Professional Documents

Culture Documents

Weekly HSE Report - FEB UGP

Uploaded by

usmancustOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weekly HSE Report - FEB UGP

Uploaded by

usmancustCopyright:

Available Formats

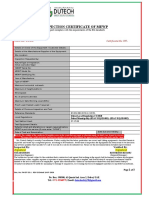

ABDULLAH A.

AL-BARRAK & SONS

COMPANY

Rev. No: 01 OCCUPATIONAL HEALTH AND SAFETY Doc. No. OHSEM/F-58

14-Mar-21 MANAGEMENT SYSETM Page 1 of 1

Weekly HSE REPORT

Project Name: UGP T&I - 2024

Company Name: Saudi Aramco

HSE Representative: Mouad Abdelouahed Email: mouad@abis.com.sa

Mobile No: 542770251 Contract Number:

Site Location : UGP : SRU3 GT3

DATE From 2/2/2024 to 8/2/2024 Shift: Day/Night shift

Expired POs Status : Valid

1.SHE Performnace Abbrev. This week To Date

FAT FAC MTC LTI

Safe Manhours SMH 15824 126592

Fatalities FAT 0 0 RWC RWD LWD MVA

First Aid Cases FAC 0 0

Medical Treatment Case MTC 0 0

Lost Time Injuries LTI 0 0

Restricted Work Cases RWC 0 0

Restricted Work days RWD 0 0

Lost Work Days LWD 0 0

Motor Vehicle Accident MVA 0 0

2.Tool Box Talk

Topic Remarks

Number of TBT: 14 Topics covered all the activities on site during this week

Corrected/

3.Nearmiss/Observation Abrev. Obsereved Observed Corrected/Reported

Reported

unsafe Act USA 12 12 15

unsafe conditions USC 6 6

Nearmisses NMS 1 1 10

Total Recordable AccidentsTRA 0 0

Traffic Violations TV 0 0 5

Work permit violation WPV 3 3

Safe life access validity SLAV 0 0 0

USA USC NMS TRA TV WPV SLAV

4. Permit Audit

Total No of

Permits Remarks

Type of Permit Audited

Hot work Permit 73

Confined Space Permit 13

Cold Work Permit 13

EOLB Permit 0

PW Audit 100

Trainings 1 Basic safety electricity training

Safety Inspection/Meeting 2 GT Store/FE Monthly inspection

5. HSE Incident Rates

TRIR FR SR LTIR

Total recordable incident

Frequency Rate Severity Rate Lost Time Injury Rate

rate

0 0 0 0

TRIR FR SR LTIR

0 0

0 0

Corrective /Mitigation actions

1✅.Monthly physical inspection was conducted on all FE in site/2✅.Raising the awareness regarding scaffolding

safety practices, Hydrotest, Electrical Safety, the importance of PTW through TBT sessions and Safety training and pre

job meetings/3✅.Complete House keeping was maintained to sru3 area/4✅.An inspection was conducted in the GT

store appropriate segregation was implemented to all damaged equipment with a do not use tag -8Air horns were

removed and one manifold was without certification , weekly checks to power tools such as grinders discs RPM and

physical conditions,Safety harnesses without suspension trauma straps were changed /5✅.Replacement of

damaged hoses and grounding wires/6✅. Stand safety boards were provided as per the LPD client requirement/7✅.

Vaccum tanker for the toilet was changed as per LPD client requirement/8✅.A Scaffold was erected to water tanker

of the washroom to provide safe access in case of filling the tanker instead of using ladder as per LPD advise./9✅.

All weekly USA,USC, NMS,WPV were reported and corrected and discussed on daily TBT To make sure it doesn't

happen again.

7. HSE Suggestions

1.Safety stand signboard

Safety signboards are the image of the company, In order to preserve the company`s image and reputation we

advise as follows:1.Standboard sign should be at least 1.5 M height and free from any damage or Impurities nor

should be attached to any wooden/paper board. 2. Three languages are required on safety signs English-Arabic-

Urdu as per the clinet requirement. 2 An

appreciation and recognition letter shall be issued to employees with the best commitment to safety and best safety

practice in the workplace to encourage all employees to make safety as their first priority in all actitvites and to

promote a positive safety culture in the workplace after the finish of every shutdown or on monthly basis.

