Professional Documents

Culture Documents

Oscar 240418

Uploaded by

Abhijeet AnkushOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oscar 240418

Uploaded by

Abhijeet AnkushCopyright:

Available Formats

ASSOCIATED PLASMATRON PVT. LTD.

REG. OFFICE & PLANT I :

R-397, TTC Indl. Area, Thane-Belapur Road, Rabale MIDC,

Navi Mumbai - 400701, Maharashtra, India.

SPECIALIZED THERMAL SPRAY COATING SERVICES

PLANT II : DETONATION SPRAY, ROBOTIC PLASMA SPRAY, ROBOTIC HVOF

Plot No. 15, 16 & 21/3, Morivali - Chikhloli MIDC, SPRAY, WIRE ARC SPRAY, WIRE FLAME SPRAY & POWDER FLAME

Ambernath(West)- 421505 , Thane, Maharashtra, India. SPRAY

CONTACT DETAILS : WELD OVERLAY SERVICES

Tel : (022) 2769 1952 / 5616 3765 / 66 PTAW & GTAW CLAD OVERLAYS

Fax : (022) 27696739

E-mail : info@plasmatronindia.com MACHINE SHOP:

Website : www.plasmatronindia.com MANUFACTURING / REPAIR OF COATED AND WELD OVERLAYED

CIN No. : U99999MH1988PTC050126 PRECISION PARTS

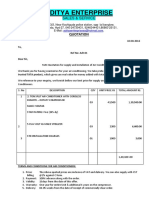

Ref. No. : PQT181900026 Date : 24/04/2018

OSCAR ENTERPRISES

Plot No. 4/1, Sector No 10, Opp. Vishweshwar

Industrial Premises Near Vishweshwar Chowk,

PCNTDA, Bhosri MIDC,

KIND ATTENTION : Mr. Onkar Joshi (Owner)

SUBJECT : QUOTATION FOR CARBIDE COATING ON EXTRUSION SCREWS

Dear Sir,

This is with reference to your inquiry regarding Tungsten Carbide coating of Extrusion screws . We here below give our lowest

offer for the same.

SCOPE OF WORK :

A. COATING AND FINAL GRINDING

- Inward inspection of component

- Masking of non-coating area to avoid over spray

- Surface preparation for better adhesion of coating

- Deposition of the coating in repeated passes upto grinding allowance

- Sealer impregnation of coating to seal inherent porosities

- Diamond grinding to achieve desired size

- Diamond polishing to achieve desired surface finish

- Final inspection of the component

- Cleaning, Packing and Final despatch

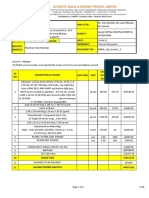

PRICE : Our charges as per the scope of work mentioned above will be :

Rate/Unit

Sr.No. Component Name Part No. Drawing No. Qty Scope MOQ

(Rupees)

1 Extrusion Screw (Dia 32mm X L 1 25,000

460mm)

1 | Page F-SAL/04 Doc No. 95 Rev No: 02

IMPORTANT NOTE :

1. Certificates for dimensional observations would be provided from our end.

2. The above quote is for a maximum finish coating thickness of 0.25mm radially. Higher coating thickness

will be charged extra.

3. The screw should not have any sharp edges. All sharp corners on the flute should be made blunt by

providing chamfer or radius.

4. Coating area should be free from rust, pin holes, dent marks or scratches.

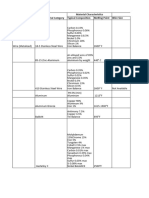

COATING PROPERTIES DESCRIPTION

COATING TYPE PIC DC09

MICRO HARDNESS 1100 to 1400 HV0.3

BOND STRENGTH > 12000 PSI

POROSITY < 0.8%

CORROSION RESISTANCE MEDIUM

ABRASION RESISTANCE EXCELLENT

EROSION RESISTANCE EXCELLENT

MAX TEMPERATURE 450 'C

COATING THICKNESS 180 to 200 Microns (Finish)

SURFACE FINISH < 0.4 Ra micron

2 | Page F-SAL/04 Doc No. 95 Rev No: 02

TERMS & CONDITIONS :

Tax The above quoted price is exclusive of all taxes.

SGST @ 9% and CGST @ 9% on basic

Taxes will be applicable as per government law at the time of despatch .

Validity Quotation valid for 30 Days

Payments 100% Against Proforma Invoice before dispatch of components.

Packing Components will be packed with stretch film, blister wrap and corrugated sheet.

