Professional Documents

Culture Documents

ICEC 25-ICMC 2014 Xu 101 Poster

ICEC 25-ICMC 2014 Xu 101 Poster

Uploaded by

Ruturaj UmaranikarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICEC 25-ICMC 2014 Xu 101 Poster

ICEC 25-ICMC 2014 Xu 101 Poster

Uploaded by

Ruturaj UmaranikarCopyright:

Available Formats

Development of compact 2K GM cryocoolers

Mingyao Xu1, Qian Bao1, Akihiro Tsuchiya1, Rui Li2

Development of compact 2K GM cryocoolers

Mingyao Xu1, Research

1: Technology Qian BaoCenter,

1, Akihiro Tsuchiya1, Rui Li2

Sumitomo Heavy Industries, Ltd.

2: Precision Equipment Group, Sumitomo Heavy Industries, Ltd.

1: Technology Research Center, Sumitomo Heavy Industries, Ltd.

2: Precision Equipment Group, Sumitomo Heavy Industries, Ltd.

Introduction Conclusion

For a superconducting electronic device, the requirement for a compact size is crucial because its size is large, comparing with a similar A new, compact GM cryocooler, which can be used for cooling superconducting electronic devices,

semiconductor device. A good example of superconducting electronic devices is a Superconducting Single Photon Detector (SSPD), which is has been developed.

now under developing at NICT, Japan by Miki et al. The size of an SSPD system is too large, which is the major obstacle to expand its application. The cylinder length is reduced by 85 mm compared with a commercial 0.1W 4K GM cryocooler.

Under no-load condition, a low temperature of 2.1 K and a temperature oscillation of about ±20 mK

Acknowledgements has been achieved.

A cooling capacity of 1 W at 44.4 K at the first stage and 20 mW at 2.23 K has also been achieved.

The research results have been achieved by “Development of a Compact Superconducting Single Photon Detector System for Photon-Quantum In order to reach the expander height reduction target, the height of the valve housing assembly will be

Information and Communication”, the National Institute of Information and Communications Technology (NICT), JAPAN. reduced in together with further cylinder length reduction.

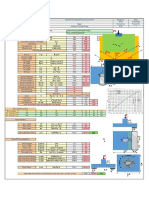

Design Target of the new 2K GM cooler Schematics of a two-stage GM cooler Simulation Model & Results

The smallest 4 K GM in the world 1st 2nd

Stage Stage

Item

To reach a no-load at 45 K at 4.2 K

temperature of 2.2 K (W) (W)

P-V power 17.5 3.27

To further reduce

Cooling capacity

the expander height after considering 17.2 0.56

] ]

to 67 % real gas effect

RDK-101 Regenerator loss 3.5 0.24

Item RDK-101D Object Shuttle loss 1.8 0.06

Pumping loss &

1st Cooling capacity at 60 K 3.0 W 1W

thermal 3.2 0.20

2nd Cooling capacity at 2.3 K Unreachable 20 mW conduction loss

No-load 2nd stage temperature >3 K 2.2 K Radiation loss 1.5 0.0

Expander height 442 mm 67 % of RDK-101D Xu, M., Morie, T., 2012. Numerical Net cooling

2nd temperature oscillation Simulation of 4K GM Cryocooler, 7.1 0.06

> ±30 mK ±20 mK capacity

displacement Cryocoolers 17, pp. 253.

Performance Improvement Cylinder Length Reduction

・ Performance improvement with a new regenerator material Improved 3.5 K and 0.05 K Length

Item Approach

Regenerator Material 1st Stage Temperature (K) 2nd Stage Temperature (K) Reduction

with a new regenerator Design

Bismuth 45.7 2.46 1st Warm-end 5 mm 85mm

material at the warm-end of Optimization

New material 42.2 2.41

the 2nd stage regenerator Stroke 4 mm

・ Performance improvement with a HoCu2/GOS hybrid regenerator Improved 3.2 K and 0.1 K 1st Regenerator 28 mm

Optimized by

Magnetic Regenerator Material 1st Stage Temperature (K) 2nd Stage Temperature (K) 1st Heat

with a HoCu2/GOS hybrid Exchanger

5 mm Simulation

HoCu2 only 50.7 2.32

regenerator Connecting New

HoCu2/GOS hybrid 46.5 2.22 21 mm

Section Configuration

・ Performance of the new 2K GM cooler New

Item Object Measured Results

Reached a no-load of 2.09 K

2nd Regenerator 10 mm Regenerator

1st stage temperature with 1 W 60 K 44.4 K Achieved a temperature Material

2nd stage temperature with 20 mW 2.3 K 2.23 K oscillation displacement of 2nd Heat Optimized by

