Professional Documents

Culture Documents

Dantal130418 R1

Uploaded by

Abhijeet AnkushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dantal130418 R1

Uploaded by

Abhijeet AnkushCopyright:

Available Formats

ASSOCIATED PLASMATRON PVT. LTD.

REG. OFFICE & PLANT I :

R-397, TTC Indl. Area, Thane-Belapur Road, Rabale MIDC,

Navi Mumbai - 400701, Maharashtra, India.

SPECIALIZED THERMAL SPRAY COATING SERVICES

PLANT II : DETONATION SPRAY, ROBOTIC PLASMA SPRAY, ROBOTIC HVOF

Plot No. 15, 16 & 21/3, Morivali - Chikhloli MIDC, SPRAY, WIRE ARC SPRAY, WIRE FLAME SPRAY & POWDER FLAME

Ambernath(West)- 421505 , Thane, Maharashtra, India. SPRAY

CONTACT DETAILS : WELD OVERLAY SERVICES

Tel : (022) 2769 1952 / 5616 3765 / 66 PTAW & GTAW CLAD OVERLAYS

Fax : (022) 27696739

E-mail : info@plasmatronindia.com MACHINE SHOP:

Website : www.plasmatronindia.com MANUFACTURING / REPAIR OF COATED AND WELD OVERLAYED

CIN No. : U99999MH1988PTC050126 PRECISION PARTS

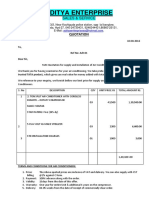

Ref. No. : PQT181900019-R1 Date : 13/04/2018

DANTAL HYDRAULICS PVT. LTD.

KIND ATTENTION : Mr. Sanjay Bajaj ()

SUBJECT : QUOTATION FOR PIC B02 COATING ON PISTON RODS

Dear Sir,

This is with reference to your inquiry regarding Ceramic coating on Piston rods. We here below give our lowest offer for the

same.

SCOPE OF WORK :

A. COATING AND FINAL GRINDING

- Inward inspection of component

- Masking of non-coating area to avoid over spray

- Surface preparation for better adhesion of coating

- Deposition of PIC B02 coating in repeated passes upto grinding allowance

- Sealer impregnation of coating to seal inherent porosities

- Diamond grinding to achieve desired size

- Polishing to achieve desired surface finish

- Final inspection of the component

- Cleaning, Packing and Final despatch

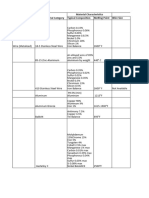

PRICE : Our charges as per the scope of work mentioned above will be :

Rate /

Sr.No. Component Name Part No. Drawing No. Qty Scope MOQ

Unit

1 Piston Rod (Dia 40mm X L 590mm) 36 A 25 22,490

1 | Page F-SAL/04 Doc No. 95 Rev No: 02

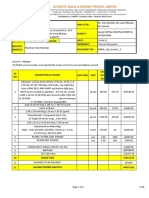

IMPORTANT NOTE :

1. Certificates for dimensional observations would be provided from our end.

2. The above quote is for a maximum finish coating thickness of 0.3mm radially. Higher coating thickness is

not advisable.

3. The above quote does not include pre-coating machining or grinding. Piston rods should be undersized

as per required pre-coating size. Hardness of the base material should be less than 30HRc

4. The coating area should be free from dent marks, pin holes or any other surface defects.

5. Charges for UT, MPI or any other testing would be additional. In case of rejection at the testing stage,

charges for testing would still be applicable.

6. Charges for Heat treatment, Bend removal and Re-centering will be extra.

COATING PROPERTIES COATING VALUES

COATING TYPE PIC B02

MICRO HARDNESS 900 to 1300 Hv0.3

BOND STRENGTH > 5000 PSI

POROSITY < 3%

CORROSION RESISTANCE EXCELLENT

ABRASION RESISTANCE EXCELLENT

EROSION RESISTANCE MEDIUM

MAX TEMPERATURE 400 'C

COATING THICKNESS 250 to 300 Microns (Finish)

2 | Page F-SAL/04 Doc No. 95 Rev No: 02

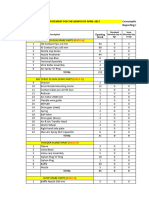

TERMS & CONDITIONS :

Tax The above quoted price is exclusive of all taxes.

