Professional Documents

Culture Documents

Calculation Pipe Header For Compressor

Uploaded by

syaifullintech0 ratings0% found this document useful (0 votes)

6 views4 pagesOriginal Title

Calculation Pipe Header for Compressor

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views4 pagesCalculation Pipe Header For Compressor

Uploaded by

syaifullintechCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

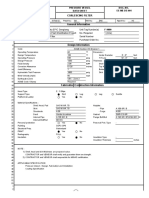

DESIGN ENGINEERING CLIENT : PT.

MARUWAI COAL

REPORT DOC NO : -

DATE : December 16, 2023

SO No. : -

PT. LINTECH DUTA PRATAMA

"We Offer HIGH QUALITY Integrated Steel Fabrication, General Construction

and Service for Mining, Oil and Gas

Office/Workshop: Wira Jatim Industrial Estate, Mastrip 70 Karangpilang, Surabaya- Indonesia 60221

Lintech Seaside Facility: Daendels Street - Paciran Cape Lamongan - 74km from Surabaya- Indonesia

Phone: +62-31-7666891 (Hunting 6 lines) Fax: +62-31-7664604

E-MAIL:admin@lintech.co.id Website: Http://www.Lintech.co.id ; Http://www.LSF.CO.ID

DESIGN ENGINEERING REPORT

DETAIL CALCULATION SHEET FOR

PIPE HEADER FOR AIR COMPRESSOR

Prepared By Approved By

D & E Engineer D & E Manager

MECHANICAL DATA SHEET SO No.

PIPE HEADER FOR AIR COMPRESSOR

REVISION 2

Equipment Name : Pipe Header for Air Compressor Date : 16 December 2023

Item No. :

Manufacturer : PT. LINTECH DUTA PRATAMA

BRAND / Model No. :-

No. of unit : 1 unit

DESIGN & TEST DATA

SERVICE DESCRIPTION : Process Liquid

REGULATION : ASME

CODE/TYPE : ASME Sec. VIII div. 1 , 2015 Ed

Design data DESCRIPTION

Internal 145 Psi 0 1,000 kPa

1 Design pressure

External - Psi - kPa

2 Design Temperature 226 F 80 C

Internal 218 Psi 1,500 kPa

3 Operating Pressure

External - Psi - kPa

4 Operating Temperature 122 F 52 C

5 Min. Design Temperature 0 °C

6 Radiography full RT-1

7 Joint Efficiency Shell 1

Head 1

8 Corrosion Allowance (ca) 0 In 1.0 mm

9 Max. Allow. Working Pressure 1,000 kPa

10 Hydrostatic Test Pressure 1,300 kPa

11 Pneumatic Test Pressure None

12 PWHT None

13 Impact Test

Material Max. Allowable Working Pressure

Shell SUS316 20,015 Psi 138,000 Kpa

Head SA36 16,534 Psi 114,000 Kpa

14 Flange SA-105 20,015 Psi 138,000 Kpa

Nozzle Pipe SA-106 Gr. B 17,114 Psi 118,000 Kpa

Reinforcement SA-36 16,534 Psi 114,000 Kpa

Support SA-36 16,534 Psi 114,000 Kpa

Vessel Dimension

Shell Diameter / Radius 20 In / 10 In 508.00 Mm / 254 mm

15 Shell Thickness 0.236 In 6.00 mm

Head Thickness 0.472 In 12.00 mm

TL / TL Length 217 In 2,225 mm

16 Vessel Position (Operation) Horizontal

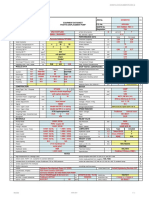

SHELL THICKNES CALCULATION Revision 2

Thickness of Shell Under Internal Pressure ( Appendix 1 )

Static Head Ph : 0.002 Psi 0.0121 Kpa

Design Pressure + Static Head Pd : 145.040 Psi 1,000 Kpa

Design Temperature Td : 226.4 °F 80 C

Material : SUS316

Outside Radius of Shell Ro : 10.000 in ( 254 mm)

