Professional Documents

Culture Documents

Revise Proposed Fabrication ITP

Uploaded by

Tech 5Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revise Proposed Fabrication ITP

Uploaded by

Tech 5Copyright:

Available Formats

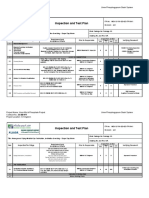

Document No: KRYFS/FAB/ITP/2024-25/01

PROPOSED INSPECTION TEST PLAN FOR STRUCTURE STEEL FABRICATION

Date: 12-02-2024

Client: KRYFS Power Components Ltd. Contractor: Desai Construction Revision No: 01

Structural Consultant: Mahimtura Consultant Pvt. Ltd. Sub Contractor: Gayatri Engineering Date: 29-02-2024

Ref Quality IS, ASME, AWS & Structural

Project: TPI: Aavishkar Group

Documents: Project Documents

Inspection Acceptance Scope of Inspection

Activity

Structural Remark

No Activity Detail of Activity Frequency Reference Document Criteria Verify Documents Contactor TPI Client / PMC

Consultant

1 Preliminaries

KRYFS/FAB/ITP/2024-

1.1 Submit ITP One Time Project Specification & QAP Technical Proposal / QAP S R R&A A

25/01

Welding Procedure

1.2 One Time AWS D 1.1 / ASME Sec IX AWS D 1.1 / ASME Sec IX WPS P W&A R R

Specification (WPS)

Welding Procedure

1.3 One Time AWS D 1.1 / ASME Sec IX AWS D 1.1 / ASME Sec IX PQR P W&A R R

Qualification Record (PQR)

Welder Performance

1.4 Documents One Time AWS D 1.1 / ASME Sec IX AWS D 1.1 / ASME Sec IX WPQ P W&A R R

Qualification Record (WPQ)

1.5 NDT Procedure One Time AWS D 1.1 AWS D 1.1 NDT Procedure NA S R&A A

1.6 NDT Operator Qualification One Time ASNT SNT-TC-1A ASNT SNT-TC-1A Qualification Record NA S R&A A

Product Datasheets, Paint

Blasting & Painting

1.7 Blasting & Painting Procedure One Time manufacturers Project Specification S R R&A A

Procedure

recommendation

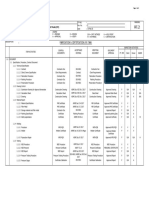

2 Material Inspection

Purchase Order / BOQ / Applicable standards as

2.1 Visual Examination 100% Inspection Report P1 P2 R R

Approved Drawings per BOQ

Purchase Order / BOQ / Applicable standards as

2.2 Dimensional Measures 10% Inspection Report P1 P2 R R

Approved Drawings per BOQ

Purchase Order / BOQ / Applicable standards as

2.3 Structural Steel Review of MTC 100% MTC S R R R

Approved Drawings per BOQ

Plates, Sections

3 sample per

and Anchor External Lab Test to confirm

challan from Applicable standards as External lab test sample mobilization

2.4 bolts Chemical & Mechanical MTC Lab Test Certificate P W R R

different heat / per MTC & charges in contractor scope

properties verification

batch

Lamination Check for structural Sec V article 23 SA 578 / SA If MTC has traceability of UT testing

