Professional Documents

Culture Documents

Rrete

Uploaded by

Alaa NayefOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rrete

Uploaded by

Alaa NayefCopyright:

Available Formats

ENGINEER’S STICKER: CONTRACTOR’S STICKER:

00 FOR APPROVAL as per Transmittal RR-EH-D-246 GA NA PH 29.07.20

A FOR APPROVAL GA NA PH 09.07.20

تنقيح سبب اإلصدار بواسطة راجعها وافق عليها التاريخ

REV. ISSUED FOR PREPARED CHECKED APPROVED DATE

المملكة العربيـــة الســـــعوديــــة

KINGDOM OF SAUDI ARABIA

المؤسسة الـعـامـــة لتحليــة الميـــاه المالحـــــة

SALINE WATER CONVERSION CORPORATION (SWCC)

رقم المشروع

PROJECT NO تنفيذ أنظمة نقل مياه محطات التحلية الصغيرة الجديدة

20SWCG00038

New Satellite Plants Water Transmission System

المهندس Ayesa Engineering and Architecture, S.A.

ENGINEER

Al-Rashid Trading & Contracting Co.

المقـــاول

CONTRACTOR

PROCEDURE FOR STORAGE AND HANDLING OF CEMENT

MORTAR LINED PIPES, BENDS AND FITTINGS

00

DOCUMENT NO: Sheet Rev.

1 0 - Z G 5 0 - F - 2 0 4 1 of 9 0

المقاول بالباطن RAYMOND INTERNATIONAL CO. LTD

SUBCONTRACTOR

KINGDOM OF SAUDI ARABIA Page: 2 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

TABLE OF CONTENTS Page No.

1.0 PURPOSE Page 3

00

2.0 REFERENCE TO APPLICABLE CONTRACT DOCUMENT Page 3

3.0 SCOPE Page 3

4.0 PROJECT SPECIFICATIONS Page 3

5.0 PROJECT DOCUMENTS Page 4

6.0 RECEPTION OF PIPES AT RAYMOND YARD Page 4

7.0 STORAGE OF CEMENT MORTAR LINED PIPE DURING Page 5

CURING PERIOD

8.0 LOADING OUT OF PIPES FROM RAYMOND YARD TO Page 5

PLACE OF STRINGING

9.0 SAND BERM SKETCH Page 6

10.0 RECEPTION OF PIPES AT PLACE OF STRINGING Page 7

11.0 DRAWING OF PIPE CRADLE SUPPORTS ON TRUCK Page 8

TYPICAL SADDLE SUPPORT AND PADDING DETAILS Page 9

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 3 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

1. PURPOSE

To provide procedure for the Storage and Handling of Bare Steel Pipes, Bends,

Fittings and Cement Mortar Lined pipes in Shop (Yard) and at Construction Site or

00 Place of Stringing as per SWCC (Saline Water Conversion Corporation) applicable

standards.

2. REFERENCE TO APPLICABLE CONTRACT DOCUMENTS

Reference is made to Contract Document M03 "Specification for Cement Mortar

Lining", M18 “Specification for Handling, Storage and Transportation of Line Pipe

Material” and L01 “Pipeline Construction”. This procedure which is prepared for the

NEOM Water Transmission System Project is in accordance with the requirements of

specification M03, M18 & L01. The Subcontractor's Method Statement 90-ZG50-F-

201 is also referred.

3. SCOPE

This procedure covers the handling requirements of 28 inch & 20 inch steel pipes with

external P.E. coating which are internally cement mortar lined at Raymond

International’s cement mortar lining plants located in the Kingdom of Saudi Arabia

and at Contractors Work Site.

4. PROJECT SPECIFICATION

Document Number Document Title

QA10-H-043 M03 Shop Applied Cement Mortar Lining

QC10-H-021 L01 Pipeline Construction

QC10-H-058 M18 Handling, Storage and Transportation of

Line Pipe Material

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 4 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 0

Index

First

Issue

Date 09.07.20 29.07.20

5. PROJECT DOCUMENTS

Document Number Document Title

01-ZG50-F-201 Method Statement Cement Mortar Lining of Steel

Pipes 28 Inch and Larger

01-ZG50-F-202 Method Statement Cement Mortar Lining of Steel

Pipes 24 Inch and Smaller

01-ZG50-N-201 Inspection and Test Plan for Cement Mortar Lining

of Steel Pipes, Fittings, Bends, Flanges

01-ZG50-F-203 Procedure for Cement Mortar Lining of Steel

Fittings, Bends, Flanges and Welded Joints of

Main Pipeline.

