Professional Documents

Culture Documents

PF0009-SLB-ST-DWG-0001 Rev - C

Uploaded by

bmanojkumar16Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PF0009-SLB-ST-DWG-0001 Rev - C

Uploaded by

bmanojkumar16Copyright:

Available Formats

1.0 GENERAL NOTES 8.

0 FIREPROOFING REFERENCE DRAWINGS / DOCUMENTS

3.12 DIAMETER OF HOLES ON CONNECTION SHALL BE AS INDICATED IN TABLE J3.3M OF THE AISC 360-16.

1.1. ALL DIMENSIONS ARE IN MILLIMETERS, CO-ORDINATES, LEVELS ARE IN METERS AND ANGLES ARE 360° DEGREES 8.1 FOR FIRE PROOFING MATERIALS, APPLICATION AND TESTING, REFER TO ENI TECHNICAL STANDARD 313400DADB12650 STANDARD DRAWING GENERAL NOTES OF CIVIL WORKS

CIRCLES U.N.O, EXCEPT FOR THE PIPE SIZES WHICH ARE SHOWN IN INCHES. BOLT HOLES NUMBER 28832.ENG.CIV.DWG. 28832.ENG.CIV.DWG. ENI TECHNICAL STANDARD FOR FIRE PROOFING

DIAMETER DIMENSIONS

1.2. ELEVATIONS INDICATED WITH EL. ARE REFERRED TO THE TOP OF BEAMS T.O.S. (TOP OF STEEL) AND 8.2 THE EXTENT OF FIRE PROOFING SHALL BE AS INDICATED/DISTINGUISHED IN THE STRUCTURAL STEEL DRAWINGS. 313400DADM12654 STANDARD DRAWING ANCHOR BOLT

M16 Ø 18

RELATED TO ELEVATION OF 100.000 OR AS SPECIFIED IN THE DRAWINGS. M20 Ø 22 313400DADB12651 STANDARD DRAWING ABBREVIATIONS AND SYMBOLS

1.3 ELEVATION AT BASE OF COLUMNS ARE REFERRED TO B.O.B.P (BOTTOM OF BASE PLATES) OF THE COLUMNS M22 Ø 24

THEMSELVES. M24 Ø 27 9.0 PAINTING

M27 Ø 30 9.1 STRUCTURAL STEEL PAINTING SHALL BE IN ACCORDANCE WITH COMPANY STANDARD DOCUMENT "ENI 29001:

1.4 CONTRACTOR SHALL CHECK & VERIFY ALL DIMENSIONS BEFORE EXECUTION OF WORK.

M30 Ø 33

1.5 ALL WORKS SHALL BE CARRIED OUT IN A SAFE & DILIGENT MANNER WITH DUE REGARD TO SAFETY OF SITE PAINTINGS AND COATING FOR ONSHORE FACILITIES".

3.13 THE DIAMETER OF HOLES ON BASE PLATE SHALL BE ESTABLISHED ACCORDING TO THE FOLLOWING CRITERIA

OPERATORS. THE METHOD OF WORKING IN RELATION TO SAFETY SHALL BE CARRIED OUT IN ACCORDANCE WITH 9.2 ALL STRUCTURAL STEELWORK SHALL BE PREPARED, PRIMED AND PAINTED. STEELWORK TO BE

df=db+4mm FOR FOUNDATION BOLTS < 24mm.

PROJECT HSSE REQUIREMENTS AND LOCAL REGULATIONS. FIREPROOFED SHALL ALSO BE PREPARED AND PRIMED.

df=db+6mm FOR FOUNDATION BOLTS 24mm < db < 42mm.

1.6 DIMENSIONS SHALL NOT BE SCALED FROM DRAWING. ONLY WRITTEN VALUE SHALL BE FOLLOWED. 9.3 IN ORDER TO MINIMIZE COATING DAMAGE ALL REASONABLE CARE SHALL BE TAKEN WHEN HANDLING

df=db+8mm FOR FOUNDATION BOLTS 42mm < db < 48mm. LEGEND:

1.7 STRUCTURES WILL BE SHOP WELDED-FIELD BOLTED IN ORDER TO MINIMIZE WELDING WORKS IN SITE. STEELWORK BETWEEN STAGES IN PAINTING, AND ESPECIALLY WHEN SLINGING AND LOADING STEELWORK

df=db+10mm FOR FOUNDATION BOLTS db > 48mm.

WHICH HAS RECEIVED ITS FINAL COAT. DIA. - DIAMETER

1.8 ALL DAMAGED GALVANIZED SURFACES AND ALL EDGES EXPOSED BY CUTTING AFTER GALVANIZING SHALL BE

WITH:

9.4 NO MATERIAL SHALL BE SHIPPED UNTIL THE FINAL SHOP COAT OF PAINT IS THOROUGHLY DRY AND CLEARLY EL. - ELEVATION

TREATED WITH TWO COATS OF ZINC RICH PAINT SPRAYED AS PER ASTM A780.

df = HOLE DIAMETER ON BASE PLATE.

