Professional Documents

Culture Documents

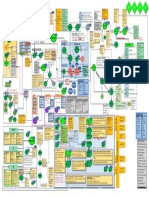

SAP MM Work Flow - Org Unit - Process - Concepts

Uploaded by

Zaid_SultanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAP MM Work Flow - Org Unit - Process - Concepts

Uploaded by

Zaid_SultanCopyright:

Available Formats

MM MRP PUR INV

OrgUnit / Concepts / Processes

OMSF Evaluations

Manage suppliers •NR •ROH (Raw) MM Doc Cat •MATnr Reqt •Consump

MatGrp PurCat Common (to “PurDoc”) •AAC Reqt •Spec Stock

OMS4 •FS + FldRef •HIBE (Supplies) Fields Definition at Client Level •RFQ [A], PR [B]

MatStatus •NR

•ProdTypGrp •HALB (Semi) •Procure [B] Activation at ValArea •PO [F] •IM Reqt •AC Modif

Client Level •Pur allow •FS Key

POrg highest MM Summation after Client •Movt allow •ProcureTyp •FERT (Finished) •Status [C] ValType is a ‘level’ of MAT •CT [K], SA [L] •GR Ctrl •AA Edit

POrg has its own PIR, Pricing, Partner role MatStat •Val / Qty Upd •ERSA (Spares) •Origin [H]

•Layout •IV Ctrl •AA Distrib

Purchasing Plant Level All Plant

•WM allow Globally, price ctrl must be “V”;

•MRP allow •AcctDet •UNBW (nonVal) •etc Specific (to “PurDoc”) •FS Key •Partial IV

N:0 •Auto PO Plant Level locally (plant), it can be either

POrg OX01 CoyCd •PurGrp Sloc Level •BOM allow •MM Views •ULAG (nonStk) •OA Follow “R” (PR) SE16:T161 •nonVal GR

•Rel Level (PR)

OX17 •MatStatus •Config. Mat •HAWA (Trading) OMWC Split OMWO DocTyp •FS

(Plant level) Material •Price Ctrl •SERV (Services) ValType 1:N ValCat

Valuation

•STO “T” (PO, SA)

OMH4 OME9

•Asset [A]

OX18

1. Plant must have POrg •Time-Dep (RFQ, SA)

N:1

2. Plant must have CoyCd •PurValKey FS Factors (MatTyp Level) •DIEN (Services) Permissible •Cost Center [K]

•Industry MsgTyp (CondTyp) FS Factors ItmCat AA_CAT •Project [P]

(one and only one) (tolerances) [V_T161P] [OMG0]

3. POrg may or may not Sloc Auto Ext •MatTyp • 1 MAT: 1 ValClass. ValClass per MAT is •Medium Msg (Output) •DocTyp •SD Order [C]

Plant •QI-Stk flag •On 1 s t GR [MMSC] OMS2

permitted by MatType (AC_CAT_REF mapping) link_rule •ItmCat

have CoyCd •Tranx •Timing Determination •PP Order [F]

•Batch Mgmt 1.Hide FS

•SourceList

•Resb Def [OMBN] •Plant MatTyp N:1 • nonMAT will base on MatGrp mapping to •Partner 2.Display

•AA_CAT <Limited Customization> •Unknown [U]* [U] => PR,

PGrp •ProcureTyp

Material Valuation

ValClass [OMQW], AAC provides the AGC TxtTyp

Text 3.Required •Tranx (ME21N=AKTV) PO [D, B], CT

•etcs (mrp) Determination 4.Optional •Activity

Basic [K] Accounting [B] Material Level Organization Level •Txt-Linkage •Rel Status Linkage CS (nonVal-GR, no IV)

P/O/G (CondProc) Follow-on Line Item

InfoUpd Flag •Para: EFB [V_T161A] (PIR needed)

•NR Plant [X] Costing [Q] Level •Fixed Indic.

