Professional Documents

Culture Documents

Utilization of Chitosan Extracted From Green Mussel Shell (Perna Viridis) As The Main Component For Fire Resistant Bubble Wrap

Uploaded by

RACHEL DAMALERIOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Utilization of Chitosan Extracted From Green Mussel Shell (Perna Viridis) As The Main Component For Fire Resistant Bubble Wrap

Uploaded by

RACHEL DAMALERIOCopyright:

Available Formats

Utilization of Chitosan Extracted from Green Mussel Shell (Perna viridis) as the Main

Component for Fire Resistant Bubble Wrap

Renalyn T. Damalerio 1,2,3, Maxine Jean S. Arellano 1,2,3, Melrhose Jade M. Balderas 1,2,3, Andrea

Rebeca F. Cabrillas 1,2,3, Franze Charls E. Camposano 1,2,3, Japchino S. Casipit Jr.1,2,3, David T.

Franco 1,2,3, Fritzy H. Mendoza 1,2,3, Paula Irishly A. Modesto 1,2,3, Alexis Rheiy M. Mojar 1,2,3,

Jeffrey B. Ramiro 1,2,3, Mikaela A. Sabido 1,2,3, Loe A. Baloro1,2,3,4

1

Science, Technology, Engineering, and Mathematics

2

Senior High School Department

3

Pamantasan ng Lungsod ng Marikina

4

Loe A. Baloro

January 2024

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

STATEMENT OF THE PROBLEM

The main objective of this study is to address current environmental issues associated

with traditional plastic-based packaging, including bubble wrap, which is commonly used

in the manufacturing sector. The use of green mussel shells and Solanum tuberosum

starch (potato starch) as main ingredients in the production of fire-resistant bubble wrap

is the main topic of this study.

Specifically, this study sought to answer the following questions:

1. Which of the following is the most effective formulation of potato starch-based

materials to produce bubble wrap?

a. 22.5 grams of potato starch, 1500 ml of water, 75 ml of glycerin, 75 ml of

acetic acid, 20 grams of chitosan

b. 22.5 grams of potato starch, 1500 ml of water, 75 ml of glycerin, 75 ml of

acetic acid, 30 grams of chitosan

c. 22.5 grams of potato starch, 1500 ml of water, 75 ml of glycerin, 75 ml of

acetic acid, 40 grams of chitosan

2. What is the level of performance of potato starch bubble wrap in the following categories:

2.1 Elasticity

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

2.2 Tensile Strength

2.3 Impact resistance

3. To what degree can the following impact the efficacy of the potato starch bubble wrap?

3.1 Biodegradability

3.2 Solubility

3.3 Fire- resistance

II. RELATED LITERATURES/STUDIES

Packaging that preserves goods similarly to traditional packaging while maintaining the quality

and strength of traditional materials is referred to as sustainable packaging, according to TIPA

(2023). However, it breaks down completely into organic compost, which is good for the

environment. Sustainable packaging includes any form of environmentally friendly material used

to wrap, ship, or store products.

Escursell et al. (2021) brought to light the rapid advances in packaging materials and

technologies. But as time goes on, it becomes increasingly difficult to cut costs and reduce the

impact on the environment. Furthermore, the continued use of unsustainable packaging materials

hinders the further development of e-commerce. More in-depth research is needed to encourage

the creation of creative packaging made from natural, abundant renewable sources. Additionally,

implementing

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

innovative and efficient techniques in distribution operations can minimize the damaging effects

of packaging on the surroundings.

In many nations, environmental protection is one of the most significant political issues. The

food sector produces a lot of waste, which biotechnology methods can help to better manage.

According to Lin et al. (2022), one of the industries that produces a significant amount of

garbage that is harmful to the environment is the potato business.

Bhausaheb (2023) claims that potato starch contains trace amounts of fat and protein. Potato

starch is a polymer composed of long chains of linked glucose molecules. Amylopectin, which is

highly branched, and amylose, which is made up of long, chain-like molecules, make up most of

the plant starch. Potato starch is a combination of these two polymers. Because of its thickening

and binding properties, potato starch is a versatile ingredient that can be used to make

construction materials, papers, adhesives, and other non-food goods. Potato starch serves as the

basis for several product innovations, including carrying bags, foam-packed chips, food-grade

trays, and biodegradable eco-plastics. Starch is categorized as a polysaccharide sugar in

biochemistry. One of its sugar's components is glucose. Two components of potato starch—

amylose and amylopectin—determine its properties. The proportion of amylopectin to amylose

is frequently 1: 4 to 1: 5.

According to Sunwane et al. (2021), the bioplastic material made from potato starch has a shelf

life of three to six months. Compared to conventional plastic, bioplastic can have less impact on

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

the environment. Every household produces more plastic waste due to the regular use of plastic

materials. One way to reduce environmental pollution is to use bioplastics. It is known to be

biodegradable and has positive effects on the environment.

According to Chae and An's (2018) research, plastics are also known to pollute soil, which is

important for raising animals and crops necessary for the security of the human food supply. In

addition, several plastic additives have been proven to be harmful to health. Based on Kumar

(2018), they may result in adult diabetes, early puberty, obesity, immune system and endocrine

system issues, irregularities in human reproduction, and other chronic disorders.

46% of the 14 million metric tons of fresh plastic debris end up in the ocean each year, according

to Quito (2022), is made of softer, low-density polyethylene, including bubble wrap.

In accordance with Tianyi et al. (2021), creating biodegradable plastic substitutes is one of the

greatest ways to lessen the issue of plastic pollution. Starch-based materials are among the most

researched and often utilized types of naturally occurring biodegradable materials. This is due

to the fact that starch is widely available in nature and offers a variety of advantages, including

being inexpensive, non-toxic, renewable, biocompatible, and able to form films. Furthermore,

the polyhydroxy structure of starch facilitates the manipulation of the substance's structural and

functional properties through the use of chemicals or enzymes.

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Kjeldsen et al. (2018) described that the ability to degrade of plastics can be defined as the

biological procedure leading to the disintegration of plastic. The two things that affect how

rapidly a material degrades in its surroundings are its chemical makeup, or what kind of plastic it

is, and its ultimate destiny after its lifespan. Timescales involved in biodegradation can be widely

standardized through process management found in controlled environments such as digesters

that are anaerobic. Numerous elements, such as the kind of soil, water, and landfill placement,

affect the environment in which items might break down. Testing the material's biodegradation

properties is necessary to comprehend the materials, decomposition processes, time scales, and

products generated by biodegradation.

According to Kundu et al. (2022), plastics made from starch decompose completely within two

months. Starch-based plastic breaks down completely in 96 hours; in the presence of fungal α-

amylase and cultured bacteria, this time drops to 48 hours. Therefore, bioplastics can be a

potential replacement for petroleum-based polymers to address environmental issues.

To produce biodegradable plastics, starch, cellulose, chitosan, and proteins obtained from

sustainable biomass are used. These environmentally friendly polymers do not require

petrochemicals and reduce greenhouse gas emissions. They reduce the need for non-renewable

resources and the consumption of fossil fuels. Compared to traditional plastic, the manufacturing

method can produce fewer greenhouse gases and use up to 65% less energy. (Verma et al. 2020)

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Dienamics (2020) states that using fire-resistant plastic won't stop interior fires from occurring;

instead, it will lessen the chance that the fire will spread outside the object. In many cases, this is

necessary to comply with product safety regulations.

According to Mensah et al. (2022), it is crucial to develop sustainable biobased FRs that enhance

polymers' fire performance without harming the environment, as not all FRs are environmentally

friendly. Adding FRs shortens the time it takes for plastics to ignite since the samples volatilize

fast, according to a few interesting analytical findings.

Halogen-based flame retardants, especially those based on bromine, have played a significant

role in flame resistant, and still do. On the other hand, there is a lot of interest in halogen-free

substitutes due to environmental concerns and waste disposal problems (Innes et al. 2012).