COLOUR CODED. FL. - FLOOR

2.0 STRUCTURAL STEEL MATERIAL db = DIAMETER OF FOUNDATION BOLT.

9.5 ADEQUATE PACKING, CRATING, BLOCKING AND/OR BRACING SHALL BE PROVIDED TO PREVENT DAMAGE TO HSB - HIGH STRENGTH BOLTS

2.1 STEEL STRUCTURE SHALL BE FABRICATED & ERECTED IN ACCORDANCE WITH GOOD WORKING PRACTICE, 3.14 THE FASTENING BOLTS FOR VESSELS (HEAT EXCHANGERS, ETC.), SUPPORTED ON STEEL STRUCTURES SHALL BE

THE FABRICATED MATERIAL WHILE LOADING, IN TRANSIT AND WHILE UNLOADING. MIN. - MINIMUM

MATERIALS, WORKMANSHIP AND TESTING GENERALLY SHALL COMPLY WITH AISC 360-16. FITTED WITH TWO WASHERS AND TWO NUTS SUPPLIED BY THE STEELWORK FABRICATOR. THESE BOLTS SHALL

9.6 PAINT SHALL BE EXCLUDED FROM AREAS WITHIN 50mm OF JOINTS TO BE FIELD WELDED. TEMPORARY MAX. - MAXIMUM

2.2 FOLLOWING ARE THE MATERIAL SPECIFICATIONS HAVE THE SAME MECHANICAL CHARACTERISTICS OF BOLTS USED FOR STRUCTURAL CONNECTIONS.

STEELWORK SHALL BE PAINTED WHITE OR FLUORESCENT. REF. - REFERANCE

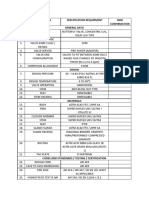

STRUCTURAL COMPONENT MATERIAL GRADE 2 NOS FLAT WASHERS THK. - THICKNESS

MAIN STRUCTURAL STEEL (BEAM, COLUMN, BASE PLATES,

EN10025 GRADE S275 JR

TYP. - TYPICAL

CONNECTION PLATES, FENCE POSTS) 2 NOS NUTS 10.0 ROOF SHEETING U.N.O - UNLESS NOTED OTHERWISE

PROFILES EUROPEAN OR EQUIVALENT

TERTIARY STEEL (LADDER, HANDRAIL, STAIR TREADS) EN10025 GRADE S235JR 10.1 ROOF SPECIFICATION SHALL BE IN ACCORDANCE WITH COMPANY STANDARD DOCUMENT "ENI 27583: CIVIL

3.15 THE BOLT LENGTH SHALL BE CHOSEN SUCH THAT AT LEAST ONE THREAD PLUS THE THREAD RUN-OUT WILL BE

PAD-EYE MAIN PLATE Z GRADE STEEL OR S355JR WORKS ROOFING AND CLADDING WITH SHEETS AND PANELS".

CLEAR BETWEEN THE NUT AND THE UNTHREADED SHANK OF THE BOLT AFTER TIGHTENING, AND AT LEAST ONE

ASTM F1554, MIN. GRADE 36, HIGHER GRADE SHALL BE USED AS PER

ANCHOR BOLTS* REQUIREMENT. CLEAR THREAD SHALL SHOW ABOVE THE NUT.

(AS PER COMPANY DRAWING 28820)

3.16 ORDINARY STRENGTH BOLT 11.0 ANCHORS FASTENERS

HIGH STRENGTH BOLTS A) SHALL BE USED FOR HANDRAILS, STAIR TREADS AND NON-STRUCTURAL ELEMENTS. 11.1 MINOR STRUCTURES SUCH AS HANDRAILS, LADDERS AND SMALL PIPE/CABLE TRAY SUPPORTS

(ALL BOLTED STRUCTURAL CONNECTIONS, INCLUDING GRADE ASTM F3125 GRADE A325M (TYPE 1)

MOMENT, SHEAR CONNECTIONS, BRACINGS, SPLICES) B) BOLT THREAD AND NUT SHALL CONFORM TO ASTM A307. SUPPORTED ON PAVING/CONCRETE USING ANCHOR FASTENERS (HILTI OR EQUIVALENT) IF

NUTS ASTM A563, GRADE DH HEAVY HEX NUTS C) BOLT HOLE DIAMETER SHALL BE SAME AS HIGH STRENGTH BOLT. REQUIRED AND SUBJECTED TO COMPANY'S APPROVAL.

WASHERS ASTM F436M TYPE 1

4.0 WELDING 12.0 GENERAL REQUIREMENTS

ORDINARY BOLTS

ASTM A307 GRADE A

(HANDRAILS, STAIR TREADS, NON-STRUCTURAL ELEMENTS) 4.1 FILLET WELD SECTION (THICKNESS & DEVELOPMENT) SHALL BE AT LEAST BE EQUAL TO 1.2 TIMES THE 12.1 BEAMS SUPPORTING DAVITS OR LIFTING FACILITIES SHALL HAVE CLEARLY AND INDELIBLY SHOWN THE VALUE OF

ASTM A1011M GRADE 36 TYPE 1 (FY=250 MPa) SMALLEST ELEMENT SECTION UNLESS SPECIFIED OTHERWISE. THE MAX. LOAD WHICH CAN BE LIFTED.