01-ZG50-F-205 Procedure to Maintain Cement Mortar Lining

Curing Condition during Construction Work

6. RECEPTION OF PIPES AT RAYMOND YARD

6.1 The 28 and 20 inch P.E. coated pipes will be unloaded from truck using a

crane provided with spreader bar and special designed aluminum ends

hooks. The hooks will be placed at the end of the pipe. The pipe will be lifted

from the truck and stored on suitable bearing supports consisting of sweet

sand berms covered with plastic sheets. Storage for 28 inch pipes shall be

in areas having sufficient size for safe movement of personnel, equipment

and trucks which are delivering P.E. Coated pipes and which are collecting

cement mortar lined pipes. Separate areas for pipe storage and cement

mortar lining shall be designated within the Raymond International plant for

the 28 and 20 inch NEW SATELLITE PLANT WATER TRANSMISSION

SYSTEM PROJECT pipes. All lifting equipment shall be accompanied by

appropriate certification that clearly indicate the date of inspection for each

piece of equipment. Handling of P.E. coated and cement mortar lined pipes

shall be done using non-abrasive slings. P.E. coated unlined pipes will be

lifted using special designed lifting hooks to avoid any damage to bevel and

the external P.E. coating.

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 5 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

6.2 The bearing supports shall provide a minimum ground clearance of 150 mm and

Be spaced approximately one fifth of the pipe length from each end of the pipe.

Pipes will be stored on the bearing supports in such a way that there is a

sufficient clearance between pipes to avoid damage to the P.E. coating by

friction.

6.3 The stacking height of all pipes, unlined or lined, shall comply with clause

6.1.2. of the L-01 Project Specification (single layer only).

7. STORAGE OF CEMENT MORTAR LINED PIPE DURING CURING PERIOD

8.1 During the curing period and any further storage in the yard, the water

Content inside the cement mortar lined pipes will be monitored by the Q/C

supervisor to ensure a moist and humid atmosphere is maintained inside the

pipe.

8.2 Cement mortar lined pipes shall be covered during the curing period with

sunscreen shade material placed over the pipes and shall be kept in place

during curing period of cement mortar lining.

8.3 At no time shall the invert of the cement mortar lined pipes become dry

during the curing and storage period. Additional water will be added into the

pipe for continuous curing. Plastic end covers at both pipe ends will always

be in place.Damaged or torn end covers will be replaced.

8. LOADING OUT PIPES FROM RAYMOND YARD TO PLACE OF STRINGING.

8.1 When testing, curing and final inspection is completed and the 28 & 20 inch

pipes are released for loading out, the pipes will be loaded from the berms

onto trucks.

8.2 The pipes will be lifted from the storage berms onto trucks using a crane

provided with a spreader bar fitted with approximately 12 Inch width

canvas slings.

8.3 Pipes shall be loaded on the truck fitted with acceptable or approved

designed rubber protected cradle supports (see section 10.0 of this

procedure) which take into consideration the 28 inch pipe diameter. Cradle

supports shall be designed and spaced in order to prevent damage to the

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 6 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

external P.E. coating by minimizing the dynamic stress encountered during

transportation.

All sharp or leading edges of vehicles and equipment used in the handling

of 28 & 20 inch pipes shall be padded. Space between the pipes on the truck

will facilitate easy access for fitment of canvas slings around the pipes for

lifting.

8.4 Tie-downs and lashing shall be provided along the pipe length in sufficient

Quantities to secure the pipes during transportation.

8.5 The 28 & 20 inch pipe ends will be provided with plastic covers during

transport and a minimum amount of water will remain inside the pipes during

transport to avoid drying out of the cement mortar lining.

8.6 In addition to the plastic end covers during transport the pipe ends

will be fitted with heavy canvas end covers. The end covers will be fixed to

the pipe with canvas or nylon bands and locked in place with a metal

clamp. The pipeline installation contractor responsible the transportation of

the 28 & 20 inch pipes for the NEW SATELLITE PLANTS WTS Project

shall provide canvas covers as required for transporting the pipes in order

to ensure that the cement mortar lining is not exposed to wind which may

have adverse effects to the cement mortar lining. The canvas end covers

will be of sufficient strength to withstand the wind forces acting on the

canvas end covers during transportation.