Halogen-free flame retardants are superior to halogen-based flame retardants in several respects,

asserts Garkhedkar (2023). In the past ten years, scientists and business experts have recognized

the harmful impacts of flame retardants based on chlorine and bromine. This insight made

halogen- free substitutes necessary. Products with brominated flame retardants displayed toxicity

profiles and durability of bioaccumulation. They pose a serious challenge to the circular

economy because, when disposed of, the halogenated flame-retardant molecules exhibit

persistent organic pollutants (POPs). There is evidence that humans, birds, water bodies,

wildlife, and soil microbes all contain harmful flame retardants.

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

According to Martinez et al. (2019), fire-resistant bubble wraps often incorporate flame-retardant

additives, and halogen-based compounds are among the chemicals used for this purpose.

Halogenated flame retardants release halogen atoms (like bromine or chlorine) when exposed to

heat, inhibiting the combustion process. While effective, there is concern about the

environmental and health impact of some halogenated flame retardants, which has led to the

exploration of more environmentally friendly options.

Due to its chemical flexibility and adaptability, phosphorus is necessary to produce effective fire-

resistant materials, as demonstrated by Velencoso et al. (2018). It can work in a variety of

oxidation stages, condensed phases, gas phases, additive components, and combinations with a

broad spectrum of other elements. For flame-resistant compounds without halogen, one of the

most promising combination is the nitrogen and phosphorus. When fire is present, the

phosphorus-nitrogen complex facilitates the development of cross-linked networks containing

polymer chains. As a result, there is a greater and more thermally stable production of char

because P is better retained in the condensed phase. Two popular forms of structure are

phosphoramidates (P-N structure) and cyclotriphosphazenes (P-N structure). The two most well-

known structural forms are phosphoramidates and cyclotriphosphazenes (P-N structure).

Phosphoramidates have improved thermal stability, lower volatility, and higher viscosity due to

hydrogen bonding when compared to equivalent phosphates.

Another newly discovered innovative family of flame retardants that addresses Combustibility

and environmental concerns is nitrogen-phosphorus (P-N)-containing compounds. P-N FRs

outperform

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

phosphorus-based FRs in terms of thermal stability and hazardous smoke emissions. Recently,

they reported on specific bisphosphoramidate-based P-N FRs that when applied to charrable

polymers like polycarbonate (PC) in the condensed phase, increase the formation of residual char

than equivalent bisphosphate FRs. These FRs also have exceptional fire retardancy. The study

indicates that the P content of FRs is one of the major variables influencing their flame

retardancy. (Vodhi and colleagues, 2019)

The use of bio-based polymer packaging has increased interest in finding alternatives to non-

biodegradable plastics that pollute the environment when fires break out (Adyel, T. 2020). In

2015, a packing materials plant experienced a fire breakout that resulted in significant damage,

as reported by Zhang D. (2023). Fire security officers investigated and discovered that foam

rolls, bubble wrap, and cardboard were among the packaging materials that caught fire. Because

petroleum constituted most of the ingredients, it ignited and burned quickly. This case supports

the requirement for packaging materials that are resistant to fire and do not solely rely on fossil

fuels.

The bubble wrap sample had the highest percentage of hydrocarbon fraction in the kerosene range

(C10–C13) Covering 19.23% of the area. According to Sari et al. (2023), kerosene is a form of

fuel that usually contains these kinds of hydrocarbons.

Frugal Entrepreneur (2023) asserts that because bubble wrap prevents heat from escaping the

thing it is wrapped around, it is ineffective as an insulator. The bubble wrap will begin to

degrade and

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

release heat when it is heated. As a result, the item enclosed in the bubble wrap will heat up and

perhaps catch fire.

Due to its non-biodegradability, end-of-life disposal, and fire dangers, plastic bubble wrap poses

a serious risk to human health and the environment (Rogers, 2017). Compared to alternative

flexible protective packaging, bubble wrap has a higher tendency to catch fire due to the

combination of plastic and air. (2019, Future Market Insights).

To create a biodegradable polymer in 2020, Mondal et al. mixed 1.5 g of potato starch with 100

ml of filtered water, 5 ml of glycerin, and 25% acetic acid. A polymer that is safe for both people

and the environment was produced when the combination was heated and combined.

According to the study by Bhausaheb (2023), biodegradable plastic can be made by diluting 7.5

g of dried potato starch with 100 ml of distilled water in a 500 ml beaker, adding 1.5 ml of

glycerin and 1 milligram of citric acid, and heating the mixture.

Potato starch is a naturally occurring, abundant, and environmentally friendly raw material that

can be used as a main element in the production of bioplastics, according to a study done by

Sonawane et al. (2021). During the test, 4.25 grams of sodium chloride, 3 milliliters of

hydrochloric acid, 2 milliliters of glycerin, and 25 milliliters of distilled water were mixed with

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

2.25 grams of potato starch. Due to their natural degradation, bioplastics made from potato starch

are considered harmless to the environment.

As by Kannankeril (2018), bubble wrap is made by gluing the first and second sheets together,

which are then sealed to form an expandable area. Ideally, the first and second layers of the film

should be identical in composition and thickness. Once the foils are sealed, the passages are

inflated. The air gas remains contained in the chamber after inflation. In response to the air, the

two leaves separate from each other, creating an inflated bubble. Seal the sheet edges to keep the

packaging in place and keep the air inside.

Tensile strength is defined as the maximum force a sample can bear before breaking when it is

stretched or pulled. The tensile strength formula is: Tensile strength= F M/A0. The material cross-

sectional size (mm2), maximum stress (N), and tensile strength unit are represented by A 0, FM,

and MPa, respectively. (Fiandini et al. 2020)

To measure the dry weight of a 1.5 cm2 sample dried for 24 hours, you can test the solubility of

the bioplastic. Once it has dried, put it inside a beaker with 50 milliliters of distilled water inside

it at room-temperature. After a full day, you extract the bioplastic by straining it from the water,

let it dry for another day, and then weigh it to determine its final mass. Apply the following

formula: (W1- W2)/W1 * 100 = Solubility in water (%) (Alsalme et al. 2021).

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

A substance is considered biodegradable when it can be broken down by bacteria, plants, or

animals. Furthermore, the environment has an impact on the decomposition process. The degree

of biodegradation of an object varies as a result. First created to assess a packaging's capacity to

compost, the EN 13432: Standard on Packaging and Wrapping is a biodegradation test for solid

materials. This benchmark is used to analyze disintegration, one of the four criteria used to

determine a material's biodegradability. There is no minimum depth requirement; the criteria

state that the material must dissolve over a maximum of 12 months, pass through a >2mm

screen, and have 90% of its material destroyed after being buried in soil. The final three

components evaluate the toxicity of soil, chemical characterization, and aerobic biodegradation

(Aitex 2020).

Kasmuri and Zait's (2018) study assesses a bioplastic's rate of biodegradation. To ascertain the

weight of every sample, they employed a weight scale. The initial data was the weight

measurement. After that, The 100 x 100 mm sample was then buried in both natural and

composted soil for two months he soil sample was extracted every seven days. After being

cleaned with distilled water, the sample was placed in an oven for 24 hours at 60 °C to dry it out.

A day later, the sample was measured and data was collected. Weight loss (%) = [(W0-Wt/W0) x

100] is the formula used to calculate weight loss, where Wt (g) is the weight of the bioplastic

after it has been buried, and W0 (g) is its initial weight before it was buried.

According to Kaluza et al. (2021), the impacts of starch origin on film qualities were compared

to generate films made from starch suited for packaging food. The starches of corn, potatoes,

oats, rice, and tapioca were combined with 50% glycerin as a plasticizer to create films using

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

the casting

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

method. Tensile strength, moisture content, wettability, surface-free energy, and water vapor

transfer rate were among the attributes assessed. According to the study, there are variations in

tensile strength depending on the starch source. The films based on potato starch had the highest

tensile strength (1.49 MPa), while the films based on oat starch had the lowest (0.36 MPa). But

neither type of film had the mechanical properties of conventional plastics.