HOT DIP GALVANIZED AS PER ASTM A153/A153M, 4.2 ALL WELDING PROCEDURE SPECIFICATIONS AND QUALIFICATIONS, WELDERS AND WELDING OPERATORS SHALL 12.2 SLIDING CONNECTION SHALL BE PROVIDED WITH AT LEAST TWO 20mm DIA. BOLTS AND TWO NUTS.

GRATINGS - TYPE1 BEARING BARS - 30 X 3mm

(FOR SKIDS, MAINTENANCE AREAS) GRATING MESH - 33/34 X 38mm BE FULLY QUALIFIED AS PER AWS D1.1. THE FIRST NUT SHALL BE HAND TIGHT TO ALLOW FOR EXPANSION & SECOND NUT SHALL BE TIGHTENED AS LOCKNUT.

LATERAL RESTRAINT - MIN. 5mm X 5mm TWISTED

CROSS-BARS AT 38mm PITCH 4.3 ALL WELDING CONSUMABLE SHALL CONFORM TO ELECTRODE E70XX IN ACCORDANCE TO AWS D.1.1. 12.3 FIREPROOFING IF ANY SHALL BE SHOWN ON ASSEMBLY DESIGN DRAWING.

WELDING ELECTRODES SHALL BE LOW HYDROGEN WITH A MINIMUM TENSILE STRENGTH OF 12.4 BRACING AND BEAMS CONSISTING OF TWO SHAPES COUPLED SHALL BE CONNECTED BETWEEN THEM BY MEANS OF

ASTM A1011M GRADE 36 TYPE 1 (FY=250 MPa)

HOT DIP GALVANIZED AS PER ASTM A153/A153M, 480 N / mm². CROSS STIFFENING PLATES ( BOLTED OR WELDED). THE DISTANCE BETWEEN EVERY CROSS STIFFENING PLATE

GRATINGS - TYPE 2 BEARING BARS - 25 X 5mm

(FOR ACCESS PLATFORMS, CROSSOVERS, STAIR TREADS)

4.4 WELDING ON SITE SHALL BE LIMITED TO THE STRICTLY NECESSARY AND WELDS TO BE MADE ON SITE SHALL BE SHALL BE INDICATED ON THE DRAWINGS. WHERE NOT SPECIFIED IT SHALL NOT BE GREATER THAN 45 TIMES THE

GRATING MESH - 33/34 X 100mm

LATERAL RESTRAINT - MIN. 5mm X 5mm TWISTED CROSS-BARS AT 100mm IDENTIFIED WITH A FLAG. MINIMUM RADIUS OF INERTIA OF A SINGLE PROFILE. MOREOVER ONE CROSS STIFFENING PLATE SHALL ALWAYS BE

PITCH

4.5 GRIND SMOOTH ALL WELD JOINTS WHERE FLUSH SURFACES ARE REQUIRED. PROVIDED AT SIDE ATTACHMENTS.

DECK PLATE (MINIMUM 6mm) EN10025 GRADE MIN. S235JR

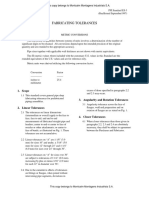

4.6 DIMENSION "S" OF NON-DIMENSIONED FILLET WELDS SHALL AT LEAST BE EQUAL TO: T1

EMBOSSED PLATE L L L

ASTM A36 (MIN. FY = 250 MPa)

MIN THICKNESS 6+2mm S = 0.8 * T FOR Fy < = 275 MPa

D

T2

AISI 304 OR 316 STAINLESS STEEL PLATE (AS PER COMPANY STANDARD S = 1.00 * T FOR 275 < Fy < = 355 MPa (TYP)

DECK PLATE FOR PREFABRICATED CONTAINER

20220) AND GALVANIZED STEEL PLATE.

WHERE:

S

H

FENCING AND GATES T = MIN (T1, T2); Fy = STEEL YIELD STRENGTH OF THE ELEMENTS TO BE CONNECTED.

A

4.7 BUTT WELDS SHALL BE COMPLETE JOINT PENETRATION WELDS UNLESS NOTED IN ENGINEERING DRAWINGS.

(TYP)

ASTM A392, HOT-DIP GALVANIZED AS PER ASTM A123/A123M. 3D

10

FENCE MESH WIRE THICKNESS NOT LESS THAN 3.4mm, AVERAGE MASS OF THE 4.8 FILLET WELDS LEG SIZE SHALL NOT BE LESS THAN 6mm FOR STRUCTURAL WELDS. MIN.

GALVANIZING COAT NOT LESS THAN 250 g/m².

4.9 ALL WELDS SHALL BE CONTINUOUS, UNLESS SHOWN OTHERWISE IN ENGINEERING DRAWING. SEAL WELDS OF 2D

(TYP)

MILD GALVANIZED STEEL, DIAMETER NOT LESS THAN 3.5mm, AVERAGE 3mm FILLET WELD SHALL BE PROVIDED IN WELDED CONNECTIONS.

BARBED WIRE

MASS OF THE GALVANIZING COAT NOT LESS THAN 250 g/m².

L L L

MINIMUM 4.5mm (IN DIAMETER) STEEL WIRE, TYPE II (GALVANIZED) IN

5.0 FLOORING AND GRATING

TENSION WIRE

ACCORDANCE WITH ASTM A824.

