Professional Documents

Culture Documents

Intze TZNK

Uploaded by

manishaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intze TZNK

Uploaded by

manishaCopyright:

Available Formats

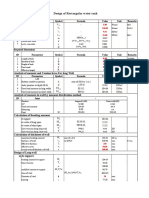

DESIGN OF INTZE TANK

S.No. Element Symbol Formula units Input

Given

# capacity of tank V 75000 GLN 75000.00

liters 340956.75

m3 340.96

# Grade of concrete,M fck 30 N/m2 30000.00

# yield strength of steel fy 500 N/m2 500000.00

# σcbc According to Grade of concrete N/m2 10.00

# σst N/m2 130.00

# σct N/m2 1.30

# σcc N/m2 6.00

#n 0.38

#j 0.87

#k m*σcbc/(m*σcbc+σst) 0.42

#m m=280/(3*σcbc) 9.33

Q 0.5*σcbc*j*k 1.82

1 DIMENSIONS / VOLUME OF TANK

# let dia. Of cylindrical portion of D , D2 round m 9.00

water tank

# dia. Of bottom ring girder D1 0.6D m 5.40

# height of top dome h1 approx D/7 m 1.50

# height of cylindrical tank h2 0.4D m 3.60

# height of conical shell h3 0.2D m 1.80

# height of bottom spherical dome h4 0.143D m 1.50

# Radius of top spherical dome R SQ.RT.(0.386D) m

# R2 R2= ((D1*D1)/4)+(h4*h4))/(2*h4) 3.18

Radius of bottom spherical dome

# Volume of tank v D=(V/0.374)pow.1/3 m 9.67

# h m 3.60

asume height of cylindrical tank wall

# Actual Volume of tank V V= v1+v2-v3 m3 480.08

v1 v1=(0.785*D*D*h2*) 228.91

v2=(0.785*h3*((D*D)+(D1*D1)+

v2 (D1*D2)) 270.11

v3=(((3.14*h4*h4)/3)*(3R2-h4))

v3 18.93

2 DESIGN OF TOP DOME

# Radius of spherical dome R1 R1= ((D*D)/4)+(h1*h1))/(2*h1) m 7.50

# Semi central angle ϴ ϴ=sin-1((D/2)*R1) 36.87

cos ϴ 0.80

# let thickness of dome t mm 100.00

m 0.10

# self weight KN/m2 3.00

# live load KN/m2 1.50

# total load T.L KN/m2 4.50

# say with fininshing load W KN/m2 4.50

# meridional thrust T1 T1=W*R1*(1/(1+cosϴ)) KN/m 18.75

# meridional stress T1/t N/mm 0.19

# circumferential force T2 T2=W*R1*(cosϴ-(1/(1+cosϴ))) KN/m 8.26

# circumferential stress T2/t N/mm 0.08

T1 and T2 should be less than 6

N/mm2

provide nominal reinforcement of

# 0.3%in circumferential and radial Ast Ast=((0.3/100)*t*1000) mm2 300.00

dirtections

# Dia of Steel bars ɸ mm 10.00

# Area of bar Aɸ 0.785*ɸ*ɸ mm2 78.50

# Spacing S S=(Aɸ/Ast)*1000 mm 261.67

DESIGN OF TOP RING ( BEAM A-A )