1.GR: 101 (stock=K)

BP •[A] both

Consumption-Based Planning Reorder pt = SafetyStk+(DailyReqt*RLT) ValArea •CoyCd

•FS Sloc [Z] Sales [V] AC_CAT_REF •Plant •[B] Plant Standard 2.GI: 411K

•One-Time Flg MRP Type for CBP MRP Area •[C] POrg Dr Exp; Cr Liability

OMSG Purchasing [E] MRP [D] MMD1 OMDQ •Reorder Point (VB) 3.MKRO:

•Plant Level K CS [Spec. Stk = “K”]

N:1

AcctGrp MRP Prof MRPType Plant Level

•VSR Level •Forecast (VV) OMWD Dr Liability; Cr A/P

(VGC)

•Time-phased (R1) Sloc Level ValClass COA Auto PR->PO [ME59N]

L SC [Spec. Stk = “O”] SC (Val-GR)

Client Level Parameter ValGrp

•MAT-> Auto •Omit err item

NB

•Plant OMI8 (PIR needed), BOM

Vendor CoyCd Level •MRPGrp OPPZ •MRP Proc MRP allows direct SA •VD-> Auto •Skip all if err S 3PL 1.TF: 541 [stock=O]

OMSK OMWM

•MatGrp OMIG •Firm Type MD01N MRP Live direct PR Transaction Level •PR w/ Supply 2.ME2O: 543+101

POrg Level •Plan Regularly (w/o Pln Ord) OMWN

•Forecast Usage

MRP Run OBYC

•BSX (Inventory)

•GBB (GI)

PR PO D Services Dr Exp; Cr Stk-RM

Dr Stk-FG; Cr Stk-Chg

•Reorder pt (posting rule) (posting key) Account

Plant Level ValString TranxKey •WRX (GR/IR)

T Text

Dr SC charge; Cr GR/IR

•Screen seq Determination •PRD (Price Diff)

(modifier) No GR allowed

VSR Level Pln Order AGC •UMD (Reval) No MATnr (STxt /MatGrp)

MRP Run for CBP Lot Size B

•Check planning file Lot Proc [OMI4 ] FO Limit Limit + Valid

ProcureTyp = F ProcureTyp = E ValString is fixed

•Net reqt calc Rd Prof [OMD1 ]

•AA_CAT

Mandate: AAC, Plant

•Lot-size calc

Source of Supply RFQ

OMFO •MovTyp

U Transport

•POrgSG [OMFP] •Scheduling

On-order Stk

Firm PlnOrd, PR PR MF Order OMJX •CalcSchema MRP PR UB

•VenSG [OMFN] •Procure determ PO MIGO ACDOCA 1.QR +SLMRP 1.QR

CT Type

1:N

OMJJ 2.SLMRP Flag 2.SL •Quantity [MK]:

PR uses MMR value price W MatGrp Level

MovTyp MATDOC ML 3.PIR Auto-Srcg 3.SA, CT

CT _, K, L, M, D

Pricing ConditionPIR, PO/RFQ/OA use conditions Reference

4.PIR (Reg VD)

•Material •Value [WK]: M Unknown (same price)

M/08 •CalType •Vendor Vendor Plant MAT Vendor MAT ProcTyp

Coll-nr _, K, W, M, D

Schema CondClass •Vendor Data User Level Control (Parameter)

Proc •ScaleBasis Client Level *Flag at Plant (SPRO) or *always consider S/4 •Quota SA Type

1:N •EditCtrl •Delivery Ctrl *Flag at MAT •Fix “Src” (Priority) User PO Auth (EFB) User Default (EVO) Message (MSV) •W/o Rel [LP]: Prof Settings

•GroupCtrl POrg Level •Last PO •Block •Alloc Qty 1.Allow non-Mat 1.InfoUpd Flg Custom user Assignment

M/06

•Conditions •Min / Max 2.PIR Ref (last PO) 2.Cond Copy (last PO) warning/error SA _, K, L, S, T CR Prof •AGG Horizon

CondItm CondTyp Plant Level •OA Copy •With Rel [LPA]: •Plant: SA-Typ •Periodicity

•Text •Lot Size 3.Adopt PO Price (from PR) 3.Source Det. ( PR/PO) Auto MRP->SA

ME01 MEQ1 4.PR/RFQ/CT Ref 4.Ord Ack (PO/CT/SA) •MAT-> Procure _, K, L, S, T •General: SA-Itm •Tolerance