2.5 100% NDT procedure NDT report S R/ P R R

Steel plates for thk > 16 mm 435 than extent of testing can be random

Technical Data Sheet of Welding consumable data sheet to be

2.6 Packing 100% ASME Sec II Part C Product Packing P1 P2 R R

Welding consumables followed

Consumables Technical Data Sheet of Welding consumable data sheet to be

2.7 Review of MTC 100% ASME Sec II Part C MTC S R R R

consumables followed

Purchase Order / BOQ / Applicable standards as

2.8 Dimensional Measures 10% in Each lot Inspection Report P1 P2 R R

Approved Drawings per BOQ

Purchase Order / BOQ / Applicable standards as

2.9 Surface Condition 10% in Each lot Inspection Report P1 P2 R R

Approved Drawings per BOQ

Purchase Order / BOQ / Applicable standards as

2.10 Fasteners Review of MTC 100% MTC S R R R

Approved Drawings per BOQ

3 sample per

External Lab Test to Confirm

challan from Applicable standards as External lab test sample mobilization

2.11 Chemical & Mechanical MTC Lab Test Certificate P W R R

different heat / per BOQ & charges in contractor scope

properties verification

batch

Painting Procedure /

Product Technical Data Product technical data sheet to be

2.12 Paint Review of MTC 100% Product Technical Data MTC S R R R

Sheet followed

Sheet

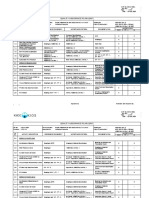

3 Fabrication

Approved Shop Drawings &

3.1 Dimension Check-up 100% Approved Shop Drawings Inspection Report P1 P2 R R

Fit-up IS 7215

3.2 Weld Preparation Check-up 100% Approved Shop Drawings WPS Inspection Report P1 P2 R R

Welding Monitoring Welding Process

3.3 Random WPS WPS Range WPS P1 P2 R R

Process variables

Approved Shop Drawings &

3.4 Welding Dimension Check-up 100% Approved Shop Drawings Inspection Report P1 P2 R R

AWS D 1.1

Inspection &

3.5 Testing Weld Visual Inspection 100% Approved NDT Procedure AWS D 1.1 Inspection Report P1 P2 R R

NDT - CJP Ultrasonic Testing /

3.6 100% Approved NDT Procedure AWS D 1.1 NDT Report S P R R

Groove Weld Radiography Testing

NDT - PJP Magnetic Particle Inspection /

3.7 100% Approved NDT Procedure AWS D 1.1 NDT Report S P R R

Groove Dye Penetrant Testing

NDT - Fillet Magnetic Particle Inspection /

3.8 25% Approved NDT Procedure AWS D 1.1 NDT Report S P R R

Weld Dye Penetrant Testing

4 Painting

Blasting & Painting Painting Procedure guideline to be

4.1 Shot Blasting Visual 100% ISO 8501 Painting Reports P1 P2 R R

Surface Procedure followed

preparation Blasting & Painting Painting Procedure guideline to be

4.2 Profile Check Once a Day ISO 8501 Painting Reports P1 P2 R R

Procedure followed

Verification of climatic Min. 3 times per Painting Procedure guideline to be

4.3 Painting Procedure SSPC / IS 1477-2 Painting Reports P1 P2 R R

condition day followed

Painting Procedure guideline to be

4.4 Painting Visual Examination Each lot Painting Procedure SSPC / IS 1477-2 Painting Reports P1 P2 R R

followed

Painting Procedure guideline to be

4.5 WFT / DFT checking Each lot Painting Procedure SSPC / IS 1477-2 Painting Reports P1 P2 R R

followed

5 Releasing for Erection

Inspection release Inspection release note with all

5.1 Dispatch Releasing Inspection Each lot NA NA S P R R

note traceable reports

Legends:

Method of Inspection Extent of inspection Others Testing

S - Submission / offer 1 - 100% / Full Scope TPI - Third Party Inspection VT - Visual Inspection

P - Perform 2 - Random / Sample MTC - Material Test Certificate UT - Ultrasonic Test

R - Review QAP - Quality Assurance Plan RT - Radiography Test

H - Hold ITP - Inspection Test Plan PT - Dye Penetrant Test

W - Witness IRN - Inspection Release note MT - Magnetic Particle test

A - Approve

You might also like

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- Document No: Rev: A Number of Page: 1 OF 4: Inspection and Test Plan (Itp)Document4 pagesDocument No: Rev: A Number of Page: 1 OF 4: Inspection and Test Plan (Itp)Ghilman0529No ratings yet

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- PBI-ITP-QA-0001 Inspection and Test Plan Rev.0Document7 pagesPBI-ITP-QA-0001 Inspection and Test Plan Rev.0Tadaya KasaharaNo ratings yet

- ITP For BLOCKWORKDocument4 pagesITP For BLOCKWORKimkashifsaleemNo ratings yet

- King Salman Airbase Project DirabDocument5 pagesKing Salman Airbase Project DirabArif Mohammed100% (1)

- Qa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Document3 pagesQa&Qc-frm-0021 Quality Inspection Plan - Static Equipment-1Ali Haider100% (1)