5.1 GRADE OF DECK PLATE SHALL COMPLY WITH EN10025 MIN. GRADE S235JR AND PAINTED.

2.3 MINIMUM STIFFENER GUSSET PLATE THICKNESS SHALL BE 8mm. CHEQUERED PLATE SHALL COMPLY WITH ASTM A36 (MIN fy = 250 MPa) AND SHALL BE HOT DIP GALVANIZED.

2.4 NO HOLES OTHER THAN THOSE SPECIFICALLY DETAILED SHALL BE ALLOWED THROUGH STRUCTURAL 5.2 GRATING PANEL AND STAIR TREAD SHALL CONFORM TO,

STEEL MEMBERS. NO CUTTING OF STEEL SHALL BE PERMITTED WITHOUT APPROVAL OF ENGINEER. TYPE : 2 (FOR ACCESS PLATFORMS, CROSSOVERS,

TYPE : 1 (FOR SKIDS, MAINTENANCE AREAS)

(TYP)

STAR TREADS) B

2.5 THE MINIMUM THICKNESS OF ANY PART OF STRUCTURAL STEEL SHAPES SHALL NOT BE LESS THAN 5mm. 3D

10

2.6 THE MINIMUM THICKNESS OF BASE PLATES SHALL BE 20mm. ASTM A1011M GRADE 36 TYPE 1 (FY = 250 MPa) OR ASTM A1011M GRADE 36 TYPE 1 (FY = 250 MPa) OR

2D

2.7 STEEL GRATINGS, HANDRAILS, LADDERS, STAIR TREADS AND CHEQUERED PLATES SHALL BE HOT DIP EUROPEAN EQUIVALENT (S235 JR EN 10025) EUROPEAN EQUIVALENT (S235 JR EN 10025) (TYP)

GALVANIZED. HOT DIP GALVANIZED AS PER ASTM A153/A153M, HOT DIP GALVANIZED AS PER ASTM A153/A153M. SIDE ATTACHMENT

BEARING BARS - 30X3mm BEARING BARS - 25 X 5mm

3.0 BOLTING GRATING MESH - 33/34 X 38mm GRATING MESH - 33/34 X 100mm

LATERAL RESTRAINT - MIN. 5mm X 5mm TWISTED LATERAL RESTRAINT - MIN. 5mm X 5mm TWISTED

3.1 BOLTS WITH DIAMETER GREATER THAN 30mm SHALL BE GENERALLY AVOIDED.

CROSS-BARS AT 38mm PITCH CROSS-BARS AT 100mm PITCH

3.2 CONNECTIONS BY A SINGLE BOLT SHALL NOT BE USED.

S=SEE STRUCTURAL STEEL DWG.

3.3 ALL STRUCTURAL CONNECTIONS SHALL BE BEARING TYPE AND FULLY THREADED, BOLT THREADS SHALL BE

5.3 CHEQUERED PLATE SHALL BE 6+2mm THICK UNLESS OTHERWISE INDICATED.

CONSIDER FOR DESIGN.

5.4 OPENING EQUAL OR LESS THAN 200mm ON GRATING OR CHEQUERED PLATE SHALL BE MADE AT FIELD.

3.4 HIGH STRENGTH BOLTS ASTM A325M WILL BE USED FOR ALL STRUCTURAL CONNECTIONS, INCLUDING: H x 1.4 FOR L < 80

OPENING LARGER THAN 200mm SHALL BE MADE AT SHOP BY STEEL WORK FABRICATOR. A

H x 1.2 FOR L > 90 CROSS STIFFENING PLATES SHALL SUBDIVIDED THE

* MOMENT CONNECTIONS

FOR OPENING OVER 100mm , A WELDED TOE BOARD MUST BE PROVIDED. H x 1.2 FOR UPN <100 BEAM LENGTH AT LEAST IN TO THREE SPANS

* SHEAR CONNECTIONS

5.5 STAIR TREADS SHALL BE OF HOT DIP GALVANIZED GRATING. H x 1.0 FOR UPN >120 < 180

CROSS STIFFENING PLATES SHALL BE EQUALLY SPACED.

* BRACINGS B H x 0.9 FOR UPN >200 < 220

5.6 GAS CUTTING SHALL NOT BE PERMITTED WITHOUT PRIOR APPROVAL. L= FOR CALCULATION OF THIS DISTANCE

* SPLICES OF COLUMNS AND BEAMS. H x 0.8 FOR UPN >240 < 260

5.7 GRATING SHALL BE ELECTRICALLY FORGED TYPE. H x 0.7 FOR UPN >280

3.5 HIGH STRENGTH BOLTS SHALL NOT BE REUSED.

5.8 WEIGHT OF A SINGLE GRATING PANEL SHALL NOT EXCEED 60 KG.

3.6 NUT SHALL BE IN ACCORDANCE WITH ASTM A563M CLASS 10S AND WASHERS WITH ASTM F436M TYPE-1.

5.9 BOLTS TO FIX THE STEPS SHALL BE ZINC-COATED BOLTING ASTM A307; EACH BOLT SHALL BE FURNISHED

3.7 ALL CONNECTION BOLTS INCLUDING NUTS AND WASHERS SHALL BE HOT DIP GALVANIZED IN ACCORDANCE WITH 13.0 ERECTION AND FABRICATION TOLERANCE EX-DE 01 C - 09/06/2023 ISSUED FOR APPROVAL Jebaraj B Carmel K Shyam S John K -

WITH 2 WASHERS.

