Professional Documents

Culture Documents

Bala 10 Plates Rev 01 FORMAT 001 000

Uploaded by

Oscar MarinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bala 10 Plates Rev 01 FORMAT 001 000

Uploaded by

Oscar MarinCopyright:

Available Formats

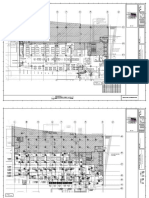

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

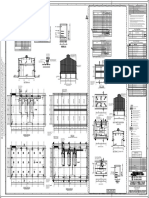

Operating Conditions

Int./ext. pressure MPa - / -

Int./ext. temperature °C - / -

Fluid Name

Service Name

Liquid Specific Gravity 1

A A

Design Conditions

Design Code ASME VIII July 2017

Stamp .Yes .No Method of receipt

- .Yes .No - .Yes .No

Int./ext. pressure MPa 1.72 /

Int./ext. temperature °C 65.556 /

Differential Pressure MPa -

MDMT (at design pressure) °C

F1 Steamout Pressure MPa -

MH2 Steamout Temperature °C -

-

MH2 C Radiography

Weld joint efficiency 1

C B A F1

3099

B D B

5

D B 5 MAWP at Design Temp MPa 1.74

18

2

E MH1 MAP in Test MPa 3.39

19939

20244

20545

20625

MAP (New and Cold) MPa -

-

1016

Insulation mm

13230

406

Hemispherical head

O.D. 3302

Thk. 28.58

Ref. 0.00

Hemispherical head

O.D. 3302

Thk. 28.58

Fireproofing mm -

R Corrosion Allowance mm

1901

60 Category -

Stress relief .Yes X No

Lethal Service .Yes X No

Hydrogen Service .Yes X No

Flammable Service .Yes X No

16

Explosive Service .Yes X No

�3302(Ext) x 23.81

.Required .To code .By Client

C C

�6

. . Shells - Heads -

Impact Piping -

COG Not Required

.

4 Bolts �27 Test Forgings -

16 16

20

250

Standard Flanges -

Nuts and Bolts -

1067

AA Code Notes

1397 2760 3 66 Earthquake .Yes -

BB

20

Wind .Yes -

22

2940 250

1600 Hydrotest Conditions

F2

SS FS

Shop Hydrotest Pressure MPa 1.51 .Vertical X Horizontal

1422.4 17881.6

Site test MPa .Vertical .Horizontal

F2 Construction Material

20884 MH1

D D

Specification (1) (2) (3) (4) (5) Notes

Overall Length 23995

AA

A Skirt-supports SA283GRC . . . . . -

. . . . -

BB

E Shells-Heads A212GrB . . . . . -

Couplings . . . . . -

Gaskets . . . . . -

Flange bolting . . . . . -

Manhole nuts . . . . . -

External clips . . . . . -

110 110

Internal parts . . . . . -

50

16

. . . . -

. . . . -

75

E Cladding . . . . . - E

75

�33

. Stiffening rings . . . . . -

Insulation supports . . . . . -

670 670 50

Blind flanges . . . . . -

(1):Normalized (2):Impact test (3):Positive material identification

1420 1420 (4):Hydrogen corrosion test requested (5):Corrosion test requested

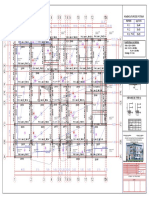

Foundation Loads

Vertical Longitudinal Shear Circular

Load Force Force Bending Moment

Wind Cross 25599 daN 7680 daN - -

Earthquake Cross - - - -

Earthquake Right - - - -

F Earthquake Left - - - - F

Table of estimated weights

Freight kg 51081 Insulation kg

Operating kg 51081 Internal lining kg

Test kg 242682 Ladders and Platforms kg

Fireproofing kg Bundle kg

Internals kg Capacity m³ 191.601

Packing kg Height of liquid mm

Trays kg

Coil Design Conditions

Pressure MPa

Temperature °C

G Test Pressure MPa G

Hemispherical head

O.D. 3302

Thk. 28.58

Ref. 0.00

Hemispherical head

O.D. 3302

Thk. 28.58

Corrosion Allowance mm

Liquid Specific Gravity

TL WL WL WL TL

Painting Requirements

WL WL WL WL WL WL WL WL WL Painting Area m² 268

External Surfaces Internal Surfaces

R Specification - -

Surface Preparation - -

Painting System: Primer - -

Painting System: Intermediate Coat - -

Painting system: Top Coat - -

Freight

�3302(Ext) x 23.81

H Overall size mm 23995 H

5

25

18

Center of Gravity mm 10161.8

Reference Standard Drawings

COG

Number Designation

.- Nozzle Loadings

.- -

1901

60 .- -

.- -

.- -

.- -

.- -

16

SS FS

.- -

50.8 2024.1 2074.9 2074.9 2074.9 2074.9 2074.9 2074.9 2074.9 2074.9 1429.1 729.9

.- -

I 50.8 I

�6

. .- -

20884

Overall Length 23995

.