Żołek-Tryznowska & Kałuża (2021) concluded that each film's mechanical properties, wet-

ability, surface-free energy, rate of vaporized water transfer, and moisture content all showed

how the starch origin affected it. Dietary starches including those in potatoes, oats, corn, tapioca,

and rice were the raw materials used to make the starch-based films. A plasticizer called whey

was added, but only 50% of the total. Out of the five films, the ones manufactured from potato

starch exhibited the highest tensile strength (3.05 MPa).

The disadvantages of potato starch bioplastics during the formulation process include

hydrophilic properties, insufficient mechanical properties, a low evaporation barrier, and low

freezing consistency. However, depending on how much amylose is present, certain properties of

bioplastics can change. To enhance the characteristics of bioplastics derived from starch,

different methods can be employed to modify the molecular structure of starch. (Halley et al.,

2021)

According to the study by Gabriel et al. (2021), nodule-based bioplastics have the best tensile

strength interaction when it comes to bioplastics based on starch source classification. This is

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

evident in the tensile strength values of potatoes, taro, and cassava, which all range between 10

and 100 MPa, the benchmark for the tensile strength of bioplastics.

Spirulina, or powdered blue-green cyanobacteria cells, was combined with heat and pressure to

create bioplastics. According to University of Washington, the mechanical qualities of their

bioplastics are on par with those of single-use plastics made from petroleum. Because of its

capacity to store carbon dioxide during cell growth, spirulina was selected to be a component of

the new bioplastics, making the biomass a carbon-neutral feedstock for plastics. Since UW stated

that their bioplastics are not yet ready to be scaled up for industrial utilization, their bioplastics

are still in the development stage. Even though these materials are robust, they still have some

brittleness. Their sensitivity to water presents another difficulty, according to UW (Worley

2023).

It is feasible to chemically modify starch to increase its hydrophobicity since glucose molecules

have three active hydroxyl groups (C2, C3, and C6). By introducing or inhibiting functional

groups, starch can be chemically modified to produce optimum physical and chemical properties

for hydrophobicity. Furthermore, the chain's integrity could not be compromised by these

changes. Thus, increasing starch's hydrophobicity will increase its industrial applications

(Ojogbo, Ogunsona, & Mekonnen, 2019).

CONCEPTUAL FRAMEWORK (IV-DV)

Independent Variable Dependent Variable

Potato starch,

chitosan from Fire-resistant

green mussel bubble wrap

shells

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

REFERENCES/CITATIONS

Escursell, S., Massana, P.L., Roncero, M.B. (2021). Sustainability in e-commerce

packaging: A review. Journal of Cleaner Production, Volume 280, Part 1

https://www.sciencedirect.com/science/article/pii/S0959652620343596#section-cited-by

Sonawane, Prachi and Panchal, Amisha and Naik, Shreeya and Mundaye, Bhagyashree

and Padalia, Unnati. Potato Starch Based Bioplastic as Alternative Packaging

Materials (2021). African Journal of Biological Sciences, Vol. 3, No. 3, July 2021, pp.

111-113., https://ssrn.com/abstract=3902389

Chae, Y., & An, Y. (2018). Current research trends on plastic pollution and

ecological impacts on the soil ecosystem: A review. Environmental Pollution, 240,

387–395. https://doi.org/10.1016/j.envpol.2018.05.008

Cheng, H., Chen, L., McClements, D. J., Yang, T., Zhang, Z., Ren, F., Miao, M., Tian,

Y., & Jin, Z. (2021). Starch-based biodegradable packaging materials: A review of their

preparation, characterization and diverse applications in the food industry. Trends in

Food Science and Technology, 114, 70–82.

https://doi.org/10.1016/j.tifs.2021.05.017

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Kjeldsen, A., Price, M., Lilley, C., Guzniczak, E., & Archer, I. (2018). A review

of standards for biodegradable plastics. Ind. Biotechnol. Innov. Cent, 33(1).

http://refhub.elsevier.com/S2405-8440(21)02021-1/sref18?

Kundu, R., & Payal, P. (2022). Biodegradation Study of Potato Starch-Based Bioplastic.

Volume 2.

https://www.eurekaselect.com/article/115373

Tai, N., Ghasemlou, M., Adhikari, R., Adhikari, B. (2021). Starch-based isocyanate- and

non-isocyanate polyurethane hybrids: A review on synthesis, performance, and

biodegradation, Carbohydrate Polymers, Volume 265.

https://www.sciencedirect.com/science/article/abs/pii/S0144861721004161?fbclid=IwAR

1ARLZd8sT49to1U-OhPDR4AaCyS-MS7S-BHUjUGvN_oYddp_Xio4IPYes

Mroczkowska, M., Culliton, D., Germaine, K. J., & Da Costa Neves, A. (2021).

Comparison of Mechanical and Physicochemical Characteristics of Potato Starch and

Gelatine Blend Bioplastics Made with Gelatines from Different Sources. Clean

Technologies, 3(2), 424–436.

https://doi.org/10.3390/cleantechnol302004

Singh, P., & Verma, R. (2020). Bioplastics: A green approach toward

sustainable environment. In Springer eBooks (pp. 35–53).

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

https://doi.org/10.1007/978-981-15-6021-7_3

Lut, L. T. Y. (2021). Assessing environmental sustainability of packaging solutions for

telecommunications network products and developing roadmap for more sustainable

packaging. LUTPub.

https://lutpub.lut.fi/handle/10024/163624

Department of Biochemistry, K. K. Wagh Institute of Agriculture and Allied Colleges,

Nashik - 03, Maharashtra, India. (February 2023). Production of Biodegradable Plastic

from Potato Starch. International Journal of Science and Research (IJSR)

www.ijsr.net

Sonawane, P. (2021). Potato Starch Based Bioplastic As Alternative Packaging

Materials.

https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3902389

Mondal, B., Hasan, M. S., Sardar, M. R. I., & Mahmud, M. (2020). Assessment of

Biodegradable Polymer from Potato-Based Starch. Chemical Engineering Research

Bulletin, 22, 1-6. https://scholar.google.com/scholar?

hl=en&as_sdt=0%2C5&q=Assessment+of+Biodegra

dable+Polymer+from+Potato-Based+Starch&btnG&fbclid=IwAR2KK9kLg0I6i5-

ZbQ1ZIk

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Kannankeril, C. (2018). The Inventor in You: A Step-By-Step Guide to Your

First Invention.Balboa Press.

Shafqat, A., Al-Zaqri, N., Tahira, A., & Alsalme, A. (2021). Synthesis and

characterization of starch-based bioplastics using varying plant-based ingredients,

plasticizers, and natural fillers. Saudi Journal of Biological Sciences.

https://doi.org/10.1016/j.sjbs.2020.12.015

Żołek‐Tryznowska, Z., & Kałuża, A. (2021). The influence of Starch Origin on the

properties of Starch Films: packaging performance. Materials, 14(5), 1146.

https://doi.org/10.3390/ma14051146

Abe, M. M., Martins, J. R., Sanvezzo, P. B., Macedo, J. V., Branciforti, M. C., Halley, P.

J., Botaro, V. R., & Brienzo, M. (2021). Advantages and Disadvantages of Bioplastics

Production from Starch and Lignocellulosic Components. Polymers, 13(15), 2484.

https://doi.org/10.3390/polym13152484

Gabriel, A. A., Solikhah, A. F., & Rahmawati, A. Y. (2021). Tensile Strength and

Elongation Testing for Starch-Based Bioplastics using Melt Intercalation Method: A

Review. Journal of Physics, 1858(1), 012028.

https://doi.org/10.1088/1742-6596/1858/1/012028

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Nandiyanto, A., Fiandini, M., Ragadhita, R., Sukmafitri, A., Salam, H., & Triawan, F.