You might also like

- Daily HSE Report (020524) NightDocument2 pagesDaily HSE Report (020524) NightusmancustNo ratings yet

- Daily Safety Report: No. Doc. Tgl. Terbit F-030 01.01.20 Rev. Halaman 06 1 Dari 5Document175 pagesDaily Safety Report: No. Doc. Tgl. Terbit F-030 01.01.20 Rev. Halaman 06 1 Dari 5hsse pdsi.51No ratings yet

- 49-JCPDI I-2004 - Contractor Weekly SHE Statistics Report (AutoRecovered)Document2 pages49-JCPDI I-2004 - Contractor Weekly SHE Statistics Report (AutoRecovered)zubair khanNo ratings yet

- DKT0/2020/J5110: Ships in Service Survey ReportDocument26 pagesDKT0/2020/J5110: Ships in Service Survey ReportLeonidas Galanis100% (1)

- PM of LT MotorDocument2 pagesPM of LT Motordevraj.singh133No ratings yet

- Weekly Report ExampleDocument3 pagesWeekly Report Examplewawan setiawanNo ratings yet

- Certificate of Examination and Test of Engine Generator: Certificate No.:DG/C1 Job No.: ASC-18N-0262Document2 pagesCertificate of Examination and Test of Engine Generator: Certificate No.:DG/C1 Job No.: ASC-18N-0262RavijNo ratings yet

- Ep Wells Daily Operations Report: Event SummaryDocument5 pagesEp Wells Daily Operations Report: Event Summarymohamed gadallahNo ratings yet

- United Caravan Trading and Contracting (Oil & Gas Division) : Initial Equipment Inspection ReportDocument1 pageUnited Caravan Trading and Contracting (Oil & Gas Division) : Initial Equipment Inspection Reportfali2006No ratings yet

- 55-1 MewpDocument3 pages55-1 MewpAkhilNo ratings yet

- Daily Safety Inspection ChecklistDocument2 pagesDaily Safety Inspection Checklistarunjith r0% (1)

- International LTD: Report of Thorough ExaminationDocument1 pageInternational LTD: Report of Thorough ExaminationChisom IkengwuNo ratings yet

- Weekly HSE Report Format.Document2 pagesWeekly HSE Report Format.Binay100% (5)

- Weekly HSE ReportDocument2 pagesWeekly HSE ReportBinay75% (8)

- Generic Safety Checklist: Truck Mounted CraneDocument3 pagesGeneric Safety Checklist: Truck Mounted Cranepawan pandeyNo ratings yet

- Procedure For Manual Ultrasonic Testing PDFDocument17 pagesProcedure For Manual Ultrasonic Testing PDFbaskaran ayyapparaj100% (2)

- MD 04 MT Rssta PD 509Document13 pagesMD 04 MT Rssta PD 509Nguyễn Đặng LâmNo ratings yet

- SOM 6.1 D3 Chief Officer Handover Report Rev 0.0Document3 pagesSOM 6.1 D3 Chief Officer Handover Report Rev 0.0Amit BhadauriaNo ratings yet

- PDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Document255 pagesPDB PTW 2019 Ra and WL Vol. 1 10-11 Nov 2020Syed AmzarNo ratings yet

- Safety Check List - Marine SafetyDocument8 pagesSafety Check List - Marine SafetyRaphael SantosNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- Inspection Report: QETO/IR/SUD/104) and Following Are The ObservationDocument2 pagesInspection Report: QETO/IR/SUD/104) and Following Are The Observationsudipta dasNo ratings yet

- Hse KpiDocument9 pagesHse KpifaizanNo ratings yet

- Weekly Report W-3 HSE PT. AWDUDocument17 pagesWeekly Report W-3 HSE PT. AWDUBerthi FoxNo ratings yet

- Online Feedback System 1723Document2 pagesOnline Feedback System 1723santosh kumarNo ratings yet

- 6143 MS CU 061 - RA (1) ApprovedDocument22 pages6143 MS CU 061 - RA (1) ApprovedMubashar Ahmad KhanNo ratings yet

- 62 EpirbDocument3 pages62 EpirbLUU QUANG HOANo ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument3 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportMohamed Yasir100% (1)

- S200-ACIFM-MNT-30-RPT-XXXXXXX-01975 ## RevisedDocument4 pagesS200-ACIFM-MNT-30-RPT-XXXXXXX-01975 ## RevisedfayasibrahimkuttyNo ratings yet

- MTPL-OM-PPM-CL-005 - PPM Checklist For FencingDocument2 pagesMTPL-OM-PPM-CL-005 - PPM Checklist For FencingVeerendra YduvanshiNo ratings yet

- MTPL-OM-PPM-CL-007 - PPM Checklist For TrackerDocument2 pagesMTPL-OM-PPM-CL-007 - PPM Checklist For TrackerVeerendra YduvanshiNo ratings yet

- SOP-04 Preventive Maintenance of DG SetsDocument11 pagesSOP-04 Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- AE278WTS-TRN-009 - HSE Inspection Report No. 10 - 18 Aug 2022Document4 pagesAE278WTS-TRN-009 - HSE Inspection Report No. 10 - 18 Aug 2022pramodsomanNo ratings yet