3

# Hoop tension H.T H.T=T1*COSϴ*(D/2) KN 67.51

# steel area Ast Ast=(H.T/σst)*1000 mm2 519.30

# steel bars no. provide no. no. 6.00

# Dia of Steel bars ɸ mm 16.00

# Ast provided Aɸ no.*(0.785)*ɸ*ɸ mm2 1205.76

# permissible value of concrete Pc N/mm2 1.30

# provide

Area of concrete

size Ac Ac =((H.T*1000)/Pc)-((m-1)*Aɸ) mm2 41882.13

# l asume mm 250.00

b asume mm 250.00

# actual area A mm2 62500.00

# Dia of Steel bars ɸ mm 16.00

# steel bars no. provide no. no. 6.00

DESIGN OF CYLINDRICAL TANK

4 WALL

P P=9.810*h KN 35.32

Pressure intensity at bottom of tank

# Hoop tension at base of tank H.T H.T=P*D/2 KN 158.92

# steel area Ast Ast=(H.T/σst)*1000 mm2 1222.48

# Dia of Steel bars ɸ mm 10.00

# Ast provided Aɸ no.*(0.785)*ɸ*ɸ mm2 78.50

# Spacing S S=(Aɸ/Ast)*1000 mm 64.21

Spacing provided Sp mm 100.00

mm2/m

# Ast provided Aɸ 2*(0.785)*ɸ*ɸ*(1000/σst) height 1570.00

# permissible value of concrete Pc N/mm2 1.30

mm2/m

# Area of concrete Ac Ac =((H.T*1000)/Pc)-(m*Aɸ) height 109164.36

Thickness of tank required mm 109.16

# let thickness of wall t mm 200.00

# percentage of distribution steel p p=0.3% % 0.30

# area of distribution steel A A=(p/100)*t*1000 mm2 600.00

# area of distribution steel required Ar A/2 mm2 300.00

on each face

# Dia of Steel bars ɸ mm 10.00

# Ast provided Aɸ (0.785)*ɸ*ɸ mm2 78.50

# Spacing S S=(Aɸ/Ar)*1000 mm 261.67

CHECK FOR COMPRESSIVE STRESS

ON TANK WALL

Vertical Component on wall(load of V1 T1*sinϴ KN 11.24

top Dome)