(2020). MECHANICAL AND BIODEGRADATION PROPERTIES OF

CORNSTARCH-BASED BIOPLASTIC MATERIAL. Materials Physics and

Mechanics, 44.

https://doi.org/10.18720/MPM.4432020_9

Kasmuri A., Zait A. (2018). Enhancement of Bio-plastic using Eggshells and Chitosan on

Potato Starch Based. International Journal of Engineering & Technology, 7 (3.32) (2018)

110-115.

https://www.researchgate.net/profile/Norhafezah-

Kasmuri/publication/327513761_Enhancement_of_Bio-

plastic_using_Eggshells_and_Chitosan_on_Potato_Starch_Based/links/5c1b2497299bf12

be38c85e2/Enhancement-of-Bio-plastic-using-Eggshells-and-Chitosan-on-Potato-Starch-

Based.pdf

Quito, A. (2022, July 20). Bubble wrap, kitchen cling wrap, and plastic poly bags

pollute our oceans more than we realize. Quartz.

https://qz.com/2151074/the-environmental-impact-of-bubble-wrap-and-plastic-

cling?fbclid=IwAR1lm4cw4S_zYgQb1QvxNMR8MZiugaQFNLLhUIBH4bbRcfJ-

ppXRCApbWHE

Velencoso, M. M., Battig, A., Markwart, J. C., Schartel, B., & Wurm, F. R. (2018).

Molecular Firefighting—How modern phosphorus chemistry can help solve the challenge

of flame retardancy. Angewandte Chemie International Edition, 57(33), 10450–10467.

https://doi.org/10.1002/anie.201711735

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Mensah, R. A., Vigneshwaran, S., Narayanan, S., Renner, J. S., Babu, K. G., Neisiany, R.

E., Försth, M., Sas, G., & Das, O. (2022). A review of sustainable and environment-

friendly flame retardants used in plastics. Polymer Testing, 108, 107511.

https://doi.org/10.1016/j.polymertesting.2022.107511

Dienamics. (2020, March 20). Fire Resistant plastics | Dienamics. Dienamics.

https://dienamics.com.au/blog/fire-resistant- plastics/#:~:text=Using%20fire%20resistance

%20plastic%20for,%2C%205VB%2C%20 or%205VA%20classes

Vothi, H., Nguyen, C., Pham, L. H., Hoang, D., & Kim, J. (2019). Novel Nitrogen–

Phosphorus flame retardant based on phosphonamidate: thermal stability and flame

retardancy. ACS Omega, 4(18), 17791–17797.

https://doi.org/10.1021/acsomega.9b02371

Staff, A. W. I. K. (2023, July 17). University of Washington develops new fire resistant,

recyclable bioplastic capable of degrading in backyard. WPDE.

https://wpde.com/news/nation-world/university-of-washington-develops-new-fire-

resistant-recyclable-bioplastic-capable-of-degrading-in-backyard-recycling-climate-

change-global-warming-carbon-emissions-plastics-manufacturing-byproducts-carbon-

neutral-atomic-bonds-petroleum

Wang, X., Huang, L. X., Zhang, C., Deng, Y., Xie, P., Liu, L., & Jiang, C. (2020).

Research advances in chemical modifications of starch for hydrophobicity and its

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

applications: A review. Carbohydrate Polymers, 240, 116292.

https://doi.org/10.1016/j.carbpol.2020.116292

Almubarak A. (2017). The Effects of Heat on Electronic Components. Int. Journal

of Engineering Research and Application. Vol.7, Issue 5, pp. 52-57.

https://www.ijera.com/papers/Vol7_issue5/Part-5/H0705055257.pdf

El‐Hack, M. E. A., El‐Saadony, M. T., Shafi, M. E., Zabermawi, N. M., Arif, M., Batiha,

G. E., Khafaga, A. F., Abd‐Elhakim, Y. M., & Al‐Sagheer, A. A. (2020). Antimicrobial

and antioxidant properties of chitosan and its derivatives and their applications: A review.

International Journal of Biological Macromolecules, 164, 2726–2744.

https://doi.org/10.1016/j.ijbiomac.2020.08.153

Abe, M. M., Martins, J. R., Sanvezzo, P. B., Macedo, J. V., Branciforti, M. C., Halley, P.

J., Botaro, V. R., & Brienzo, M. (2021b). Advantages and Disadvantages of Bioplastics

Production from Starch and Lignocellulosic Components. Polymers, 13(15), 2484.

https://doi.org/10.3390/polym13152484

Shrivastava, A. (2018). Plastic properties and testing. In Elsevier eBooks (pp. 49–110).

https://doi.org/10.1016/b978-0-323-39500-7.00003-4

John, M. J. (2019). Flammability performance of biocomposites. In Elsevier eBooks (pp.

43–58).

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

https://doi.org/10.1016/b978-0-08-102177-4.00002-1

Kumar, V. (2023, March 3). UL 94 Standard Flammability Test for Plastic Materials

Used in Devices and Appliances. Infinita Lab.

https://infinitalab.com/material-testing-service/ul-94-standard-flammability-test-for-

plastic-materials-used-in-devices-and-appliances/

Chaudhary T. (2023). Market Research Future. (n.d.). Bubble Wrap Packaging Market

Size, Share, Growth | Report, 2030.

https://www.marketresearchfuture.com/reports/bubble-wrap-packaging-market-1796

Chan, N. (2023, November 13). Filipino Online Shopping behavior: Statistics & Trends

you need to know. Spiralytics.

https://www.spiralytics.com/blog/filipino-online-shopping-behavior-statistics-trends/

Statista. (2020, January 6). Items per order for electronic devices online shopping of U.S.

consumers 2018.

https://www.statista.com/forecasts/961429/items-per-order-for-electronic-devices-online-

shopping-of-us-consumers

Adyel, T.M. Accumulation of plastic waste during COVID-19. Science 2020, 369, 1314–

1315.

[Google Scholar] [CrossRef] [PubMed]

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Rochman, C.M.; Browne, M.A.; Halpern, B.S.; Hentschel, B.T.; Hoh, E.; Karapanagioti,

H.K.; Rios-Mendoza, L.M.; Takada, H.; Teh, S.; Thompson, R.C. Classify plastic waste

as hazardous. Nature 2013, 494, 169–171.

[Google Scholar] [CrossRef] [PubMed]

Zhang, D. Fire-Safe Biobased Composites: Enhancing the Applicability of

Biocomposites with Improved Fire Performance. School of Chemistry and Chemical

Engineering, Nanjing University of Science and Technology, Nanjing 210094, China.

Fire 2023, 6(6), 229; https://doi.org/10.3390/fire6060229

Sari, M. M., Inoue, T., Rofiah, R., Septiariva, I. Y., Prayogo, W., Suryawan, I. W. K.,

& Arifianingsih, N. N. (2023). Transforming Bubble Wrap and Packaging Plastic

Waste into Valuable Fuel Resources. Journal of Ecological Engineering, 24(8), 260–

270. https://doi.org/10.12911/22998993/166554

Prodex Total Institution. (2023). Bubble Wrap Insulation: What, When, Where, Why &

How.

https://www.insulation4less.com/bubble-wrap-insulation

View of Evaluating Bubble Wrap and Proposing Post-consumer Textile Waste as

Alternative Material: A review. (n.d.).

https://ijibs.utm.my/index.php/ijibs/article/view/124/100

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Malouf, S. (2023, November 7). How hot do shipping containers get? EPGNA.

https://epgna.com/how-hot-do-shipping-containers-get/?fbclid=IwAR04rkEOWU-

01_6PtCppYMNQbkrPi-bB0Vbk2sCu7PcjfoBCrH9gFPpnq6g

Silva, R. R. A., Marques, C. S., Arruda, T. R., Teixeira, S. C., & De Oliveira, T. V.

