Professional Documents

Culture Documents

Swms Installing Light Poles

Uploaded by

92qhnqmrhsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swms Installing Light Poles

Uploaded by

92qhnqmrhsCopyright:

Available Formats

Samark North Qld Pty Ltd

SWMS Manual

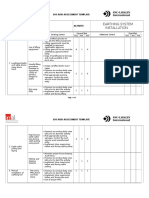

SWMS No 012 Samark North Qld Pty Ltd ABN : 99 082 958 487 Electrical Contractors License C37121 Page 2 of 6

Safe Work Method Statement Title: SWMS:012 INSTALLING LIGHT POLES

Hazard Risk Residual

Work Method / Task Description Recommended Actions / Controls for Prevention P.P.E Risk

Identification Level

1. Check layout and crane access for Tripping, 2 Ensure area, in particular, walkways are clear of trip hazards 5

standing & unloading poles. pedestrians & Implement any pedestrian & traffic control. Wear safety foot 10

traffic wear, gloves, helmet & Hi Vis Clothing. 5

2. Receive poles & lights on site and Struck by 2 Use appropriate protective gloves. Check access 9 5

confirm correct numbers and types. falling objects Keep lifting area clear of people. Barricade work area 4

Implement manual handling risk control procedures in

accordance with SWMS 015

Test and confirm cables before commencing work. Isolate 5

3. Install cable underground or overhead. Manual 2 and fit danger tags as appropriate where running near

handling live equipment. 5

Falling from 2 Use ladders or work platforms appropriately in accordance

heights with SWMS 019 and SWMS 005.

Manual lifting PPE procedures to be used.

4. Check light fitting base or bracket and Struck by 1 Keep lifting area clear of people. Barricade work area 4

terminate cabling into fitting. falling objects.

5. Check crane or other lifting equipment Pedestrians 1 Use spotter to control unauthorised access 4

and operator’s qualifications are up to Unsafe 1 Pre op check of equipment 4

date. Ensure spotter available to prevent equipment 1 Use spotter as required 4

pedestrians entering work area & traffic Overhead 2 Implement manual handling risk control procedures in 10 5

management as required. cables. accordance with WMS 015 and Code of Practice for Manual 5

Manual Tasks 2010. Check PPE is worn 9

handling Wear safety foot wear, gloves, helmet & Hi Vis Clothing. 4

Version 2.1 01/03/2017 Review Date 01/03/2018

Samark North Qld Pty Ltd

SWMS Manual

SWMS No 012 Samark North Qld Pty Ltd ABN : 99 082 958 487 Electrical Contractors License C37121 Page 3 of 6

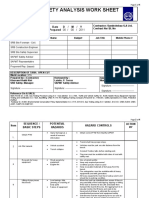

Safe Work Method Statement Title: SWMS:012 INSTALLING LIGHT POLES

Hazard Risk Residual

Work Method / Task Description Recommended Actions / Controls for Prevention P.P.E.

Identification Level Risk

6. 6. Install pole, ensure it is secure and Manual 2 Use appropriate protective gloves. 9 5

installed to specifications. handling Barricade work area.

Struck by

falling objects

Falling

7. Complete the fitting of any other parts Manual 2 Use ladders or work platforms appropriately in 5

and wiring to the light poles. handling accordance with SWMS 019 and SWMS 005.

Cable Confirm all connected cables are isolated & tagged.

connections &

testing

Version 2.1 01/03/2017 Review Date 01/03/2018

Samark North Qld Pty Ltd

SWMS Manual

SWMS No 012 Samark North Qld Pty Ltd ABN : 99 082 958 487 Electrical Contractors License C37121 Page 4 of 6

Safe Work Method Statement Title: SWMS:012 INSTALLING LIGHT POLES

Personnel Qualifications and Experience Required Personnel Duties and Responsibilities Training Required to Complete Work

Minimum of Electrical Worker Grade 4 or apprentice Supervisor to carry out daily inspections of work Supervisor to be trained in risk identification, assessment

working under the effective supervision of a qualified site for hazards. and control e.g. Job Safety Analysis (JSA).