Weight of wall per meter W t*h2*25 KN 18.00

Wb l*l*25 KN 1.56

Weight of Top ring beam per meter

Total Weight V2 V1+Wb+W kN 30.81

Total Compressive Stress V2/(t*1000) N/mm2 0.15

The compressive stress in very less

therefore mimimum steel of 0.3% as

provided is safe

DESIGN OF BOTTOM RING BEAM (B-

5 B)

let width and depth b' mm 600.00

l' mm 350.00

# self weight of ring beam l4 l4=l'*b'*1*25 KN/m 5.25

# total load V.L=V1+W+Wb+V2+l4 KN 36.06

# a tan-1(h3/((D-D1)/2)) degree 45.00

Slope of conical dome with vertical

# hoop tension due to this load H1 H1=V1*tana*(D/2) KN 162.12

# H.P H.P=9.800*h*(D/2) KN 158.76

hoop tension due to water pressure

# total hoop tension in the beam T.H T.H=H1+H.P KN 320.88

# Provided steel Ast Ast=(H.P*1000)/σst mm3 2468.34

# steel bars no. provide no. no. 8.00

# Dia of Steel bars ɸ mm 20.00

# Ast provided Aɸ no.*(0.785)*ɸ*ɸ mm2 2512.00

# permissible value of concrete Pc N/mm2 1.30

mm2/m

# Area of concrete Ac Ac =((H.P*1000)/Pc)-((m-1)*Aɸ) height 101189.74

Provide 1200 mm and 600 mm 210000.00

beam

# Dia of Steel bars ɸ mm 25.00

# Ast provided Aɸ (0.785)*ɸ*ɸ mm2 490.63

# Spacing S S=(Aɸ/Ar)*1000 mm

(D-D1)/2 1.80

6 DESIGN OF CONICAL DOME

# Total load from cylindrical wall T.l T.l=V1*3.14*D KN

# Weight of water Wȣ Wȣ=V*9800

Area of water section standing on 0.5*(2h2+h3)(D-D1)/2=(area of

Aw trap) m2 8.10

conical slab

(((h2+h3)+(2*h2))/

x (2h2+h3))*(0.5*(D-D1)/3) m 0.84

CG of water section

Weight of water resting on conical Ww 9.81*Aw*2*3.14*(0.5*D1+x) kN 2455.15

slab

0.71

3.24

S.L=SQRT((((D-D1)/2)pow,2)+

# slanting length S.L ((h3)pow,2)) m 1.99

# Dia. At mid-height D.T D.T=(D+D1)/2) m 7.20

# assuming thickness t ts mm 350.00

# Total load of conical slab ws ws=3.14*ts*S.L*l*fck KN 392.94

((Ww+Ws)/2*3.14)+Ww*tan a

Hoop Tension /2*3.14

((Ww+Ws)/2*3.14) 453.52

Ww*tan a /2*3.14 390.64

((Ww+Ws)/2*3.14)+Ww*tan a

/2*3.14 844.16

Hoop Tension

Hoop Steel Hoop Tension/σst 6493.50

# area of steel on each face Ar Ast/2 mm2 3246.75

# Dia of Steel bars ɸ mm 20.00

# Ast provided Aɸ (0.785)*ɸ*ɸ mm2 314.00

# Spacing S S=(Aɸ/Ar)*1000 mm 96.71

Design for bending moment

Load per meter width of the conical

slab Ls (Ww+Ws)/(2*3.14*D.T.) 62.99

Maximum Bending Moment Ls*((D-D1)/2)/8 14.17

Axial compression T2 V2/sina 43.58

Effective Depth in Slab Deff ts-cov=ts-35 315.00

DESIGN OF BOTTOM SPHERICAL

9 DOME

# Central rise c m 1.50

# Radius of the dome R2 R2= (((D1*D1)/16)-1) m 3.18

# angle ϴ2 ϴ2=sin-1((D1/2)/R2) degree 25.12

# let thickness of dome t 250.00

# then self weight w' w'=t*25 KN/m2 6.25

Ww=(0.785*D1*D1*(h+h4)-

# Weight of water Ww ((3.14/3)*h4*h4*(3R2-h4))*9.8 KN 1026.86

# Total load TL TL=w'+Ww KN 1033.11

Area of Dome Surface Ad 2*3.14*R2*c 29.96

# Load per unit area L.U L.U=TL/Ad KN/m2 34.49

Total Load intensity on bottom w'+LU 40.74

dome

# T' T'=(w'+LU)*R2/(1+cosϴ2) KN/m 67.99

Meridonial thrust at springing level

# Meridional stress M.S M.S=(T'*1000)/(t*1000) N/mm2 0.27

# percentage Min. Reinforcement p p=0.3% 0.30

provided

# Min. Reinforcement provided Ast Ast=(p/100)*t*1000 mm2 750.00

Ast on each face Ar Ast/2 mm2 375.00

# Dia of Steel bars ɸ mm 10.00

# Ast provided Aɸ (0.785)*ɸ*ɸ mm2 78.50

# Spacing S S=(Aɸ/Ar)*1000 mm 209.33

#

#

# DESIGN OF BOTTOM RING GIRDER

Total weight of water V*9.81 KN 4704.79

10 Weight of top wall and dome 3.14*D*V2 kN 870.59

Weight o conical wall kN 392.94

# Weight of lower dome w'*Ad 187.22

# Assume width of girder bg 400.00

# Assume length of girder lg 600.00

self weight sw sw=lg*bg*25*3.14*D1 KN/m 101.74

Total vertical load TV TV=VI+sw KN/m 6257.28

The girder is support on columns col. 8.00

# angle ɸ ɸ=360/col.

# MAX. shear force S.F S.F=TV/(2*col.) KN 391.08

# support moment S.M S.M=0.0083*TV*D1/2 KN-m 140.23

# Mid-Span moment Msm Msm=0.00416*TV*D1/2 KN-m 70.28

# MAX. torsional moment Mtm Mtm=0.0006*TV*(D1/2) KN-m 10.14

#

# Design moment D.M D.M=max. moment KN-m 140.23

Depth Reqd d=sqrt(1000000*M/Q*1000) mm 277.41

D=d+cov=d+34 mm 312.41

Depth provided mm 600.00

Effective Depth

# Equivalent Sheat Force V V=S.F+Mtm*1.6/bg KN 431.63

Equivalent Nominal Shear Stress τv τ v=(Vu*1000)/(lg*bg) N/mm2 1.80

τ v shouldbe less than τ c , then it is

# safe

Permissible shear stress is 2.2 N/mm2 as per Table 24 of IS 456-2000

Hence nominal shear reinforcement

can be provided to take care of

shear.