(2023). Biodegradation of Polymers: Stages, measurement, standards, and

prospects. Macromol, 3(2), 371–399.

https://doi.org/10.3390/macromol3020023

Sharma, S. (2023, March 21). Drop tester for packaging: Ensuring product

protection during transport. Pacorr Testing Instruments Pvt. Ltd.

https://www.pacorr.com/blog/ensuring-product-protection-during-transport/

Wang, M., Yin, G., Yang, Y., Fu, W., Palencia, J. L. D., Zhao, J., Wang, N., Jiang, Y., &

Wang, D. (2023). Bio-based flame retardants to polymers: A review. Advanced Industrial

and Engineering Polymer Research, 6(2), 132–155.

https://doi.org/10.1016/j.aiepr.2022.07.003

Kaewprachu, P., & Jaisan, C. (2023). Physicochemical Properties of Chitosan from

Green Mussel Shells (Perna viridis): A Comparative Study. Polymers, 15(13), 2816.

https://doi.org/10.3390/polym15132816

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Fan, Y., Wu, W. J., Yu, L., Gaucher, C., Pei, S., Zhang, J., & Xia, X. (2019). Edaravone-

Loaded Alginate-Based nanocomposite hydrogel accelerated chronic wound healing in

diabetic mice. Marine Drugs, 17(5), 285.

https://doi.org/10.3390/md17050285

Apollo Display Technologies. (2022, August 22). How high temperatures can affect your

electronics.

https://www.apollodisplays.com/blog/how-high-temperatures-can-affect-your-

electronics/?fbclid=IwAR3-QuHc93DUi_FnhSG_8aLCELqHh1_6xqbDVh-

DOcopABbldRjiGHm2tA8

Ismail, R., Fitriyana, D. F., Santosa, Y. I., Nugroho, S., Hakim, A. J., Mulqi, M. S. A.,

Jamari, J., & Bayuseno, A. (2021). The potential use of green mussel (Perna Viridis)

shells for synthetic calcium carbonate polymorphs in biomaterials. Journal of Crystal

Growth, 572, 126282.

https://doi.org/10.1016/j.jcrysgro.2021.126282

Lin, C., Zhang, K., Zhao, S., Wang, W., Ru, X., Jiang, S., Cong, H., & Qian, Y. (2022).

Screening and identification of a strain of Aureobasidium pullulans and its application in

potato starch industrial waste. Environmental Research, 214, 113947.

https://doi.org/10.1016/j.envres.2022.113947

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Garkhedkar, R. (2023, November 27). Halogen-Free Flame Retardants: implementation

complexities. Stellarix.

https://stellarix.com/halogen-free-flame-retardants-implementation-

complexities/?fbclid=IwAR22pXGLw_1FLJZbB3JOQmxLpgJdLjVFnqQfMmAmIz2D

O7-VozgS13sr4CU

Innes, A., & Innes, J. (2012b). Flame retardants. In Elsevier eBooks (pp. 309–335).

https://doi.org/10.1016/b978-1-4377-3455-3.00010-9

Martinez L., Kharissova O., Kharisov B. (2019). Handbook of Ecomaterials. (2019). In

Springer eBooks.

https://doi.org/10.1007/978-3-319-68255-6

BIODEGRADABLE PRODUCTS: TOWARDS a SUSTAINABLE FUTURE. (2020,

March 17). Aitex.

https://www.aitex.es/biodegradable-products-towards-a-sustainable-future/?lang=en

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

When a material is evaluated tensile, its elongation at break is its final fracture. The elongation at

break is expressed: Elongation at break = L-L 0 / L0 * 100% where 𝐿 represents the material's

ultimate elongation (in millimeters) and 𝐿0 is the material's beginning length (in millimeters)

(Fiandini et al. 2020).

Almubarak (2017) states that overheating has additional macro effects. Certain types of

capacitors are prone to explosion when exposed to temperatures above their limiting capacity.

This leads to significant damage to an electrical component. Of course, fire can occur through

combustion. An electrical device could explode and cause serious injury and danger.

The size of laptops and cell phones decreased significantly in the last several years, leaving them

more susceptible to thermal damage, according to Apollo Display Technologies (2022). Since

their electronics are smaller than ever, their systems operate at a higher heat density, which

causes them to heat up far quicker than in the past. Even though a lot of businesses try to

incorporate cooling systems into their products, they can't compete with the summertime heat

outside or inside without air conditioning.

Abe et al. (2021) state that bioplastics based on polysaccharides brittle, infrequent, rigid, and

delicate. when manufactured without any additives, and that continuous bioplastics are made

with plasticizer molecules. Two plasticizers that are effective with polysaccharides are sorbitol

and glycerol.

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

The lowest amount of oxygen in an oxygen/nitrogen mixture needed to keep polymer

combustion going is known as the limiting oxygen index, or LOI. A glass cylinder is filled with

the plastic sample vertically, and the specimen's upper edge is illuminated. From the bottom of

the chamber, a constant stream of nitrogen and oxygen is given to keep the flame burning. The

plastic sample is exposed to progressively less oxygen until it extinguishes (Shrivastava 2018).

As it can precisely ascertain a material's flammability and ignitability, According to John (2019),

this strategy is still among the most crucial for quality assurance and screening in the plastics

sector. The fact that LOI provides a dependable and simple method for calculating a

flammability index is one of its advantages. In addition, the cost of the test apparatus is

affordable, and the quantity of material needed for testing is minimal.

Kumar (2023) states that the UL 94 testing standard determines the degree of flame resistance

necessary for a plastic to be used in consumer goods. In an HB series test, the sample stick is

positioned horizontally, and the duration of the flame's burn across it establishes its ranking. UL

94 testing gives a clear picture of how much a plastic can withstand and when it will fail, with its

HB series vs. V series designations and multiple ranks within each classification.

Drop testing is a type of impact test that simulates the impact forces seen during package

dropping. In this test, the impact forces are measured when a package is dropped from a

predefined height onto a hard surface. Raising the drop height with each test run ensures that the

package either passes or fails to meet the required standards (Sharma 2023). Drop testing comes

in a variety of forms for packaging, such as: (a) Flat drop test: in this test, a package is

dropped onto a firm

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

surface, flat on its base, from a specified height. (b) Edge drop test: in this test, a package is

dropped onto a hard surface on its edge from a predetermined height. (c) Corner drop test: in this

test, a package is dropped onto a hard surface on its corner from a predetermined height. (d)

Rotational drop test: to replicate the impact forces experienced during transit, a package is

dropped from a predetermined height while rotating.

The bubble wrap packaging industry was estimated to be worth USD 2.6 billion (Php 143.8

billion) in 2022, according to Chaudhary (2023). According to projections, The market for

bubble wrap packaging would rise at an 8.1% compound annual growth rate (CAGR) from USD

3.1 billion (Php 171.4 billion) in 2023 to USD 5 billion (Php 276.5 billion) by 2030. The market

for bubble wrap packaging is expanding quickly in tandem with the rise in consumer goods

demand; the main factors driving this expansion are primarily electronics.

In the Philippines, electronics account for the largest portion of e-commerce spending, at $6.85

billion (Php 3.7 trillion). Furniture and products for personal and home care are other common

goods that consumers purchase (Chan 2023). Also, the findings of an online purchasing survey

that was carried out in the US in 2018 were included in the Kunst (2020) research. According to

64% of the participants, when they shop online for electronics, they typically order at least one

item.

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Polyhydroxy groups are found in natural compounds such chitosan, lignin, cyclodextrin, and

starch. Due to their esterification during burning, which creates a cross-link to carbon, they can

be utilized as carbon sources for intumescent flame retardants (IFR) (Wang et al. 2023). The

most preferred biopolymer is chitosan because of its non-toxicity, biocompatibility, and

biodegradability. It is extensively used in many different industries, including the food,

cosmetics, pharmaceutical, and biomedical sectors. Films made of biopolymer composites can

also be made from it. But nothing is known about how to produce chitosan from green mussel

shells and how to use it in applications like biopolymer films (Jaisan et al., 2023).

During the deacetylation process, chitin is converted into chitosan, a polysaccharide and

biopolymer, according to Malucelli (2020). Chitosan, which is thought to be a halogen- free fire

retardant, is primarily present in the cell walls of fungi, some mollusks, insects, and the

exoskeletons of crustaceans. By erecting a barrier that acts as a flame retardant, it stops flames

from spreading. On the other hand, halogen-based flame retardants are made of elements like

chlorine or bromine. Decolorization, deacetylation, demineralization, and deproteinization are

often steps in the chemical extraction of chitosan. Chitin is often obtained by subjecting the

exoskeletons of invertebrates to acidic and alkaline environments, which breakdown protein and

calcium carbonate, respectively. When chitin is exposed to concentrated alkali solutions at high

temperatures (over 100 °C), such as 50% sodium hydroxide, it can be transformed into chitosan.