Electrical Worker minimum Grade 5.

Appropriate industry and site induction. All personnel to maintain tidy work area on site at Supervisor to be appropriately trained, qualified and

all times. Personal Protective Equipment (PPE) to competent in OH&S and electrical practices for the task.

be worn at all times on site.

Elevated Work Platform training and national Barricading to be used as appropriate to protect On the job skills training to be conducted by Supervisor to

certification as required dependent upon equipment to others from working below elevated work, crane personnel. Training on specific elevated work platform to be

be used. Traffic Management and other plant and equipment. used if using EWP.

Engineering Details / Certificates / WorkCover Approvals / Australian Referenced – Codes of Practice / Regulations / Legislation

Standards

Installation to be in accordance with AS 3000 Standards and client's Work Health and Safety Act and Regulations 2011, Electrical Safety Act 2002 and

specifications. Floor capacity sufficiently engineered to carry weight of elevated Regulations 2013, Electrical Safety Code of Practice 2010, Hazardous Manual Tasks

work platform/s. Footings and rag bolts correct size for size and weight of poles. Code of Practice 2010, Plant Code of Practice 2005, Mobile Crane COP 2006,

Industry Standard for Electrical Installations on Construction Sites 2010.

Plant / Equipment Required (Mobile or Static) Maintenance Checks / Calibration Intervals

Portable hand tools, electrical power tools, drills, leads and ladders. Hazard Hand tools and ladders to be checked daily.

Identification to be conducted for plant used e.g. Scissor lift, boom lift, cherry Elevated Work Platform/s in accordance with manufacturer’s recommendations and

picker. log book.

Truck crane in accordance with manufacturers recommendations and log book.

Persons responsible for ensuring compliance with this

1. Mark McDonald 2. Austin Wilds

SWMS

P

P

E

1 2 3 4 5 6 7 8 9 10 11 12 13

Version 2.1 01/03/2017 Review Date 01/03/2018

You might also like

- Work Method Statement PDFDocument8 pagesWork Method Statement PDFUsiwo Abed Soteria Otowa100% (3)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Method Statement & Risk Assessment: Industrial Security Doors LTDDocument8 pagesMethod Statement & Risk Assessment: Industrial Security Doors LTDNathi MaphangaNo ratings yet

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- Hazard Identification and Risk Assessment For Pipe LoweringDocument4 pagesHazard Identification and Risk Assessment For Pipe LoweringAchalere Shekhar Kashinath67% (3)

- JSA Cable LayingDocument2 pagesJSA Cable Layingnishanth100% (2)

- Geoprobe: Spectra TestersDocument437 pagesGeoprobe: Spectra TestersMoses Gitonga KathuriNo ratings yet

- Nema Ics 2 PDFDocument122 pagesNema Ics 2 PDFEslam ElsayedNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- Safety Work Procedure (New)Document13 pagesSafety Work Procedure (New)ajith balajeeNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (1)

- Inbound 5425125211198410005Document3 pagesInbound 5425125211198410005Rabeh BàtenNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- EWP SOP Vs 5 20131122Document4 pagesEWP SOP Vs 5 20131122Mohammed Amer PashaNo ratings yet

- Landscaping Victoria SWMSDocument9 pagesLandscaping Victoria SWMScjNo ratings yet

- Method Statement For Magnetic Flux Leakage Test: DCSM Project 2019Document5 pagesMethod Statement For Magnetic Flux Leakage Test: DCSM Project 2019Thinh NguyenNo ratings yet

- WMS - MV PANEL Maintenance - BIN MAHMOUD PLAZADocument7 pagesWMS - MV PANEL Maintenance - BIN MAHMOUD PLAZAvipinkmlNo ratings yet

- Power and Control Cable Laying, Glading and TerminationDocument9 pagesPower and Control Cable Laying, Glading and Terminationsalman100% (1)

- METHOD STATEMENT FOR WORKING AT HEIGHT Rev A0Document8 pagesMETHOD STATEMENT FOR WORKING AT HEIGHT Rev A0M.A.N100% (2)