#

# Equivalent

Bending moment reduces M M=S.M-sw KN-m

# Mu Mu=1.5*M KN-m

# Tu Tu=1.5*Mtm KN-m

# Me Me=Mu+Tu*((1+(l'/b'))/1.7) KN-m

# Shear reinforcement Ast Ast=Aɸ mm2

# p p=(Ast/(b'*l'))*100

# τc N/mm2

τ c from, table 19 of IS: 456-2000

# Vus Vus=Vu-(τ c-b*d) N

# Using no. legged stirrups no. 4.00

# dai of bar ɸ mm 12.00

# Ast provided Asv Asv=no.*(0.785)*ɸ*ɸ mm2

# Spacing Sv Sv=(0.87*fy*Asv*d)/Vus mm

# Side face reinforcement Asr Asr=(0.1/100)*b'*l' mm2

# provide bars no.

# dai of bar ɸ mm

# Net horizontal thrust Ph Ph=(Tc*sinθ)-(T2*cosθ) KN/m

# Hoop compression H.C H.C=Ph*(D1/2) KN

# Direct compression in concrete Dc Dc=(H.C*1000)/(b'*l') N/m2

#

# Hence safe

#

0.80019569

(on each face)

10.3399703

You might also like

- Zn-Al Tank-175kL Design 12M STAGING - SMTDocument63 pagesZn-Al Tank-175kL Design 12M STAGING - SMTRajendra MittalNo ratings yet

- Areva T& D India Limited: Design of Circular Sump Input DataDocument2 pagesAreva T& D India Limited: Design of Circular Sump Input DatajatinNo ratings yet

- 10klglr DesignokDocument17 pages10klglr DesignokRajkumar PritimaniNo ratings yet

- Design of Overhead Intz tank with 150,000 litre capacityDocument22 pagesDesign of Overhead Intz tank with 150,000 litre capacityshivanandarcotNo ratings yet

- Intake Structure DesignDocument4 pagesIntake Structure DesignSripara KrishnaNo ratings yet

- Design of Moment Connection 2Document2 pagesDesign of Moment Connection 2gops1963No ratings yet

- Intze Tank-175kL Design 18M STAGING BASI BLOCK - SMTDocument55 pagesIntze Tank-175kL Design 18M STAGING BASI BLOCK - SMTRajendra MittalNo ratings yet

- Reference BS 449 Part 2: Design of Moment Connection Flush End Plate Moment ConnectionDocument2 pagesReference BS 449 Part 2: Design of Moment Connection Flush End Plate Moment ConnectionMazenMowafyNo ratings yet

- Design of 3000mm MS Pipe for Sewerage NetworkDocument9 pagesDesign of 3000mm MS Pipe for Sewerage Networknavneet3bawaNo ratings yet

- Moment Conn-FlDocument2 pagesMoment Conn-Flmahmoud Ibrahem100% (1)

- Covered Drain Design Calculations for Service RoadDocument1 pageCovered Drain Design Calculations for Service RoadKS LeeNo ratings yet

- Design CalculationDocument28 pagesDesign CalculationParth GandhaNo ratings yet

- Design of 1.50KL OH Tank 9M Staging PDFDocument21 pagesDesign of 1.50KL OH Tank 9M Staging PDFshivanandarcotNo ratings yet