- Report Week 13Document6 pagesReport Week 13Farooq AzizNo ratings yet

- Online Feedback System 1656Document2 pagesOnline Feedback System 1656santosh kumarNo ratings yet

- General Method Statement For Cathodic Protection Rev.ADocument13 pagesGeneral Method Statement For Cathodic Protection Rev.ANeil JavierNo ratings yet

- General Method Statement For Cathodic Protection Rev. CDocument12 pagesGeneral Method Statement For Cathodic Protection Rev. CNeil JavierNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorDocument6 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final Incharge Premkumar-OperatorVasanth KumarNo ratings yet

- 007 Mobile Crane ChecklistDocument2 pages007 Mobile Crane Checklistchandral86No ratings yet

- + Contractor Safety Weekly Statistic Report FormDocument1 page+ Contractor Safety Weekly Statistic Report FormNathaniel Kwek100% (2)

- CRS SEC - 10632 - Warranty Inspection Procedure For TransformersDocument2 pagesCRS SEC - 10632 - Warranty Inspection Procedure For TransformersKhaja SayeedNo ratings yet

- NFI-015-UT Crosscheck 15-12-2018Document1 pageNFI-015-UT Crosscheck 15-12-2018THI SEN NGUYENNo ratings yet

- Weekly HSE Report - 13-05-2023Document24 pagesWeekly HSE Report - 13-05-2023abhinav djNo ratings yet

- Online Feedback System 1670Document2 pagesOnline Feedback System 1670santosh kumarNo ratings yet

- USCG - Foreign Freight Vessel Examination Book PDFDocument47 pagesUSCG - Foreign Freight Vessel Examination Book PDFRahul SinghNo ratings yet

- Handover Notes-Melchor To Arnel Feb. 15 2024Document1 pageHandover Notes-Melchor To Arnel Feb. 15 2024App JerNo ratings yet

- JCY1900 APT Procedure-NewDocument29 pagesJCY1900 APT Procedure-NewMacro Love0% (1)

- Monthly Safety ReportDocument8 pagesMonthly Safety ReportRaju Tiwary60% (5)

- Why Why - Analysis (06.08.2023)Document3 pagesWhy Why - Analysis (06.08.2023)Saptarshi BarikNo ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- Cg-840 Hull Inspection BookDocument38 pagesCg-840 Hull Inspection Bookgreatenick.nbNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- EngDocument44 pagesEngzomglolzscribdNo ratings yet

- ELV (ED Coating)Document2 pagesELV (ED Coating)Mohit SinghNo ratings yet

- 5 - HSE Statistics - Last 05 YearsDocument1 page5 - HSE Statistics - Last 05 YearsMohammad Mokhtarul HaqueNo ratings yet

- S200 Acifm MNT 30 RPT XXXXXXX 02015Document2 pagesS200 Acifm MNT 30 RPT XXXXXXX 02015fayasibrahimkuttyNo ratings yet

- Native Inspection - Report - CleanedDocument6 pagesNative Inspection - Report - CleanedPrathamesh OmtechNo ratings yet

- Il - 107000170884-Eppm-Lt-Ir #002 - Mr-041 Gate Valve Manual - L&T Rev-0Document53 pagesIl - 107000170884-Eppm-Lt-Ir #002 - Mr-041 Gate Valve Manual - L&T Rev-0usmanNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Incident Notification GuideDocument13 pagesIncident Notification GuideusmancustNo ratings yet

- Safety EducationDocument1 pageSafety EducationusmancustNo ratings yet

- No Mask No EntryDocument1 pageNo Mask No EntryusmancustNo ratings yet

- Hot Work PermitDocument3 pagesHot Work PermitusmancustNo ratings yet

- NEBOSH IGC2 Past Exam Paper September 2012 PDFDocument2 pagesNEBOSH IGC2 Past Exam Paper September 2012 PDFusmancustNo ratings yet

- Material ListDocument1 pageMaterial ListusmancustNo ratings yet

- PTS Challan Form PDFDocument4 pagesPTS Challan Form PDFusmancustNo ratings yet

- ISP Fee ReceiptDocument1 pageISP Fee ReceiptusmancustNo ratings yet

- NEBOSH IGC2 Past Exam Paper April 2005 PDFDocument2 pagesNEBOSH IGC2 Past Exam Paper April 2005 PDFusmancustNo ratings yet

- PTS Challan FormDocument4 pagesPTS Challan FormusmancustNo ratings yet

- Muslim Girls Names FinalDocument166 pagesMuslim Girls Names FinalusmancustNo ratings yet