- Electrical Work: Phase Hazard AnalysisDocument11 pagesElectrical Work: Phase Hazard AnalysisazerNo ratings yet

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDocument5 pagesSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNo ratings yet

- Jsa - SWP For Lifting and Lowering MaterialDocument4 pagesJsa - SWP For Lifting and Lowering MaterialSantosh Singh50% (2)

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementAjith NairNo ratings yet

- Bat (Rams)Document10 pagesBat (Rams)sodiqismail11No ratings yet

- Method-Statement SignageDocument4 pagesMethod-Statement SignageGopan V NairNo ratings yet

- Methodology Statement & Risk Assessment For FcuDocument9 pagesMethodology Statement & Risk Assessment For FcuLibin VargheseNo ratings yet

- Electrical Work: Phase Hazard AnalysisDocument10 pagesElectrical Work: Phase Hazard AnalysisBNCHNo ratings yet

- Method Statement ExampleDocument4 pagesMethod Statement ExampleAya MagdyNo ratings yet

- SP0509 Circuit Breaker Testing SWPDocument6 pagesSP0509 Circuit Breaker Testing SWPEnthusiastNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Assembly of Steel StructuresDocument2 pagesAssembly of Steel StructuresDelta akathehuskyNo ratings yet

- Running Procedures 13.375 Inch Hydril 521Document12 pagesRunning Procedures 13.375 Inch Hydril 521nardo_ingNo ratings yet

- Fill-Up This Card Before Commencement of Critical WorksDocument4 pagesFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyNo ratings yet

- Jsa For KahsDocument3 pagesJsa For Kahsfrancis_e_tan100% (2)

- Inter Tank Transfers - SWPDocument5 pagesInter Tank Transfers - SWPPriince MogomotsiNo ratings yet

- Step by Step-Health and Safety For Working With or Near Electrical Lines-July-2020Document44 pagesStep by Step-Health and Safety For Working With or Near Electrical Lines-July-2020Kyaw Kyaw Win100% (1)

- 01.05.2021 Method Statement For Electrical & InstrumentationDocument6 pages01.05.2021 Method Statement For Electrical & InstrumentationPangky Abasolo100% (1)

- 11 Concrete Mixer PDF PDFDocument1 page11 Concrete Mixer PDF PDFekkyagungNo ratings yet

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 pagesJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNo ratings yet

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- PCW Pipe Installation JhaDocument2 pagesPCW Pipe Installation Jhafatimah100% (1)

- (English) IBRUP-Weekly HSE Review Summary 2024-01-13 19Document2 pages(English) IBRUP-Weekly HSE Review Summary 2024-01-13 19mahesh27945No ratings yet

- SWP-039 False Ceiling & Partition Wall WorksDocument4 pagesSWP-039 False Ceiling & Partition Wall Worksadrianlim13No ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- Working in Close Proximity To Overheadpowerlines: Huawei ConfidentialDocument5 pagesWorking in Close Proximity To Overheadpowerlines: Huawei ConfidentialmosesNo ratings yet

- Job Safety Analysis (Jsa) FormDocument4 pagesJob Safety Analysis (Jsa) FormNaukhez A. KashifNo ratings yet

- Ocef Relay TestingDocument6 pagesOcef Relay TestingPandrayar MaruthuNo ratings yet

- SWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Document8 pagesSWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Md Shahbaz AlamNo ratings yet

- A-2.2-11-33-01 - Monitoring Checklist For Mobile Crane OperationDocument1 pageA-2.2-11-33-01 - Monitoring Checklist For Mobile Crane Operationtivopa3612No ratings yet

- CCRP - IP-20N ManualDocument281 pagesCCRP - IP-20N ManualelchevaraNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- GL 18 WorkingatheightDocument1 pageGL 18 WorkingatheightTC Ozlem ZenginyurekNo ratings yet

- Wap2 Cp05a MS 0008 01 - Installation of PanelDocument6 pagesWap2 Cp05a MS 0008 01 - Installation of PanelElisco Pher SalmasanNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Professional Rope Access: A Guide To Working Safely at HeightFrom EverandProfessional Rope Access: A Guide To Working Safely at HeightNo ratings yet