EX-DE 00 B - 03/05/2023 ISSUED FOR COMMENTS Jebaraj B Carmel K Shyam S John K -

ASTM F2329M.

5.10 GRATING CLAMPS SHALL BE PROVIDED AS PER STANDARD DRAWING WITH A MINIMUM OF 4 CLAMPS FOR 13.1 UNLESS OTHERWISE NOTED, REFER TO AISC 303 ON ALLOWABLE FABRICATION AND ERECTION TOLERANCES. EX-DE - A - 28/04/2023 ISSUED FOR SDC (INTERNAL) Jebaraj B Carmel K Shyam S John K -

Validity Client SLB Rev. Vendor

3.8 ALL BOLTED MAIN CONNECTION SHALL HAVE A MIN. TWO NUMBERS OF M20 BOLTS & PURLINS, LADDER, STAIRS, Prepared Approved Contractor Company

EACH PANEL. IN NO CASE SHALL THESE BE EXCEEDED WITHOUT WRITTEN APPROVAL FROM COMPANY. Status Rev. No. No. Rev. No. Date Description Checked

Approved Approved

by by by

Revision Index

HANDRAIL AND NON-STRUCTURAL ELEMENTS SHALL HAVE A MINIMUM OF 2 NUMBERS M16 BOLTS.

3.9 THE FASTENING BOLTS FOR VESSELS , SUPPORTED ON STEEL STRUCTURES SHALL BE FITTED WITH TWO

6.0 INSPECTION AND TESTING LCI Activity Code

LCI-EG-2023-0004

Company Document ID:

6.1 INSPECTION AND TESTING OF MATERIALS AND WELDS SHALL COMPLY WITH THE SPECIFICATION FOR STEEL Project Code 313400DADE12967

WASHERS AND NUTS SUPPLIED BY THE STEELWORK FABRICATOR. THESE BOLTS SHALL HAVE THE SAME

000532 Job N.:

MECHANICAL CHARACTERISTICS OF BOLTS USED FOR STEEL CONNECTIONS. STRUCTURE DESIGN, FABRICATION AND ERECTION. PETROJET (PTJ) /SLB Contractor Document ID:

3.10 BOLTS PROVIDED ON INCLINED FLANGES OF IPN AND UPN SHAPES SHALL BE MOUNTED WITH SUITABLE WEDGE 7.0 ERECTION PF0009-SLB-ST-DWG-0001

TYPE PLATE. 7.1 THE CONSTRUCTION CONTRACTOR SHALL PROPERLY ALIGN EACH PART OF THE STRUCTURE BEFORE Job N.:

Vendor Logo and Business Name Vendor Document ID:

MAKING THE FIELD CONNECTIONS.

7.2 THE CONTRACTOR SHALL BE ENTIRELY RESPONSIBLE FOR THE STABILITY OF THE STEELWORK DURING NA NA

Purchase Order N.:

WEDGE TYPE ERECTION AND SHALL ARRANGE FOR ALL TEMPORARY GUYING, BRACING AND SUPPORTS TOGETHER WITH Facility and Sub Facility description Project and SoW description Scale Sheet of Sheets

PLATES Meleiha Phase II – New Gas Treatment Plant

DET. "A" DETAIL "A" ANY ADDITIONAL TACK BOLTS NECESSARY FOR THE STABILITY OF THE STEELWORK UNTIL FINAL BOLTING UP. 3134 & 00 - General NA 1/1

(EPF)

3.11 BOLTS CONNECTING MEMBERS SUPPORTING VIBRATING EQUIPMENT SHALL BE PROVIDED WITH LOCK-WASHERS 7.3 PERMISSIBLE DEVIATION AS PER THE PROJECT SPECIFICATION. Document Title Superseeded N.

OR OTHER EQUIVALENT SYSTEM TO PREVENT IT BECOMING LOOSE. Superseeded by N.

STANDARD DRAWING Plant Area Functional Unit

GENERAL NOTES STEELWORK NA 000

This document is property of Eni S.p.A. It shall neither be shown to Third Parties nor used for purposes other than those for which it has been sent.