12 mm

No-load 2nd stage temperature 2.2 K 2.09 K about ±20 mK Exchanger Simulation

Achieved a cooling capacity Total 85 mm

Expander height 67 % of RDK-101D 81 % of RDK-101D

of 20 mW at 2.23 K Reduced the cylinder length by 85 mm (19%

2nd temperature oscillation displacement ±20 mK ±20 mK

reduction in total height) compared to RDK-101D Existing 0.1W 4K GM New 2K GM

Presented at ICEC 25 –ICMC 2014 July. 7 – 11

You might also like

- Is 875 2015 Wind Loads Calculation Typical FrameDocument2 pagesIs 875 2015 Wind Loads Calculation Typical FrameMangesh Chorge100% (2)

- CFD Analysis of Regenerator of Gifford Mcmahon Cryocooler at 2k TemperatureDocument6 pagesCFD Analysis of Regenerator of Gifford Mcmahon Cryocooler at 2k TemperatureIJIRSTNo ratings yet

- Document Submission Status: For Construction: KDL 120Mw Combined Cyle Power Plant ProjectDocument28 pagesDocument Submission Status: For Construction: KDL 120Mw Combined Cyle Power Plant ProjectAnand JeevaNo ratings yet

- INONESIA POWER - Suralaya Coal Power PlantDocument31 pagesINONESIA POWER - Suralaya Coal Power PlantEko TjahjantokoNo ratings yet

- SEBU7563-07 Operation & Maintenance Manual PDFDocument134 pagesSEBU7563-07 Operation & Maintenance Manual PDFHazem RamdanNo ratings yet

- Heat Pump Combi Unit Pkom: Comfort VentilationDocument16 pagesHeat Pump Combi Unit Pkom: Comfort Ventilationsbattina100% (1)

- Role of An Individual in The Conservation of EnvironmentDocument10 pagesRole of An Individual in The Conservation of EnvironmentSrini Vas33% (3)

- Boiling and CondensingDocument2 pagesBoiling and CondensingZia Ul NoorNo ratings yet

- Money-Time Relationships and EquivalenceDocument22 pagesMoney-Time Relationships and EquivalenceKorinaVargas0% (1)

- Compressor Sizing Using DWSIMDocument21 pagesCompressor Sizing Using DWSIMHassanNo ratings yet

- Lecture6 CombinationallogicDocument31 pagesLecture6 Combinationallogic조동올No ratings yet

- Wei-Lun Hsu, Soumyadeep Paul, Jubair A. Shamim, Hirofumi DaigujiDocument1 pageWei-Lun Hsu, Soumyadeep Paul, Jubair A. Shamim, Hirofumi DaigujiJubairAhmedNo ratings yet

- LP App MapDocument2 pagesLP App MapMohamed RashidNo ratings yet

- Tentative Lighting Load R1Document2 pagesTentative Lighting Load R1Sharique BaigNo ratings yet

- 13GCSDocument12 pages13GCSIbarra JonathanNo ratings yet

- 01 Mee05k358 yDocument68 pages01 Mee05k358 yvidaurreoscar22No ratings yet

- K2 User Manual 1509Document39 pagesK2 User Manual 1509Ghofur Al MusthofaNo ratings yet

- Minimizing Leakage Power-IDocument25 pagesMinimizing Leakage Power-IPULAGAMPALLI MANJULANo ratings yet

- Crankcase Pressure RegulatorDocument10 pagesCrankcase Pressure RegulatorKhaldoun BayazidNo ratings yet

- Thermal Performance of Air Flow WindowsDocument115 pagesThermal Performance of Air Flow WindowsJohn MuhammadNo ratings yet

- 스털링 냉동기 강의교재 2021 USPAS Lecture 20Document37 pages스털링 냉동기 강의교재 2021 USPAS Lecture 20kjhfaiscaNo ratings yet

- Sacyr Ecebol Oruro 02-1-224144 Packer: FinalDocument130 pagesSacyr Ecebol Oruro 02-1-224144 Packer: FinalProgramadores & PlanificadoresNo ratings yet

