Professional Documents

Culture Documents

F51 110 General Information

Uploaded by

Fayez Al-ahmadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F51 110 General Information

Uploaded by

Fayez Al-ahmadiCopyright:

Available Formats

VE RTIC AL T U R B I N E FI R E PUM P | File No: f51.

110

Date: aug. 15, 2005

Supersedes: new

G E N E R A L I N F O R M AT I O N Date: new

Fire pumps are purchased and installed to protect buildings and water supplies and submergence

property against fire loss. As a result, fire insurance premiums

Vertical turbine fire pumps can be used to pump water from

are significantly reduced and in certain cases the savings will

sumps, reservoirs, and wells. When the fire pump installation

pay for the entire fire pump system in a short period of time.

calls for a sump water supply, the second impeller from the

The National Fire Protection Association (nfpa) was formed to bottom of the bowl assembly must be below the lowest water

establish standards and codes for all members to use as guides level. In a properly designed sump this will insure adequate

in designing and manufacturing the safest and most reliable fire submergence for both npshr and vortex suppression. When

pump systems. Insurance companies now follow those guide- pumping from wells, the maximum pumping level may not ex-

lines as published in nfpa Pamphlet 20 as the standard on which ceed 200’ when pumping at 150% capacity. In cases where the

to approve fire pump systems. Approval authorities include the static water level exceeds 50’ the pump must be oil lubricated.

Underwriters’ Laboratories’ (u.l.) and Factory Mutual (f.m.). All wells must be properly certified prior to installing a listed

Fire pumps are classified in one of two ways: approved with fire pump. In well installations, the second impeller must be

either u.l. or f.m. label or unapproved without label. Approved submerged 10’ below the water level when the pump is operat-

pumps conform to specific laboratory standards, performance, ing at 150% capacity. In both cases submergence should be

and materials of construction and can only be used in fire pro- increased one foot for each 1,000' of elevation above sea level.

tection systems. Unapproved fire pumps may be standard or Vertical turbine barrel pumps can be used in a booster pump

special construction pumps to meet specific needs. To obtain configuration to increase pressure when water is drawn from

maximum insurance benefits, however, the unapproved pumps the city mains.

must be approved for that specific job through the local insurer.

Unapproved pumps do not necessarily have to conform to ul or performance

fm standards, although usually they are required to conform to

Listed fire pumps are designed with very specific performance

nfpa Pamphlet 20.

characteristics: head at shut-off may not exceed 140% of the

design head and may not be less than 65% at 150% of the

approved fire pumps design capacity.

Fire insurance may be purchased from either a stock or mutual

company. Both types of companies have agencies which engineer features

maintain standards and supervise and inspect fire pump instal-

All listed Armstrong Fire pumps are manufactured in accor-

lations. The largest group of insurers consists of the stock com-

dance with nfpa-20 and the Underwriters’ Laboratories or

panies which function through the Underwriters’ Laboratories.

Factory Mutual standards. Standard ratings include:

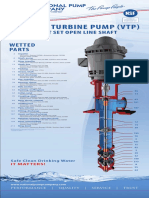

• Vertical turbine type pumps for large and small capacities.

s ystem r equir ement s

250 to 5000 gpm, 58 to 500 psig

To provide the system which best meets the user’s needs, the

• Vertical turbine can type pumps for large and small capacities.

fire pump sales engineer requires certain types of informa-

250 to 1000 gpm, 60 to 500 psig

tion including, but not necessarily limited to the type of driver

required, the electrical power characteristics, site elevation, Special alloys: Special alloys (stainless steel, zincless bronze

average temperatures, capacity and pressure requirements, and aluminum bronze) are available for use in corrosive

maximum lift below grade, optional controller features, and, if environments such as sea water. Under corrosive conditions

present, the size of existing piping. pumps must be constructed of acceptable corrosion resistant

materials selected in accordance with chemical analysis and

Armstrong manufactures a complete line of u.l. listed and f.m.

experience in the area. Special coatings on column pipe are also

approved standard construction vertical turbine fire pumps as

available to resist corrosion.