You might also like

- General Construction NotesDocument1 pageGeneral Construction NotesjanelleNo ratings yet

- 2 StructuralDocument11 pages2 StructuralRuffy OiraNo ratings yet

- PROPOSED CHURCH BUILDING ArchitectureDocument30 pagesPROPOSED CHURCH BUILDING Architecturesyedstructures3No ratings yet

- S 001Document1 pageS 001Rashed SiddiqiNo ratings yet

- General Concrete Slab Concrete Hollow Block Structural SteelDocument1 pageGeneral Concrete Slab Concrete Hollow Block Structural Steelparkrocky0No ratings yet

- STR Final 02112319473547375Document20 pagesSTR Final 02112319473547375Muhammad AfrasiyabNo ratings yet

- 2.8 09 S002-General Notes - Sheet 2 - 02 PDFDocument1 page2.8 09 S002-General Notes - Sheet 2 - 02 PDFSaiful IslamNo ratings yet

- Weight by Drawing Sheet: RevisionDocument1 pageWeight by Drawing Sheet: RevisionOseni MomoduNo ratings yet

- Tunis MallDocument16 pagesTunis Mallعبدالمجيد اشرف عادل مجيدNo ratings yet

- Nfef 60 44 Ci DR TD 001 - d2 - 000Document1 pageNfef 60 44 Ci DR TD 001 - d2 - 000Abid AyubNo ratings yet

- ENS0211 - Arc Welding Quality Rev.DDocument58 pagesENS0211 - Arc Welding Quality Rev.Dsophia com vocêsNo ratings yet

- Ju 001 06 Aus 0000 23 21 0001 - 0Document1 pageJu 001 06 Aus 0000 23 21 0001 - 0Marco Antonio Ysrael Escobedo EscalanteNo ratings yet

- Project General Notes and HVAC LegendDocument14 pagesProject General Notes and HVAC Legendmjbriceno100% (1)

- 006 STRCT1Document1 page006 STRCT1kingjam dimacaling2019No ratings yet

- 02 Schedule of Column & FootingDocument1 page02 Schedule of Column & Footingvishal jainNo ratings yet

- General construction notesDocument1 pageGeneral construction notesMac KYNo ratings yet

- Combined Structural WorkDocument17 pagesCombined Structural WorkEKWUE ChukwudaluNo ratings yet

- General Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersDocument1 pageGeneral Construction Notes: Codes and Standards General Notes Reinforcing Steel Beams and GirdersByen VillanuevaNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- 01laboratory Design 101023Document14 pages01laboratory Design 101023Mushe MwanzaNo ratings yet

- Structural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkDocument1 pageStructural Steelwork For Reinforced Concrete Structural Steelwork For Steel Trusses General Notes Concrete BlockworkOladunni AfolabiNo ratings yet

- CHB Connection Details: 1.0 General NotesDocument1 pageCHB Connection Details: 1.0 General NotesSabling DritzcNo ratings yet

- 01 StructuralDocument39 pages01 StructuralSaifullahNo ratings yet

- Bound Brook 300 - Structural PackageDocument25 pagesBound Brook 300 - Structural PackageGuillermo Romero HuertasNo ratings yet

- Manhole Drawings A4Document1 pageManhole Drawings A4nawnitNo ratings yet

- E. Formworks: (Structural)Document1 pageE. Formworks: (Structural)Nonoy Justiniane-Giray JrNo ratings yet

- EMX 11 G MB - EN EA 005-En - 111A ARR - CABLE TRAY & INSTRUMENTATION PDFDocument17 pagesEMX 11 G MB - EN EA 005-En - 111A ARR - CABLE TRAY & INSTRUMENTATION PDFcarlosNo ratings yet

- BH Plans ST 1Document1 pageBH Plans ST 1Soner, John LloydNo ratings yet

- Project Title: Project Location: Prepared By: Sheet Content: Sheet # Raymar R. Bartolome Carlo C. Cairel SB - 1 6 Submitted ToDocument1 pageProject Title: Project Location: Prepared By: Sheet Content: Sheet # Raymar R. Bartolome Carlo C. Cairel SB - 1 6 Submitted ToRaymar BartolomeNo ratings yet

- Feeder Pillar SpecDocument21 pagesFeeder Pillar SpecashameensNo ratings yet

- Foundation Plan 2Nd Floor Framing Plan: B C D A B C D ADocument1 pageFoundation Plan 2Nd Floor Framing Plan: B C D A B C D AMark Ruby OpawonNo ratings yet

- BY PASS BRIDGES (1 - 4) - ModelDocument1 pageBY PASS BRIDGES (1 - 4) - ModelHelen Joy AdvientoNo ratings yet

- General Notes Foundations: Two - Storey Residential Building With Roof DeckDocument1 pageGeneral Notes Foundations: Two - Storey Residential Building With Roof DeckKarlo CabanginNo ratings yet

- Datasheet For Butterfly ValveDocument3 pagesDatasheet For Butterfly ValvevishnuvarthanNo ratings yet

- 3- Mason Duplex (Amended) - Lot 74 Hillock Cr. - 07.03.14Document8 pages3- Mason Duplex (Amended) - Lot 74 Hillock Cr. - 07.03.14patelriaNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- LUS-CP07B-QDSBG-DWG-AR-49000 DEQ UpdatedDocument1 pageLUS-CP07B-QDSBG-DWG-AR-49000 DEQ UpdatedSohail KhanNo ratings yet

- Rack and Bridge Assembly DrawingDocument14 pagesRack and Bridge Assembly DrawingFahad NaveedNo ratings yet

- Construction of Multi-Level ParkingDocument13 pagesConstruction of Multi-Level Parkingdunknown15No ratings yet

- CW - 03 General Notes (Sheet 01 of 02)Document1 pageCW - 03 General Notes (Sheet 01 of 02)Hurriyat AliNo ratings yet