- J-2r All - Files (Rev G)Document50 pagesJ-2r All - Files (Rev G)juan carlos pulidoNo ratings yet

- 22-09-2014 - KS - Yadama Residence - Prelim Design Development - V01Document12 pages22-09-2014 - KS - Yadama Residence - Prelim Design Development - V01Anouer BelkadiNo ratings yet

- PCG-51111W Gd3-Cb-Atheros-Dvt-0827aDocument7 pagesPCG-51111W Gd3-Cb-Atheros-Dvt-0827aficoNo ratings yet

- Report On Generating Substation 220 KV Gs SDocument61 pagesReport On Generating Substation 220 KV Gs SPayal meenaNo ratings yet

- Experiment 7: Pid Controller Tuning of Simulated Gas Mass Flow ProcessDocument6 pagesExperiment 7: Pid Controller Tuning of Simulated Gas Mass Flow ProcessPMNo ratings yet

- Design Calculation Sheet: 1-Determine The Area of Sprinkler Operation (FTDocument1 pageDesign Calculation Sheet: 1-Determine The Area of Sprinkler Operation (FTHassan Attallah MohamedNo ratings yet

- Codo 90º CH62318A-0940Document1 pageCodo 90º CH62318A-0940ARTURO ARELLANONo ratings yet

- Infineon ICE5ARxxxxBZS DS v02 - 10 EN PDFDocument36 pagesInfineon ICE5ARxxxxBZS DS v02 - 10 EN PDFanand shekhawatNo ratings yet

- 220v VC Pro Service ManualDocument116 pages220v VC Pro Service ManualOmer Ahmed AlansaryNo ratings yet

- l011663 Hmi PLC Hp043 20dt User ManualDocument56 pagesl011663 Hmi PLC Hp043 20dt User ManualAcisac Autocontrol100% (1)

- Manufacturing With A Focus On Small Modular Light Water Reactor DesignsDocument31 pagesManufacturing With A Focus On Small Modular Light Water Reactor DesignsAníbal DI LUCHNo ratings yet

- Micro-Power Voltage Detectors: Features General DescriptionDocument13 pagesMicro-Power Voltage Detectors: Features General DescriptionHenryRamirezNo ratings yet

- Reporte Midea App Tio OttoDocument8 pagesReporte Midea App Tio OttoJosgreisiNo ratings yet

- Report To CB Ph1Document22 pagesReport To CB Ph1ramesh cuppuNo ratings yet

- Heat Radiation ReportDocument9 pagesHeat Radiation ReportChitradeep FalguniyaNo ratings yet

- Indoor Lighting Calculation Table (Normal) - P220 Attachment # 1-2-1Document1 pageIndoor Lighting Calculation Table (Normal) - P220 Attachment # 1-2-1Elle ShagzzNo ratings yet

- WP Contentuploads202206datasheet SPARTAN Bulkhead Zone 2 0940 D 00009 Rev3 PDFDocument6 pagesWP Contentuploads202206datasheet SPARTAN Bulkhead Zone 2 0940 D 00009 Rev3 PDFZaki ElsayedNo ratings yet

- Optimize Output Filter On D-CAP2™ For Stability Improvement: Application ReportDocument8 pagesOptimize Output Filter On D-CAP2™ For Stability Improvement: Application ReportLeonardo SoaresNo ratings yet

- Tunable White LED Drivers With BCR601 and BCR602: AN - 2007 - PL39 - 2009 - 125229Document32 pagesTunable White LED Drivers With BCR601 and BCR602: AN - 2007 - PL39 - 2009 - 125229Avs ElectronNo ratings yet

- EE-101 - S2 - W10 - 3: Vivek AgarwalDocument26 pagesEE-101 - S2 - W10 - 3: Vivek AgarwalDiptashree BanerjeeNo ratings yet

- 201 - M CVTDocument3 pages201 - M CVTAshutosh KumarNo ratings yet

- 1.0 A Negative Voltage Regulators MC7900 Series: TO 220 T Suffix Case 221abDocument17 pages1.0 A Negative Voltage Regulators MC7900 Series: TO 220 T Suffix Case 221abjoseNo ratings yet

- Diod S A0012994310 1-2543882Document6 pagesDiod S A0012994310 1-2543882Philippe Englert VelhaNo ratings yet