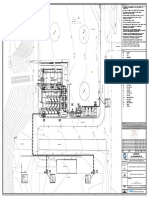

9. SAND BERM SKETCH.

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 7 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

10. RECEPTION OF PIPES AT PLACE OF STRINGING.

10.1 The pipeline installation contractor be responsible for all handling and pipe

stacking at the location of 28 & 20 inch pipe stringing along the NEW

SATELLITE PLANTS WTS Project right of way.

10.2 The pipes will be unloaded from trucks using a crane or side boom fitted with

a spreader bar and provided with approximately 12 inch width canvas slings.

The pipes will be lifted off trucks and stored on sandbags or temporary sand

berms covered with plastic sheets.

10.3 The pipes will be stored in the horizontal position. The pipeline installation

contractor shall maintain plastic end covers on each end of the pipes right up

until the time of installation in the trench.

10.4 In order to continue the curing process of the cement mortar lining, the

pipeline installation contractor shall maintain sufficient quantities of clean

water in each pipe during storage along the right of way. The curing process

will be maintained right up until the time of installation in the trench.

10.5 All safety measures shall be followed strictly by all stages of storage and

handling cement mortar lined pipes

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 8 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

11. DRAWINGS PIPE CRADLE SUPPORTS ON TRUCK.

NEW SATELLITE PLANTS WTS- 28” DIA CEMENT LINED PIPES

TYPICAL FOR 20’’ & SMALLER DIA CEMENT LINED PIPES

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

KINGDOM OF SAUDI ARABIA Page: 9 of 9

Saline Water Conversion Corporation

Document Number:

NEW SATELLITE PLANTS WATER TRANSMISSION SYSTEM PROJECT

PROCEDURE FOR STORAGE AND HANDLING OF

Subject: CEMENT MORTAR LINED PIPES, BENDS AND 10-ZG50-F-204

FITTINGS

Revision

Rev. A 00

Index

First

Issue

Date 09.07.20 29.07.20

TYPICAL SADDLE SUPPORT AND PADDING DETAILS

Final Engineering Contractor Subcontractor

IBG Al-Rashid Trading & Contracting Co. RAYMOND INTERNATIONAL CO. LTD.

You might also like

- Inspection and Test Plan: DESCRIPTION: Manhole ConstructionDocument4 pagesInspection and Test Plan: DESCRIPTION: Manhole ConstructionDelta akathehusky50% (2)

- Method Statement Rev 222Document11 pagesMethod Statement Rev 222babjihanumanthuNo ratings yet

- MST For Manhole ConstructionDocument17 pagesMST For Manhole ConstructionDelta akathehusky0% (1)

- Drilling Fluids Processing HandbookFrom EverandDrilling Fluids Processing HandbookRating: 4.5 out of 5 stars4.5/5 (4)

- Manual Power Bass ASA600Document24 pagesManual Power Bass ASA600Fernando OlaveoNo ratings yet

- Weber Lush Zavaliangos Anand 1990 PDFDocument44 pagesWeber Lush Zavaliangos Anand 1990 PDFChandra ClarkNo ratings yet

- Cec 500 2010 043Document172 pagesCec 500 2010 043my_khan20027195No ratings yet

- Waste Management in Leather IndustryDocument27 pagesWaste Management in Leather IndustryStan Larisa50% (4)

- Engineer'S Sticker: Contractor'S StickerDocument28 pagesEngineer'S Sticker: Contractor'S StickerAlaa NayefNo ratings yet

- Engineer'S Sticker: Contractor'S StickerDocument14 pagesEngineer'S Sticker: Contractor'S StickerAlaa NayefNo ratings yet

- Engineer'S Sticker: Contractor'S StickerDocument12 pagesEngineer'S Sticker: Contractor'S StickerAlaa NayefNo ratings yet

- 96-QC20-J-415 - DESIGN CALCULATION OF STEEL TANK FOR GHAZYAL-REV (D) .pdf02Document35 pages96-QC20-J-415 - DESIGN CALCULATION OF STEEL TANK FOR GHAZYAL-REV (D) .pdf02Hgagselim Selim100% (2)

- Pile Foundation Design V 82510 - R1Document39 pagesPile Foundation Design V 82510 - R1Tarique MosharrufNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- 11 ZG20 F 667 Methodstatement Cable InstallationDocument22 pages11 ZG20 F 667 Methodstatement Cable InstallationIbrahim AliNo ratings yet