4 Bolts �27

16 16

20

250

2940

250

J J

110 110

16

K K

75

75

�33

.

670 670

1420 1420

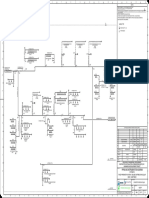

2 1 Type WD1 Type WD2

3 9 5

5 7

1 a

2 2 a c

4

3 8

4

1 6 3 1 6 b b

L L

Nozzle Neck Flange Pad

Tag Designation

Diam. Thk. /axis Nom. d. Type Clas. Face Thk. x Wid. 1 2 (°) 3 4 (°) 5 6 Tag 7 8 (°) 9 W.Tag W.Detail Thk.Sup. Thk.Noz.Thk.xWid. Pad a c b

MH1 Manhole NPS 18 9.52 23.8 x211.1 381 90 ShellG W18 WD2 23.81 9.52 23.81 x211.14 9.525 14.288 9.525

A Feed inlet NPS 6 10.97 23.8 x71.4 203.2 90 ShellJ W19 WD2 23.81 10.97 23.81 x71.44 9.525 14.288 9.525

B Shell Inlet NPS 2 5.54 203.2 270 ShellJ W12 WD1 23.81 5.54 6.35 6.35

C Reflux inlet NPS 2 5.54 203.2 270 ShellJ W13 WD1 23.81 5.54 6.35 6.35

F1 Level alarm NPS 3 7.62 23.8 x60.3 203.2 270 ShellJ W20 WD2 23.81 7.62 23.81 x60.33 7.938 14.288 7.938

F2 Level alarm NPS 3 7.62 203.2 90 1600.2 90 HeadB W14 WD1 28.58 7.62 7.938 7.938

AA Level glass NPS 1 6.35 200.4 1066.8 90 HeadB W15 WD1 28.58 6.35 6.35 6.35

M M

BB Level register NPS 0.5 4.78 206 1397 90 HeadB W16 WD1 28.58 4.78 6.35 6.35

D Pressure safety valve NPS 4 8.56 23.8 x71.4 203.2 270 ShellA W21 WD2 23.81 8.56 23.81 x71.44 9.525 14.288 9.525

E Drain NPS 1.5 5.08 203.2 90 ShellA W17 WD1 23.81 5.08 6.35 6.35

MH2 Manway NPS 30 12.7 2159 NPS 30 WN 23.8 x346 508 270 2159 ShellB W22 WD2 23.81 12.7 23.81 x345.99 9.525 14.288 9.525

N N

O O

My Company Sheet : 1

AutoPIPE Vessel Revision :

P P

1 2 3 4 5 6 7 10 11 12 13 14 15 16

You might also like

- Alcatel One Touch-806D Circuit DiagramDocument10 pagesAlcatel One Touch-806D Circuit DiagramEdgar Jose Aranguibel MorilloNo ratings yet

- Bala 08 Plates - Rev - 01 FORMAT - 001 000Document1 pageBala 08 Plates - Rev - 01 FORMAT - 001 000Oscar MarinNo ratings yet

- WD Centre Line PlanDocument1 pageWD Centre Line PlanRaj GuptaNo ratings yet

- B129/B130/B168/B169 POINT TO POINT DIAGRAM: Power Pack-BCT (PCB11)Document4 pagesB129/B130/B168/B169 POINT TO POINT DIAGRAM: Power Pack-BCT (PCB11)Caroline DanielNo ratings yet

- 8-1. Schematic Diagram (Main)Document2 pages8-1. Schematic Diagram (Main)CADiLONo ratings yet

- 250MW Gov With EHA 2-2180-07Document2 pages250MW Gov With EHA 2-2180-07Siva KulanjiNo ratings yet

- Osc 00 SS6 0101 - 04Document1 pageOsc 00 SS6 0101 - 04akın bektaşNo ratings yet

- Demin Water SystemDocument1 pageDemin Water Systemmohamed abourayaNo ratings yet