- KV enDocument4 pagesKV enMostafaNo ratings yet

- Shutdown Activity 21 September 2021 - Rev02Document17 pagesShutdown Activity 21 September 2021 - Rev02rektboyyNo ratings yet

- Illustrative Worked Examples: Commentary of Irc: 6-2017Document2 pagesIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singlaNo ratings yet

- Voltage Detector RT9818-11Document14 pagesVoltage Detector RT9818-11Quỳnh ChồnNo ratings yet

- Emerging Trends in Mechanical Engineering: Course Code - 22652 (AE/PG/PT/ME) Unit 2 - Process EngineeringDocument15 pagesEmerging Trends in Mechanical Engineering: Course Code - 22652 (AE/PG/PT/ME) Unit 2 - Process EngineeringKunal AhiwaleNo ratings yet

- HS21 P1112Document20 pagesHS21 P1112MarioNo ratings yet

- 2N6178 RcaDocument8 pages2N6178 RcaJohnnysNo ratings yet

- Cryocooler Technical Instruction, RDK-205DDocument12 pagesCryocooler Technical Instruction, RDK-205DluwerNo ratings yet

- Buoyancy and Floating Structure Calculation For Paraxylene Storage Tanks (TK-2090 A/B)Document19 pagesBuoyancy and Floating Structure Calculation For Paraxylene Storage Tanks (TK-2090 A/B)Bilal ZahidNo ratings yet

- Department of Thermal Engineering Faculty of Heat - Refrigeration Engineering Industrial University of Ho Chi Minh CityDocument67 pagesDepartment of Thermal Engineering Faculty of Heat - Refrigeration Engineering Industrial University of Ho Chi Minh CityTrung Hiếu NguyễnNo ratings yet

- Engineering in Chemical and Pharmaceutical Processes: Particle SizingDocument18 pagesEngineering in Chemical and Pharmaceutical Processes: Particle SizingPa1 Kumar MNo ratings yet

- 10h00 Miniature Substations - What They Are Really Capable of Delivering - Rhett Kelly, Greg WhyteDocument24 pages10h00 Miniature Substations - What They Are Really Capable of Delivering - Rhett Kelly, Greg WhyteAbdul AzimNo ratings yet

- Tanishk Jharwal - 18ESKEE110 - Industrial Training Report (VII-SEM)Document61 pagesTanishk Jharwal - 18ESKEE110 - Industrial Training Report (VII-SEM)TANISHK JHARWALNo ratings yet

- Test Flow After RepairDocument4 pagesTest Flow After RepairdavidvazquezalvarezNo ratings yet

- Toyota Hilux 2018 Overall EWD Vehicle Exterior Power Window (RHD All Door Jam Protection)Document2 pagesToyota Hilux 2018 Overall EWD Vehicle Exterior Power Window (RHD All Door Jam Protection)gabrielzinho43No ratings yet

- Transformadores SecosDocument17 pagesTransformadores SecosOPERACIONES ITSANo ratings yet

- Shallow - Foundation Design TemplateDocument1 pageShallow - Foundation Design TemplateTesfaye100% (1)

- Flextures Hourglass PivotDocument2 pagesFlextures Hourglass PivotReyginald MarronNo ratings yet

- A053P508Document2 pagesA053P508Ivan_UwaisNo ratings yet

- Evlq-Cv3 Eeden16 Data BookDocument23 pagesEvlq-Cv3 Eeden16 Data BookDamian OvidiuNo ratings yet

- Semiconducting III–V Compounds: International Series of Monographs on SemiconductorsFrom EverandSemiconducting III–V Compounds: International Series of Monographs on SemiconductorsNo ratings yet

- Solved ISRO Scientist or Engineer Refrigeration & Air-Conditioning 2014 Paper With SolutionsDocument21 pagesSolved ISRO Scientist or Engineer Refrigeration & Air-Conditioning 2014 Paper With SolutionsRuturaj UmaranikarNo ratings yet

- SSRN Id4291400Document25 pagesSSRN Id4291400Ruturaj UmaranikarNo ratings yet

- Labyrinth SealingDocument6 pagesLabyrinth SealingRuturaj UmaranikarNo ratings yet