- 11-ZG20-F-654 Method Statement For MV SWGR ErectionDocument27 pages11-ZG20-F-654 Method Statement For MV SWGR ErectionIbrahim AliNo ratings yet

- 90 Qd60 F 205 - 0 Welding Control ProcedureDocument43 pages90 Qd60 F 205 - 0 Welding Control ProcedureErkan Horasan100% (1)

- Qc-Sop-0 - Drilling of PoleDocument7 pagesQc-Sop-0 - Drilling of PoleAmeerHamzaWarraichNo ratings yet

- Galvanic Anode Installation Method of StatementDocument13 pagesGalvanic Anode Installation Method of StatementNeil JavierNo ratings yet

- QM-099-DP - XXXX Procedure For Concrete Finishing Rev ADocument11 pagesQM-099-DP - XXXX Procedure For Concrete Finishing Rev AGaneshNo ratings yet

- MIP17-MS-1022 Method of Statement For Steel Structure - ErectionDocument12 pagesMIP17-MS-1022 Method of Statement For Steel Structure - ErectionAmeerHamzaWarraichNo ratings yet

- Storage Tank Hydrotest ProcedureDocument16 pagesStorage Tank Hydrotest ProcedureAhmad AltaieNo ratings yet

- C22-Yb60-F-4761 - 0 Sa3-Ps2, Butterfly Valve, Nde ProceduresDocument23 pagesC22-Yb60-F-4761 - 0 Sa3-Ps2, Butterfly Valve, Nde ProceduressartajNo ratings yet

- Method Statement For Retaining WallDocument19 pagesMethod Statement For Retaining Wallamerna.alvinNo ratings yet

- C-CS-10-003 Inspection Testing Rev1Document13 pagesC-CS-10-003 Inspection Testing Rev1Johnny vargas suclupeNo ratings yet

- Hydrostatic Test Procedure For Fire Water TankDocument15 pagesHydrostatic Test Procedure For Fire Water TankMohamedNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidDocument14 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- Jms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001 - 1 Code 3Document11 pagesJms Site Preparation - RGTP p20220019 Esb Con Jms 9243 0001 - 1 Code 3amir hakim100% (1)

- ZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NODocument52 pagesZULUF PROJECT (0-8887) : 10-08643-0005 Saudi Aramco 0-8887-2-P-3130-MC2-A GAS-JGC-MOS-MECH-006 FA NMR Ref NORiaz Ali Khan BangashNo ratings yet

- MWP-C-CS-PC-0009 Tank Erection Procedure-BDocument17 pagesMWP-C-CS-PC-0009 Tank Erection Procedure-BKing王No ratings yet

- c25-Ye80-D-4981 - A - Rta3, Transformer Rectifiers Data Sheet and Wiring DiagramDocument12 pagesc25-Ye80-D-4981 - A - Rta3, Transformer Rectifiers Data Sheet and Wiring DiagramsartajNo ratings yet

- Method Statement For Installation of DI Pipes at HETDocument9 pagesMethod Statement For Installation of DI Pipes at HETJahangir AlamNo ratings yet

- Installation of Fuel Pipe Line Method Statement - CompressDocument10 pagesInstallation of Fuel Pipe Line Method Statement - Compresscutie paaiNo ratings yet

- METHOD STATEMENT FOR PVC - Upvc-CpvcDocument17 pagesMETHOD STATEMENT FOR PVC - Upvc-CpvcAhmed Imran100% (2)

- 002-PDS-CON-006 Method Statement For FencingDocument17 pages002-PDS-CON-006 Method Statement For FencingMalik ZamanNo ratings yet

- Method Statement - Site Preparation & Back FillDocument8 pagesMethod Statement - Site Preparation & Back Fillmahesh naikNo ratings yet

- 59-Qa60-R-201 - 0 - Equipment Numbering SystemDocument59 pages59-Qa60-R-201 - 0 - Equipment Numbering SystemNad EemNo ratings yet

- RWR Method Statement-R00Document18 pagesRWR Method Statement-R00Rahul Kumar PatelNo ratings yet

- SOP FOR Bored Cast in Situ Pile WorkDocument13 pagesSOP FOR Bored Cast in Situ Pile Workom prakashNo ratings yet