Charges for wooden box would be additional and will not exceed 2% of the order

value.

Extra Charges Extra charges will be applicable for additional work apart from the scope of work

specified in the above offer. Same will be shared with you for your approval

Delivery Within 2 to 3 weeks from date of receipt of components along with firm order

Inspection Inspection will be at our works

Transportation Transportation in your scope

Insurance In your scope

GSTIN No. : 27AACCA9023C1Z3 PAN No. : AACCA9023C

We hope our offer is to your satisfaction and remain in anticipation of your valued order .

We assure you JOB QUALITY AND SERVICE ON TIME.

Thanking you,

Yours faithfully,

Vivek Kudva

Director

3 | Page F-SAL/04 Doc No. 95 Rev No: 02

You might also like

- QT-096690-5 Last ProposalDocument9 pagesQT-096690-5 Last ProposalMoustafa ZakiNo ratings yet

- Field Joints Coating Offer-DemechDocument4 pagesField Joints Coating Offer-DemechVineet KhanduriNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Supplier ListDocument213 pagesSupplier ListAbhijeet AnkushNo ratings yet

- Home BMW F11 530D Xdrive Touring Wiring Diagrams and Functional DescriptionDocument1 pageHome BMW F11 530D Xdrive Touring Wiring Diagrams and Functional DescriptionOliver AlfaroNo ratings yet

- (World of Art) John Boardman - Athenian Black Figure Vases-Thames and Hudson (1974)Document128 pages(World of Art) John Boardman - Athenian Black Figure Vases-Thames and Hudson (1974)Karen SantosNo ratings yet

- Shree Valinath120618Document3 pagesShree Valinath120618Abhijeet AnkushNo ratings yet

- Dantal130418 R1Document3 pagesDantal130418 R1Abhijeet AnkushNo ratings yet

- Silcon 090518Document3 pagesSilcon 090518Abhijeet AnkushNo ratings yet

- An and 190318Document3 pagesAn and 190318Abhijeet AnkushNo ratings yet

- LaminateDocument68 pagesLaminatedesignNo ratings yet

- JB#410713 Sierra Proto Express R1500116X, 8-26-2021Document2 pagesJB#410713 Sierra Proto Express R1500116X, 8-26-2021HanamantrayaNo ratings yet

- High-Performance Epoxy Coating for Heavy-Duty ApplicationsDocument3 pagesHigh-Performance Epoxy Coating for Heavy-Duty ApplicationsHASNo ratings yet

- Offer For Kiln Tyre Crack Repair - DroliaDocument5 pagesOffer For Kiln Tyre Crack Repair - DroliaNapoleon Das100% (1)

- AC - ARK StructuralDocument9 pagesAC - ARK StructuralM Q ASLAMNo ratings yet

- Ervin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyDocument2 pagesErvin Germany GMBH - Rudower Chaussee 48 - 12489 Berlin - GermanyreynaldoUHNo ratings yet

- Fast Cables LTD: QuotationDocument1 pageFast Cables LTD: QuotationAli ShahzadNo ratings yet

- D-O-C (08-21-540-Sp-Im) - Bark Al MustakbalDocument2 pagesD-O-C (08-21-540-Sp-Im) - Bark Al MustakbalRamy AbdallaNo ratings yet

- Quotation BQ6175 To Ratan SikchiDocument4 pagesQuotation BQ6175 To Ratan SikchiRatan KumarNo ratings yet

- SIMACRYLIC COATING Data SheetDocument2 pagesSIMACRYLIC COATING Data SheetSAEFUDDIN SAEFUDDINNo ratings yet

- WORK ORDER - Local Job Work ReceiptDocument2 pagesWORK ORDER - Local Job Work ReceiptprakashNo ratings yet

- Q221241973 Kit Display Repair QuoteDocument2 pagesQ221241973 Kit Display Repair QuoteMuthukumaran TNo ratings yet

- Duralife NotesDocument5 pagesDuralife Notesjava netNo ratings yet

- RFQ DocumentDocument9 pagesRFQ DocumentdulciholdingsNo ratings yet

- Motorized & Manual Roller BlindsDocument2 pagesMotorized & Manual Roller BlindsathullaluNo ratings yet

- Metal roofing sheet quoteDocument2 pagesMetal roofing sheet quoteashishkumar boharaNo ratings yet

- B587-000-06-41-PLS-03 - Rev 0Document14 pagesB587-000-06-41-PLS-03 - Rev 0SAUGAT DUTTANo ratings yet

- BSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartDocument9 pagesBSEZ - (PCCL-GKB) - MAR-094. Touch Up Paint For Galvanized PartHồng Trung DươngNo ratings yet

- L & T Glass Installation QuoteDocument4 pagesL & T Glass Installation QuoteJessica Spears100% (1)

- Aditya Enterprise: Sales & ServiceDocument2 pagesAditya Enterprise: Sales & Servicejyothi jagadishNo ratings yet

- Automark Industries-PO (Road Marking)Document3 pagesAutomark Industries-PO (Road Marking)LN MALVIYANo ratings yet

- Ds Tata Power Solar Systems Limited 1: Outline AgreementDocument8 pagesDs Tata Power Solar Systems Limited 1: Outline AgreementM Q ASLAMNo ratings yet

- Revised Technical Specifications CNC HMC 630X630 MM (8-8851T)Document18 pagesRevised Technical Specifications CNC HMC 630X630 MM (8-8851T)admin embNo ratings yet

- S F 003-Amndt-01Document1 pageS F 003-Amndt-01sakil mollllllNo ratings yet

- 0573-Balkrishna Polymer-30 MM Hooks (06.09.2023)Document1 page0573-Balkrishna Polymer-30 MM Hooks (06.09.2023)officebackup allmailNo ratings yet

- FTP Secureftp - Amns.in UPLOAD 2022 March 6000063762 IN 6000063762Document4 pagesFTP Secureftp - Amns.in UPLOAD 2022 March 6000063762 IN 6000063762mohanananda chakrabortyNo ratings yet

- Anti-corrosion Lining for Concrete PoolsDocument4 pagesAnti-corrosion Lining for Concrete Poolsmuchamad yasinNo ratings yet

- Road Marking Paint SB AcrylicDocument4 pagesRoad Marking Paint SB AcrylicAngga PratamaNo ratings yet

- December 23, 2020 Ref. No. CP-0697-02: Presence Across The CountryDocument8 pagesDecember 23, 2020 Ref. No. CP-0697-02: Presence Across The CountryAnwar TextilesNo ratings yet

- Tendernotice 1Document32 pagesTendernotice 1Harshal DalneNo ratings yet

- Datasheet of Sealxtra Pu FR: BGC Igcc - Construction Framework AgreementDocument4 pagesDatasheet of Sealxtra Pu FR: BGC Igcc - Construction Framework AgreementAhmedNo ratings yet

- GGG 40.3 Test ReportDocument1 pageGGG 40.3 Test ReportcqigNo ratings yet

- Mb-9731-22, Hidden Snap Button-18l, Epyllion Style Limited.Document1 pageMb-9731-22, Hidden Snap Button-18l, Epyllion Style Limited.Shahadat Hossain BayzidNo ratings yet

- HDP 2676Document6 pagesHDP 2676pankaj singhalNo ratings yet

- QES2023-10-006-PC-EH-Hajj Terminal-R2Document4 pagesQES2023-10-006-PC-EH-Hajj Terminal-R2فرفشه اضحك بجدNo ratings yet

- Request For Quotation Local Purchase Section: RFQ NumberDocument3 pagesRequest For Quotation Local Purchase Section: RFQ NumberHazemNo ratings yet

- Supply of Steel Capping To Protect The Liner On Top.: Info@siproindia - inDocument4 pagesSupply of Steel Capping To Protect The Liner On Top.: Info@siproindia - inVivek SardaNo ratings yet

- Surface CareDocument18 pagesSurface CareChristi ThomasNo ratings yet

- QTN NO. 74 - Rate Offer - For Fischer Fis V Plus 360s CHEMICAL & FISCHER EM 585 S CHEMICAL (S.M. NIRMAN)Document2 pagesQTN NO. 74 - Rate Offer - For Fischer Fis V Plus 360s CHEMICAL & FISCHER EM 585 S CHEMICAL (S.M. NIRMAN)reddyrabadaNo ratings yet

- Work order for painting 96 pipesDocument1 pageWork order for painting 96 pipesAlfian ImaduddinNo ratings yet

- 304 Hex Nut M10-1.5Document1 page304 Hex Nut M10-1.5ugi putriNo ratings yet

- GS_2024_25_0011 GS CONTROL OFFER OF HEAT TRACING PANEL (1)Document5 pagesGS_2024_25_0011 GS CONTROL OFFER OF HEAT TRACING PANEL (1)Gautam MishraNo ratings yet