- ItpDocument5 pagesItpMuhammad Fajar100% (1)

- ITP For Asphalt WorksDocument3 pagesITP For Asphalt WorksBleep News100% (1)

- Wooden Doors & WindowsDocument6 pagesWooden Doors & Windowsparesh.ahirNo ratings yet

- RIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFDocument16 pagesRIAU-WV02-G10-QA-0002 - Shop Test and Inspection Plans - Rev0 PDFSiriepathi SeetharamanNo ratings yet

- Interior Painting: Inspection & Test PlanDocument3 pagesInterior Painting: Inspection & Test PlanDominguez MegoNo ratings yet

- Ajts QCP Fab Format Rev 01Document4 pagesAjts QCP Fab Format Rev 01Pradip DabhiNo ratings yet

- Ceiling Works - Grid & Tile SystemDocument5 pagesCeiling Works - Grid & Tile Systemparesh.ahirNo ratings yet

- Forte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationDocument2 pagesForte (Plots D1D2) : Main Contract Works: Inspection and Test Plan For Abseil Hook InstallationfrancisbautistaNo ratings yet

- Ceiling Works - Gypsum Plaster BoardDocument5 pagesCeiling Works - Gypsum Plaster Boardparesh.ahirNo ratings yet

- PMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Document3 pagesPMI-MS-QAC-2022-03 - Method Statement For Grounding System Works - ITP 2Emmanuel TamayoNo ratings yet

- Inspection and Test Plan 2Document3 pagesInspection and Test Plan 2EdNo ratings yet

- Bed 2381 Q Itp XX 000 00 PDFDocument1 pageBed 2381 Q Itp XX 000 00 PDFKareem GhazyNo ratings yet

- PROJECT Site Record Acceptance Norms RefDocument6 pagesPROJECT Site Record Acceptance Norms Refvanchai sapaNo ratings yet

- Itp For Formworks (Ringlock System)Document3 pagesItp For Formworks (Ringlock System)damianNo ratings yet

- Kc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationDocument2 pagesKc-Con-Qcp-Ss-01 - QCP Structural Steel InstallationMitendra Kumar ChauhanNo ratings yet

- 2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02Document7 pages2023-OS-0007-BCP-0003 Tank Inspection Test Plan (ITP) Rev.02teethai2524No ratings yet

- PMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationDocument6 pagesPMT Machines LTD Inspection and Test Plan For Bogie Frame FabricationAMIT SHAHNo ratings yet

- ITP - 028 (Lighting Fixtures)Document2 pagesITP - 028 (Lighting Fixtures)mohamed wahebNo ratings yet

- ITP - Miscellaneous Metal WorksDocument2 pagesITP - Miscellaneous Metal Worksmohsin.meizaNo ratings yet

- ITP For Structural Cabling System Testing and CommissioningDocument1 pageITP For Structural Cabling System Testing and CommissioningRommel Espinosa ParasNo ratings yet

- Quality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDDocument6 pagesQuality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDRajnikant PatelNo ratings yet

- 4.1i Inspection &test PlanDocument8 pages4.1i Inspection &test PlanISAACNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Hollow Core SlabsDocument2 pagesEtihad Towers Project: Inspection & Test Plan - Hollow Core SlabsjiniNo ratings yet

- Inspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management ServicesDocument11 pagesInspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management Servicespunk cmNo ratings yet

- Inspection and Test Plan Piping Work ActivitiesDocument2 pagesInspection and Test Plan Piping Work ActivitiesAbram Berkat100% (2)

- Inspection and Test PlanDocument58 pagesInspection and Test PlanTouil Houssem100% (1)

- M Storm Drainage System IC M SDS 00Document2 pagesM Storm Drainage System IC M SDS 00achusanachuNo ratings yet

- ITP For False Ceiling Works of BuildingsDocument4 pagesITP For False Ceiling Works of BuildingsYay B. Gico0% (1)

- ITP-3041 For PipeDocument8 pagesITP-3041 For PipeSkinhead TvNo ratings yet

- Fiberglass and Foster - Inspection Test Plan - ITPDocument4 pagesFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- Drainage Work - Inspection Test Plan - ITPDocument4 pagesDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- STC Bec Mat HVC Gen 0245 00 PDFDocument235 pagesSTC Bec Mat HVC Gen 0245 00 PDFAdel MorsyNo ratings yet