- Isolated-Tappered With Actual SurchargeDocument1 pageIsolated-Tappered With Actual SurchargeAnil kumar RNo ratings yet

- Design of Square Footing for Column LoadDocument1 pageDesign of Square Footing for Column LoadZaidNo ratings yet

- 45 - Design of Thrust Block HorizontalDocument2 pages45 - Design of Thrust Block HorizontalShivkumar PujariNo ratings yet

- BeamDocument2 pagesBeamWintun73No ratings yet

- CWR600KLDocument22 pagesCWR600KLArse AbiNo ratings yet

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Document1 pageDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemNo ratings yet

- DESIGN OF FLOOR SLAB (0.15m Thick)Document9 pagesDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Genset Pad 10ftx2ftDocument7 pagesGenset Pad 10ftx2ftAmmad AlizaiNo ratings yet

- Design Concrete Box CulvertsDocument9 pagesDesign Concrete Box CulvertsSUPERINTENDING ENGINEER100% (1)

- Calculos Torre de AireacionDocument8 pagesCalculos Torre de AireacionMonica Alexandra Rueda RamirezNo ratings yet

- Pipe splicing calculation dimensions and capacitiesDocument2 pagesPipe splicing calculation dimensions and capacitiesAnonymous ZMLlQvBopNo ratings yet

- Concrete Cover DesignDocument2 pagesConcrete Cover DesignScribdTranslationsNo ratings yet

- TimeSheet Calculator TrumpExcelRevised 2017 v1Document50 pagesTimeSheet Calculator TrumpExcelRevised 2017 v1RAJNo ratings yet

- Strap FotingDocument22 pagesStrap FotingDAWITNo ratings yet

- Design of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit RemarksDocument5 pagesDesign of Rectangular Water Tank: SN Design Parameters Symbol Formula Value Unit Remarkskiran_karki_8No ratings yet

- Project:-Date: - Description: - By:-: Dimension MaterialDocument2 pagesProject:-Date: - Description: - By:-: Dimension MaterialMustefa Mohammed AdemNo ratings yet

- Eccentric Footing by WS PDFDocument10 pagesEccentric Footing by WS PDFThirumaleshNo ratings yet

- Foundation and Column 13ftx5ftDocument17 pagesFoundation and Column 13ftx5ftAmmad AlizaiNo ratings yet

- Composite Slab Deck ACI318Document4 pagesComposite Slab Deck ACI318jflttwNo ratings yet

- Calc Leg Check of Cross BracingDocument4 pagesCalc Leg Check of Cross Bracingdinesh_akabariNo ratings yet

- Abusag Bridge Sheet Pile CalculationDocument20 pagesAbusag Bridge Sheet Pile CalculationRolly Marc G. SoteloNo ratings yet

- Summary of Structural Calculation of 1-Barrel Box Culvert: 1 Design Dimensions and Bar Arrangements #N/ADocument37 pagesSummary of Structural Calculation of 1-Barrel Box Culvert: 1 Design Dimensions and Bar Arrangements #N/ATonny SuakNo ratings yet

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78No ratings yet

- ESR ST - DesignDocument33 pagesESR ST - DesignTarkeshwar Lal SrivastavaNo ratings yet

- Abut. Screen WallDocument17 pagesAbut. Screen WallAakash RastogiNo ratings yet

- Sump .XLS (7.00 Lakhs)Document58 pagesSump .XLS (7.00 Lakhs)subramanyam kumarNo ratings yet

- Sump .Xls (7.00 Lakhs) - 1Document38 pagesSump .Xls (7.00 Lakhs) - 1subramanyam kumarNo ratings yet

- Proposed 1450 KL RCC Ground Level Service ReservoirDocument35 pagesProposed 1450 KL RCC Ground Level Service Reservoirsubramanyam kumarNo ratings yet

- Sump .XLS (1.50 Lakhs)Document55 pagesSump .XLS (1.50 Lakhs)subramanyam kumarNo ratings yet

