Professional Documents

Culture Documents

Civil & Piping Work at Cast House

Uploaded by

Vinayaga MoorthiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Civil & Piping Work at Cast House

Uploaded by

Vinayaga MoorthiCopyright:

Available Formats

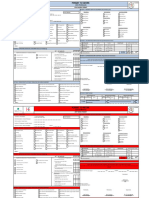

Form No: A-GFS-GHX-15501, Rev 2

Date:27/09/2015

Work Method Statement WMS#:077

(Job Safety & Environmental Analysis)

PRINCIPAL CONTRACTOR : SOHAR ALUMINIUM CONTRACTOR NAME : DOHAT AL KHALEEJ LLC

PO NO : 5500018818 ADDRESS : SOHAR

PHONE : 26701881

WORK LOCATION: Cast house , Sohar Aluminium

CONTRACTOR ABN:

Job Description : Civil and Piping work

PLANNED HIGH RISK CONSTRUCTION ACTIVITY:

Work at Heights (>2.0m) Work on Roof (pitch > 24°) Entering Excavation (1.5m Deep) Using a Confined Space

Using a Hazardous Substance Demolition Work Asbestos Removal Bodily Injury

EMERGENCY ACTION:

In the event of injury is a member of the team First Aid Qualified? YES NO

Point where an injured person may receive treatment: MINOR INJURY: SA Health Centre SERIOUS INJURY: BADR AL SAMA

WORK METHOD STATEMENT DEVELOPED BY: REVIEWED BY THE FOLLOWING PERSONNEL:

No Name Signature Position Ph. No. No Name Signature Position Date.

Mechanical

1 Sureandar Engineer

94292723

2 Sudarsan Kurumboor HSE officer 95121842

3 Karan Kumar Supervisor 9400461

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

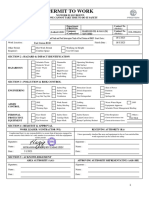

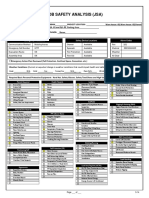

P.P.E REQUIREMENTS PLANT, EQUIPMENT & TOOLS FOR JOB TAGGING & SIGNS PERMITS &

INSTRUCTION

“Check ” “Check ” “Check ” “Check ”

Men Working

Safety Harness SCBA Ladder Excavator MSDS’s

Above

Static Line Airline Hand Tools Winch Barrier Mesh Instruction Manuals

Air Purifying Extension

Steel Capped Boots Shovel Flagging Procedures

Respirator Leads

Welding

Confined Space

Hard Hat Machine for Backhoe Personal Locks Work Instructions

Harness

HDPE

Tinted Safety Personal Danger

Gloves - PVC Compactor Power Source Hot Work Permit

Glasses Tags

Clear Safety Gloves – Hyflex

Drill Fork Lift Out of Service Tags Isolation

Glasses (Nitrile)

Gloves -Leather

Goggles Jack hammer Fans Information Tags Excavation Permit

Riggers

Confined Space

Face Shield Cotton gloves Scaffold Scissor Lift Barricade

Permit

Half filtered dust Authorized Persons General Work

Sun Screen Fire Extinguisher Power Float

mask only permit

Hearing Protection Fire Blanket Keep out

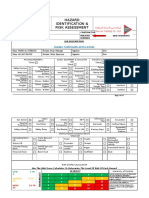

HAZARD PROMPT – Identify the job hazards and assess the RISK personnel may b

e exposed to before safe guards are implemented. Mark as “H” (high), “M” (medium), “L” (low) or “N/A” (or –). DO NOT

LEAVE BLANKS!!