- Pfi Es 3Document2 pagesPfi Es 3EstefaníaNo ratings yet

- Thickness CalculationDocument19 pagesThickness Calculationajiths89No ratings yet

- T SHD Ug 23377 01 23 0539 00Document5 pagesT SHD Ug 23377 01 23 0539 00Taiwo OshinNo ratings yet

- Sample WorksDocument11 pagesSample WorkspelvensonNo ratings yet

- CAIRN-TSG-L-SP-0015-A1-Specification For Piping Fabrication and Installation For Offshore Application PDFDocument11 pagesCAIRN-TSG-L-SP-0015-A1-Specification For Piping Fabrication and Installation For Offshore Application PDFMahesh Pandit Pandit100% (1)

- BAFSA Technical Guidance No 1, November 2012Document30 pagesBAFSA Technical Guidance No 1, November 2012flegheton100% (1)

- Potable Water OHT Near GLSR - Zone 4Document1 pagePotable Water OHT Near GLSR - Zone 4Mohit AgarwalNo ratings yet

- Key structural notes and legend for general building projectDocument1 pageKey structural notes and legend for general building projectMazen Ismail0% (1)

- General notes on reinforced concrete structuresDocument1 pageGeneral notes on reinforced concrete structuresDJNo ratings yet

- ST 009Document1 pageST 009MahMoudAbdEl-KaderNo ratings yet

- S1Document1 pageS1joemarferrerjoemz1234No ratings yet

- Arch Plans v2 (Approved)Document12 pagesArch Plans v2 (Approved)rabbetmrNo ratings yet

- Proposed Retaining Wall at CHR - Gen NotesDocument1 pageProposed Retaining Wall at CHR - Gen NotesErica PaciaNo ratings yet

- Bengal MergedDocument13 pagesBengal MergedChad MinottNo ratings yet

- 7-68-0106 Rev 6Document1 page7-68-0106 Rev 6rajanjisri2259No ratings yet

- General Notes:: First Framing PlanDocument1 pageGeneral Notes:: First Framing Planghadeer mattarNo ratings yet

- Instrumentation Tubing and Their Connections-Nirbhay GuptaDocument127 pagesInstrumentation Tubing and Their Connections-Nirbhay Guptanirbhay111100% (13)

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingFrom EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghNo ratings yet

- PF0009 SLB MR DAT 0009 - Rev.00Document7 pagesPF0009 SLB MR DAT 0009 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0011 - Rev.00Document7 pagesPF0009 SLB MR DAT 0011 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB CV SPC 0001Document19 pagesPF0009 SLB CV SPC 0001bmanojkumar16No ratings yet

- 3.3 Reciprocating (LP-HP)Document3 pages3.3 Reciprocating (LP-HP)bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0010 - Rev.00Document7 pagesPF0009 SLB MR DAT 0010 - Rev.00bmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0007 - Rev.0Document7 pagesPF0009 SLB MR DAT 0007 - Rev.0bmanojkumar16No ratings yet

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16No ratings yet

- PF0009 SLB MR DAT 0008 - Rev.00Document7 pagesPF0009 SLB MR DAT 0008 - Rev.00bmanojkumar16No ratings yet

- Aug 2023Document1 pageAug 2023bmanojkumar16No ratings yet

- GBRG1-MX7771-00001-R02-Mech Spec For Mobile NAG Well Equalisation and Killing Facility PackageDocument22 pagesGBRG1-MX7771-00001-R02-Mech Spec For Mobile NAG Well Equalisation and Killing Facility Packagebmanojkumar16No ratings yet

- Aug 2023Document1 pageAug 2023bmanojkumar16No ratings yet

- Cover Page - LG DSDocument2 pagesCover Page - LG DSbmanojkumar16No ratings yet

- TP-WMS-05816-DAS-A4-D1-L - Swing Check Valve DatasheetDocument1 pageTP-WMS-05816-DAS-A4-D1-L - Swing Check Valve Datasheetbmanojkumar16No ratings yet

- SKid GAD CRS - Revised FormatDocument1 pageSKid GAD CRS - Revised Formatbmanojkumar16No ratings yet

- 21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBoreDocument3 pages21DBBV12M-7 42inch (In) DimensionADoubleBlockandBleedNeedleValvewithFullBorebmanojkumar16No ratings yet

- Installation and Maintenance Manual for Chemical Injection PackagesDocument10 pagesInstallation and Maintenance Manual for Chemical Injection Packagesbmanojkumar16No ratings yet

- MATERIAL LIST AND TECHNICAL DETAILS FOR FLANGE HOLE ORI. COMPDocument1 pageMATERIAL LIST AND TECHNICAL DETAILS FOR FLANGE HOLE ORI. COMPbmanojkumar16No ratings yet

- Marechal PNCX Range enDocument2 pagesMarechal PNCX Range enbmanojkumar16No ratings yet

- Haliba Well Chemical Injection Package GADDocument2 pagesHaliba Well Chemical Injection Package GADbmanojkumar16No ratings yet

- Marechal DX2 Decontactor Range enDocument2 pagesMarechal DX2 Decontactor Range enbmanojkumar16No ratings yet

- IG 85 MESC 14d - 2021Document1 pageIG 85 MESC 14d - 2021bmanojkumar16No ratings yet