Max Allowable Stress at Td S : 20,015 Psi 138,000 Kpa

Joint Efficiency E : 1

Corrosion Allowance CA : 0.0394 in 1 mm

Minimum Required Thickness (App. 1 (1-1)'(a)(1)) tr : 0.112 in ( 2.84 mm)

tr = (Pd*Ro) / (S*E+0.4*Pd) + CA

Minimum Thickness as per UG-16(b-4) tr+CA : 0.137795275 in 3.5 mm

Thickness Used (nominal shell thickness) t : 0.236 in ( 6 mm)

t under Tolerance 12.5% ( 4.25 mm)

RESULT Nominal Shell Thickness > Min. Required Thickness (UG-16 (b-4) OK

HEAD THICKNES CALCULATION Revision 2

Thickness of Head Under Internal Pressure ( Appendix 1 )

Static Head Ph : 0.002 Psi 0.0121 Kpa

Design Pressure + Static Head Pd : 145.040 Psi 1,000 Kpa

Design Temperature Td : 226.4 °F 80 C

Material : SA36

Outside Radius of Head Ro : 10.000 in ( 254 mm)

Max Allowable Stress at Td S : 20,015 Psi 138,000 Kpa

Joint Efficiency E : 1

Corrosion Allowance CA : 0.0394 in 1 mm

Minimum Required Thickness (App. 1 (1-1)'(a)(1)) tr : 0.112 in ( 2.84 mm)

tr = (Pd*Ro) / (S*E+0.4*Pd) + CA

Minimum Thickness as per UG-16(b-4) tr+CA : 0.137795275 in 3.5 mm

Thickness Used (nominal shell thickness) t : 0.472 in ( 12 mm)

t under Tolerance 12.5% ( 9.50 mm)

RESULT Nominal Shell Thickness > Min. Required Thickness (UG-16 (b-4) OK

You might also like

- 50 BBL Surge Tank Design CalculationDocument22 pages50 BBL Surge Tank Design CalculationLaskar Pejuang100% (1)

- MD PV ASME v0.1Document34 pagesMD PV ASME v0.1nileshNo ratings yet

- DFGSDFDocument181 pagesDFGSDFArbaaz Parvez100% (1)

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Operating & Design Compress Air SystemDocument8 pagesOperating & Design Compress Air SystemFiauni VoNo ratings yet

- Pressure Vessel Data Sheet for TEG ContactorDocument2 pagesPressure Vessel Data Sheet for TEG ContactorElias EliasNo ratings yet

- ET Subsea Ball ValvesDocument9 pagesET Subsea Ball ValvesAndrew BaileyNo ratings yet

- Sizing Tank Blanketing RegulatorsDocument3 pagesSizing Tank Blanketing RegulatorslazunovNo ratings yet

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileDocument20 pagesUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SNo ratings yet

- PRESSURE VESSEL STRENGTH CALCULATIONDocument52 pagesPRESSURE VESSEL STRENGTH CALCULATIONClaudia BonocoreNo ratings yet

- Wilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetDocument3 pagesWilo Mather and Platt Pumps Pvt. LTD: Technical DatasheetViral ParmarNo ratings yet

- NPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level GaugeDocument5 pagesNPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level Gaugekkumar_717405No ratings yet

- HMF-02 Installation and Start-Up InstructionsDocument4 pagesHMF-02 Installation and Start-Up InstructionsxxshNo ratings yet

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocument2 pagesPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Compressor ControlsDocument167 pagesCompressor ControlsAnonymous 70lCzDJvNo ratings yet

- Buffer Vessel Data SheetDocument4 pagesBuffer Vessel Data SheetUmair A. KhanNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Pressure Vessel Data Sheet for Residue Gas ScrubberDocument2 pagesPressure Vessel Data Sheet for Residue Gas ScrubberElias EliasNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- ISPE Good Practice Guide Compressed Air Specifications - Compressed Air Testing - Trace AnalyticsCompressed Air Testing - Trace AnalyticsDocument2 pagesISPE Good Practice Guide Compressed Air Specifications - Compressed Air Testing - Trace AnalyticsCompressed Air Testing - Trace AnalyticsAnonymous FZs3yBHh7No ratings yet