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

Green mussels (Perna viridis) are produced in the Philippines. Green mussels make around 10%

of the mussels produced worldwide, along with P. canaliculus. Mytilus edulis, M.

Galloprovincialis and blue mussels make up the remainder (2019 Gonzalez).

Large quantities of green mussel shells are produced and thrown away as garbage. Biopolymer

compounds like chitosan can be made from such waste ( Jaisan et al. 2023). Additionally,

according to Fan et al. (2019), in the seafood processing industry, green mussel shells are

regarded as waste since they are frequently thrown away once the edible part of the mussel has

been removed. Since the shells are not usually eaten during the cooking process, they are

categorized as waste or byproducts. To lessen environmental contamination, 216,902 tons of

discarded mussel shells must be disposed of properly if green mussel shells make up 70% of the

mussels' total weight. Alternatively, a substantial portion of these shell wastes could be recycled

to create useful products. (Santosa et al. 2021).

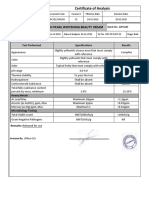

1.1 Green Mussel Shells Preparation

After being thoroughly cleaned under running water, the shells were placed in a tray dryer and

left to dry for the whole night at 70°C. Gathered and stored at room temperature until required

again, the dried shell samples were placed in a polyethylene zip-lock bag. (Jaisan et al. 2023).

1.2 Extraction of Chitosan from Green Mussel Shells

To eliminate all organic elements, the green mussel shells were immersed in 0.5 M hydrochloric

acid in a 1:15 (w/v) ratio at room temperature for six hours. They were then rinsed with distilled

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

water and dried overnight at 70 °C in a hot air oven (Jaisan et al., 2023). The deproteinized shells

were dried for a whole night at 70 °C after being rinsed under running tap water until they

attained a neutral pH. The deproteinized shells were treated with 1 M hydrochloric acid at a ratio

of 1:20 (w/v) at room temperature for 48 hours to demineralize both sizes of shells. After being

demineralized, the shells were cleaned with running tap water until their pH was neutral, and

they were then let to dry overnight at 70 °C. The item acquired was “chitin”. The process of

obtaining chitosan from extracted chitin entails deacetylation, as moderately modified from the

research by Alishahi et al. (2011). After being steeped for 24 hours in 400 milliliters of 50%

sodium hydroxide, the extracted chitin was heated for 120 minutes at 120 degrees Celsius in an

autoclave. The residue was then filtered through a Bucher funnel, dried at 70 °C for an entire

night, and rinsed with running tap water until it attained a neutral pH. The terms "CHS" and

"CHB" refer to the chitosan that was derived from the small and big sizes, respectively. The

following equation was used to calculate the % yield of CHS and CHB:

CHS or CHB yield (%)=Weight of CHS or CHB (g)/Weight of starting shells (g)× 100

1.3 Making Films

The CH, CH/CHS, and CH/CHB blended films were made, with minor adjustments, using the

technique outlined by Rachtanapun et al. (2021). CH 1% (w/v) and 2% (v/v) acetic acid were

combined. After 30 minutes of stirring the mixture at 65–70 °C, 40% of the mixture, w/w,

depending on the CH concentration, was added to the solution as CHS or CHB. 25% w/w

glycerol (based on CH content) was added and mixed for an additional half-hour after the initial

thirty minutes of mixing. The film-forming solution (FFS) of the CH, CH/CHS, and CH/CHB

blended FFS (without the addition of extracted chitosan) was placed in a 500 W ultrasonic

cleaner (GT

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

sonic-D27, GT Sonic, China) at 50 °C for 15 minutes to eliminate the bubbles. After pouring the

FFS onto a 50 x 50 mm silicone plate, it was dried for 24 hours at 40 °C in the oven.

It was successful to prepare the extracted chitosan from green mussel shells of various sizes. Ash

and calcium carbonate were present in considerable concentrations in both sizes of green mussel

shells. The physicochemical characteristics of the chitosan that was produced were considerably

impacted by the varying diameters of the green mussel shells. A lower level of deacetylation

(DDA) was associated with CHS and CHB's decreased solubility. When compared to the CH, the

physicochemical qualities of the CHS and CHB were subpar, particularly in DDA. Both isolated

chitosan samples contained traces of minerals, as seen by the XRD patterns. Additionally, the

attributes of the CH film were significantly affected by the composite material of extracted

chitosan (CHS or CHB), which increased the film's thickness value, strength, WVP, and

yellowness. To increase the physicochemical qualities of the resulting chitosan, more research is

required to optimize the chitosan extraction process.

PAMANTASAN NG LUNGSOD NG SENIOR HIGH SCHOOL

MARIKINA

You might also like

- Experiment 8 The Preparation of AcetanlideDocument12 pagesExperiment 8 The Preparation of AcetanlideRadhwanNo ratings yet

- Equivalent Materials ChartDocument3 pagesEquivalent Materials Chartarianaseri100% (1)

- Bir 1701Document2 pagesBir 1701RAYNAN MARCELO100% (1)

- Bir 1701Document2 pagesBir 1701RAYNAN MARCELO100% (1)

- Green Cleaning RecipesDocument2 pagesGreen Cleaning Recipesmbastidasluis100% (1)

- 12 Stem 2 Group 2Document10 pages12 Stem 2 Group 2jsfowen18No ratings yet

- Capstone Chapter 1 3Document15 pagesCapstone Chapter 1 3De-Andrie GotuatoNo ratings yet

- Utilizing Colocasia Esculenta Taro Starch in Developing Biodegradable PlasticDocument40 pagesUtilizing Colocasia Esculenta Taro Starch in Developing Biodegradable PlasticLizbeth Pucate0% (1)

- Producing Biodegradable Plastic Bags from Banana PeelsDocument44 pagesProducing Biodegradable Plastic Bags from Banana Peelsava tsukumoNo ratings yet

- An Experimental Investigation On Bio-Plastics - HBRP PublicationDocument6 pagesAn Experimental Investigation On Bio-Plastics - HBRP PublicationLIYA ASKARNo ratings yet

- Fuel Properties Effect on Aircraft and InfrastructureDocument172 pagesFuel Properties Effect on Aircraft and InfrastructureFrancisco BaptistaNo ratings yet

- A Comparative Study On The Effectiveness of Potato Starch (Solanum Tuberosum) and Milk As An Alternative Element For Biodegradable PlasticDocument17 pagesA Comparative Study On The Effectiveness of Potato Starch (Solanum Tuberosum) and Milk As An Alternative Element For Biodegradable PlasticALEX ANTHONY ULEPNo ratings yet

- Chapters1-3REVISED Potato Starch As Bio-Plastic - 2Document23 pagesChapters1-3REVISED Potato Starch As Bio-Plastic - 2Kristel Anne Runas100% (2)

- The Use of Pea Starch As Main Component in Making Bio Plastic in Barangay Saimsim, Calamba CityDocument20 pagesThe Use of Pea Starch As Main Component in Making Bio Plastic in Barangay Saimsim, Calamba Cityczar alinsunurin100% (1)

- Banana Peels Make Eco BioplasticsDocument14 pagesBanana Peels Make Eco BioplasticsErik RoxasNo ratings yet

- Chapter 1 BioplasticDocument7 pagesChapter 1 BioplasticLuna MaxineFelicianaNo ratings yet

- Lyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticDocument13 pagesLyceum of The Philippines University Cavite Potential of Peanut Hulls As An Alternative Material On Making Biodegradable PlasticJayr Mercado0% (1)

- OPHTHALMIC PREPARATIONS QUALITY TESTSDocument10 pagesOPHTHALMIC PREPARATIONS QUALITY TESTSFauziah K. AminNo ratings yet