- Dominos Customer Story Infographic RoadmapDocument1 pageDominos Customer Story Infographic RoadmapAishwarya MathurNo ratings yet

- Master Scheduling Chapter 1Document19 pagesMaster Scheduling Chapter 1Bosco GodfreyNo ratings yet

- P HSSE 003 E Monitoring Contract Performance During Contr ExecutionDocument7 pagesP HSSE 003 E Monitoring Contract Performance During Contr Executionagaricus100% (1)

- Unit-2 Components of CIMDocument20 pagesUnit-2 Components of CIMMurali Krishnan SelvarajaNo ratings yet

- Entrepreneurship An Evolving ConceptDocument14 pagesEntrepreneurship An Evolving ConceptJivaansha SinhaNo ratings yet

- 10 Questions On Oracle Application ExpressDocument4 pages10 Questions On Oracle Application ExpressLewis Cunningham94% (16)

- Build Payroll Integration ADPDocument33 pagesBuild Payroll Integration ADPKishore KattaNo ratings yet

- Rebate Processing PDFDocument42 pagesRebate Processing PDFrajesh1978.nair238186% (7)

- WPS-PQR ListDocument1 pageWPS-PQR ListSandra SandersNo ratings yet

- HFM IG 2021 Final All Small CRXDocument292 pagesHFM IG 2021 Final All Small CRXvaio readerNo ratings yet

- Optional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsDocument7 pagesOptional Service Bulletin OSB 42-134/1 OSB 42NG-073/1: I Technical DetailsSameer KshitizNo ratings yet

- 3.enex General 070616Document23 pages3.enex General 070616Ropiudin EnergiNo ratings yet

- MRFDocument11 pagesMRFRohit Gunwani0% (1)

- Excel Template Inventory ControlDocument27 pagesExcel Template Inventory ControlMC Mejia100% (1)

- Bobs Clock Repair Trouble Shooting Notes - B.tascioneDocument31 pagesBobs Clock Repair Trouble Shooting Notes - B.tascionenebojsadj6411100% (3)

- AMSO User ManualDocument60 pagesAMSO User ManualJab5450No ratings yet

- TheModelEngineersHandbook TubalCainDocument226 pagesTheModelEngineersHandbook TubalCainDan Agu100% (21)

- Example: (Industrial Training Project Report)Document44 pagesExample: (Industrial Training Project Report)shaik SohailNo ratings yet

- Tips and Hints For Sharing Data PDFDocument5 pagesTips and Hints For Sharing Data PDFMadhuri MalayathiNo ratings yet

- Revised ThesisDocument44 pagesRevised ThesisKyle Jezrel GimaoNo ratings yet

- 18 - Decrypting Innovation - A Practical Approach - Francesco Fazio - DoblinDocument61 pages18 - Decrypting Innovation - A Practical Approach - Francesco Fazio - DoblinBenício Avellar100% (1)

- G A 863 Co Pomdb11-1 S DB11053Document30 pagesG A 863 Co Pomdb11-1 S DB11053Avinash RamnathNo ratings yet

- Bitsource Solutions Private Limited - Company Profile - ChemicalDocument5 pagesBitsource Solutions Private Limited - Company Profile - ChemicalAtheeva RajNo ratings yet

- RN SeriesDocument8 pagesRN SeriesCristian DiblaruNo ratings yet

- HP Man ITGk-V5.0userguides-Usingworkbench PDFDocument68 pagesHP Man ITGk-V5.0userguides-Usingworkbench PDFutkarsh_m83No ratings yet

- Specification For AWS Accreditation of Certified Welding FabricatorsDocument20 pagesSpecification For AWS Accreditation of Certified Welding Fabricatorsandres23sNo ratings yet

- Checklist For Rope Suspended Platform HSE OCP 16Document1 pageChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalNo ratings yet

- r11x RaymarineDocument90 pagesr11x RaymarineAnonymous nC9gpUWPNo ratings yet