Radiation (Hot SMF or

Electrical M Vehicles M Pressure L Weather L Work / Sun)

M Heat H Asbestos

N/A

Rotating N/A

Chemical N/A Height N/A Access H Bacteria N/A Equipment N/A Dehydration H Engulfment

Tools H Depth L Vibration H Dust H

Moving

H

Hot / Cold

H Lighting N/A

Equipment Objects

Slip / Lifting Overhead Manual

Gasses N/A Weight M Noise M Trip

H Equipment

H hazards

H Handling

H

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

RISK SCORE CALCULATOR

Use the Risk Score Calculator To Determine The Level Of Risk Of Each Hazard

5X5 MATRIX: QUALITATIVE ASSESSMENT

CONSEQUENCE

LIKELIHOOD 1-Minor 2-Medium 3-Serious 4-Major 5-Catastropic

5-Almost Certain Moderate High Critical Critical Critical

4-Likely Moderate High High Critical Critical

3-Possible Low Moderate High Critical Critical

2-Unlikely Low Low Moderate High Critical

1-Rare Low Low Moderate High High

Likelihood Likelihood description Frequency Substance Exposure

Almost Certain Recurring event during the life-time Occurs more than twice per Frequent(daily) exposure at >10XOEL

of an operation. year. (Occupational exposure limit)

Likely Event that may occur frequently Typically occurs once or twice Frequent (daily) exposure at >OEL

during the life-time of an operation. per year.

Possible Event that may occur during the life- Typically occurs in 1 – 10 year. Frequent (daily) exposure at >50% of

time of an operation. OEL

Unlikely Event that is unlikely to occur during Typically occurs in 10 – 100 Frequent (daily) exposure at > 10% OEL

the life-time of an operation. year. Infrequent exposure at > 50% of OEL

Rare Event that is very unlikely to occur Greater than 100 year event. Frequent (daily) exposure at > 10% of

very during the life-time of an OEL

operation. Infrequent exposure at > 10% of OEL

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

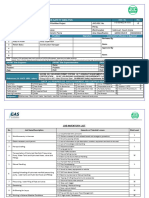

Control Methods & Monitoring

New

No. Work Method Step Hazard / Risk Risk

Risk

Action

Score What hazard safe guards will be used? By

Describe the task step by step What are the hazards of each step? Score

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Obtain GWP and communicate with all

personnel on daily before start the SA/

1 Permit Operational Hazard

work. DAK

Obtain SA Permit To Work.

Discuss Work Method Statement And

Sign On.

Identify area for assembly point before

starting work.

Conduct a Pre- Start Meeting & Hazards Specific To Site Conditions

Conduct A Start Card Briefing With All

2 safe Start card Briefing Based On Assigned Work Location, Area 2x1

Personnel; Discuss All Known And

1x1 All

Layout, and Adjacent Areas

Potential Hazards In And Around Work

Area And Adjacent Areas, Document

Briefing On Start Card, And Ensure All

Personnel Sign The Document

Accordingly.

Use proper PPE.

Ensure The Material Should Only Be

Pinch point.

Stored As Priority Basis.

Moving equipment’s

Proper barricading.

3 Mobilization Manual handling 3x3

New worker To Be Guided to Shift

1x3 DAK

Material in Proper Location, Hand Tool

Should be handled carefully.

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

Control Methods & Monitoring

New

No. Work Method Step Hazard / Risk Risk

Risk

Action

Score What hazard safe guards will be used? By

Describe the task step by step What are the hazards of each step? Score

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Moving Equipment like Canter and Proper Barrication

Pick-up. Proper PPE

Slip/trip hazards Proper handling of materials

Equipment failure Provide the 3 meter distance with

Lack of knowledge in handling of vehicle & equipment’s

4 Shifting of materials

materials.

2x3

Banks man and signboards

1x3 DAK

Pinch point Provide adequate quantity of drinking

Heat stress water and refreshment intermediate

Dust rest

Use proper dust mask

GWP and excavation permit

Use proper PPE

Proper housekeeping

Dust inhalation

Pre use inspection for power tools and

Noise

equipment’s

Hand and finger injury

Swap the employees

Slip/trip hazards

Provide adequate quantity of drinking

Improper access & egress

water and refreshment intermediate

Hazard energy

rest.

Equipment or power tools failure

Isolate the EOT crane if required

5 Breaking the concrete Vibration 5x4

Follow HEC procedures 2x4

DAK

Ergonomics

Maintain proper distance from the line of

Heat

fire

HOT materials area

Follow SA golden rule and Departmental

Hazard energy

LSR.

EOT Crane movement

Maintain distance from the moving

Under suspended load

equipment

Vehicle / equipment movements

Proper barricading and provide

information sign boards.