- Bioplastic production from soybean hullsDocument17 pagesBioplastic production from soybean hullsAlberto Suarez100% (1)

- Bioplastic IncDocument11 pagesBioplastic IncMikaella Manzano33% (3)

- BIOPLASTICDocument16 pagesBIOPLASTICMikaella ManzanoNo ratings yet

- Chapters1 3REVISED Potato Starch As Bio Plastic 2Document22 pagesChapters1 3REVISED Potato Starch As Bio Plastic 2LIYA ASKARNo ratings yet

- CassavaDocument19 pagesCassavaMaria Cristina Peradilla Magpantay100% (3)

- Feasibility of Banana (Musa Sapientum) Peelings As Biodegradable PlasticDocument9 pagesFeasibility of Banana (Musa Sapientum) Peelings As Biodegradable PlasticJasmine GoleNo ratings yet

- The Effectiveness of Saba Banana (Musa Acuminata Balbisiana) Peel As A BioplasticDocument17 pagesThe Effectiveness of Saba Banana (Musa Acuminata Balbisiana) Peel As A BioplasticAllenGlennLagado0% (1)

- Taro and Seagrapes RRLDocument5 pagesTaro and Seagrapes RRLMarianne Nathalie Sarmiento50% (2)

- Dosh DocumentsDocument5 pagesDosh DocumentsmohdmasriNo ratings yet

- Group7 204-FR7Document35 pagesGroup7 204-FR7RACHEL DAMALERIONo ratings yet

- GROUP7_204-FP2 (1)Document17 pagesGROUP7_204-FP2 (1)RACHEL DAMALERIONo ratings yet

- Waste Paper as a Potential Component for Cellulose-Based BioplasticDocument22 pagesWaste Paper as a Potential Component for Cellulose-Based BioplasticAndrei Jose GilNo ratings yet

- Waste Paper as a Potential Component for Cellulose-Based BioplasticDocument22 pagesWaste Paper as a Potential Component for Cellulose-Based BioplasticAndrei Jose GilNo ratings yet

- Final FINAL FINAL FINAL Revise Chapter 1 2 3 Huhu...Document19 pagesFinal FINAL FINAL FINAL Revise Chapter 1 2 3 Huhu...Elijah ParreñoNo ratings yet

- Karakterisasi Bioplastik Dari Rumput Laut (Eucheuma Cottonii) Dan Pati Singkong Dengan Penambahan Pati Dari Limbah Biji DurianDocument10 pagesKarakterisasi Bioplastik Dari Rumput Laut (Eucheuma Cottonii) Dan Pati Singkong Dengan Penambahan Pati Dari Limbah Biji DurianANMANo ratings yet

- Bioplastics - An Eco-Friendly Alternative To PetroDocument11 pagesBioplastics - An Eco-Friendly Alternative To Petrosumit kaushikNo ratings yet

- Plagiarism - ReportDocument58 pagesPlagiarism - ReportabrhshNo ratings yet

- Chapter 1Document18 pagesChapter 1jadeshades12No ratings yet

- PineappleDocument8 pagesPineappleJessie Jr Dela CruzNo ratings yet

- Cornstarch BioplastsDocument3 pagesCornstarch Bioplasts13004453No ratings yet

- Bioplastic Group7SIPDocument21 pagesBioplastic Group7SIPJanella Mhay P. BallesterosNo ratings yet

- BioplasticDocument16 pagesBioplasticShubham JaiswalNo ratings yet

- Production of Biodegradable Plastic from Banana PeelDocument7 pagesProduction of Biodegradable Plastic from Banana PeelKeanne MiguelNo ratings yet

- Production of Biodegradable Plastic from Banana PeelDocument7 pagesProduction of Biodegradable Plastic from Banana PeelGirlie Kate DaguroNo ratings yet

- Biopolimeros Capaces de Reemplazar A Los Plasticos 1rehqynt1oDocument18 pagesBiopolimeros Capaces de Reemplazar A Los Plasticos 1rehqynt1oCarlos Alberto Dávalos MamaniNo ratings yet

- Artikel 1Document11 pagesArtikel 1siti kholijah mohd abdulnajariNo ratings yet

- Research FinalDocument27 pagesResearch FinalPattyyPattyy Pattyy PattyyPattyy PattyyNo ratings yet

- Defenition of TermsDocument3 pagesDefenition of TermsDanica Joy GardiolaNo ratings yet

- Bananaleaffoodpackaging IOSR JESTFT 2020Document6 pagesBananaleaffoodpackaging IOSR JESTFT 2020kannaNo ratings yet

- 2022 - Leads and Hurdles To Sustainable Microbial Bioplastic Production - CompressedDocument15 pages2022 - Leads and Hurdles To Sustainable Microbial Bioplastic Production - Compressedchristelle malabananNo ratings yet

- STUDYDocument8 pagesSTUDYMathew Rovinz GuatnoNo ratings yet

- con-2Document8 pagescon-2Emelin Sánchez IniestaNo ratings yet

- Chapter 1 2Document10 pagesChapter 1 2daluzcristyjoyNo ratings yet

- Review of LiteratureDocument20 pagesReview of Literaturejennyfer ramirezNo ratings yet

- FINALE Water Soluble Starch Based Plastic Packaging A Sustainable Replacement For Plastic Packaging in E Commerce IndustryDocument21 pagesFINALE Water Soluble Starch Based Plastic Packaging A Sustainable Replacement For Plastic Packaging in E Commerce IndustryDEVERA, ROGELIO JR., C.No ratings yet

- Elsa Stem12d Pr1 Final (Meera)1Document21 pagesElsa Stem12d Pr1 Final (Meera)1ShehanaNo ratings yet

- 1.8 PG Microplastics...Document4 pages1.8 PG Microplastics...Joel Gitau MuthoniNo ratings yet

- Main Draft 1Document9 pagesMain Draft 1batusaigamer4231No ratings yet

- Water Soluble Starch-Based, Packaging: A Sustainable Replacement For Plastic Packaging in E-Commerce IndustryDocument21 pagesWater Soluble Starch-Based, Packaging: A Sustainable Replacement For Plastic Packaging in E-Commerce IndustryDEVERA, ROGELIO JR., C.No ratings yet

- Edson Quijano - Research Proposal Format 2023Document4 pagesEdson Quijano - Research Proposal Format 2023Cookie BoyieNo ratings yet

- Bio-Plastic (Generating Plastic From Banana Peels)Document4 pagesBio-Plastic (Generating Plastic From Banana Peels)Jade AusteroNo ratings yet

- Nag 2021Document22 pagesNag 2021environment farelabsNo ratings yet

- Bioplastics As Better Alternative To Petroplastics and Their Role in National Sustainability: A ReviewDocument8 pagesBioplastics As Better Alternative To Petroplastics and Their Role in National Sustainability: A ReviewEzanaNo ratings yet

- Trends in Food Science & Technology: Dietz Carina, Shubham Sharma, Amit K. Jaiswal, Swarna JaiswalDocument14 pagesTrends in Food Science & Technology: Dietz Carina, Shubham Sharma, Amit K. Jaiswal, Swarna JaiswalXenia SabinaNo ratings yet

- Tarap Leaves As Bioplastic STEM12 CAPSTONE2023 2Document23 pagesTarap Leaves As Bioplastic STEM12 CAPSTONE2023 2Jiverlyn PatNo ratings yet

- 10889726-1Document5 pages10889726-1delarosabogart06No ratings yet

- Final Pr2 Manuscript Na Pinasa 1Document18 pagesFinal Pr2 Manuscript Na Pinasa 1KarloPangilinanNo ratings yet

- University of Cagayan Valley School of Liberal Arts and Teacher EducationDocument15 pagesUniversity of Cagayan Valley School of Liberal Arts and Teacher EducationCyril CauilanNo ratings yet

- Research Paper G 5Document13 pagesResearch Paper G 5Aira IberoNo ratings yet

- Bacterial Cellulose: Sustainable Material for TextilesFrom EverandBacterial Cellulose: Sustainable Material for TextilesNo ratings yet