- MoS For Piping Support InstallationDocument19 pagesMoS For Piping Support Installationilliasuddin100% (1)

- S 000 5316 201 (Underground Pipe Design Rev.1)Document9 pagesS 000 5316 201 (Underground Pipe Design Rev.1)Midhun K ChandraboseNo ratings yet

- Fresh Water Tanks MS Rev.0Document11 pagesFresh Water Tanks MS Rev.0Zezo darkNo ratings yet

- 311-QD60-F-4002 Test Package of Station Pipe Section of Utility Water Supply System at HTS Station-Rev.0Document32 pages311-QD60-F-4002 Test Package of Station Pipe Section of Utility Water Supply System at HTS Station-Rev.0Mohammad gani100% (1)

- Pre-Pour & Concrete Pouring of CAU - 2MDocument7 pagesPre-Pour & Concrete Pouring of CAU - 2MAKHIL RAJNo ratings yet

- Admore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurDocument12 pagesAdmore Gas (PVT) LTD: Bulk Oil Installation Depot at DaulatpurBilal Mustafa SiddiquiNo ratings yet

- MST For Concret CoatingDocument6 pagesMST For Concret CoatingDelta akathehusky100% (1)

- Piping Fabrication ProcedureDocument11 pagesPiping Fabrication ProcedureMohammed Elsaid Yousef Harhera100% (2)

- CP Deep Anode Bed Method of StatementDocument11 pagesCP Deep Anode Bed Method of StatementNeil JavierNo ratings yet

- Sour Water Stripper Project Ras TanuraDocument31 pagesSour Water Stripper Project Ras TanuraAnanthakrishnan VNo ratings yet

- MST For Ductbank ConstructionDocument7 pagesMST For Ductbank ConstructionDelta akathehusky100% (1)

- Sample Design Calculations For Vertical VesselsDocument14 pagesSample Design Calculations For Vertical VesselsFaris QoceyNo ratings yet

- Inspection & Testing Services For Concrete Paving and Earthworks Construction SpecificationDocument11 pagesInspection & Testing Services For Concrete Paving and Earthworks Construction SpecificationJohnny vargas suclupeNo ratings yet

- SAIC-H-2001 Rev 7Document4 pagesSAIC-H-2001 Rev 7isslam elhoussanyNo ratings yet

- 1 SATIP-L-108-01 Valve Installation-Rev 2Document15 pages1 SATIP-L-108-01 Valve Installation-Rev 2Md ShariqueNo ratings yet

- SACIC-T-5709 OSP Ductbank-Duct Bank Fabrication, Installation and Mandrel TestDocument3 pagesSACIC-T-5709 OSP Ductbank-Duct Bank Fabrication, Installation and Mandrel TestArshad ImamNo ratings yet

- Engineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemDocument45 pagesEngineer'S Stamp: Contractor'S Stamp:: Al Qunfudhah New City Feeder Water Transmission SystemUmar ShehzadNo ratings yet

- MPS Bare Pipe EN 10219 - Kraken Australia Pty LTD Rev.0Document26 pagesMPS Bare Pipe EN 10219 - Kraken Australia Pty LTD Rev.0Alfian ImaduddinNo ratings yet

- Aug 7 Sacrificial Anode Installation Method of StatementDocument13 pagesAug 7 Sacrificial Anode Installation Method of StatementNeil JavierNo ratings yet

- C211050 01 VCS Iocl Tender 001 - D2Document619 pagesC211050 01 VCS Iocl Tender 001 - D2Aqib Khan VCSPNo ratings yet

- SAIC-H-2001 Rev 7Document3 pagesSAIC-H-2001 Rev 7Satheesh Rama SamyNo ratings yet

- Ajyal - IntroductionDocument17 pagesAjyal - IntroductionRajamanickam Kalavathi SubramanianNo ratings yet

- 18-1039 Draft Report (Nuberg Engg.) Complete PDFDocument73 pages18-1039 Draft Report (Nuberg Engg.) Complete PDFYatendra TyagiNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- Processing, Properties, and Design of Advanced Ceramics and CompositesFrom EverandProcessing, Properties, and Design of Advanced Ceramics and CompositesGurpreet SinghNo ratings yet

- 20SWCG00038: Ayesa Engineering and Architecture, S.ADocument1 page20SWCG00038: Ayesa Engineering and Architecture, S.AAlaa NayefNo ratings yet