- Powder Coating - Quote - Red FinishingDocument2 pagesPowder Coating - Quote - Red FinishingHariHaranNo ratings yet

- TENDER ENQUIRY NO:ENQ/15-16/000974/MM05 (03) /DATE:08/07/2015 /page - 1Document10 pagesTENDER ENQUIRY NO:ENQ/15-16/000974/MM05 (03) /DATE:08/07/2015 /page - 1Vijayakumar SengottuveluNo ratings yet

- Product certification report analysisDocument2 pagesProduct certification report analysisFreddy Taipe CruNo ratings yet

- Ca3-23-219-R01 PVDFDocument6 pagesCa3-23-219-R01 PVDFahmed ahmadNo ratings yet

- Grasim PO 1Document8 pagesGrasim PO 1rakesh kumar pandeyNo ratings yet

- 30 MM Gi Threaded Rod GR 8.8 - Tbi PDFDocument1 page30 MM Gi Threaded Rod GR 8.8 - Tbi PDFm.aliNo ratings yet

- CCL Purchase Order for 11KV Power CablesDocument22 pagesCCL Purchase Order for 11KV Power Cablesokman17No ratings yet

- Govt. Licensed Class - I Electrical Contractor & Engineers: 1,666,000.00 TotalDocument1 pageGovt. Licensed Class - I Electrical Contractor & Engineers: 1,666,000.00 TotalGURUMOORTHY PNo ratings yet

- 028120-SPL-008 Protective Coating Riser Neoprene Rev. CDocument8 pages028120-SPL-008 Protective Coating Riser Neoprene Rev. CRokan Pipeline100% (1)

- Offer For 7888T - SEMLDocument3 pagesOffer For 7888T - SEMLNapoleon DasNo ratings yet

- Welding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesFrom EverandWelding Tips & Tricks: All you need to know about welding machines, welding helmets, and welding gogglesRating: 1 out of 5 stars1/5 (1)

- Https WWW Konkanindustrialpublications Com Web-2-0-Directory Atul-Engineering-Works w2dc Action PdflistingDocument1 pageHttps WWW Konkanindustrialpublications Com Web-2-0-Directory Atul-Engineering-Works w2dc Action PdflistingAbhijeet AnkushNo ratings yet

- NodalOfficersList 22102021Document336 pagesNodalOfficersList 22102021Abhijeet AnkushNo ratings yet

- CSR DataDocument50 pagesCSR DataAbhijeet AnkushNo ratings yet

- Company ProfileDocument79 pagesCompany ProfileAbhijeet AnkushNo ratings yet

- Nodalofficers 15062021Document335 pagesNodalofficers 15062021Abhijeet AnkushNo ratings yet

- PM-27 Hvof 2Document1 pagePM-27 Hvof 2Abhijeet AnkushNo ratings yet

- PM-28 PlasmaDocument1 pagePM-28 PlasmaAbhijeet AnkushNo ratings yet

- Interpack Exhibition - 2023-24Document6 pagesInterpack Exhibition - 2023-24Abhijeet AnkushNo ratings yet

- Preventive Maintenance Check List - Wire Flame Spray - AmbernathDocument1 pagePreventive Maintenance Check List - Wire Flame Spray - AmbernathAbhijeet AnkushNo ratings yet

- Insert Stock Statement For The Mont of April-2017Document12 pagesInsert Stock Statement For The Mont of April-2017Abhijeet AnkushNo ratings yet

- Oscar 240418Document3 pagesOscar 240418Abhijeet AnkushNo ratings yet

- Swot AnalysisDocument1 pageSwot AnalysisAbhijeet AnkushNo ratings yet

- Material Master List - Powder & Wire PIC CodeDocument22 pagesMaterial Master List - Powder & Wire PIC CodeAbhijeet AnkushNo ratings yet

- Raw MaterialDocument14 pagesRaw MaterialAbhijeet AnkushNo ratings yet

- Insert Stock Statement For The Mont of April-2017Document12 pagesInsert Stock Statement For The Mont of April-2017Abhijeet AnkushNo ratings yet

- Bio 7Document198 pagesBio 7Abhijeet AnkushNo ratings yet

- Machine Spair Parts Stock Statements April-2017Document24 pagesMachine Spair Parts Stock Statements April-2017Abhijeet AnkushNo ratings yet