- Sump .Xls (1.00 Lakhs) - 1Document35 pagesSump .Xls (1.00 Lakhs) - 1subramanyam kumarNo ratings yet

- Intze Tank-50kL Design 18M STAGING - SBC 8TON PER SMTDocument53 pagesIntze Tank-50kL Design 18M STAGING - SBC 8TON PER SMTRajendra MittalNo ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- AK Consultant,: Indian School DarsaitDocument44 pagesAK Consultant,: Indian School DarsaitBehroozNo ratings yet

- Design ExamplesDocument42 pagesDesign ExamplesARSENo ratings yet

- DESIGN OF CANTELEVER RETAINING WALLDocument4 pagesDESIGN OF CANTELEVER RETAINING WALLayan khanNo ratings yet

- STP Design SheetsDocument86 pagesSTP Design Sheetskiran raghukiran100% (1)

- STP Design Sheets D PochampallyDocument121 pagesSTP Design Sheets D Pochampallykiran raghukiranNo ratings yet

- Wind OpeartingDocument3 pagesWind OpeartingrichardchiamNo ratings yet

- Underground fuel tank structure design and load calculationsDocument4 pagesUnderground fuel tank structure design and load calculationsChanNo ratings yet

- RCC retaining wall design calculationsDocument5 pagesRCC retaining wall design calculationsAmit KushwahaNo ratings yet

- New Bridge Centre, BLK 336, Smith Street # 0 6 - 3 0 5, S I N G A P O R E 0 5 0 3 3 6Document1 pageNew Bridge Centre, BLK 336, Smith Street # 0 6 - 3 0 5, S I N G A P O R E 0 5 0 3 3 6ThaungMyintNo ratings yet

- 07 Steel Lagging PDFDocument1 page07 Steel Lagging PDFThaungMyintNo ratings yet

- Rectangular Water TankDocument4 pagesRectangular Water TankRAYEES NABI NAQASHBANINo ratings yet

- Circular Baseplate Bolt ForcesDocument6 pagesCircular Baseplate Bolt ForcesRagavanNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- GeM-Bidding-6242003Document6 pagesGeM-Bidding-6242003manishaNo ratings yet

- GeM Bidding 4405839Document5 pagesGeM Bidding 4405839Kartik RajputNo ratings yet

- GeM Bidding 4654483Document5 pagesGeM Bidding 4654483bharatiya technologyNo ratings yet

- GeM Bidding 4654483Document5 pagesGeM Bidding 4654483bharatiya technologyNo ratings yet

- Worked Example - Retaining Wall Design - The Structural WorldDocument14 pagesWorked Example - Retaining Wall Design - The Structural WorldmanishaNo ratings yet

- Ikby Uhao DH Fmt+Kkbu VKSJ Fuekz.K JHFR Lafgrk: HKKJRH EkudDocument17 pagesIkby Uhao DH Fmt+Kkbu VKSJ Fuekz.K JHFR Lafgrk: HKKJRH EkudSumit OmarNo ratings yet

- SJ-20160119164028-015-ZXR10 5960 Series (V3.02.20) All 10-Gigabit Data Center Switch Configuration Guide (IDC)Document127 pagesSJ-20160119164028-015-ZXR10 5960 Series (V3.02.20) All 10-Gigabit Data Center Switch Configuration Guide (IDC)keslleyNo ratings yet

- The Essential Building Blocks of E2E Network SlicingDocument11 pagesThe Essential Building Blocks of E2E Network Slicingyadav_dheeraj19815No ratings yet

- Financial DistressDocument9 pagesFinancial Distressvierya_ableNo ratings yet

- MRI ScriptDocument1 pageMRI ScriptPeter BolocelliNo ratings yet

- Bascom Avr Demonstration BoardDocument8 pagesBascom Avr Demonstration BoardNitish KumarNo ratings yet