Material

Subtot M/07 SL QR 5.CT manual assign

6.Edit/View Cond [OMET] [OMFI] [OMCQ]

•SL-> MRP=2

AccessSeq MatGrp •MRP->SL=2/3

*for nonstock mat Block Level Supplier Evaluation

Condition Validity •Plant / MAT

MEK1 •PO is indep. Sourcing S4 PurCat LIS

ME11 •Vendor / MAT ME54N VA01 Price Deter Auto PO from GR MIRO•For FX PO, if Fixed Exch Rate flagged, S4 Fiori Inbox

CondRec AccessTbl 1.Client Level 1.POrg Level

•CT & PIR time-dep

•SA & RFQ -> SPRO

PIR •OA (RelOrd,SA) PR Rel.Stg PO 1.OA (wrt) (into UR-Stk only,

only for 101, 161)

Invoice PO rate is used for GR and IV; else rate •Single Apps for

Procure Approval

Request 2.Hard facts 2.Time/Qty,

2.PIR Cond Dr Expense will be as per GR and IV.

Rel.Stg (Time/Qty, Quality, Price +

*for STO, Src=Plant 1.POTyp<- MB01 •IV-park can have prepayment function

•PR/PO, INV

Quality, Price) Invoice,

ME41 3.PIR Last PO Cr A/P

RFQ PO-itm 2.MovTyp ->AutoPO Sourcing Service,

Release Strategy 4.Manual PO S4 Analytics + Soft facts

W/O Classifi. [Default] •Material, Condition 3.MMR ->valuated •Subseq Dr/Cr update value only (Cr/Dr Project (Internal Substain

Transfer •Rel. Char: AAC, MatGrp, Plant •Delivery (StkTyp, nonVal-GR, Del-Compl) 4.PIR for Pricing

Dr/Cr Memo

Memo update qty & value).

•Smart Business FW

Questionnaire) 3.Avail post-

Del-Comple te •Fiori

OLMB •Rel. Level: item Outline Agreemt

•Del.Schedule 3.Realtime eval run

Plant Transfer Sloc Transfer Transfer •RelObj With Classification

•Open Qty = 0 •If addition cost/under invoice, Subseq •Real-time

Parameters

(1=PR; 2=“PD”) ME31K •Invoice (ERS, IV-Plan, DP, Final) •Commit cancel Subseq Dr/Cr Debit; else Credit Auction 4.Avail in BN-

•1Step: 301 •1Step: 311 •QIS->URS: 321 •Rel. Char: Any (customizing) •Not MRP relv.

•2Step: 303+305 •2Step: 313+315 •BKS->URS: 343 MMBE •Overall Rel. •Rel. Level: item / total

CT •AC Assignment Ord Ack Default •Canbe archive Cr Memo is to reduce the invoice Qty (RFX) Sht

•PO History

•STO: 351/101 1Step - any combi •BKS->QIS: 349 Inventory •Class of Char.

(w/ Classifi.) •Text, Confirmation

•Personal Settings

•User Para EVO ME91F ME2DP •MAT (Material)

Ariba Network

All - URS- URS Only 2Step - URS-URS Only •Mat2Mat: 309 ME31L •PIR InvoicingPlan DP

SA •Park/Held function Expedite Awarding •MMR ( Material Rec)

•Vendor Monitor

OMBN •Personal PO Settings •UR-Stk (urestricted)

GI Default (Plant)

MB25 •Movt Allow •For stock mat.: •QI-Stk (quality)

MIGO •For “S” ctrl, PO vs GR price diff is posted MRIS •IV Plan are periodic IV postings; whilst ERS are GR-based IV.

Consumption Sample ( nondest) Scrapping RESB •Retention Rel.Grp •before IV, post to GR/IR GL; IV-Plan •BK-Stk (blocked)

•Days Allow GR into price diff. Stock price = Std. •No GR or nonVal GR is used by IV Plan; ERS mandates GR.