- Lab1Start v5Document2 pagesLab1Start v5Abhijeet AnkushNo ratings yet

- Bio 3Document76 pagesBio 3Abhijeet AnkushNo ratings yet

- Bio 7Document198 pagesBio 7Abhijeet AnkushNo ratings yet

- Antivo ProfileDocument10 pagesAntivo ProfileAbhijeet AnkushNo ratings yet

- Bio 3Document76 pagesBio 3Abhijeet AnkushNo ratings yet

- b1 Preliminary For Schools Classroom Posters and Activities PDFDocument13 pagesb1 Preliminary For Schools Classroom Posters and Activities PDFNat ShattNo ratings yet

- Piano: Grade 2: PiecesDocument4 pagesPiano: Grade 2: PiecesnolozeNo ratings yet

- RSG 303Document196 pagesRSG 303Makinde TimiNo ratings yet

- Qualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIDocument23 pagesQualitative Research On Vocabulary and Spelling Skills of A Student Chapters I IIIarniza blazoNo ratings yet

- PIRA - 2022 - ESTIMATED FMV As of October 2022Document48 pagesPIRA - 2022 - ESTIMATED FMV As of October 2022Aggy ReynadoNo ratings yet

- Vaping in Preganacy A Systematic ReviewDocument8 pagesVaping in Preganacy A Systematic ReviewMia LouwNo ratings yet

- Hatsun Supplier Registration RequestDocument4 pagesHatsun Supplier Registration Requestsan dipNo ratings yet

- F5 GTM Concepts Guide v11Document209 pagesF5 GTM Concepts Guide v11Majnu SmNo ratings yet

- Bismillah Skripsi Herlina Rozaaaa-1Document57 pagesBismillah Skripsi Herlina Rozaaaa-1Saidi NetNo ratings yet

- Chapter 3 Week 1 Inductive and Deductive ReasoningDocument57 pagesChapter 3 Week 1 Inductive and Deductive ReasoningDiane Agcaoili Edra50% (6)

- DGN ExamDocument5 pagesDGN ExamMaiga Ayub HusseinNo ratings yet

- 32 Productivity Increase in A PeirceSmith Convert 153013Document14 pages32 Productivity Increase in A PeirceSmith Convert 153013amirlpNo ratings yet

- Particle Physics Brick by Brick - Atomic and Subatomic Physics Explained... in LEGO - Dr. Ben Still (Firefly Books 2018 9781844039340 Eng)Document177 pagesParticle Physics Brick by Brick - Atomic and Subatomic Physics Explained... in LEGO - Dr. Ben Still (Firefly Books 2018 9781844039340 Eng)KonstantineNo ratings yet

- WholeDocument397 pagesWholedelbot01No ratings yet

- Fundamentals Deep Learning Activation Functions When To Use ThemDocument15 pagesFundamentals Deep Learning Activation Functions When To Use ThemfaisalNo ratings yet

- (MATH1013) (2016) (F) Midterm Wsuab 41338Document9 pages(MATH1013) (2016) (F) Midterm Wsuab 41338陳希程No ratings yet

- List of Trigonometric IdentitiesDocument16 pagesList of Trigonometric IdentitiesArnab NandiNo ratings yet

- Dispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsDocument41 pagesDispersion of Carbon Nanotubes in Water and Non-Aqueous SolventsSantiago OrtizNo ratings yet

- ES Model Question Paper With Solution KeyDocument10 pagesES Model Question Paper With Solution Keyvidhya_bineeshNo ratings yet

- Contoh Skripsi Bahasa Inggris Case StudyDocument18 pagesContoh Skripsi Bahasa Inggris Case StudyRizki Fajrita100% (14)

- HistoryDocument20 pagesHistoryAlexandru RomînuNo ratings yet

- Advantages and Disadvantages of Becoming EntrepreneurDocument2 pagesAdvantages and Disadvantages of Becoming EntrepreneurbxndNo ratings yet

- Customer Satisfaction in Maruti SuzukiDocument31 pagesCustomer Satisfaction in Maruti Suzukirajesh laddha100% (1)

- CUMSUM Process ControlDocument6 pagesCUMSUM Process Controljess fantonalgoNo ratings yet

- v16 n3Document219 pagesv16 n3Mark ReinhardtNo ratings yet

- Rate of ChangeDocument22 pagesRate of ChangeTrisha MariehNo ratings yet

- SP Manual Addendum For OS 3 - 03Document2 pagesSP Manual Addendum For OS 3 - 03kevmac88No ratings yet

- OTISLINE QuestionsDocument5 pagesOTISLINE QuestionsArvind Gupta100% (1)