IGST @ 18% on basic

Taxes will be applicable as per government law at the time of despatch .

Validity Quotation valid for 30 Days

Payments 100% Against Proforma Invoice before dispatch of components.

Packing Components will be packed in wooden boxes provided by you. Charges for new

wooden box or repair of existing wooden box will be additional and be charged on

actuals

Extra Charges Extra charges will be applicable for additional work apart from the scope of work

specified in the above offer. Same will be shared with you for your approval

Delivery Within 4 to 6 weeks from date of receipt of components along with firm order

Inspection Inspection will be at our works

Transportation Transportation in your scope

Insurance In your scope

GSTIN No. : 27AACCA9023C1Z3 PAN No. : AACCA9023C

We hope our offer is to your satisfaction and remain in anticipation of your valued order .

We assure you JOB QUALITY AND SERVICE ON TIME.

Thanking you,

Yours faithfully,

Vivek Kudva

Director

3 | Page F-SAL/04 Doc No. 95 Rev No: 02

You might also like

- Oscar 240418Document3 pagesOscar 240418Abhijeet AnkushNo ratings yet

- Shree Valinath120618Document3 pagesShree Valinath120618Abhijeet AnkushNo ratings yet

- Silcon 090518Document3 pagesSilcon 090518Abhijeet AnkushNo ratings yet

- An and 190318Document3 pagesAn and 190318Abhijeet AnkushNo ratings yet

- JB#410713 Sierra Proto Express R1500116X, 8-26-2021Document2 pagesJB#410713 Sierra Proto Express R1500116X, 8-26-2021HanamantrayaNo ratings yet

- LaminateDocument68 pagesLaminatedesignNo ratings yet

- Quotation BQ6175 To Ratan SikchiDocument4 pagesQuotation BQ6175 To Ratan SikchiRatan KumarNo ratings yet

- AC - ARK StructuralDocument9 pagesAC - ARK StructuralM Q ASLAMNo ratings yet

- Offer For Kiln Tyre Crack Repair - DroliaDocument5 pagesOffer For Kiln Tyre Crack Repair - DroliaNapoleon Das100% (1)

- D-O-C (08-21-540-Sp-Im) - Bark Al MustakbalDocument2 pagesD-O-C (08-21-540-Sp-Im) - Bark Al MustakbalRamy AbdallaNo ratings yet

- Fast Cables LTD: QuotationDocument1 pageFast Cables LTD: QuotationAli ShahzadNo ratings yet

- High-Performance Epoxy Coating for Heavy-Duty ApplicationsDocument3 pagesHigh-Performance Epoxy Coating for Heavy-Duty ApplicationsHASNo ratings yet

- HDP 2676Document6 pagesHDP 2676pankaj singhalNo ratings yet

- FTP Secureftp - Amns.in UPLOAD 2022 March 6000063762 IN 6000063762Document4 pagesFTP Secureftp - Amns.in UPLOAD 2022 March 6000063762 IN 6000063762mohanananda chakrabortyNo ratings yet

- GS_2024_25_0011 GS CONTROL OFFER OF HEAT TRACING PANEL (1)Document5 pagesGS_2024_25_0011 GS CONTROL OFFER OF HEAT TRACING PANEL (1)Gautam MishraNo ratings yet

- REPAIR PROCEDURE -ZPI-3LPE-01Document3 pagesREPAIR PROCEDURE -ZPI-3LPE-01Suresh KrishnanNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- 0573-Balkrishna Polymer-30 MM Hooks (06.09.2023)Document1 page0573-Balkrishna Polymer-30 MM Hooks (06.09.2023)officebackup allmailNo ratings yet

- Ca3-23-219-R01 PVDFDocument6 pagesCa3-23-219-R01 PVDFahmed ahmadNo ratings yet

- Techno-Commercial OfferDocument6 pagesTechno-Commercial OfferharishNo ratings yet

- WORK ORDER - Local Job Work ReceiptDocument2 pagesWORK ORDER - Local Job Work ReceiptprakashNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- Duralife NotesDocument5 pagesDuralife Notesjava netNo ratings yet

- Tendernotice 1Document32 pagesTendernotice 1Harshal DalneNo ratings yet

- Aditya Enterprise: Sales & ServiceDocument2 pagesAditya Enterprise: Sales & Servicejyothi jagadishNo ratings yet