- Inspection & Test Plan: Doc N°: Irps Qc-001-01/28-02-20Document8 pagesInspection & Test Plan: Doc N°: Irps Qc-001-01/28-02-20Walha WassimNo ratings yet

- ITP - 031 (Earthing)Document2 pagesITP - 031 (Earthing)mohamed wahebNo ratings yet

- Inspection and Test Plan-1Document1 pageInspection and Test Plan-1Dan SarmientoNo ratings yet

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- QCP - Concrete WorksDocument3 pagesQCP - Concrete WorksMitendra Kumar Chauhan100% (1)

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- CDP RDC Ar Mal Qac 0001Document5 pagesCDP RDC Ar Mal Qac 0001ElvinNo ratings yet

- QCP - BuildingsDocument4 pagesQCP - BuildingsMitendra Kumar ChauhanNo ratings yet

- Material Submittal For Ductile Iron Fittings - Rev.1Document16 pagesMaterial Submittal For Ductile Iron Fittings - Rev.1unnicyriacNo ratings yet

- Fabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Document3 pagesFabrication & Certification LPG Tank:: 0: 10-Feb-20:::: Field Inspection & Test Plan (Itp)Rifki HasyaNo ratings yet

- Quality Assurance Plan (Qap)Document3 pagesQuality Assurance Plan (Qap)Kingston RivingtonNo ratings yet

- Abb Itp-Ega - PCC Extension Panel - Itp - Rev0Document12 pagesAbb Itp-Ega - PCC Extension Panel - Itp - Rev0naumanNo ratings yet

- Manufacturing Traveler - ASME U Stamp Vessel - 2Document8 pagesManufacturing Traveler - ASME U Stamp Vessel - 2Muhammad ZubairNo ratings yet

- Qap - NRLDocument1 pageQap - NRLStructures ProductionNo ratings yet

- 00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleDocument4 pages00257650-0000-33EG-0001 - Rev PB - Attachment A - ITP ExampleSubrata Das100% (1)

- Inspection & Test Plan (ITP) For Simple Package EquipmentDocument2 pagesInspection & Test Plan (ITP) For Simple Package Equipmentxajo50% (2)

- ITP - 030 (Fire Alarm)Document4 pagesITP - 030 (Fire Alarm)mohamed wahebNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Pipeline Planning and Construction Field ManualFrom EverandPipeline Planning and Construction Field ManualRating: 5 out of 5 stars5/5 (3)

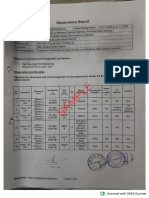

- Site Visit Report: KryfsDocument3 pagesSite Visit Report: KryfsTech 5No ratings yet

- Sample Inspection Report - MMRDADocument45 pagesSample Inspection Report - MMRDATech 5No ratings yet

- Site Visit Technopolis Knowledge ParkDocument2 pagesSite Visit Technopolis Knowledge ParkTech 5No ratings yet

- Quality Management at Split Presentation TC at AG - OptDocument43 pagesQuality Management at Split Presentation TC at AG - OptTech 5No ratings yet

- AG-Product Profile - VadodaraDocument59 pagesAG-Product Profile - VadodaraTech 5No ratings yet

- Product Sourcing at Presentation at AG - OptDocument48 pagesProduct Sourcing at Presentation at AG - OptTech 5No ratings yet

- Technical Services at Presentation at AG - OptDocument112 pagesTechnical Services at Presentation at AG - OptTech 5No ratings yet

- Paes 406Document12 pagesPaes 406Denver LangahinNo ratings yet

- Public Speaking ScriptDocument2 pagesPublic Speaking ScriptDhia MizaNo ratings yet

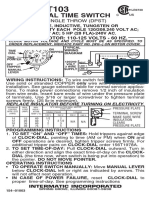

- T103 InstructionsDocument1 pageT103 Instructionsjtcool74No ratings yet

- Ppr.1 Circ.5 Gesamp Ehs ListDocument93 pagesPpr.1 Circ.5 Gesamp Ehs ListTRANNo ratings yet