well as special construction models as required. All Armstrong

Fire pumps conform to nfpa-20 requirements. Stainless steel shaft

Flanged column pipe

Below ground discharge head (type 'vu')

g en era l Vertical Turbine

i n fo rm at ion fire pump

160

Maximum psi at Shut-off drivers

(140% rated psi)

140

A listed fire pump is usually driven by either an electric motor

percent of rated pressure

120 Design point or diesel engine. The electric motor option includes a verti-

100 Maximum psi at 150% cal hollow shaft motor with nrr, with a 1.15 service factor. The

of Rated capacity

(65% rated psi) diesel engine driver is the only internal combustion engine ap-

80

proved for fire pump service. It must be water cooled through a

60

heat exchanger or radiator cooled with engine driven fan, have

40 a water cooled or specially insulated exhaust manifold, and be

20 equipped with all accessories as listed in nfpa-20. If electric

starting is employed, dual battery units are required. Also re-

0

0 20 40 60 80 100 120 140 160 180 200 quired for use with a vertical turbine pump and a diesel engine

percent of rated capacity driver is a right angle, vhs, gear drive. Steam turbines are also

acceptable, but rarely used, drivers.

fittings and other accessories

Fire pump systems include valves and fittings to insure the controllers

proper delivery and control of water to the sprinkler heads or All fire pumps must be equipped with a u.l. listed or f.m.

hydrants. Although each fire pump system is different, most approved control panel. Water pressure in the system is

systems include a pressure gauge on the discharge of the monitored by a pressure switch. When the pressure falls below

pump, discharge tee, relief tee, air release valve, relief valve, a preset level, such as when sprinkler heads open in response

open or closed relief cone, hose valve manifold, hose valves to a fire, the controller automatically starts the fire pump.

with caps and chains, water level gauge, and other miscella- The controller contains a manual stop/start mechanism, local

neous fittings. alarm, and a relay for a remote alarm.

An electric drive controller is similar to a regular permit automatic starting and stopping through a

combination motor starter but can tolerate locked pressure switch is usually acceptable to the local

rotor current for a short period of time. This feature approving agency.

is to insure that the most amount of water possible

will get to the fire. Electric motor controllers also

jockey pumps

incorporate an isolating switch so that the circuits

can be isolated for repair and maintenance. Jockey Pumps are normally used to maintain

constant line pressure in the fire protection system.

Signalling devices are also included to indicate

Their purpose is to prevent frequent operation of

various states of system readiness.

the primary fire pump when system leakage allows

toronto Like the electric drive controller the diesel engine the line pressure to drop below the minimum level.

+1 416 755 2291 controller reacts to drops in system pressure. It The low capacity jockey pump is normally designed

must also be capable of starting the diesel engine to start at a pressure about 5 to 10 psi above the

buffalo and monitoring critical functions such as oil pres- system operating pressure.

+1 716 693 8813

sure, coolant temperature, engine failure, battery

The specific size, type, and operating pressure of

failure, and over speed.

birmingham the jockey pump must conform to the requirements

+44 (0) 8444 145 145 Jockey pump controllers are not covered by nfpa- of the authority having jurisdiction over the fire

20 standards. Consequently, any device that will pump installation. The jockey pump, however, does

manchester not require u.l. or f.m. approval.

+44 (0) 8444 145 145

bangalore

+91 (0) 80 4906 3555

a r m s t r o n g f lu i d t e c h n o lo g y

shanghai established 1934 a r m s t r o n g f lu i d t e c h n o lo g y. c o m

+86 21 3756 6696

You might also like

- F51 10 Advantages of VTF Pump PDFDocument4 pagesF51 10 Advantages of VTF Pump PDFCarlos Fernando Roca AkamineNo ratings yet

- Fire Product Systems CatalogueDocument16 pagesFire Product Systems CatalogueDamarys A. Ulloa S.No ratings yet

- Double Suction Split Case Fire Pump: Series 4800Document8 pagesDouble Suction Split Case Fire Pump: Series 4800Carlos EafNo ratings yet