- Grasim PO 1Document8 pagesGrasim PO 1rakesh kumar pandeyNo ratings yet

- RFQ DocumentDocument9 pagesRFQ DocumentdulciholdingsNo ratings yet

- S F 003-Amndt-01Document1 pageS F 003-Amndt-01sakil mollllllNo ratings yet

- Ds Tata Power Solar Systems Limited 1: Outline AgreementDocument8 pagesDs Tata Power Solar Systems Limited 1: Outline AgreementM Q ASLAMNo ratings yet

- 007.MTL-NSS-AB-2023-007 - Quotation For SS Fabrication & Coating - MR-SS-0145Document1 page007.MTL-NSS-AB-2023-007 - Quotation For SS Fabrication & Coating - MR-SS-0145abasithamNo ratings yet

- Automark Industries-PO (Road Marking)Document3 pagesAutomark Industries-PO (Road Marking)LN MALVIYANo ratings yet

- Metal roofing sheet quoteDocument2 pagesMetal roofing sheet quoteashishkumar boharaNo ratings yet

- Field Joints Coating Offer-DemechDocument4 pagesField Joints Coating Offer-DemechVineet KhanduriNo ratings yet

- Q221241973 Kit Display Repair QuoteDocument2 pagesQ221241973 Kit Display Repair QuoteMuthukumaran TNo ratings yet

- GeM Bidding 3545617Document4 pagesGeM Bidding 3545617Study WayNo ratings yet

- Repair Procedure Cbr 3lpe 00Document3 pagesRepair Procedure Cbr 3lpe 00Suresh KrishnanNo ratings yet

- Datasheet of Sealxtra Pu FR: BGC Igcc - Construction Framework AgreementDocument4 pagesDatasheet of Sealxtra Pu FR: BGC Igcc - Construction Framework AgreementAhmedNo ratings yet

- Tender for Refusal Boxes and Parts for Ball and Tube MillDocument5 pagesTender for Refusal Boxes and Parts for Ball and Tube MillSimhadri StoresNo ratings yet

- Guntur ACP CladdingDocument2 pagesGuntur ACP Claddingramakrishna550No ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Powder Coating - Quote - Red FinishingDocument2 pagesPowder Coating - Quote - Red FinishingHariHaranNo ratings yet

- Laurus Software Technologies Pvt. LTD.: Lcontrol Base Card EXCT CardDocument1 pageLaurus Software Technologies Pvt. LTD.: Lcontrol Base Card EXCT CardArvind NangareNo ratings yet

- Motorized & Manual Roller BlindsDocument2 pagesMotorized & Manual Roller BlindsathullaluNo ratings yet

- Ingal - As NZS 4680 2006 - Ingalsm3Document6 pagesIngal - As NZS 4680 2006 - Ingalsm3Ramiro RivasNo ratings yet

- Gscontrol Offer of Fire Fighting PanelDocument5 pagesGscontrol Offer of Fire Fighting PanelGautam MishraNo ratings yet

- HDP 2674Document6 pagesHDP 2674pankaj singhalNo ratings yet

- December 23, 2020 Ref. No. CP-0697-02: Presence Across The CountryDocument8 pagesDecember 23, 2020 Ref. No. CP-0697-02: Presence Across The CountryAnwar TextilesNo ratings yet

- GS Control Offer of Extension Board and MeterDocument4 pagesGS Control Offer of Extension Board and MeterGautam MishraNo ratings yet

- ACCOR Engineering Solutions: QuotationDocument38 pagesACCOR Engineering Solutions: QuotationgopalraojiNo ratings yet

- 304 Hex Nut M10-1.5Document1 page304 Hex Nut M10-1.5ugi putriNo ratings yet

- Hai Point JKR Requirement Channel and Batten 2020Document23 pagesHai Point JKR Requirement Channel and Batten 2020kimchewlim82No ratings yet

- SIMACRYLIC COATING Data SheetDocument2 pagesSIMACRYLIC COATING Data SheetSAEFUDDIN SAEFUDDINNo ratings yet

- Wo-Ec546wod7000042 Stay CableDocument3 pagesWo-Ec546wod7000042 Stay CableJkkhyhNo ratings yet

