-2019Document7 pagesAHA - Electric Switchboard Installation - 19-3-2019Eyal BabuNo ratings yet

- Excavation Permmit To WorkDocument3 pagesExcavation Permmit To WorkWilson Wambua0% (1)

- JSA For TC JumpingDocument16 pagesJSA For TC JumpingZakeer ShaikhNo ratings yet

- AHA - Installation of Doors and Wooden Items - 27-3-2019 RevDocument6 pagesAHA - Installation of Doors and Wooden Items - 27-3-2019 RevEyal BabuNo ratings yet

- iFUEL CON Risk AssessmentDocument3 pagesiFUEL CON Risk AssessmentHoang Quoc DungNo ratings yet

- NC-FRM-DRA 6-2 Rev.0 Workshop ActivitiesDocument2 pagesNC-FRM-DRA 6-2 Rev.0 Workshop ActivitiesPatrick Bibila NdansiNo ratings yet

- 3DSEJ-JSA SP Missfire - EngDocument3 pages3DSEJ-JSA SP Missfire - EngHSE BGP HONo ratings yet

- Risk Assessment of Cantilever ScaffoldDocument1 pageRisk Assessment of Cantilever ScaffoldGyanendra Srivastava100% (1)

- RA For Site Fabrication Work - 05Document10 pagesRA For Site Fabrication Work - 05alla malikNo ratings yet

- Elephant Project - Sayakha GujaratDocument8 pagesElephant Project - Sayakha Gujaratalla malikNo ratings yet

- L Risk Assessment Code (RAC) MatrixDocument6 pagesL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- Risk Assessment-Maintance of Tanks, VesselsDocument5 pagesRisk Assessment-Maintance of Tanks, VesselsKono Nor AtanNo ratings yet

- Material Handling JHA - Boom Truck, Crane Lifts & Forklift - SampleDocument4 pagesMaterial Handling JHA - Boom Truck, Crane Lifts & Forklift - Sampleluis VelozNo ratings yet

- Lifting of Mechanical Grab ExcavatorDocument12 pagesLifting of Mechanical Grab Excavatorlittle papaNo ratings yet

- HSE Risk AssessmentDocument4 pagesHSE Risk AssessmentWasique NesarNo ratings yet

- Hira - CivilDocument20 pagesHira - Civilmurthy100% (1)

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- HSSE Risk Register V4Document38 pagesHSSE Risk Register V4dennisjuntakNo ratings yet

- Hira - IbsplDocument7 pagesHira - IbsplAbdul Raheem100% (1)

- Hirard ConcretingDocument3 pagesHirard ConcretingJames JoviNo ratings yet

- Loading Scrap Iron Into BinDocument8 pagesLoading Scrap Iron Into BinMahendren JayapalanNo ratings yet

- Risk AssessmentDocument10 pagesRisk AssessmentKyaw Kyaw Aung89% (9)

- JSA Demolition and DisposalDocument7 pagesJSA Demolition and Disposalm4l4ysia60% (5)

- Recreational ActivityDocument5 pagesRecreational ActivityKenneth LoNo ratings yet

- Utilization of Silver Hydrogel Sheet Dressing On Post-Surgical Incisions: A Pilot Study in Foot and Ankle SurgeryDocument1 pageUtilization of Silver Hydrogel Sheet Dressing On Post-Surgical Incisions: A Pilot Study in Foot and Ankle SurgeryDougNo ratings yet

- Anatomy-Head and NeckDocument94 pagesAnatomy-Head and NeckXahid IqbalNo ratings yet

- Prayers of HealingDocument5 pagesPrayers of HealinglynnverbNo ratings yet

- Face Studio Contract Small Function FinalDocument2 pagesFace Studio Contract Small Function Finalapi-138096780No ratings yet

- Anesthesia For Cataract Surgery: Chapter - 4Document8 pagesAnesthesia For Cataract Surgery: Chapter - 4Anggi Junita Endamia BangunNo ratings yet

- Tracts of The Spinal CordDocument21 pagesTracts of The Spinal Corddr.a.k.gupta6924100% (10)

- 2014-Dynamic High-Resolution Ultrasound of The Shoulder How We Do it-ESDocument12 pages2014-Dynamic High-Resolution Ultrasound of The Shoulder How We Do it-ESAsim AliNo ratings yet

- Clinical Case Report Powerpoint PresentationDocument24 pagesClinical Case Report Powerpoint Presentationapi-354139540100% (1)

- Golf Fitness PDFDocument8 pagesGolf Fitness PDFsafriduotriocuartetoNo ratings yet

- Doctrine of Last Clear ChanceDocument2 pagesDoctrine of Last Clear ChanceMiguel CastricionesNo ratings yet

- Dehisced Surgical Wounds - Medihoney Power Webinar Episode 9Document42 pagesDehisced Surgical Wounds - Medihoney Power Webinar Episode 9Lynn Paredes MargullisNo ratings yet

- Ingles I - TP 1Document7 pagesIngles I - TP 1Martu Diaz OrtegaNo ratings yet

- Osteogenesis Imperfecta Power PointDocument29 pagesOsteogenesis Imperfecta Power PointJonathan Jeffry Pratama100% (1)

- Nama Otot Yang Terlibat Dalam Aktiviti Teh TarikDocument2 pagesNama Otot Yang Terlibat Dalam Aktiviti Teh TarikKhanz WongNo ratings yet

- Ergonomics at Work: Reference PosturesDocument2 pagesErgonomics at Work: Reference PosturesJohn WNo ratings yet

- Index: Acinetobacter BaumanniiDocument11 pagesIndex: Acinetobacter BaumanniiHeruWidartNo ratings yet

- Law and MedicineDocument2 pagesLaw and MedicineCP Ispat Unit IINo ratings yet

- ResidentialLease Custom Edit 00Document5 pagesResidentialLease Custom Edit 00thephuryNo ratings yet

- Live Cricket Scores, Commentary, Match Coverage - Cricket News, Statistics - ESPN CricinfoDocument5 pagesLive Cricket Scores, Commentary, Match Coverage - Cricket News, Statistics - ESPN CricinfoRudra Pradeepta Sharma KNo ratings yet

- 43951NCJRSDocument211 pages43951NCJRSRoman MamunNo ratings yet

- Cambodian School of Prosthetics and Orthotics: CSPO ManualDocument60 pagesCambodian School of Prosthetics and Orthotics: CSPO ManualBilalNo ratings yet

- Anes - Premedication and PositioningDocument7 pagesAnes - Premedication and PositioningChristine MendozaNo ratings yet

- Elbow Joint ConditionsDocument3 pagesElbow Joint ConditionsMarilia FarensenaNo ratings yet

- CPP - Primary and Secondary SurveyDocument6 pagesCPP - Primary and Secondary SurveyRizal Sven Vollfied100% (1)

- Kobe Bryant: From Wikipedia, The Free Encyclopedia Jump To:, Kobe BryantDocument10 pagesKobe Bryant: From Wikipedia, The Free Encyclopedia Jump To:, Kobe BryantJames BronxNo ratings yet

- Awareness On Working at HeightDocument3 pagesAwareness On Working at Heightsubhadipmanna8100% (1)

- HEADACHE in NeurologyDocument80 pagesHEADACHE in NeurologyIhsanAkbarNo ratings yet

- Ponsetti MethodDocument32 pagesPonsetti MethodHerlangga Fadhillah AkbarNo ratings yet

- WAMUNC Participant Release Form PDFDocument3 pagesWAMUNC Participant Release Form PDFStefan InderbitzinNo ratings yet