- Sobha Hartland Greens - Phase 02: InvestmentsDocument1 pageSobha Hartland Greens - Phase 02: InvestmentsrajatNo ratings yet

- Ice Load For This Floor 1.0Kn/M2: M/L DWG No. H-11400-1360-1209Document1 pageIce Load For This Floor 1.0Kn/M2: M/L DWG No. H-11400-1360-1209Chiều TànNo ratings yet

- B011 000 16 50 01201 - Rev 2Document1 pageB011 000 16 50 01201 - Rev 2GLOBUS ENGINEERSNo ratings yet

- EASY-PIC4 Schematic v101Document1 pageEASY-PIC4 Schematic v101r.dubordNo ratings yet

- B436 100 16 50 00202 - Rev 2Document1 pageB436 100 16 50 00202 - Rev 2suraj kumarNo ratings yet

- Plan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000Document1 pagePlan at El.2268 MM Tos: WBCD Support at El.45100, Buckstay Guide at El.50000shisNo ratings yet

- SCHOOL BUILDING FIRST FLOOR PLAN - ModelDocument1 pageSCHOOL BUILDING FIRST FLOOR PLAN - ModelAATVIK SHRIVASTAVANo ratings yet

- A8rx CHT XXXX Tel Lay XXX 01Document1 pageA8rx CHT XXXX Tel Lay XXX 01kuse2456No ratings yet

- Binyamin Region 2014 Touring MapDocument1 pageBinyamin Region 2014 Touring MapmirelaNo ratings yet

- Secondary Reheater CoilDocument1 pageSecondary Reheater CoilHardik MehraNo ratings yet

- 313700bedp70204 Cdfe01 01Document1 page313700bedp70204 Cdfe01 01Amr AhmedNo ratings yet

- Js200w Гидросхема с ДавлениямиDocument1 pageJs200w Гидросхема с ДавлениямиNikolay KuznetsovNo ratings yet

- Renr1242 02Document2 pagesRenr1242 02AJCMANDEMAQNo ratings yet

- Coring LocationDocument1 pageCoring LocationOrly L. AlmerinoNo ratings yet

- S-03710 P42118-Rev. 3-P18-Steam DrumDocument1 pageS-03710 P42118-Rev. 3-P18-Steam Drumwylie01No ratings yet

- Paras Ventures - (Ground Floor)Document1 pageParas Ventures - (Ground Floor)AriyanNo ratings yet

- SUM 41 Noots Bajo y GuitarrasDocument1 pageSUM 41 Noots Bajo y GuitarrasIgor Boullosa GarcíaNo ratings yet

- Hydraulic Schematic 6050 FS: Old Hydraulikschaltplan 6050 LSDocument1 pageHydraulic Schematic 6050 FS: Old Hydraulikschaltplan 6050 LSJHONATAN ESTEBAN VALENZUELA ALBIÑONo ratings yet

- Ug-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08Document2 pagesUg-Til-43-Sin1-415702 - 02 - Afc - 20220623 - JBR09 To JBR08AHMED LASSOUEDNo ratings yet

- Mr. J.B. BluesDocument3 pagesMr. J.B. BluesSimone GaggioliNo ratings yet

- CMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736Document1 pageCMN.18.477 Smart Plant Documentation Ruwais NGL Train 3: From El.93 800 To Above LP Flare Piping Ga Plan Area TD Zone 736steepa22No ratings yet

- PressedDocument6 pagesPressedVijay KumarNo ratings yet

- 3W-200697-01 R12-AREA-01 Roquette India Pvt. Ltd. Belgaum (200502) COFFE...Document1 page3W-200697-01 R12-AREA-01 Roquette India Pvt. Ltd. Belgaum (200502) COFFE...Dk WatranaNo ratings yet

- Gre Eec D 99 Co P 10036 03 004Document5 pagesGre Eec D 99 Co P 10036 03 004Carlos GamarraNo ratings yet

- Fuga A 5 Pro Organo Pleno BachDocument12 pagesFuga A 5 Pro Organo Pleno BachSilva BielsilvaNo ratings yet

- Acmv - Piping Laoyut - Dlsu Fit-Out - Rev.04Document2 pagesAcmv - Piping Laoyut - Dlsu Fit-Out - Rev.04Orly L. AlmerinoNo ratings yet

- Piping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Document1 pagePiping and Instrumentation Diagram: Fixed Firewater System - Deluge Distribution Cellar Deck / Sump Deck System 53Mohd KhaidirNo ratings yet