•CC: 201 •Sample: 323 •Scrap: 551/3/5 To allow GI update to RESB,•Sloc MMR after IV, post to stock GL

Dr Goods •For “V” ctrl, the Stock price = Avg. Settle •Both IV Plan & ERS needs AutoEvalGRSetmtDel flag and Tax •VD (Vendor)

•PS: 221 •Rel: 321 Returns and/or price-diff (if diff for “S” Ordering

•AA: 241 Sample ( destuct)

set “Movt Allow” in resb record.

ctrl).

Cr GR/IR in POitem. •SL (Source List)

•ME21N: 161 If RESB is not required, set •In addition, ERS requires GR-Bsd-IV flag (def in PIR), ERS flag Status

•MF: 261 •Sample: 333/1/5 •Rel. Preq. •For nonstock. mat.: ML81N MRRL •QR (Quota Arrange)

•Manual: 122 “Final Issue” in the movt doc. •SES base on Serv Master (“Serv-GR”). (def in Vendor), and PayTerm (def in Vendor)

Rel.Stg •Rel. Char. •post into consump. GL. SES ERS •PR (Purch. Requisit)

(If GI Qty = RESB Qty, auto set) •After SES is entered, acceptance has to

•Rel. Indic. If there is IV diff, post to happen, before it triggers IV. Serv Spec is

GR ME2ON MKRO •RFQ (Req for Quote)

Rel. ID (PR) consump again. If no GR, then in the PO. No GR. SC CS Invoicing

GR Other GR (no ref) Plant/Sloc Ext. Interface -> Process

•Rel for PO full IV into consump. Settle Settle •SA (Scl. Agreemt)

posts non-ref counts 1.P/I Doc [MI01] Status •CT (Contract)

•Wrt PO: 101 (URS) •BOC: 561/3/5 Spec. Stock and difference (Block/Freeze Indic.) •Rel for RFQ

•Cond Acp: 103 (BKS) •W/O PO: 501/3/5

Stock

2.Result [MI04] Rel.Code •Firm MRP •Stock mat. -> Only Val-GR •PO (Purchase Order)

•Cond Rel: 105 •W/O MF: 521/3/5 3.Post Diff [MI07] •FS Key Deliver Cost (Planned) are charged into freight clearing Unplanned Cost (cost that incur after-PO)

Count •Changeability

•nonStock mat. -> AA_CAT

(instead of GR/IR). For “S” control, this goes to price-diff; for can be either [per CoyCd]: •DL (Delivery)

•C/A RET: 124 •FOC: 511 Frequency •nonVal-GR -> no GR/IR

•Origin Acp 107 (BKS) •RET: 451 •Periodic OMJ2 Rel. ID (PO) •Multiple AA -> nonVal-GR def

“V” control, this goes into stock. (1) be allocated to POitem by value OR •IV (Invoice)

•Origin Rel 109 •PI Diff: 701/2 •Continuous Tolerance •Block PO -> (2) post into separate GL (OBYC: UPF) with defaulted tax (OMR2). •SC (Subcontract)

•Cycle M_EINK_FRG no Output •CS (Consignment)

You might also like

- SAP S4 HANA SD 1709 Overview (Mindmap Edition) Final PDFDocument1 pageSAP S4 HANA SD 1709 Overview (Mindmap Edition) Final PDFAsterx Le Gaulois100% (1)

- HR Project List SPB LASER PRINTING: 9971719495Document33 pagesHR Project List SPB LASER PRINTING: 9971719495mirzaNo ratings yet

- MEB Issue 37 Screen Format-SDocument52 pagesMEB Issue 37 Screen Format-SPaolo Di MarcoNo ratings yet

- SAP S4 HANA MM CertificationDocument1 pageSAP S4 HANA MM CertificationYong Benedict100% (4)

- 1.S4 MM Flow DetailedDocument1 page1.S4 MM Flow DetailedPrakash Praky100% (1)

- Corel Draw Keyboard ShortcutsDocument5 pagesCorel Draw Keyboard ShortcutsZaid_SultanNo ratings yet