- Kozyrev - Aether, Time and Torsion - Divine CosmosDocument1 pageKozyrev - Aether, Time and Torsion - Divine Cosmospaulsub63No ratings yet

- Thin-Walled - Thick Walled Pressure VesselDocument16 pagesThin-Walled - Thick Walled Pressure VesselMark Niño JavierNo ratings yet

- BBS Model Question 2020Document44 pagesBBS Model Question 2020JALDIMAINo ratings yet

- Checklist Design ReviewDocument2 pagesChecklist Design Reviewmuhannad11061975100% (1)

- Image Classification Using CNN: Page - 1Document13 pagesImage Classification Using CNN: Page - 1BhanuprakashNo ratings yet

- ChlorantraniliproleDocument3 pagesChlorantraniliproleLaura GuarguatiNo ratings yet

- Unit 1 Modern ProcessorsDocument52 pagesUnit 1 Modern ProcessorsSudha PalaniNo ratings yet

- The Cost of Uncertainty For Nitrogen Fertilizer Management: A Sensitivity AnalysisDocument8 pagesThe Cost of Uncertainty For Nitrogen Fertilizer Management: A Sensitivity AnalysisSha-ReeNo ratings yet

- Drowsy Driving A Look at The Monitoring and Detection SystemDocument4 pagesDrowsy Driving A Look at The Monitoring and Detection SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Answers To Exercises and Review Questions: Part Three: Preliminary AnalysesDocument10 pagesAnswers To Exercises and Review Questions: Part Three: Preliminary Analysesjhun bagainNo ratings yet

- PBE 5AC Series - DS PDFDocument11 pagesPBE 5AC Series - DS PDFtravieso112No ratings yet

- NS 6145 Laser and LightDocument69 pagesNS 6145 Laser and LightMeesixNo ratings yet

- Discrete Random Variables: Scott She EldDocument16 pagesDiscrete Random Variables: Scott She Eldjokydin92No ratings yet

- Methods of Analysis and Solutions of Crack ProblemsDocument562 pagesMethods of Analysis and Solutions of Crack ProblemsgedysonlimaNo ratings yet

- Cambridge Lower Secondary Checkpoint: Anisah AbdulssalamDocument20 pagesCambridge Lower Secondary Checkpoint: Anisah AbdulssalamAnisahNo ratings yet

- GIS in Physical PlanningDocument7 pagesGIS in Physical PlanningGianni GorgoglioneNo ratings yet

- Sky TowerDocument19 pagesSky TowerAlcohol You LaterNo ratings yet

- Terminal Block Diaphragm Switch: D1T, D2T SeriesDocument2 pagesTerminal Block Diaphragm Switch: D1T, D2T Serieschris a gutierrexNo ratings yet

- Current Pillar DesignDocument24 pagesCurrent Pillar DesignjmgumbwaNo ratings yet

- Deep Learning For Environmentally Robust Speech Recognition - An Overview of Recent Developments PDFDocument28 pagesDeep Learning For Environmentally Robust Speech Recognition - An Overview of Recent Developments PDF福福No ratings yet

- MongoDB Update One or More Fields of One or All DocumentsDocument1 pageMongoDB Update One or More Fields of One or All DocumentsYusto Malik Omondi100% (1)

- Physics ART INTEGRATED PROJECTDocument24 pagesPhysics ART INTEGRATED PROJECTPRATHAM BANSAL67% (3)

- Digital Assignment - 1: 1. National - Holiday With 3 Instance Variables Name, Day, and Month IsDocument14 pagesDigital Assignment - 1: 1. National - Holiday With 3 Instance Variables Name, Day, and Month IsSanjanesh Ganesh100% (1)

- Queue Tree QoS for Multiple InterfacesDocument13 pagesQueue Tree QoS for Multiple InterfacesTony Cervantes0% (1)

- PCCP Thickness DesignDocument11 pagesPCCP Thickness DesignArmand Mikhail G. TempladoNo ratings yet