- Contact Point ContoursDocument69 pagesContact Point ContourstarekrabiNo ratings yet

- 4.section 3 - Routine MaintenanceDocument96 pages4.section 3 - Routine MaintenanceMyo minNo ratings yet

- Mediclinic Weekly Progress Report No 29Document27 pagesMediclinic Weekly Progress Report No 29Julius Ceasar SanorjoNo ratings yet

- Emergency War Surgery Nato HandbookDocument384 pagesEmergency War Surgery Nato Handbookboubiyou100% (1)

- Protein Metabolism and Urea Recycling in Rodent HibernatorsDocument5 pagesProtein Metabolism and Urea Recycling in Rodent HibernatorsBud Marvin LeRoy RiedeselNo ratings yet

- Evaluation of Whole-Body Vibration (WBV) On Ready Mixed Concrete Truck DriversDocument8 pagesEvaluation of Whole-Body Vibration (WBV) On Ready Mixed Concrete Truck DriversmariaNo ratings yet

- November 2013 (v3) QP - Paper 6 CIE Biology IGCSEDocument12 pagesNovember 2013 (v3) QP - Paper 6 CIE Biology IGCSEAfra AhamedNo ratings yet

- Chapter 3.2 Futures HedgingDocument19 pagesChapter 3.2 Futures HedginglelouchNo ratings yet

- Module 6 - Addictions Prayer ServiceDocument6 pagesModule 6 - Addictions Prayer Serviceapi-450520432No ratings yet

- Ryder Quotation 2012.7.25Document21 pagesRyder Quotation 2012.7.25DarrenNo ratings yet

- DM - BienAir - CHIROPRO 980 - EngDocument8 pagesDM - BienAir - CHIROPRO 980 - Engfomed_twNo ratings yet

- ត្នោត (Borassus flabellifer L.)Document11 pagesត្នោត (Borassus flabellifer L.)yeangdonalNo ratings yet

- Osma Osmadrain BG Pim Od107 Feb 2017pdfDocument58 pagesOsma Osmadrain BG Pim Od107 Feb 2017pdfDeepakkumarNo ratings yet

- De Thi Chon HSGDocument10 pagesDe Thi Chon HSGKiều TrangNo ratings yet

- 120-202 Lab Manual Spring 2012Document107 pages120-202 Lab Manual Spring 2012evacelon100% (1)

- Polyken 4000 PrimerlessDocument2 pagesPolyken 4000 PrimerlessKyaw Kyaw AungNo ratings yet

- NHT Series High-Throughput Diffusion PumpsDocument12 pagesNHT Series High-Throughput Diffusion PumpsJosé Mauricio Bonilla TobónNo ratings yet

- Esc200 12Document1 pageEsc200 12Anzad AzeezNo ratings yet

- JAR Part 66 Examination Mod 03Document126 pagesJAR Part 66 Examination Mod 03Shreyas PingeNo ratings yet

- 2013 Casel GuideDocument80 pages2013 Casel GuideBobe MarinelaNo ratings yet

- UntitledDocument18 pagesUntitledSpace HRNo ratings yet

- Fitness Program: Save On Health Club Memberships, Exercise Equipment and More!Document1 pageFitness Program: Save On Health Club Memberships, Exercise Equipment and More!KALAI TIFYNo ratings yet

- Choke Manifold Procedures 3932324 01Document4 pagesChoke Manifold Procedures 3932324 01Saïd Ben Abdallah100% (1)

- JOHARI Window WorksheetDocument2 pagesJOHARI Window WorksheetAnonymous j9lsM2RBaINo ratings yet

- Installation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDocument32 pagesInstallation and Operation Manual: Proact™ Ii Electric Powered Actuator and DriverDjebali MouradNo ratings yet

- Edunsol@gmail - Com, 09996522162, Career Counseling, Direct Admissions, MBBS, BDS, BTECH, MBA, Pharmacy, New Delhi, Mumbai, Pune, Bangalore....Document377 pagesEdunsol@gmail - Com, 09996522162, Career Counseling, Direct Admissions, MBBS, BDS, BTECH, MBA, Pharmacy, New Delhi, Mumbai, Pune, Bangalore....Education SolutionsNo ratings yet