- SAP S - 4HANA MM Mindmap by Benedict YongDocument1 pageSAP S - 4HANA MM Mindmap by Benedict Yongtucu23456100% (1)

- Comparative Analysis of Coke and PepsiDocument17 pagesComparative Analysis of Coke and Pepsisbanik1071% (7)

- Highlevel PP & CO Integration ProcessesDocument1 pageHighlevel PP & CO Integration ProcessesABDELMALEK .TEBOUDANo ratings yet

- SAP PP Certification Overview (Mindmap Edition)Document1 pageSAP PP Certification Overview (Mindmap Edition)Yong BenedictNo ratings yet

- ComproDocument16 pagesComproRachmat AditiyaNo ratings yet

- Operations Strategy - TESCO - FinalDocument9 pagesOperations Strategy - TESCO - FinalSrujana Gattu100% (1)

- QuestionnairesDocument6 pagesQuestionnairesak0987% (15)

- Orgunit / Concepts / Processes: MaterialDocument1 pageOrgunit / Concepts / Processes: MaterialPrakash Praky100% (1)

- SAP S4 HANA SD CertificationDocument1 pageSAP S4 HANA SD CertificationYong Benedict80% (5)

- Concurrent EngineeringDocument12 pagesConcurrent Engineeringamit chaudhari100% (1)

- Zulser PumpsDocument56 pagesZulser PumpsManuel CarreñoNo ratings yet

- Webinar SIMATIC PCS7 PDFDocument84 pagesWebinar SIMATIC PCS7 PDFLuis Jonathan Bahamaca FernandezNo ratings yet

- IS Oil - DownstreamDocument1 pageIS Oil - DownstreamtalebiNo ratings yet

- The New Cisco Partner ProgramDocument47 pagesThe New Cisco Partner ProgramZaid_SultanNo ratings yet

- SZ Sales ProgramDocument28 pagesSZ Sales ProgramrossifrancescoNo ratings yet

- SAP PP, PM, PS - All in One DeckDocument3 pagesSAP PP, PM, PS - All in One Deckjohn leon100% (1)

- Cottle-Taylor India: 02 Income Statement (Patel) 03 Income Statement (Lang) 04 Proposed Income StatementDocument16 pagesCottle-Taylor India: 02 Income Statement (Patel) 03 Income Statement (Lang) 04 Proposed Income StatementDeepakRamNo ratings yet

- MiloDocument16 pagesMiloAvnish AhalawatNo ratings yet

- Kaviya ProjectDocument66 pagesKaviya ProjectATS PROJECT DEPARTMENTNo ratings yet

- Dialog Editted Marketing Plan - Original-2Document9 pagesDialog Editted Marketing Plan - Original-2Poorni Perera67% (3)

- Project On OriflameDocument60 pagesProject On Oriflamepaulroja95% (39)

- Gennady Fedorov - Technical Consulting Engineer Intel Architecture, Graphics and Software (IAGS) LRZ Workshop, June 2020Document25 pagesGennady Fedorov - Technical Consulting Engineer Intel Architecture, Graphics and Software (IAGS) LRZ Workshop, June 2020Hacı ÖZIŞIKNo ratings yet

- Origin Field Software Features: File Survey (GNSS Mode)Document2 pagesOrigin Field Software Features: File Survey (GNSS Mode)MLOO CONTINEXNo ratings yet

- MR J4 Rotary MotorsDocument24 pagesMR J4 Rotary Motorsjesus roblesNo ratings yet

- QEP Range: Which Model Will You Choose?Document2 pagesQEP Range: Which Model Will You Choose?Ahmad El KhatibNo ratings yet

- Flow Data MaintenanceDocument7 pagesFlow Data MaintenanceKesialan yg ku dapat.No ratings yet

- Capabilities Chart: GeneralDocument3 pagesCapabilities Chart: GeneralFernando Acevedo FernandezNo ratings yet

- Recap: Smurfit-Stone Container Operational Excellence Boot CampDocument85 pagesRecap: Smurfit-Stone Container Operational Excellence Boot CampK TNo ratings yet

- Slagging in Steam Generators: Root Cause AnalysisDocument8 pagesSlagging in Steam Generators: Root Cause AnalysispiyushagaNo ratings yet