- MPH STD Int L00 1003Document1 pageMPH STD Int L00 1003m AhmedNo ratings yet

- Sony - 1 862 611 12 - (SCH)Document2 pagesSony - 1 862 611 12 - (SCH)RenatoNo ratings yet

- Rbs College StationDocument1 pageRbs College StationPooja waniNo ratings yet

- Key Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Document6 pagesKey Plan: RSXX-DT Capacitor Bank RSXX-CAP-01Mrinal KayalNo ratings yet

- St150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedDocument1 pageSt150030 Aru Elc 06 z15 DRG Le 0006 s3 x01 Redline UpdatedJamie CannellNo ratings yet

- R e L L o H: Calle Loma de OroDocument1 pageR e L L o H: Calle Loma de OroMaria Celeste Ramirez HurtadoNo ratings yet

- Proposed Land Use Map Planning District: 1Document1 pageProposed Land Use Map Planning District: 1Babu reddyNo ratings yet

- 26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumDocument1 page26071-203-M6-315-00005 - Piping and Instrumentation Diagram Fuel Oil and Fuel Gas System (Unit 315) Fuel Gas KO DrumJeroan AyamNo ratings yet

- 10083a 1X M6 Ab 00006 04Document1 page10083a 1X M6 Ab 00006 04wael zakariaNo ratings yet

- Ebaz 4205Document1 pageEbaz 4205jjzyjjjNo ratings yet

- Bhe T4 L07 DR S 1070Document1 pageBhe T4 L07 DR S 1070bharanidharanNo ratings yet

- BJ Existing SchematicsDocument7 pagesBJ Existing SchematicsNassif Abi AbdallahNo ratings yet

- Sx90 Operator Manual EnglishDocument78 pagesSx90 Operator Manual Englishchulapon10No ratings yet

- L1 L2 L3 N: Option 2NGO1Document19 pagesL1 L2 L3 N: Option 2NGO1Anderson VieiraNo ratings yet

- XC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18Document1 pageXC2003 Controller Notes:: X2:1 X2:6 X2:7 X2:8 X2:9 X2:6 X2:14 X2:15 X2:11 X2:17 X2:20 X2:21 X2:22 X2:24 X2:26 X2:25 X2:18percyctba FilhoNo ratings yet

- CBD Bp18a C127D2 SDW Co Co NL 07025 01Document1 pageCBD Bp18a C127D2 SDW Co Co NL 07025 01rakeshamechNo ratings yet

- Grave of The FirefliesDocument2 pagesGrave of The Firefliesflora xuNo ratings yet

- Uncontrolled If Printed: KeyplanDocument2 pagesUncontrolled If Printed: KeyplansayedNo ratings yet

- Pelo Telefone PDFDocument2 pagesPelo Telefone PDFAntonioNo ratings yet

- Mot Buoc Yeu Van Dam Dau SheetDocument5 pagesMot Buoc Yeu Van Dam Dau Sheetvanh291005No ratings yet

- Plancher Haut RDCDocument1 pagePlancher Haut RDChaidaru adamsNo ratings yet

- Hpcl-Mittal Energy LTD., P Ih LKH, Y & Ferry, Uzth FyfevsmDocument1 pageHpcl-Mittal Energy LTD., P Ih LKH, Y & Ferry, Uzth Fyfevsmiqbal6982No ratings yet

- Nguoi Gieo Mam Xanh - Hoang Dung-PianoDocument12 pagesNguoi Gieo Mam Xanh - Hoang Dung-Pianolingmeiguo20102007No ratings yet

- P&id Demineralized Water DistributionDocument1 pageP&id Demineralized Water DistributionAjeng OctaviaNo ratings yet

- Blasthole Drilling PDFDocument304 pagesBlasthole Drilling PDFSanjay Kapoor100% (2)

- WrightRE Web12 5 PDFDocument12 pagesWrightRE Web12 5 PDFOscar MarinNo ratings yet

- Turbine Meter Tech GuideDocument22 pagesTurbine Meter Tech GuideOscar MarinNo ratings yet

- Weldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Document1 pageWeldolet - Sockolet - Threadolet: ASME B16.11 - 3000LBS MSS-SP97Oscar MarinNo ratings yet

- Operation Manual: Dakota UltrasonicsDocument155 pagesOperation Manual: Dakota UltrasonicsOscar MarinNo ratings yet

- PH: (780) 459 6720 Fax: (780) 459 7837: WarrantyDocument2 pagesPH: (780) 459 6720 Fax: (780) 459 7837: WarrantyOscar MarinNo ratings yet