- Section 1520 Data (Diesel Fire Pump)Document8 pagesSection 1520 Data (Diesel Fire Pump)Shoukat Ali ShaikhNo ratings yet

- Fire Pumps Scopes UL-FMDocument34 pagesFire Pumps Scopes UL-FMMiguel Mendoza0% (1)

- Fire Pumps and Pump GroupsDocument44 pagesFire Pumps and Pump GroupsDamarys A. Ulloa S.No ratings yet

- Tab Fire Pump TestingDocument7 pagesTab Fire Pump TestingabdulafoajjawiNo ratings yet

- Armstrong PumpDocument7 pagesArmstrong Pumprogel_ganaNo ratings yet

- Sistema Fire PumpsDocument44 pagesSistema Fire PumpsMohamadIbnuHassanNo ratings yet

- Fire Pump 5 JanDocument4 pagesFire Pump 5 JanMarco CetiNo ratings yet

- Brochure B1500 All Fire PumpsDocument4 pagesBrochure B1500 All Fire PumpsTECHDRILLAND CONSTRUCTION MEXICONo ratings yet

- Fire Pump SelectionDocument13 pagesFire Pump SelectionMarjhel HalligNo ratings yet

- 012 SPP Presentation Oslo 2018Document44 pages012 SPP Presentation Oslo 2018Svetla KolevaNo ratings yet

- FM GuideDocument167 pagesFM Guidemartin.ruben100% (1)

- Pump FirePumps-BDocument12 pagesPump FirePumps-BCARLOS RIAÑONo ratings yet

- Brochure Fire Pumps (B-1500)Document4 pagesBrochure Fire Pumps (B-1500)Eduardo Andres Lagos SotoNo ratings yet

- ATURIA FireFighting 0513-6005E WebDocument12 pagesATURIA FireFighting 0513-6005E Webverat81No ratings yet

- Ruhrpumpen Fire-Systems-Brochure-EN-SG-oct18Document10 pagesRuhrpumpen Fire-Systems-Brochure-EN-SG-oct18jarivillasNo ratings yet

- Fire Alarm System DBRDocument19 pagesFire Alarm System DBRKirty VardhanNo ratings yet

- Cap de BombasDocument11 pagesCap de BombasCarlos Rivera YauliNo ratings yet

- Brochure B1500 All Fire PumpsDocument4 pagesBrochure B1500 All Fire Pumpseng_elbarbaryNo ratings yet

- Design Calculations: Pump Selection and TestingDocument2 pagesDesign Calculations: Pump Selection and TestingEvriMert RüzgArda100% (1)

- Fire Pump PropertiesDocument62 pagesFire Pump Propertiesyamaha100% (2)

- SPP Fire Pumps - General Brochure PDFDocument8 pagesSPP Fire Pumps - General Brochure PDFAhmed El Morsy100% (1)

- Technical Data - Copenhagen Pump PDFDocument146 pagesTechnical Data - Copenhagen Pump PDFPhạm Hoài AnhNo ratings yet

- SIT - Fire Pump Catalog For ApprovalDocument37 pagesSIT - Fire Pump Catalog For ApprovalAob AprilNo ratings yet

- Boletin Bombas Peerless Tisa Seccion 1620 5 Jul 2011Document4 pagesBoletin Bombas Peerless Tisa Seccion 1620 5 Jul 2011cristobal_tl2277No ratings yet

- Submittal 250@8 End SuctionDocument99 pagesSubmittal 250@8 End SuctionAshraf FouadNo ratings yet

- Fairbanks Nijhuis Fire Pumps Brochure, GeneralDocument8 pagesFairbanks Nijhuis Fire Pumps Brochure, GeneralFerdinan Tulus Yones Tobing100% (1)

- Cat. Fairbanks Nijhuis PumpDocument8 pagesCat. Fairbanks Nijhuis PumpYosses Sang NahkodaNo ratings yet

- Firewater Pump PresentationDocument56 pagesFirewater Pump PresentationFredie UnabiaNo ratings yet

- Research - Kirloskar Fire Fighting Pumps PDFDocument8 pagesResearch - Kirloskar Fire Fighting Pumps PDFYogeshNo ratings yet