- PABT Battlemax IN Range BrochureDocument2 pagesPABT Battlemax IN Range Brochuresf wNo ratings yet

- PABT Battlemax PR Range BrochureDocument2 pagesPABT Battlemax PR Range Brochuresf wNo ratings yet

- PL444 Technical Set UpDocument26 pagesPL444 Technical Set UpBilel Ben SlamaNo ratings yet

- Materi Trainning Sales ProcessDocument8 pagesMateri Trainning Sales ProcessAlif ShofianNo ratings yet

- 3 AmadeusAlteaNDC SeatAvailability 18.1 ImplementationGuide 20230623Document81 pages3 AmadeusAlteaNDC SeatAvailability 18.1 ImplementationGuide 20230623thanhhuyenNo ratings yet

- Materi Webinar Open Pit / Tambang TerbukaDocument32 pagesMateri Webinar Open Pit / Tambang TerbukaNanda Yuri HayuNo ratings yet

- AutoTrak Service LevelsDocument2 pagesAutoTrak Service LevelspendexxNo ratings yet

- EDGECAM 2020.1 Feature ChartDocument10 pagesEDGECAM 2020.1 Feature ChartrajeshpdcNo ratings yet

- PABT Battlemax VS Range BrochureDocument2 pagesPABT Battlemax VS Range Brochuresf wNo ratings yet

- Fortigate Ii: Last Modified: Wednesday, April 29, 2020 Fortigate 5.4.1Document50 pagesFortigate Ii: Last Modified: Wednesday, April 29, 2020 Fortigate 5.4.1Mohsine AzouliNo ratings yet

- Advanced Fixed Asset ReportingDocument28 pagesAdvanced Fixed Asset ReportingreymranNo ratings yet

- 7 OrderReshop 18.1 Implementation GuideDocument295 pages7 OrderReshop 18.1 Implementation Guidesubhayan.nittNo ratings yet

- Ch4 SheetMetalDocument10 pagesCh4 SheetMetalmaurya21No ratings yet

- Po48811109 LDocument1 pagePo48811109 LKaveri SinghNo ratings yet

- Course OutlineDocument3 pagesCourse OutlineLishaNo ratings yet

- World Renown For: High Reliability, Precision, & SpeedDocument11 pagesWorld Renown For: High Reliability, Precision, & SpeedDavid ParishNo ratings yet

- Komatsu Pc35r 8Document6 pagesKomatsu Pc35r 8elminetorsystemNo ratings yet

- Tr435 Aaes Pra - ProductionDocument130 pagesTr435 Aaes Pra - ProductionSarvesh AgrawalNo ratings yet

- Mpa-Fm: Medium Voltage - Electric Fire Pump ControllerDocument2 pagesMpa-Fm: Medium Voltage - Electric Fire Pump ControllerAle LabraNo ratings yet

- Operation Drilling Daily Report1Document2 pagesOperation Drilling Daily Report1Islam AtifNo ratings yet

- SP PDFDocument7 pagesSP PDFVikram JainNo ratings yet

- Lowering Congestion Standards To Improve Growth Management: ITE 2007 Spring ConferenceDocument20 pagesLowering Congestion Standards To Improve Growth Management: ITE 2007 Spring ConferenceM-NCPPCNo ratings yet

- Microwave Journal-November 2021Document132 pagesMicrowave Journal-November 2021Petros TsenesNo ratings yet

- RLX Precision Range-8pDocument8 pagesRLX Precision Range-8pAngela MarkovskaNo ratings yet

- Conversions Formulas R1Document81 pagesConversions Formulas R1Raj143143No ratings yet

- Business-Model-Canvas Vf.Document1 pageBusiness-Model-Canvas Vf.Chan D. ArdilaNo ratings yet

- Numerical Non Directional Overcurrent Protection Relay TypeDocument4 pagesNumerical Non Directional Overcurrent Protection Relay TypeSudipta HalderNo ratings yet

