Professional Documents

Culture Documents

Tunnel Work Permit

Tunnel Work Permit

Uploaded by

vseem zahirCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tunnel Work Permit

Tunnel Work Permit

Uploaded by

vseem zahirCopyright:

Available Formats

Environment, Health and Safety

Integrated Management System

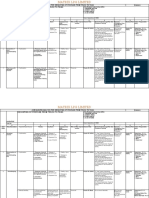

Tunnel Work Permit IM:10A-1

Part 1 Location: Date:

1. Details of Tunnel Name: Permit no:

Engineer / Shift In charge

– TBM

Sign:

2. Number of persons

involved in work Full list of workmen names must be entered in Page - 2

3. Nature of work carried out Mining/ TBM Maintenance/TBM Services/ Housekeeping

in the tunnel /Communications/Pedestrian access / other works -

4. Precise location of

operation within tunnel

From Ring No…………………….to Ring No…………. or

Location…..………………………………..

5. DPSVB Given Hazards involved:

6. Emergency Measures Alarms / Intercom Telephones / Self Rescuers / Fire Extinguishers &

Hoses / First Aid

Kits/Eye Wash Station / Stretcher / Emergency Exit Signages & Clear

Exit ways

Declaration By Authorized Person:

I hereby declare that the work details on this permit are correct. Hazards associated w.r.t these

activities are briefed to all workmen involved and I do ensure all safety measures while working.

Name : Sign:

Part 2 – by Safety Engineer - Tunnel

This permit is valid from: Time…………………. Hrs to ………………………. Hrs on Date…………………….

Name: Sign:

PERMIT CANCELLATION

Part 3 – by Tunnel Engineer / Shift In charge / EHS Engineer / Authorized Person - Tunnel

I hereby declare that the work details on this permit has been completed or stopped and the area left

safe. All operatives under my control have been withdrawn from the area.

Works must be suspended if conditions of issue were changed.

Name: Sign:

Time: Date:

Sensitivity: LNT Construction Internal Use

Environment, Health and Safety

Integrated Management System

S. No Name I’D No Signature

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Sensitivity: LNT Construction Internal Use

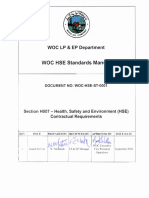

Environment, Health and Safety

Integrated Management System

Forenoon:

Description Current % / PPM STEL - LTEL Levels

Oxygen 19% - 23%

H2S 10% - 15%

4.4% - 14% (Explosive

LEL (CH4)

limits)

Results of

CO2 5000PPM -15000PPM

Multiple

Parameters CO 30 PPM – 200PPM

testing Other Gas (Specify) -

Air Flow: Humidity: Temperature:

Illumination: Noise:

Above Testing completed by on ……/… ../……..

at ………. hrs

Afternoon:

Description Current % / PPM STEL - LTEL Levels

Oxygen 19% - 23%

H2S 10% - 15%

4.4% - 14% (Explosive

LEL (CH4)

limits)

Results of CO2 5000PPM -15000PPM

Multiple

Parameters CO 30 PPM – 200PPM

testing

Other Gas (Specify) -

Air Flow: Humidity: Temperature:

Illumination: Noise:

Above Testing completed by on ……/… ../……..

at ………. hrs

Immediately inform Shift EHS In charge/ TBM in charge/ Tunnel Manager if found any limits

exceeding for further decision on evacuation & initiating Emergency Procedures in place.