- Fire Pump Systems Design and SpecificationDocument5 pagesFire Pump Systems Design and Specificationasdج asdNo ratings yet

- Section 1520 Data PDFDocument8 pagesSection 1520 Data PDFJulio César Elías RiveraNo ratings yet

- Dvukhvintovye Nasosy Houttuin Serii 231.50 Prospekt Na Angliyskom YazykeDocument6 pagesDvukhvintovye Nasosy Houttuin Serii 231.50 Prospekt Na Angliyskom Yazykedindin6666No ratings yet

- Fire OfferDocument14 pagesFire OfferaneeshNo ratings yet

- Sec - 320 - Series 475Document7 pagesSec - 320 - Series 475JOSE INESNo ratings yet

- Fire Pump 6 184Document111 pagesFire Pump 6 184Senghy MaoNo ratings yet

- Guide To Fire Protection in Malaysia (2006) - 7. Hose Reel System PDFDocument6 pagesGuide To Fire Protection in Malaysia (2006) - 7. Hose Reel System PDFMFaiz RHamiraNo ratings yet

- External Fire Fighting WorksDocument28 pagesExternal Fire Fighting WorksSaurabh Kumar Sharma100% (1)

- Tib 23 Stationary Fire Pumps Peerless PumpDocument6 pagesTib 23 Stationary Fire Pumps Peerless PumphanloveNo ratings yet

- Marathahalli Project - BlankDocument12 pagesMarathahalli Project - BlankSajad ManjadikkalNo ratings yet

- Specifications - Vertical Turbine Fire PumpsDocument20 pagesSpecifications - Vertical Turbine Fire PumpsFayez Al-ahmadiNo ratings yet

- PWD E/M fire protection scheduleDocument27 pagesPWD E/M fire protection scheduleMdMesbaul HoqueNo ratings yet

- Especificaciones TecnicasDocument20 pagesEspecificaciones TecnicasIsrael GarciaNo ratings yet

- Vertical Turbine Fire Pump Technical SpecificationsDocument20 pagesVertical Turbine Fire Pump Technical Specificationsalberto cardenasNo ratings yet

- FPD 21 e PDFDocument8 pagesFPD 21 e PDFrasheedillikkal100% (1)

- NFPA 20 - Certified Protection Requirements - ExtractionDocument1 pageNFPA 20 - Certified Protection Requirements - ExtractionDiego MorenoNo ratings yet

- Section 1510 SelectionDocument10 pagesSection 1510 SelectionMyat Kyaw HeinNo ratings yet

- Fire Pump SisDocument63 pagesFire Pump SisReggie millerNo ratings yet

- Fire Protection SystemsDocument7 pagesFire Protection SystemsGrundfosEgyptNo ratings yet

- Fire Pump Drive Engine: CFP15E-F20 CFP15EVS-F20Document7 pagesFire Pump Drive Engine: CFP15E-F20 CFP15EVS-F20Jorge Calcaneo MartinezNo ratings yet

- H 010984Document1 pageH 010984Anonymous uKoNmLxkNo ratings yet

- Electrobomba - SPP Products CatalogDocument33 pagesElectrobomba - SPP Products CatalogDennis Walter Ramos TafurNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- SOP 018-12 Issue 3Document5 pagesSOP 018-12 Issue 3Fayez Al-ahmadiNo ratings yet

- Specifications - Vertical Turbine Fire PumpsDocument20 pagesSpecifications - Vertical Turbine Fire PumpsFayez Al-ahmadiNo ratings yet

- Closeout Checklist: Substantial Completion XX/XX/20XX 11-XXXX-000 Closeout #Value! 1.0 AdministrationDocument5 pagesCloseout Checklist: Substantial Completion XX/XX/20XX 11-XXXX-000 Closeout #Value! 1.0 AdministrationFoisulAlamNo ratings yet

- lessons learned reportDocument7 pageslessons learned reportFayez Al-ahmadiNo ratings yet