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

Control Methods & Monitoring

New

No. Work Method Step Hazard / Risk Risk

Risk

Action

Score What hazard safe guards will be used? By

Describe the task step by step What are the hazards of each step? Score

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Use proper PPE.

Sharp edges & Pinch point. Pre check the tools and equipment

Hand & Finger injury Awareness of manual handling.

Injury from tools Strict supervision.

Manual handling. Provide experience worker

Dust Keep the working area clean

Improper tools/equipment Maintain proper access & egress

Poor housekeeping Provide adequate quantity of drinking

Slip/trip hazard water and refreshment intermediate

Heat rest.

6 Installation of piping

HOT materials area

4x3

Isolate the EOT crane if required

2x3 DAK

Hazard energy Follow HEC procedures

EOT Crane movement Maintain proper distance from the line of

Under suspended load fire

Vehicle / equipment movements Follow SA golden rule and Departmental

LSR.

Maintain distance from the moving

equipment

Proper barricading and provide

information sign boards.

Sharp edges & Pinch point. Use proper PPE.

Hand & Finger injury Pre check the tools and equipment

Injury from tools Awareness of manual handling.

Manual handling. Strict supervision.

Dust Provide experience worker

Improper tools Keep the working area clean

7 Plate fixing the top of trench

Poor housekeeping

4x3

Maintain proper access & egress

2x3 DAK

Slip/trip hazard Provide adequate quantity of drinking

Heat water and refreshment intermediate

HOT materials area rest.

Hazard energy Isolate the EOT crane if required

EOT Crane movement Follow HEC procedures

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

Control Methods & Monitoring

New

No. Work Method Step Hazard / Risk Risk

Risk

Action

Score What hazard safe guards will be used? By

Describe the task step by step What are the hazards of each step? Score

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Under suspended load Maintain proper distance from the line of

Vehicle / equipment movements fire

Follow SA golden rule and Departmental

LSR.

Maintain distance from the moving

equipment

Proper barricading and provide

information sign boards.

Unfit personnel Medically fit personnel should perform

Sling/chain collapse the task

No proper access and egress All slings and lifting should be inspected

Persons carelessness before the task

Pinch points Provide the correct access and egress

Slip/trip hazards Person perform the task should be

Simultaneous activities mentally fit

Improper communications Use proper hand gloves

Unprotected sides Access should be cleared

EOT Crane failure Plan activities accordingly

Wrong signal from the rigger Proper communication

Improper tools Use proper PPE and inspect before the

Shifting the equipment by EOT

8

Crane

Line of fire 5x4 task 2x4 DAK

Suspended load EOT Crane inspection need to be done

Heat stress before task

Fatigue Certified rigger to be used

Vehicle movements Third party certificate for operator

Fall of materials All lifting equipment’s should be

Heat calibrated

HOT materials area Use proper tools

Hazard energy Follow SA golden Rule of line of fire and

EOT Crane movement suspended load

Under suspended load Don’t work under suspended load

Vehicle / equipment movements Drink more water and take adequate

rest between the tasks

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

Form No: A-GFS-GHX-15501, Rev 2

Control Methods & Monitoring

New

No. Work Method Step Hazard / Risk Risk

Risk

Action

Score What hazard safe guards will be used? By

Describe the task step by step What are the hazards of each step? Score

How will the effectiveness of the controls be

determined? (Inspection & ongoing monitoring)

Barricade the area properly

Materials to be secured

Provide proper barricade and flag man

Follow HEC procedures

Maintain proper distance from the line of

fire

Follow Departmental LSR.