- 20SWCG00038: Ayesa Engineering and Architecture, S.ADocument1 page20SWCG00038: Ayesa Engineering and Architecture, S.AAlaa NayefNo ratings yet

- 20SWCG00038: Ayesa Engineering and Architecture, S.ADocument1 page20SWCG00038: Ayesa Engineering and Architecture, S.AAlaa NayefNo ratings yet

- 20SWCG00038: Ayesa Engineering and Architecture, S.ADocument1 page20SWCG00038: Ayesa Engineering and Architecture, S.AAlaa NayefNo ratings yet

- JSS Academy of Technical Education: Project GuideDocument11 pagesJSS Academy of Technical Education: Project GuidearunNo ratings yet

- Specs For NG - MFO Fired Thermal Oil HeaterDocument52 pagesSpecs For NG - MFO Fired Thermal Oil HeaterRakapradiftaNo ratings yet

- Multi-Component FTIR Emission Monitoring System: Abb Measurement & Analytics - Data SheetDocument16 pagesMulti-Component FTIR Emission Monitoring System: Abb Measurement & Analytics - Data SheetRonaldo JuniorNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/42Document13 pagesCambridge IGCSE: CHEMISTRY 0620/42Maram MohanNo ratings yet

- Management of Change: Did You Know?Document1 pageManagement of Change: Did You Know?baaziz2015No ratings yet

- BoilerDocument3 pagesBoilerTerry YongNo ratings yet

- Temperature Limits Iec60282-1Document2 pagesTemperature Limits Iec60282-1carlosNo ratings yet

- 4 3RU11, 3RB10, 3RB12 Overload RelaysDocument66 pages4 3RU11, 3RB10, 3RB12 Overload RelaysMahmoud_EldeekNo ratings yet

- Water ReuseDocument12 pagesWater ReuseKiata WayuyabNo ratings yet

- Atena-Modelling of Crack Development in Young ConcreteDocument11 pagesAtena-Modelling of Crack Development in Young ConcreteBuiDucVinhNo ratings yet

- Huntsmann EU ELECTRONICS-Selector-GuideDocument24 pagesHuntsmann EU ELECTRONICS-Selector-GuideXavierNo ratings yet

- Astm A 240-2020Document12 pagesAstm A 240-2020Mohammed AliNo ratings yet

- Seminar On:: Generation of Electricity From Speed Breakers (Power HumpDocument34 pagesSeminar On:: Generation of Electricity From Speed Breakers (Power HumpAnu KpNo ratings yet

- Cleaning-In-Place in The Dairy IndustryDocument11 pagesCleaning-In-Place in The Dairy IndustryihllhmNo ratings yet

- Feasibility Report: Proposed Expansion of Cement PlantDocument37 pagesFeasibility Report: Proposed Expansion of Cement PlantAkash DasNo ratings yet

- American Woodworker #157 December 2011-January 2012Document68 pagesAmerican Woodworker #157 December 2011-January 2012Brian Neill100% (2)

- Redox and Electrochemistry PDFDocument95 pagesRedox and Electrochemistry PDFErnest NsabimanaNo ratings yet

- Coal Handling PLantDocument8 pagesCoal Handling PLantPrasanna kumar subudhiNo ratings yet

- Properties & Manufacturing & Applications & Limitations of PolymethylmethacrylateDocument4 pagesProperties & Manufacturing & Applications & Limitations of PolymethylmethacrylateRohith RaviNo ratings yet

- Tyre Life Management SystemDocument30 pagesTyre Life Management Systemash31399941100% (2)

- 25MVA Solar Transformer-Bihar 25MW PDFDocument10 pages25MVA Solar Transformer-Bihar 25MW PDFamulya00428No ratings yet

- MAXON PresentationDocument27 pagesMAXON PresentationJaroslav KurucNo ratings yet

- Pistol Crossbow Mostly With Hand ToolsDocument4 pagesPistol Crossbow Mostly With Hand Toolsmarius_danila8736No ratings yet

- S355MCDocument2 pagesS355MCPankaj GuptaNo ratings yet

- The ABC's of Nondestructive Weld ExaminationDocument10 pagesThe ABC's of Nondestructive Weld Examinationlethanhhai0306No ratings yet

- HZS150P-36: Polycrystalline Solar Module FeatureDocument2 pagesHZS150P-36: Polycrystalline Solar Module FeatureEdrViidaurreGonzalesNo ratings yet