- ePermit2024-0098-8306 (2)Document5 pagesePermit2024-0098-8306 (2)RACHEL DAMALERIONo ratings yet

- 2307 Jan 2018 ENCS v3 Annex BDocument2 pages2307 Jan 2018 ENCS v3 Annex BAnonymous Z37BIV88% (24)

- OJT-EVALUATION.docx-rating-1-1-1Document2 pagesOJT-EVALUATION.docx-rating-1-1-1RACHEL DAMALERIONo ratings yet

- 2307 Jan 2018 ENCS v3 Annex BDocument2 pages2307 Jan 2018 ENCS v3 Annex BAnonymous Z37BIV88% (24)

- Adjusted Trial BalanceDocument1 pageAdjusted Trial BalanceRACHEL DAMALERIONo ratings yet

- 521252526-REquest-for-Manual-PaymentDocument1 page521252526-REquest-for-Manual-PaymentRACHEL DAMALERIONo ratings yet

- 2307 Jan 2018 ENCS v3 Annex BDocument2 pages2307 Jan 2018 ENCS v3 Annex BAnonymous Z37BIV88% (24)

- Milano One Inc. Unique FileDocument874 pagesMilano One Inc. Unique FileRACHEL DAMALERIONo ratings yet

- 2307 Thedeleons Co LTDDocument2 pages2307 Thedeleons Co LTDRACHEL DAMALERIONo ratings yet

- New HubDocument3 pagesNew HubRACHEL DAMALERIONo ratings yet

- 2307 Jan 2018 ENCS v3 Annex BDocument2 pages2307 Jan 2018 ENCS v3 Annex BAnonymous Z37BIV88% (24)

- 2307 Thedeleons Co LTDDocument2 pages2307 Thedeleons Co LTDRACHEL DAMALERIONo ratings yet

- 2307 - CTT Synergy - CorporationDocument2 pages2307 - CTT Synergy - CorporationRACHEL DAMALERIONo ratings yet

- Letter For Consultant MS. BELCHEZDocument1 pageLetter For Consultant MS. BELCHEZRACHEL DAMALERIONo ratings yet

- Underloading Form Less Than 15 Units LoadDocument1 pageUnderloading Form Less Than 15 Units LoadMARION JUSTINE CHANNo ratings yet

- Republic of The Philippines University of Rizal System Antipolo CampusDocument1 pageRepublic of The Philippines University of Rizal System Antipolo CampusJose Walo Camilon IIINo ratings yet

- Title Proposal Group7 A2 2023 2024Document7 pagesTitle Proposal Group7 A2 2023 2024RACHEL DAMALERIONo ratings yet

- Letter For Consultant MS. BELCHEZDocument1 pageLetter For Consultant MS. BELCHEZRACHEL DAMALERIONo ratings yet

- Periodic Method-Joseph MerchandiseDocument8 pagesPeriodic Method-Joseph MerchandiseRACHEL DAMALERIONo ratings yet

- MAS ProbDocument1 pageMAS ProbRACHEL DAMALERIONo ratings yet

- MFC Extra Payroll System 0513-192022Document166 pagesMFC Extra Payroll System 0513-192022RACHEL DAMALERIONo ratings yet

- Table of ContentsDocument5 pagesTable of ContentsRACHEL DAMALERIONo ratings yet

- MicroplasticDocument2 pagesMicroplasticRACHEL DAMALERIONo ratings yet

- Q4Lesson10 HandoutDocument2 pagesQ4Lesson10 HandoutRACHEL DAMALERIONo ratings yet

- Japanese Organic Agriculture Standard for PlantsDocument12 pagesJapanese Organic Agriculture Standard for PlantsNereyda SanchezNo ratings yet

- Santo Righello Corporate PresentationDocument16 pagesSanto Righello Corporate PresentationAlexander ChaturvediNo ratings yet

- Quiz 2chemistry Quizs On Qunatm MechanicsDocument5 pagesQuiz 2chemistry Quizs On Qunatm Mechanics06201K0129No ratings yet

- Enzyme and Acid - Base CatalysisDocument64 pagesEnzyme and Acid - Base Catalysisbinseung skzNo ratings yet

- CARBENEsDocument19 pagesCARBENEsriza_ali92No ratings yet

- Salt AnalysisDocument17 pagesSalt AnalysisHimanshu GautamNo ratings yet

- Prop 3lisitsin2008Document9 pagesProp 3lisitsin2008AlejandraNo ratings yet

- EDEXCEL-Organics, Spectroscopy and MechanismsDocument65 pagesEDEXCEL-Organics, Spectroscopy and MechanismsZiarr TowfiqNo ratings yet

- General Chemistry 1 / Chemistry For Engineers: CH4701, CH4001Document21 pagesGeneral Chemistry 1 / Chemistry For Engineers: CH4701, CH4001Tadhg O'ShaughnessyNo ratings yet

- USP Monographs - Pyridoxine Hydrochloride Injection - PIRIDOXINA - CLORAMIDADocument2 pagesUSP Monographs - Pyridoxine Hydrochloride Injection - PIRIDOXINA - CLORAMIDADulce SalazarNo ratings yet

- Colloid and Colloidal SolutionDocument18 pagesColloid and Colloidal SolutionkashemNo ratings yet

- 8.2 Transport of Oxygen and Carbon DioxideDocument13 pages8.2 Transport of Oxygen and Carbon DioxideFarista KabirNo ratings yet

- 2649 PDFDocument8 pages2649 PDFA MahmoodNo ratings yet

- Mobilgard-312-412 SeriesDocument2 pagesMobilgard-312-412 Seriescesar floresNo ratings yet

- Machined Seals: Product RangeDocument43 pagesMachined Seals: Product RangeAnonymous r3MoX2ZMTNo ratings yet

- Journal of the American Oil Chemists' Society Volume 29 Issue 12 1952 [Doi 10.1007%2Fbf02631723] Daniel Swern; Winfred E. Parker -- Application of Urea Complexes in the Purification of Fatty Acids, Esters, And AlcDocument2 pagesJournal of the American Oil Chemists' Society Volume 29 Issue 12 1952 [Doi 10.1007%2Fbf02631723] Daniel Swern; Winfred E. Parker -- Application of Urea Complexes in the Purification of Fatty Acids, Esters, And AlcbexigaobrotherNo ratings yet

- Beauty CreamDocument1 pageBeauty Creammuhammad imran azizNo ratings yet

- Closed-Book Practice-Ch 02 (2017!06!19)Document9 pagesClosed-Book Practice-Ch 02 (2017!06!19)JuanNo ratings yet

- Fluoride Electrode ManualDocument26 pagesFluoride Electrode ManualNilesh SomtiyaNo ratings yet

- Consort: Manual Handleiding Mode D'Emploi AnleitungDocument32 pagesConsort: Manual Handleiding Mode D'Emploi AnleitungwijdaneNo ratings yet

- Biology Transition Work 2023Document5 pagesBiology Transition Work 2023Sriihari BalasubramaniyamNo ratings yet

- Mechanical, Chemical, and Curing Characteristics of Cardanol-Furfural-based Novolac Resin For Application in Green CoatingsDocument9 pagesMechanical, Chemical, and Curing Characteristics of Cardanol-Furfural-based Novolac Resin For Application in Green CoatingsChanin NgudsuntearNo ratings yet

- FTI Tech AdvancedCladdingPreInsulationSystemsDocument5 pagesFTI Tech AdvancedCladdingPreInsulationSystemseoseos12No ratings yet

- By-Products of Palm Oil Extraction and RefiningDocument3 pagesBy-Products of Palm Oil Extraction and RefiningneiryNo ratings yet

![Journal of the American Oil Chemists' Society Volume 29 Issue 12 1952 [Doi 10.1007%2Fbf02631723] Daniel Swern; Winfred E. Parker -- Application of Urea Complexes in the Purification of Fatty Acids, Esters, And Alc](https://imgv2-2-f.scribdassets.com/img/document/202507010/149x198/7d24f8805c/1390828797?v=1)