- Technip Separations PDFDocument50 pagesTechnip Separations PDFProcess Engineer100% (1)

- CGVDocument97 pagesCGVMohammad AbbasiNo ratings yet

- Strength Calcul SheetDocument379 pagesStrength Calcul Sheetmustufa akolawalaNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Big CKD in Cal 002 Orifice Sizing Rev.ADocument7 pagesBig CKD in Cal 002 Orifice Sizing Rev.ASafaruli DeviyantiNo ratings yet

- Overpressure Relief of Chlorine InstallationsDocument17 pagesOverpressure Relief of Chlorine InstallationsvipinsunejaNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- Data Sheet Amine Contactor (V-1040)Document2 pagesData Sheet Amine Contactor (V-1040)Elias EliasNo ratings yet

- EF1aV008 AS DatasheetDocument1 pageEF1aV008 AS DatasheetAnuj VermaNo ratings yet

- Datahseet For Strainer With Air EliminatorDocument4 pagesDatahseet For Strainer With Air Eliminatorvinoj chandranNo ratings yet

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderDocument19 pagesSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiNo ratings yet

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Alcorcon Fluid Machineries ReviewerDocument14 pagesAlcorcon Fluid Machineries Revieweresto_domingo100% (1)

- AAC. Submittal BOMBAS ARMSTRONGDocument3 pagesAAC. Submittal BOMBAS ARMSTRONGLuis Carlos Perez OstosNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- A3080 6040 Dat MC 142 eDocument11 pagesA3080 6040 Dat MC 142 erameshqcNo ratings yet

- Sales and Marketing Presentation - 2019 - Rev1Document36 pagesSales and Marketing Presentation - 2019 - Rev1HANIF AKBARNo ratings yet

- Fire Water Tank DatasheetDocument3 pagesFire Water Tank DatasheetFikri MakhlufNo ratings yet

- RDJ GM 620 047 - (En)Document14 pagesRDJ GM 620 047 - (En)fouad kerkarNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Job No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedDocument3 pagesJob No. Item No: Doc. No. Tag No. Client Fine Filter Skid FD-38063A/B Bharat Heavy Electricals LimitedgauravNo ratings yet

- 2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Document2 pages2.6.5 Retro Lavado Del Sistema de Ultrafiltración (5450 - PP-008 A-B)Jennifer FigueroaNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 288Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 288JHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- 80315-01 r4 Technical Data Sheet PX-Q300Document1 page80315-01 r4 Technical Data Sheet PX-Q300JOSÉ VILLALOBOS CORALNo ratings yet

- 2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Document2 pages2.6.4 Alimentación Al Sistema de Ultrafiltración (5450-PP-007 A-B)Jennifer FigueroaNo ratings yet

- HPCL Pev DC & Gad 95v01 CommentedDocument136 pagesHPCL Pev DC & Gad 95v01 CommentedAvish BhandariNo ratings yet

- Design Data Sheet: Insulating JointsDocument1 pageDesign Data Sheet: Insulating Jointsibra benaNo ratings yet

- Ds-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Document5 pagesDs-pp-0106 - Mechanical Data Sheet For Hose Assemblies (Rev.e) - 30!10!2023Panisa BanimaNo ratings yet

- PI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Document1 pagePI16008GTE-011-In-HD-001 (Hoja Datos Valvula de Control)Annie De WildeNo ratings yet

- Ga Air Compressor SystemDocument7 pagesGa Air Compressor SystemBayu Reza FauziNo ratings yet

- Flame Arrestor DatasheetDocument3 pagesFlame Arrestor Datasheetvictor japposanNo ratings yet

- NPM40 Hn8239 W (20080902)Document21 pagesNPM40 Hn8239 W (20080902)Bui Duy ThanhNo ratings yet

- Closed Drain Pump ProposalDocument6 pagesClosed Drain Pump ProposalaurinkokelloNo ratings yet

- 2061-MIX-001 Rev1Document2 pages2061-MIX-001 Rev1Emmanuel Ber SNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