- Technical Instruction F-50SH Compressor Unit - IM - CD33ZZ-080 - A 3 2Document65 pagesTechnical Instruction F-50SH Compressor Unit - IM - CD33ZZ-080 - A 3 2Ruturaj UmaranikarNo ratings yet

- Manual DBAire2-R410a-R407c-50Hz-60Hz - MS0705A-0714 - Csize - NpyDocument28 pagesManual DBAire2-R410a-R407c-50Hz-60Hz - MS0705A-0714 - Csize - NpyCarlos GonzalezNo ratings yet

- Grupos de Tipos de Contenedor - Hapag-LloydDocument2 pagesGrupos de Tipos de Contenedor - Hapag-LloydDIANA MERCHAN HNo ratings yet

- FMDS-07-01 (04.2020) - Fire Protection For Textile MillsDocument42 pagesFMDS-07-01 (04.2020) - Fire Protection For Textile MillsFogo NeptúnNo ratings yet

- MFL71143102 - ManualOwner - (EN+SP) - LW1019IVSM - Rev 02 - 111919 - (P12816-18202123)Document60 pagesMFL71143102 - ManualOwner - (EN+SP) - LW1019IVSM - Rev 02 - 111919 - (P12816-18202123)julio ariasNo ratings yet

- Comfort Polaris: Circular Unit Heater Air ConditionerDocument16 pagesComfort Polaris: Circular Unit Heater Air ConditionerAzra ŽunićNo ratings yet

- En J02.DAI.74 Daikin RZASG M Technical Data RZASG MV1 Data BookDocument49 pagesEn J02.DAI.74 Daikin RZASG M Technical Data RZASG MV1 Data BookNuno MotaNo ratings yet

- Installation, Operation, and Start-Up InstructionsDocument116 pagesInstallation, Operation, and Start-Up InstructionsizzyonNo ratings yet

- Standards in PreparationDocument16 pagesStandards in Preparationnitvan82No ratings yet

- Engine Coolant Expansion Tanks Recovery SystemsDocument4 pagesEngine Coolant Expansion Tanks Recovery SystemsTendai AlfaceNo ratings yet

- BoqDocument45 pagesBoqShabbir OsmaniNo ratings yet

- VW Jetta 5 Auxiliary Heater Webasto Thermo Top V EngDocument49 pagesVW Jetta 5 Auxiliary Heater Webasto Thermo Top V EngJanos HallaNo ratings yet

- Belshaw Adamatic Manual Mark II-Mark IIGP Item Numbers 21622-21637-21638Document75 pagesBelshaw Adamatic Manual Mark II-Mark IIGP Item Numbers 21622-21637-21638JORGE RODRIGUEZNo ratings yet

- toshiba-VRF BrochureDocument60 pagestoshiba-VRF BrochureMurali Das100% (1)

- Thank You For Downloading PPL Electric Utilities' (PPL EU) Application For Electric ServiceDocument7 pagesThank You For Downloading PPL Electric Utilities' (PPL EU) Application For Electric ServiceAsghar AliNo ratings yet

- Velan Steam TrapDocument25 pagesVelan Steam TrapHongLam LÊNo ratings yet

- D 1518 - 85 R98 - Rde1mtgtodvsothfmq - PDFDocument8 pagesD 1518 - 85 R98 - Rde1mtgtodvsothfmq - PDFmyusuf123No ratings yet

- 340 ManualDocument178 pages340 Manualllouis8944No ratings yet

- COA Rules and Regulations PDFDocument38 pagesCOA Rules and Regulations PDFAyushi JainNo ratings yet

- 104T4152 Flow Sensor 95VL Calibration ProcedureDocument25 pages104T4152 Flow Sensor 95VL Calibration ProcedureSilva NumaNo ratings yet

- Canada Multifamily Energy Model Simulation Guidelines For NECB ACPDocument18 pagesCanada Multifamily Energy Model Simulation Guidelines For NECB ACPjwNo ratings yet

- Minetruck mt65 k1Document8 pagesMinetruck mt65 k1sebastian titiroNo ratings yet

- Tender Doc CPI7204P22Document485 pagesTender Doc CPI7204P22Murugaraj SelvarajNo ratings yet

- Boq Ductable AirconditionerDocument3 pagesBoq Ductable AirconditionerAPNIT MISHRANo ratings yet

- Zamil-ALY SeriesDocument48 pagesZamil-ALY SeriesSafwa Abuelazayem100% (1)