- QTN NO. 74 - Rate Offer - For Fischer Fis V Plus 360s CHEMICAL & FISCHER EM 585 S CHEMICAL (S.M. NIRMAN)Document2 pagesQTN NO. 74 - Rate Offer - For Fischer Fis V Plus 360s CHEMICAL & FISCHER EM 585 S CHEMICAL (S.M. NIRMAN)reddyrabadaNo ratings yet

- National Aluminium Company Limited: (Purchase Dept)Document19 pagesNational Aluminium Company Limited: (Purchase Dept)Hytech Pvt. Ltd.No ratings yet

- Chandan Steel MTC for Stainless Steel Round Bars to ArgentinaDocument1 pageChandan Steel MTC for Stainless Steel Round Bars to ArgentinaAceros DessolNo ratings yet

- Request For Quotation Local Purchase Section: RFQ NumberDocument3 pagesRequest For Quotation Local Purchase Section: RFQ NumberHazemNo ratings yet

- viewNitPdf 2550035Document12 pagesviewNitPdf 2550035Pratik GuptaNo ratings yet

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Company ProfileDocument79 pagesCompany ProfileAbhijeet AnkushNo ratings yet

- CSR DataDocument50 pagesCSR DataAbhijeet AnkushNo ratings yet

- PM-28 PlasmaDocument1 pagePM-28 PlasmaAbhijeet AnkushNo ratings yet

- NodalOfficersList 22102021Document336 pagesNodalOfficersList 22102021Abhijeet AnkushNo ratings yet

- Nodalofficers 15062021Document335 pagesNodalofficers 15062021Abhijeet AnkushNo ratings yet

- Interpack Exhibition - 2023-24Document6 pagesInterpack Exhibition - 2023-24Abhijeet AnkushNo ratings yet

- Https WWW Konkanindustrialpublications Com Web-2-0-Directory Atul-Engineering-Works w2dc Action PdflistingDocument1 pageHttps WWW Konkanindustrialpublications Com Web-2-0-Directory Atul-Engineering-Works w2dc Action PdflistingAbhijeet AnkushNo ratings yet

- Swot AnalysisDocument1 pageSwot AnalysisAbhijeet AnkushNo ratings yet

- Preventive Maintenance Check List - Wire Flame Spray - AmbernathDocument1 pagePreventive Maintenance Check List - Wire Flame Spray - AmbernathAbhijeet AnkushNo ratings yet

- PM-27 Hvof 2Document1 pagePM-27 Hvof 2Abhijeet AnkushNo ratings yet

- Machine Spair Parts Stock Statements April-2017Document24 pagesMachine Spair Parts Stock Statements April-2017Abhijeet AnkushNo ratings yet

- Insert Stock Statement For The Mont of April-2017Document12 pagesInsert Stock Statement For The Mont of April-2017Abhijeet AnkushNo ratings yet

- Raw MaterialDocument14 pagesRaw MaterialAbhijeet AnkushNo ratings yet

- Insert Stock Statement For The Mont of April-2017Document12 pagesInsert Stock Statement For The Mont of April-2017Abhijeet AnkushNo ratings yet

- Supplier ListDocument213 pagesSupplier ListAbhijeet AnkushNo ratings yet

- Material Master List - Powder & Wire PIC CodeDocument22 pagesMaterial Master List - Powder & Wire PIC CodeAbhijeet AnkushNo ratings yet

- Lab1Start v5Document2 pagesLab1Start v5Abhijeet AnkushNo ratings yet

- Antivo ProfileDocument10 pagesAntivo ProfileAbhijeet AnkushNo ratings yet

- Bio 7Document198 pagesBio 7Abhijeet AnkushNo ratings yet

- Bio 7Document198 pagesBio 7Abhijeet AnkushNo ratings yet

- Bio 3Document76 pagesBio 3Abhijeet AnkushNo ratings yet

- Bio 3Document76 pagesBio 3Abhijeet AnkushNo ratings yet

- Indian Oil Cooperation LTD (Assam Oil Division Digboi Refinery)Document64 pagesIndian Oil Cooperation LTD (Assam Oil Division Digboi Refinery)NingSeng SingphoNo ratings yet

- Mini Metal Lathe 7x12 Owner's Manual Safety GuideDocument13 pagesMini Metal Lathe 7x12 Owner's Manual Safety GuideVicente Banda ZuñigaNo ratings yet