- Specifications - Vertical Turbine Fire PumpsDocument20 pagesSpecifications - Vertical Turbine Fire PumpsFayez Al-ahmadiNo ratings yet

- 30 Zla0064 000Document1 page30 Zla0064 000Fayez Al-ahmadiNo ratings yet

- Electric Motor CatalogDocument68 pagesElectric Motor CatalogFayez Al-ahmadiNo ratings yet

- Fairbank Vertical TurbineDocument6 pagesFairbank Vertical TurbineKitikhun VichanarksornsitNo ratings yet

- Po 300000003533341 Con-Po-22000008776 0Document4 pagesPo 300000003533341 Con-Po-22000008776 0Fayez Al-ahmadiNo ratings yet

- Vertical Pumps Part 1 Specialist Explains VS1, VS2, VS3 ModelsDocument69 pagesVertical Pumps Part 1 Specialist Explains VS1, VS2, VS3 ModelsFayez Al-ahmadiNo ratings yet

- Con PR 22000006581Document4 pagesCon PR 22000006581Fayez Al-ahmadiNo ratings yet

- NSF/ANSI Certified Submersible Turbine Pump Materials ListDocument1 pageNSF/ANSI Certified Submersible Turbine Pump Materials ListFayez Al-ahmadiNo ratings yet

- 30 Zla0064 000Document1 page30 Zla0064 000Fayez Al-ahmadiNo ratings yet

- STP IOM214FinalDocument28 pagesSTP IOM214FinalFayez Al-ahmadiNo ratings yet

- Vertical Turbine Pump Installation GuideDocument70 pagesVertical Turbine Pump Installation Guideagmibrahim5055No ratings yet

- 31-SAMSS-004 Dec, 24Document45 pages31-SAMSS-004 Dec, 24Fayez Al-ahmadiNo ratings yet

- VTP CatalogDocument8 pagesVTP CatalogPoothares WongchindaNo ratings yet

- Short Set Component PartsDocument1 pageShort Set Component PartsFayez Al-ahmadiNo ratings yet

- Safe Clean Drinking Water Vertical Turbine PumpDocument1 pageSafe Clean Drinking Water Vertical Turbine PumpFayez Al-ahmadiNo ratings yet

- Subs4 6 8 - IOM - 7 2016FINALDocument12 pagesSubs4 6 8 - IOM - 7 2016FINALFayez Al-ahmadiNo ratings yet

- 17 Samss 503Document14 pages17 Samss 503Fayez Al-ahmadiNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerFayez Al-ahmadiNo ratings yet

- 26 Samss 088Document8 pages26 Samss 088Fayez Al-ahmadiNo ratings yet

- Print Work Definition Report - 300000133439714Document11 pagesPrint Work Definition Report - 300000133439714Fayez Al-ahmadiNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument2 pagesInspection & Testing Requirements Scope:: Test and Inspection PerFayez Al-ahmadiNo ratings yet

- ATP Discharge HeadsDocument19 pagesATP Discharge HeadsFayez Al-ahmadiNo ratings yet

- Standard Specification For Castings, Austenitic-Ferritic (Duplex) Stainless Steel, For Pressure-Containing PartsDocument6 pagesStandard Specification For Castings, Austenitic-Ferritic (Duplex) Stainless Steel, For Pressure-Containing PartsFayez Al-ahmadiNo ratings yet

- PN11 - Deluge PumpDocument2 pagesPN11 - Deluge PumpFayez Al-ahmadiNo ratings yet

- Standard Specification For Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationDocument8 pagesStandard Specification For Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, For General ApplicationFayez Al-ahmadiNo ratings yet

- Rheem Classic RrnaDocument44 pagesRheem Classic RrnaRedmanJackieNo ratings yet

- Steam HeaderDocument9 pagesSteam Headervijayanmks100% (1)

- 1082.21.b Body Boiler TH.V 1250 1.250.000kcal.h 1.453 KW Quemadores Chile S.P.ADocument13 pages1082.21.b Body Boiler TH.V 1250 1.250.000kcal.h 1.453 KW Quemadores Chile S.P.Acristian villegasNo ratings yet