Maintain distance from the moving

equipment

Proper barricading and provide

information sign boards

Slip/Trip hazard Workers to be guided to shift material in

Pinch point proper Location

9 Demobilize and House keeping Figure injury 3x2 Follow SA golden rules 2x2 DAK

Use proper PPE

IF IT’S NOT SAFE – DON’T DO IT THAT WAY DAK/SA/PROJ 0134/006 REV 00

You might also like

- Installation of Earthing, Lightning Protection System JSADocument2 pagesInstallation of Earthing, Lightning Protection System JSAAsif Hussain100% (1)

- JSA - Sand Blasting and PaintngDocument8 pagesJSA - Sand Blasting and PaintngJohn100% (1)

- Mp1 Type 1 ManualDocument69 pagesMp1 Type 1 ManualJerryNo ratings yet

- Gamma Ray Spectroscopy ExperimentDocument15 pagesGamma Ray Spectroscopy ExperimentLizelleNiit100% (1)

- Diesel Tank StorageDocument4 pagesDiesel Tank StorageyashNo ratings yet

- Blasting & Painting JHADocument8 pagesBlasting & Painting JHADedy Kurniawan100% (1)

- Taoism and The KabbalahDocument26 pagesTaoism and The KabbalahJim Weaver100% (2)

- Assignment 1 (Total Marks: 70) EEE 323: Power System IIDocument2 pagesAssignment 1 (Total Marks: 70) EEE 323: Power System IIShahriar SauravNo ratings yet

- Jsa MV Cable Pulling, Termination and TestingDocument11 pagesJsa MV Cable Pulling, Termination and TestingMohammad AqilNo ratings yet

- Sepcoii II: Job Safety Analysis (J S A)Document8 pagesSepcoii II: Job Safety Analysis (J S A)Abdus SamadNo ratings yet

- JSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020Document6 pagesJSEA Job Safety and Environmental Analysis Format SWMS 2 Oct 2020sarge18No ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- JSA - Low Voltage PanelDocument19 pagesJSA - Low Voltage PanelASLAM MULANINo ratings yet

- 034 - Heavy Plant OperationsDocument6 pages034 - Heavy Plant OperationsKimpoy MarceloNo ratings yet

- Curing Compound ApplicationDocument12 pagesCuring Compound ApplicationyashNo ratings yet

- Welding and Grinding HazardsDocument6 pagesWelding and Grinding HazardsJeremia Samosir100% (2)

- Riyadh Cargo Terminal Project Zamil SteelDocument41 pagesRiyadh Cargo Terminal Project Zamil SteelGhost RiderNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitherdianNo ratings yet

- Cold Work PermitDocument1 pageCold Work PermitherdianNo ratings yet

- PTW Cold&hot All New YisuDocument4 pagesPTW Cold&hot All New YisuUD. Gunung JatiNo ratings yet

- GAS-JGC-SHE-JSA-017 Hydrotesting of Metallic PipeDocument8 pagesGAS-JGC-SHE-JSA-017 Hydrotesting of Metallic PipeRiaz Ali Khan BangashNo ratings yet

- Permit To Work: No Work Is So Urgent That We Cannot Take Time To Do It Safely 0073020Document2 pagesPermit To Work: No Work Is So Urgent That We Cannot Take Time To Do It Safely 0073020maldisaNo ratings yet

- Permit to Work for Hot Work and Confined Space EntryDocument3 pagesPermit to Work for Hot Work and Confined Space EntryIdham ZawawiNo ratings yet

- PTW Sample in RAPIDDocument3 pagesPTW Sample in RAPIDIdham ZawawiNo ratings yet

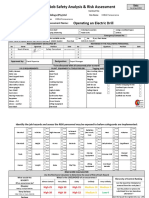

- Job Safety Analysis & Risk Assessment: Operating An Electric DrillDocument6 pagesJob Safety Analysis & Risk Assessment: Operating An Electric DrillH.J KENo ratings yet

- PPM PAGA System 230522Document3 pagesPPM PAGA System 230522Idham ZawawiNo ratings yet

- S-900-1242-022 - 6a - 005 - A4 (Cold Work Permit)Document1 pageS-900-1242-022 - 6a - 005 - A4 (Cold Work Permit)umar saidNo ratings yet

- PTW Form PredsolDocument2 pagesPTW Form PredsolNamig BabazadehNo ratings yet

- PTW Sample To REM WorkDocument3 pagesPTW Sample To REM WorkIdham ZawawiNo ratings yet

- JSA MANUAL EXCAVATION TO INSTALL NEW FIRE WATER LINE & FIRE HYDRANT FOR NEW OME BUILDING 0000Document12 pagesJSA MANUAL EXCAVATION TO INSTALL NEW FIRE WATER LINE & FIRE HYDRANT FOR NEW OME BUILDING 0000thennarasuNo ratings yet