- IHA AssessmentDocument4 pagesIHA Assessmentbmanojkumar16No ratings yet

- IG 77 MESC 14d - 2021Document5 pagesIG 77 MESC 14d - 2021bmanojkumar16No ratings yet

- IG 74 MESC 14d - 2021Document3 pagesIG 74 MESC 14d - 2021bmanojkumar16No ratings yet

- Line List - Methanol SkidDocument3 pagesLine List - Methanol Skidbmanojkumar16No ratings yet

- Line List - All PackagesDocument42 pagesLine List - All Packagesbmanojkumar16No ratings yet

- IG 81 MESC 14d - 2021Document1 pageIG 81 MESC 14d - 2021bmanojkumar16No ratings yet

- IG 76 MESC 14d - 2021Document3 pagesIG 76 MESC 14d - 2021bmanojkumar16No ratings yet

- P105576 IC IDF 203 - Rev01Document5 pagesP105576 IC IDF 203 - Rev01bmanojkumar16No ratings yet

- Carbon Alloy SteelDocument2 pagesCarbon Alloy SteelDeepak HoleNo ratings yet

- PaperDocument8 pagesPaperPedro DiegoNo ratings yet

- PulverizationDocument26 pagesPulverizationVasantha SudasinghaNo ratings yet

- Lewis MillDocument9 pagesLewis MillCelso Ari Schlichting100% (2)

- Geometrical Modeling of Rotary Milling Operation of Crankshaft PinsDocument10 pagesGeometrical Modeling of Rotary Milling Operation of Crankshaft PinsMuhammad Bachtiar YusufNo ratings yet

- NUST SMME Advanced Manufacturing Processes Fall 2022Document5 pagesNUST SMME Advanced Manufacturing Processes Fall 2022Abuzar AliNo ratings yet

- DLL SMAW For COTDocument11 pagesDLL SMAW For COTemmabentonioNo ratings yet

- 09 TL-SH26-0001 Cementing PlugDocument6 pages09 TL-SH26-0001 Cementing PlugMaria ArdilaNo ratings yet

- Mold Cleaners LubricantsDocument3 pagesMold Cleaners LubricantsEliasNo ratings yet

- H2S ScavengerDocument7 pagesH2S ScavengerRizwan FaridNo ratings yet

- SOP STEWARDING STAFF CAFETARIA - Cleaning The Garbage BinsDocument4 pagesSOP STEWARDING STAFF CAFETARIA - Cleaning The Garbage BinsKumarSvNo ratings yet

- Billet Defects: Off-Corner Formation, Prevention and EvolutionDocument15 pagesBillet Defects: Off-Corner Formation, Prevention and Evolutionamit gajbhiyeNo ratings yet

- How Surgical Instruments are CraftedDocument2 pagesHow Surgical Instruments are CraftedRashid Ali100% (1)

- M32 Machine SpecificationsDocument4 pagesM32 Machine SpecificationsbadrezzineNo ratings yet

- Injection Blow MoldingDocument3 pagesInjection Blow MoldingMaximiliano RiccaNo ratings yet

- Timetal: 6-4, 6-4 ELI & 6-4-.1RDocument2 pagesTimetal: 6-4, 6-4 ELI & 6-4-.1RVíctor MozerNo ratings yet

- Cement 1Document36 pagesCement 1Shakil AhamedNo ratings yet

- CSWIP - Question & Answer 150 220111Document85 pagesCSWIP - Question & Answer 150 220111Maxu Dipsona100% (14)

- Catalytic Converters For Vehicle Exhaust: Fundamental Aspects and Technology Overview For Newcomers To The FieldDocument17 pagesCatalytic Converters For Vehicle Exhaust: Fundamental Aspects and Technology Overview For Newcomers To The FieldROCK STAR GAMMINGNo ratings yet

- sch80c July12019Document12 pagessch80c July12019alif suryantoNo ratings yet

- MAG2158Document1 pageMAG2158mamat kopetNo ratings yet

- Absheron EPS WPQT Status ReportDocument3 pagesAbsheron EPS WPQT Status ReportIlkin hasanovNo ratings yet

- TDS Byk-094 enDocument2 pagesTDS Byk-094 enHiroshi PhanNo ratings yet

- Corrosion Control and Paint Systems: Types of Marine CorrosionDocument17 pagesCorrosion Control and Paint Systems: Types of Marine CorrosionanangwahjudiNo ratings yet

- Af 163-2Document10 pagesAf 163-2lacsmm982No ratings yet

- Sec. 9.2 Straightening: 72 AWWA D100-11Document10 pagesSec. 9.2 Straightening: 72 AWWA D100-11Ali RasnNo ratings yet

- 1485 - EC2092-signedDocument4 pages1485 - EC2092-signedDeepak HoleNo ratings yet

- Design of Jigs and Fixtures 2 MarksDocument16 pagesDesign of Jigs and Fixtures 2 MarksParamasivam Veerappan100% (1)

- Repair Procedure Lens RingDocument3 pagesRepair Procedure Lens Ringqaisarabbas9002No ratings yet

- Internal Combustion Engine TypesDocument35 pagesInternal Combustion Engine TypesMuhammad FaizNo ratings yet