- Flange 6Document5 pagesFlange 6Muhammad RafiNo ratings yet

- Double RC Beam (WSD)Document15 pagesDouble RC Beam (WSD)api-19753598No ratings yet

- Test Bank For Organic Chemistry Structure and Function 6th Edition Vollhardt DownloadDocument18 pagesTest Bank For Organic Chemistry Structure and Function 6th Edition Vollhardt Downloadchristopherwilliamsmcrjpeynzf100% (21)

- Modather Structural Analysis RebortDocument23 pagesModather Structural Analysis RebortomneiatsulimanNo ratings yet

- Comparison of Capstan and Turret LathesDocument1 pageComparison of Capstan and Turret Lathessanjeevbijarnia01No ratings yet

- MKT 00079 00RAF - REDUCT Surg. Tech. Guide - 6 7 18Document8 pagesMKT 00079 00RAF - REDUCT Surg. Tech. Guide - 6 7 18Daniel Quijada LucarioNo ratings yet

- Datasheet A S50iaDocument2 pagesDatasheet A S50iavantuan17792No ratings yet

- TWINDISC - Marine Trans Service Manual 1021346Document281 pagesTWINDISC - Marine Trans Service Manual 1021346Jorge Lopes86% (14)

- WOVEN FABRIC MANUFACTURING PROCESSDocument64 pagesWOVEN FABRIC MANUFACTURING PROCESSGadisa AbrahimNo ratings yet

- Fire Fighting System in Skyscrapers (Burj Khalifa)Document18 pagesFire Fighting System in Skyscrapers (Burj Khalifa)Dharshini Deivasigamani100% (1)

- HPS1000 Pump & GearboxDocument2 pagesHPS1000 Pump & GearboxFrederik CañabiNo ratings yet

- C 8 1 09Document1 pageC 8 1 09Sandino TorresNo ratings yet

- Presentation On Foundations.Document32 pagesPresentation On Foundations.shrikant100% (6)

- Stress - Strain GraphDocument12 pagesStress - Strain GraphpradeepNo ratings yet

- 3858 Parts CatalogueDocument48 pages3858 Parts CatalogueSergey Slomchinskiy100% (6)

- Analisis Prinsip Kerja Alat Grate Cooler Di PT. Semen Baturaja (Persero) TBKDocument16 pagesAnalisis Prinsip Kerja Alat Grate Cooler Di PT. Semen Baturaja (Persero) TBKCia VhirgianiNo ratings yet

- Hand ToolsDocument2 pagesHand ToolsIsaiah LuleNo ratings yet

- PLMB-A210017-43-DWG-010-R.2 SHT 3 of 3Document1 pagePLMB-A210017-43-DWG-010-R.2 SHT 3 of 3Albet MulyonoNo ratings yet

- Inspection & Test Plan Mechanical (ITP)Document6 pagesInspection & Test Plan Mechanical (ITP)hari banggaNo ratings yet

- Maintenant Part - Recc. ListDocument4 pagesMaintenant Part - Recc. ListNguyen TrungNo ratings yet

- TRW Steering Box Service ManualDocument0 pagesTRW Steering Box Service ManualJuanLopez64Ch100% (1)

- 186-2023 Chennai Pile G+2 STR 03Document1 page186-2023 Chennai Pile G+2 STR 03manishkerranNo ratings yet

- Corrected Valve Sizes 21.10.'23Document2 pagesCorrected Valve Sizes 21.10.'23Padmakumar T CNo ratings yet

- B. Equivalent Axial (N) and Lateral (Q) Loads: SD SDDocument2 pagesB. Equivalent Axial (N) and Lateral (Q) Loads: SD SDRahul Malani100% (1)

- Wa0030.Document3 pagesWa0030.Muhammad Shihabudin AhmedNo ratings yet

- W7 DoorDocument33 pagesW7 DoorTeoh Zhi TongNo ratings yet

- Study of Grinding Machines: Types, Operations & ClassificationDocument10 pagesStudy of Grinding Machines: Types, Operations & Classificationdeepa82ece100% (1)

- Hydraulic Oil Control Valve, 4-Valve (1 9) (With ECSS) (#60638-)Document2 pagesHydraulic Oil Control Valve, 4-Valve (1 9) (With ECSS) (#60638-)Marcelo ArayaNo ratings yet