- Slab Shear CoefficientDocument1 pageSlab Shear CoefficientIsbel0% (1)

- Chapter 1Document10 pagesChapter 1آڃمْڊ آلُنْمْرNo ratings yet

- Pad Eye CalculationsDocument28 pagesPad Eye CalculationsEnrique BarajasNo ratings yet

- Boiler Efficiency Technical ReportDocument6 pagesBoiler Efficiency Technical ReportVhence BelandresNo ratings yet

- ATENA - Theory Nonlinear RCDocument282 pagesATENA - Theory Nonlinear RCPreloxNo ratings yet

- Heat TransferDocument4 pagesHeat TransferRoem EsmernaNo ratings yet

- SJCPL-HSE-FR-23 Noise Level Survey ReportDocument1 pageSJCPL-HSE-FR-23 Noise Level Survey ReportVikas YamagarNo ratings yet

- GATE IES Thin Cylinder and SpringDocument6 pagesGATE IES Thin Cylinder and Springbachayadav100% (1)

- Unit Operations of Chemical Engineering - W. L. McCabe, J. C. Smith and P. HarriotDocument178 pagesUnit Operations of Chemical Engineering - W. L. McCabe, J. C. Smith and P. HarriotKhushii NaamdeoNo ratings yet

- IB SL Physics Unit 3 Study GuideDocument1 pageIB SL Physics Unit 3 Study GuideAdrianMirandaNo ratings yet

- STP 1498-2011Document328 pagesSTP 1498-2011TertulianoPinto100% (1)

- Design of Composite Bridges Use of BS 5400: Part 5: 1979: The Highways Agency BD 16/82Document23 pagesDesign of Composite Bridges Use of BS 5400: Part 5: 1979: The Highways Agency BD 16/82Bobby WongNo ratings yet

- Heat Pump Lab ReportDocument11 pagesHeat Pump Lab ReportPrecisionetica63% (8)

- Colligative Properties of Dilute SolutionsDocument4 pagesColligative Properties of Dilute SolutionsVinay KaraguppiNo ratings yet

- EEE Pipe FrictionDocument7 pagesEEE Pipe FrictionmahabubNo ratings yet

- Flows: Pressure Drops and Void Fractions in Horizontal Two-Phase PotassiumDocument9 pagesFlows: Pressure Drops and Void Fractions in Horizontal Two-Phase Potassiumshah_gen89No ratings yet

- Prosper® Tutorial 04: Modelling An Horizontal Oil WellDocument50 pagesProsper® Tutorial 04: Modelling An Horizontal Oil WellPedro MarquezNo ratings yet

- FordsonDocument54 pagesFordsonDalibor DušićNo ratings yet

- Roe SchemeDocument8 pagesRoe SchemeSunny KhadkaNo ratings yet

- Column. Numerical Modelling Techniques of Soft Soil Improvement Via Stone Columns - A Brief ReviewDocument14 pagesColumn. Numerical Modelling Techniques of Soft Soil Improvement Via Stone Columns - A Brief ReviewjyjiaNo ratings yet

- Analysis Manual MasonryDocument21 pagesAnalysis Manual MasonryhahaerNo ratings yet

- Contoh Liquid SolidDocument9 pagesContoh Liquid Solidloey scaa100% (1)

- Waba Dam Permanent DeformationDocument8 pagesWaba Dam Permanent DeformationerginliNo ratings yet

- Numerical Simulation of Sleeve Repair Welding On In-Service 16Mn Crude Oil PipelinesDocument5 pagesNumerical Simulation of Sleeve Repair Welding On In-Service 16Mn Crude Oil PipelinesjangdiniNo ratings yet

- Performance Based Design (Eddie Hong, M - SC - )Document78 pagesPerformance Based Design (Eddie Hong, M - SC - )Angga AriefNo ratings yet

- AJ Physics S.3 ENDDocument5 pagesAJ Physics S.3 ENDJohn MUTNo ratings yet

- Refrigeration and Air-Conditioning - S K MondalDocument0 pagesRefrigeration and Air-Conditioning - S K MondalShaheen S. RatnaniNo ratings yet

- AERO2358 Propeller Blade Element 2011Document27 pagesAERO2358 Propeller Blade Element 2011Daniel 'funkD' Quan100% (1)

- Topic 1 ACMVDocument21 pagesTopic 1 ACMVEmi ArisNo ratings yet

- NPSH Calculator For Process EngineerDocument14 pagesNPSH Calculator For Process Engineerlutfi awnNo ratings yet