- Input Data Sheet For E-Class Record: Region Division School Name School Id School YearDocument18 pagesInput Data Sheet For E-Class Record: Region Division School Name School Id School YearRonie DacubaNo ratings yet

- Keynote Address On Bonded LabourDocument13 pagesKeynote Address On Bonded LabourRavinder SinghNo ratings yet

- Science Direct Photoluminescence From Colloidal Silver NanoparticlesDocument6 pagesScience Direct Photoluminescence From Colloidal Silver NanoparticlesYu Shu HearnNo ratings yet

- Yellow Book (Analysis of Rate)Document161 pagesYellow Book (Analysis of Rate)antt phweNo ratings yet

- Wastewater TreatmentDocument60 pagesWastewater TreatmentPC YeapNo ratings yet

- CHAPTER LLDocument11 pagesCHAPTER LLDeege BaeNo ratings yet

- Educational Institutes MysoreDocument8 pagesEducational Institutes MysoreMadhavi KurraNo ratings yet

- Gsa PPDocument15 pagesGsa PPSheikh Sahil MobinNo ratings yet

- Mapeh 10 QuestionnaireDocument4 pagesMapeh 10 Questionnairemerryjoey heranaNo ratings yet

- Msds of Spray Dried LactoseDocument8 pagesMsds of Spray Dried LactoseAnandaNo ratings yet

- Indian Income Tax Return Acknowledgement 2021-22: Assessment YearDocument1 pageIndian Income Tax Return Acknowledgement 2021-22: Assessment YearPrateek GuptaNo ratings yet

- TCW241 Ethernet I O Module User Manual R4.2Document49 pagesTCW241 Ethernet I O Module User Manual R4.2Rodolfo OliveiraNo ratings yet

- Tutorial 1B Principal Stresses and PlanesDocument2 pagesTutorial 1B Principal Stresses and PlanesumarkamranNo ratings yet

- Epekto NG Paninigarilyo Sa Kabataan ThesisDocument5 pagesEpekto NG Paninigarilyo Sa Kabataan ThesisWriteMyPaperCollegeWichitaFalls100% (1)

- KPMG Covid 19 Economic ImpactDocument30 pagesKPMG Covid 19 Economic Impactsomapala88No ratings yet

- English Report EssayDocument3 pagesEnglish Report EssayTen Fatin67% (3)

- Press Release: Semarang, 22 October 2017 - PT Kalbe Farma TBK (Kalbe) Through Kalbe EthicalDocument2 pagesPress Release: Semarang, 22 October 2017 - PT Kalbe Farma TBK (Kalbe) Through Kalbe EthicalYessy YasmaraldaNo ratings yet

- SA Steam GenerationDocument6 pagesSA Steam GenerationRajagopalNo ratings yet

- Gray Hat Hacking The Ethical Hackers Handbook Sixth Edition Daniel Regalado Full ChapterDocument51 pagesGray Hat Hacking The Ethical Hackers Handbook Sixth Edition Daniel Regalado Full Chaptereugene.poremski145100% (5)

- Material - 5. Injection Moulding Technology Part 3 - 3Document127 pagesMaterial - 5. Injection Moulding Technology Part 3 - 3Sachin KumarNo ratings yet

- Home Page Principles Practitioners Help Yourself Contact: Main NavigationDocument2 pagesHome Page Principles Practitioners Help Yourself Contact: Main NavigationAbdurrahmanUsmanNo ratings yet

- PurinaDocument24 pagesPurinaDee Dee YengNo ratings yet

- UntitledDocument37 pagesUntitledDevanathan ChinnasamyNo ratings yet

- How To Read A Prescription Drug LabelDocument3 pagesHow To Read A Prescription Drug LabelJefriyanto Saud100% (2)

- Mounting Solutions: Multi-Parameter Patient MonitorDocument2 pagesMounting Solutions: Multi-Parameter Patient Monitor杨敏杰No ratings yet

- Certified Coding Specialist CCS Exam Preparation OCRDocument319 pagesCertified Coding Specialist CCS Exam Preparation OCRKian Gonzaga100% (32)

- Deutz Fahr AGROTRON 118 Tractor Service Repair ManualDocument21 pagesDeutz Fahr AGROTRON 118 Tractor Service Repair ManuallaopaodunNo ratings yet

- AP SCERT 1-4 HighlightedDocument41 pagesAP SCERT 1-4 Highlightedyamuna0% (1)

- BPED 101 Prelim ExamDocument4 pagesBPED 101 Prelim ExamJOANA MANAOGNo ratings yet

- Faculty 460 Eng 334 Kust20201 l2 p2 Paragraph WritingDocument20 pagesFaculty 460 Eng 334 Kust20201 l2 p2 Paragraph WritingMuhammad UsmanNo ratings yet