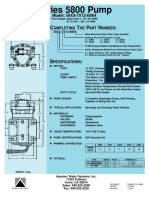

- Series 5800 Pump: C T P NDocument2 pagesSeries 5800 Pump: C T P NYESSYTAESNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- CODELCO GABY CAUDAL AGUA TAMBOR ACIDIFICADORDocument1 pageCODELCO GABY CAUDAL AGUA TAMBOR ACIDIFICADORgerardoNo ratings yet

- ANTAM Datasheet 10LAD21AA121 00Document1 pageANTAM Datasheet 10LAD21AA121 00heviNo ratings yet

- Product Catalogue Launcher and ReceiverDocument49 pagesProduct Catalogue Launcher and Receiverraja syahNo ratings yet

- I-FD-3010.92-5121-600-SMN-002_CDocument2 pagesI-FD-3010.92-5121-600-SMN-002_CAdalton BritoNo ratings yet

- Additional Development OF Luhais & Subba Oil Field ProjectsDocument6 pagesAdditional Development OF Luhais & Subba Oil Field ProjectsMohamedHussein MohamedHusseinNo ratings yet

- Za 6Document21 pagesZa 6Yashvant NayarNo ratings yet

- Pneumatic Supplementary Loading System Design DifferencesDocument31 pagesPneumatic Supplementary Loading System Design DifferencesErikikoNo ratings yet

- PT and Fittings Exam 4Document7 pagesPT and Fittings Exam 4Panitan MungsongNo ratings yet

- Asme Swps AppendixDocument3 pagesAsme Swps Appendixrohit singhNo ratings yet

- Fugacity and ITS EstimationsDocument13 pagesFugacity and ITS EstimationsSanika TalathiNo ratings yet

- Incidents Related To CO2 StorageDocument8 pagesIncidents Related To CO2 StoragearunperthNo ratings yet

- Rans DerivationDocument16 pagesRans Derivationuday gouthamaNo ratings yet

- Integrating ASHRAE-Funded Research Into Airflow Modeling SoftwareDocument25 pagesIntegrating ASHRAE-Funded Research Into Airflow Modeling Softwareyunying21No ratings yet

- Flow RestrictorsDocument4 pagesFlow RestrictorsMadhur BhaiyaNo ratings yet

- CO2 Mollier Chart PDFDocument1 pageCO2 Mollier Chart PDFmarko quirozNo ratings yet

- Brayton CycleDocument5 pagesBrayton CycleAnonymous yorzHjDBd100% (1)

- Hydrocarbon Processing: Deep Water FLNGDocument1 pageHydrocarbon Processing: Deep Water FLNGnirmal_subudhiNo ratings yet

- L P GDocument11 pagesL P GPhi MacNo ratings yet

- Model: TSB1390YGS: Technical Data SheetDocument1 pageModel: TSB1390YGS: Technical Data Sheeterick gomezNo ratings yet

- PVA Main Grades and SpecificationsDocument2 pagesPVA Main Grades and Specifications郭哲宏No ratings yet

- MPower (Mostro) Data Sheet Gate Valve S43 NEW Edition 2009Document9 pagesMPower (Mostro) Data Sheet Gate Valve S43 NEW Edition 2009el_apache10No ratings yet

- Osborne Reynold ExperimentDocument6 pagesOsborne Reynold ExperimentUthpala WanninayakeNo ratings yet

- Flow Diagram SymbolsDocument5 pagesFlow Diagram SymbolshussainNo ratings yet

- 9 PVC Pipe FittingsDocument9 pages9 PVC Pipe FittingsLambert G. RequinaNo ratings yet

- EMT6165GK DatasheetDocument4 pagesEMT6165GK Datasheetnilesh yedveNo ratings yet

- 0.55 W Low Power Solenoid Valves FeaturesDocument10 pages0.55 W Low Power Solenoid Valves FeaturesMuhammad HafizhNo ratings yet

- Viscoso-Graph Sep 2005Document2 pagesViscoso-Graph Sep 2005mangerbang_mNo ratings yet

- FL - Gas Piping For Laboratory and Healthcare Facilities - ConbracoDocument33 pagesFL - Gas Piping For Laboratory and Healthcare Facilities - ConbracoKaruna KaranNo ratings yet