- NSRP LLM WPQTDocument3 pagesNSRP LLM WPQTtranvando1986No ratings yet

- Sample ArchitectureDocument1 pageSample ArchitectureprasannnaNo ratings yet

- Creo Harness Manufacturing Extension Data SheetDocument3 pagesCreo Harness Manufacturing Extension Data SheetnirusatyaNo ratings yet

- Project On: Relaibility Improvement of Chain Conveyor at Battery 5,6 & 7 TSL (India)Document8 pagesProject On: Relaibility Improvement of Chain Conveyor at Battery 5,6 & 7 TSL (India)saurabh kumarNo ratings yet

- Slides PDF - MGMT90032 Week 02Document35 pagesSlides PDF - MGMT90032 Week 02Sam ChawlaNo ratings yet

- AWS Vs Azure Vs GCPDocument5 pagesAWS Vs Azure Vs GCPZaid_SultanNo ratings yet

- Tasheel Beheshti Zewar - Asatza Jamiatur RasheedDocument537 pagesTasheel Beheshti Zewar - Asatza Jamiatur RasheedZaid_SultanNo ratings yet

- Excel 2007: Formulas & FunctionDocument20 pagesExcel 2007: Formulas & FunctionZaid_SultanNo ratings yet

- MODULE 3 - Consumer BehaviourDocument34 pagesMODULE 3 - Consumer Behaviourdigvijay babuNo ratings yet

- Zomato Phase 3 AnalysisDocument9 pagesZomato Phase 3 AnalysisRajat ShahaNo ratings yet

- Methods of Analyzing and Evaluating The MarketingDocument10 pagesMethods of Analyzing and Evaluating The MarketingIoana-Daniela PîrvuNo ratings yet

- Midterm TestDocument13 pagesMidterm TestbebeNo ratings yet

- SWOT Analysis of Telecom Sector in IndiaDocument28 pagesSWOT Analysis of Telecom Sector in IndiaBhakti AgarwalNo ratings yet

- Deepen Relationships With Purposeful Channel: ExpansionDocument4 pagesDeepen Relationships With Purposeful Channel: ExpansionAmisha SinghNo ratings yet

- Ch07 Entrepreneurship Revised For ADMN1016Document23 pagesCh07 Entrepreneurship Revised For ADMN1016Ramandeep SinghNo ratings yet

- Review Jurnal PDFDocument25 pagesReview Jurnal PDFTantriiNo ratings yet

- Nadia Pfe eDocument63 pagesNadia Pfe eel kati Abdu El YemlahiNo ratings yet

- A.Suneel Kumar - 2019JULB01278 - Tech MahindraDocument15 pagesA.Suneel Kumar - 2019JULB01278 - Tech MahindraAvolupati Suneel kumarNo ratings yet

- Olivarez College: Learning InsightDocument17 pagesOlivarez College: Learning InsightTricia JavierNo ratings yet

- McDonalds Franchise Disclosure DocumentDocument2 pagesMcDonalds Franchise Disclosure DocumentPrabjot Singh0% (1)

- Sales Manager Resume ObjectiveDocument4 pagesSales Manager Resume Objectiveguj0zukyven2100% (2)

- Marketing Plan For The National Security Technology IncubatorDocument14 pagesMarketing Plan For The National Security Technology IncubatorRafael DoblesNo ratings yet

- Marketing Case 1Document1 pageMarketing Case 1Muntaha ZyanNo ratings yet

- RMP Review Center Proposal ThesisDocument30 pagesRMP Review Center Proposal ThesisGelyn RaguinNo ratings yet

- Rural Marketing Environment (Unit-4)Document36 pagesRural Marketing Environment (Unit-4)yuktha sNo ratings yet

- Online platform (đủ các yếu tố)Document16 pagesOnline platform (đủ các yếu tố)Hoang Minh AnhNo ratings yet

- Bangladesh University of Professionals (BUP) Faculty of Business Studies (FBS)Document27 pagesBangladesh University of Professionals (BUP) Faculty of Business Studies (FBS)Md Nasir HossainNo ratings yet

- Matching Product With Target MarketDocument8 pagesMatching Product With Target MarketMary Chris Bacnis Cabuang100% (1)