- Outstanding Work Orders ReportDocument11 pagesOutstanding Work Orders ReportModyNo ratings yet

- CN3135 Introduction To Loss Prevention 1 (Questions)Document2 pagesCN3135 Introduction To Loss Prevention 1 (Questions)Kiang Teng LimNo ratings yet

- Jacking Oil SystemDocument7 pagesJacking Oil Systemcrespo123456100% (4)

- Nuclear PipingDocument49 pagesNuclear PipingSaravanan RagupathyNo ratings yet

- Production of Power From HeatDocument3 pagesProduction of Power From Heathameed1966No ratings yet

- 4255-Solar Operated ORCDocument5 pages4255-Solar Operated ORCARRI1No ratings yet

- Reheat-Regenerative CycleDocument8 pagesReheat-Regenerative CycleBenjamin MabuteNo ratings yet

- Amity Design LTD - 01.11.2020Document15 pagesAmity Design LTD - 01.11.2020NOMANNo ratings yet

- Calculation sheet for chimney heightDocument3 pagesCalculation sheet for chimney heightDarshan PatelNo ratings yet

- 1998 Sec 6-Turbocharger, Vacuum Pump, Exhaust (Vol 4)Document31 pages1998 Sec 6-Turbocharger, Vacuum Pump, Exhaust (Vol 4)Luis TomboNo ratings yet

- Project ProposalDocument12 pagesProject Proposalredevils90No ratings yet

- Me-323b-Steam Power EnggDocument56 pagesMe-323b-Steam Power EnggPetingco, Jemimah Grace, ME2BNo ratings yet

- Application of ASME Performance Test Codes To Geothermal Plant Performance TestingDocument18 pagesApplication of ASME Performance Test Codes To Geothermal Plant Performance Testingmrizalygani99No ratings yet

- Thermal Engineering (ME 2301) 2 Mark Question and Answers PDFDocument10 pagesThermal Engineering (ME 2301) 2 Mark Question and Answers PDFA.R. Pradeep Kumar89% (9)

- Ee010 306 (Me) Mechanical TechnologyDocument2 pagesEe010 306 (Me) Mechanical TechnologyBrandon AllenNo ratings yet

- A Presentation OF Vocational Training On Combined Cycle Power PlantDocument20 pagesA Presentation OF Vocational Training On Combined Cycle Power PlantramezhosnyNo ratings yet

- Reality Check: Enver Karakas, Elliott Group, Cryodynamic Products, USADocument4 pagesReality Check: Enver Karakas, Elliott Group, Cryodynamic Products, USAptonnelNo ratings yet

- Green, M. A., Et Al. Solar Cell Efficiency Tables (Version 55) .Document13 pagesGreen, M. A., Et Al. Solar Cell Efficiency Tables (Version 55) .gxf980518No ratings yet

- Combustion TheoryDocument30 pagesCombustion TheoryYuvaraj KumarNo ratings yet

- Curva de Rendimiento Blower Lobular 5LDocument1 pageCurva de Rendimiento Blower Lobular 5LEmilio Altamirano CortezNo ratings yet

- Fdocuments - in - Shell Dep ListDocument25 pagesFdocuments - in - Shell Dep Listdeyanshu7No ratings yet

- Steam boiler diagram and parts explainedDocument4 pagesSteam boiler diagram and parts explainedZahid NabiNo ratings yet

- Engineering Learning ModulesDocument158 pagesEngineering Learning Moduleskarthikraja21100% (2)

- Case - Material Stream Feed and Product StreamsDocument8 pagesCase - Material Stream Feed and Product StreamsMohammed GhanemNo ratings yet

- Gas Turbine MCQDocument6 pagesGas Turbine MCQnimymech100% (1)

- Abccomp Corporate Brochure EnglishDocument12 pagesAbccomp Corporate Brochure EnglishnghiaNo ratings yet

- Turbomachinery Centrifugal Pump Design: Progress ReportDocument3 pagesTurbomachinery Centrifugal Pump Design: Progress ReportMay John Jenon BaroyNo ratings yet