- PTW No 0072429 Permit to Work for Membaiki Lampu FasciaDocument2 pagesPTW No 0072429 Permit to Work for Membaiki Lampu FasciamaldisaNo ratings yet

- PTW SampleDocument3 pagesPTW SampleIdham ZawawiNo ratings yet

- Permit to Work Safety RequirementsDocument3 pagesPermit to Work Safety RequirementsIdham ZawawiNo ratings yet

- PTW Evcavation ENDocument1 pagePTW Evcavation ENATSI HadjilaNo ratings yet

- PPM Inst 4510-Mov-C1-G1Document3 pagesPPM Inst 4510-Mov-C1-G1Naufal MalbarNo ratings yet

- RA 002 - ExcavationDocument8 pagesRA 002 - Excavationsedat.cotNo ratings yet

- Induction FormDocument3 pagesInduction Formnorafikatolah1992No ratings yet

- Installation of Seismic Stoppers and Elastomeric BearingsDocument51 pagesInstallation of Seismic Stoppers and Elastomeric BearingsPlanning C7100% (1)

- RA 003 - Sea Outfall Drainage Pipe InstallationDocument8 pagesRA 003 - Sea Outfall Drainage Pipe Installationsedat.cotNo ratings yet

- JSA Pipping & InstrumentDocument6 pagesJSA Pipping & Instrumentkristina panjaitanNo ratings yet

- JHA 58-A - CML & CIG 4,5 Pump Header & Water Line Modification - DIP2Document3 pagesJHA 58-A - CML & CIG 4,5 Pump Header & Water Line Modification - DIP2cmgent2022No ratings yet

- 3 JSA For SealantDocument11 pages3 JSA For SealantAkbar SyahrezaNo ratings yet

- Job Safety Analysis Work SheetDocument3 pagesJob Safety Analysis Work SheetHaleemUrRashidBangashNo ratings yet

- JSA Welding & GrindingDocument2 pagesJSA Welding & GrindingtaufikNo ratings yet

- JHA BlastingDocument2 pagesJHA BlastingNevin RoldonNo ratings yet

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- CWP Cert PDFDocument4 pagesCWP Cert PDFmurtazagulzar3No ratings yet

- JSA-012-Welding and Gas CuttingDocument2 pagesJSA-012-Welding and Gas Cuttingk dharma100% (1)

- Job Safety Analysis for Fabrication WorkDocument4 pagesJob Safety Analysis for Fabrication WorkAbhi SandiNo ratings yet

- 001 - JSA For Back Filling - TCF AreaDocument5 pages001 - JSA For Back Filling - TCF AreaSalah Abd Eldayem100% (2)

- JHA Dryer Hot CommissioningDocument5 pagesJHA Dryer Hot CommissioningJowel MercadoNo ratings yet

- Job Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisDocument25 pagesJob Safety Analysis Baseline Risk Assessment/ Job Safety AnalysisFaraz KhalidNo ratings yet

- (Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateDocument5 pages(Task Specific Risk Assessment) : No Name Signature Position Date N Name Signature Position DateRavi Shankar TurlapatiNo ratings yet

- Permit To WorkDocument2 pagesPermit To WorkMuhammad HaziqNo ratings yet

- Electrical Works SopDocument1 pageElectrical Works SopmizimahmudNo ratings yet

- Hsse 151 Jsa Flushing Line Piping WCP, Cooking (A.isa)Document5 pagesHsse 151 Jsa Flushing Line Piping WCP, Cooking (A.isa)Suci NurfajriahNo ratings yet

- RA 005 - Formwork, Reinforcement and Concrete Rev 01Document10 pagesRA 005 - Formwork, Reinforcement and Concrete Rev 01sedat.cotNo ratings yet

- Job Safety AnalysisDocument13 pagesJob Safety AnalysisnagarjunaNo ratings yet

- Packing Pumps New - FO-GL-HAL-HSE-0103FDocument4 pagesPacking Pumps New - FO-GL-HAL-HSE-0103FMohamed El-SawahNo ratings yet

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDocument3 pagesR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- SWMS Crane 1711211774Document13 pagesSWMS Crane 1711211774Sarmad AbbasiNo ratings yet

- Hazardous Waste Identification GuidanceDocument105 pagesHazardous Waste Identification GuidanceMiguel TorresNo ratings yet

- SOLAR DRYER v1Document43 pagesSOLAR DRYER v1Maria Angelica Borillo100% (1)

- MR Skin Prick TestingDocument9 pagesMR Skin Prick TestingAyuAnatrieraNo ratings yet

- Hospitality Case StudiesDocument26 pagesHospitality Case StudiesKarthik PalaniswamyNo ratings yet

- Analyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphDocument13 pagesAnalyzing the Effects of Changing the Values of a, b, and c in the Equation of a Quadratic Function on Its GraphRamil NacarioNo ratings yet

- Troubleshooting Directory for LHB Type RMPU EOG AC CoachesDocument44 pagesTroubleshooting Directory for LHB Type RMPU EOG AC Coachesdivisional electrical engg100% (6)

- CCTmanual 56Document226 pagesCCTmanual 56Jim Barrón GarcíaNo ratings yet

- Nireesh Kumar Paidi - Updated ResumeDocument5 pagesNireesh Kumar Paidi - Updated ResumeNikhil Reddy NamreddyNo ratings yet

- African Healthcare Setting VHF PDFDocument209 pagesAfrican Healthcare Setting VHF PDFWill TellNo ratings yet

- Advances in The Study of The Genetic Disorders PDFDocument484 pagesAdvances in The Study of The Genetic Disorders PDFhayamasNo ratings yet

- Fe412farm Module N Cost BenefitDocument34 pagesFe412farm Module N Cost BenefitYaswanth NaikNo ratings yet

- DTP - Digital Transformer ProtectionDocument13 pagesDTP - Digital Transformer ProtectionHBNBILNo ratings yet

- Hydrocarbon ReactionsDocument2 pagesHydrocarbon ReactionsJessa Libo-onNo ratings yet

- 3D Bioprinting From The Micrometer To Millimete 2017 Current Opinion in BiomDocument7 pages3D Bioprinting From The Micrometer To Millimete 2017 Current Opinion in Biomrrm77No ratings yet

- Facts on Timber Engineering and StructuresDocument73 pagesFacts on Timber Engineering and StructuresNaresworo NugrohoNo ratings yet

- Atoms & Ions Worksheet 1 /63: Atomic Number and Mass NumberDocument4 pagesAtoms & Ions Worksheet 1 /63: Atomic Number and Mass Numbercate christineNo ratings yet

- Man and Mystery Vol 13 - Monsters and Cryptids (Rev06)Document139 pagesMan and Mystery Vol 13 - Monsters and Cryptids (Rev06)Pablo Jr AgsaludNo ratings yet

- Viscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Document40 pagesViscous Fluid Flow Ch1-Preliminary Concepts: Kfupm ME 532-172Majid KhanNo ratings yet

- Shell Marine Pocketbook For International MarineDocument60 pagesShell Marine Pocketbook For International MarineGage Cendk HNo ratings yet

- Towards Sustainable Water Management in SoharDocument48 pagesTowards Sustainable Water Management in SoharMiss Preyashi kumarNo ratings yet

- Remote Sensing Mineral Exploration LithiumDocument16 pagesRemote Sensing Mineral Exploration LithiumGerald Darshan MogiNo ratings yet

- 85 KW RequestDocument3 pages85 KW Requestاختر بلوچNo ratings yet

- Footing BiaxialDocument33 pagesFooting BiaxialSanthoshkumar RayavarapuNo ratings yet

- Farha WCM Project-1Document110 pagesFarha WCM Project-1a NaniNo ratings yet

- User Manual For Digital Logic Trainer KitDocument6 pagesUser Manual For Digital Logic Trainer KitHonnura HarijanaNo ratings yet

- Book Review - Water, Ecosystems and Society A Confluence of Disciplines. by Jayanta BandyopadhyayDocument2 pagesBook Review - Water, Ecosystems and Society A Confluence of Disciplines. by Jayanta BandyopadhyayPDNo ratings yet