Sensitivity: LNT Construction Internal Use

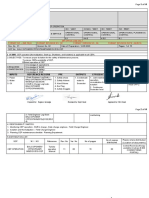

Environment, Health and Safety

Integrated Management System

Additional measures to be checked Yes / No / NA Remarks

Approved Method Statement & Risk Assessment available and

relevant to the task

Daily Pre-Start briefing has conducted

Site supervision is adequately present for different work

locations

Hourly readings from the gas monitors (if alarms observed)

Third Party inspection certificates available for lifting equipment

& gear, pressure vessels

Tunnel Entry system (Tally board) in place and monitored (by

EHS)

Has all the entrants completed Confined space entry training /

Tunnel EHS inducted

Risk assessments & SWM for every activity was available

Underground utilities identified and protected (if required)

Operatives are competent (For MSV, Erector, Cranes)

Does all the entrants were having Proper PPE

Edge protection, warning signposts has been provided at

applicable locations

First Aid Box was available

Trained banksman available (if required for MSV)

Safe Access and Egress is provided

Availability of drinking water facility

Condition of Eye Wash Station

Safety harnesses available (if required for Work at Height in

TBM)

Electrical cables & hoses not interfering with walkways

Dewatering system and in order (if required)

Emergency Response Plan in Place and Briefed to all workers

entering the tunnel

Other applicable permits e.g. Hot Work Permit, Work at Height

permit, Cutter Head Entry Permit Etc (Specify)

Gas test shall be carried out and results to be recorded every 04 hours throughout the shift

Sensitivity: LNT Construction Internal Use

You might also like

- JSA For HVAC WorkDocument8 pagesJSA For HVAC Worksathakathulla100% (3)

- JHA CoatingDocument9 pagesJHA Coatingبسام كريم100% (1)

- Emergency Pathophysiology - Clinical Applications For Prehospital Care, 1E (2013) (PDF) (UnitedVRG)Document429 pagesEmergency Pathophysiology - Clinical Applications For Prehospital Care, 1E (2013) (PDF) (UnitedVRG)Francis Maldonado80% (5)

- EHS Risk AssessmentDocument8 pagesEHS Risk AssessmentSanjay SinghNo ratings yet

- Job Hazard Analysis For Decanting of Propane From Truck To TankDocument17 pagesJob Hazard Analysis For Decanting of Propane From Truck To TankAdebiyi Ismail RaitoNo ratings yet

- Barriers To CommunicationDocument25 pagesBarriers To Communicationkamal tanwar100% (30)

- Anger Management InterventionsDocument10 pagesAnger Management InterventionsAsih Nor ZahidahNo ratings yet

- SAME SEX MARIAGE Position PaperDocument6 pagesSAME SEX MARIAGE Position PaperMybaby Skrrtt100% (1)

- ACKNOWLEGEMENT WaiverDocument178 pagesACKNOWLEGEMENT WaiverAllen PerladoNo ratings yet

- Sample CMR PDFDocument20 pagesSample CMR PDFAnonymous YRygFzMeac88% (26)

- Hot Work PermitHSE-PTWDocument2 pagesHot Work PermitHSE-PTWHSE S4No ratings yet

- Confined Space Entrant Log Brieser Construction: Location and Job Number UnitDocument2 pagesConfined Space Entrant Log Brieser Construction: Location and Job Number UnitAkshay JadhavNo ratings yet

- Pre Incident Plan Toxic Gas Release at TCOTDocument1 pagePre Incident Plan Toxic Gas Release at TCOTkamen55No ratings yet

- Jha RT CpeccDocument10 pagesJha RT Cpeccبسام كريمNo ratings yet

- Confind Space Basic SafetyDocument57 pagesConfind Space Basic SafetyVigneshwaraNo ratings yet

- Environmental Engineering Laboratory Open-Ended Lab Report: Marks CommentsDocument18 pagesEnvironmental Engineering Laboratory Open-Ended Lab Report: Marks Commentssiti HawaNo ratings yet

- 22 SOP of Vaccum PullingDocument18 pages22 SOP of Vaccum PullingSiddhant Satpathy100% (1)

- 208-Audit Checklist-Autoclave Operation - FinalDocument6 pages208-Audit Checklist-Autoclave Operation - FinalCherry Hope MistioNo ratings yet

- Hot & Cold Work PermitDocument10 pagesHot & Cold Work PermitSubratNo ratings yet

- General Work Permit - HSE-CTN-HPP-FMT-021Document3 pagesGeneral Work Permit - HSE-CTN-HPP-FMT-021Radha BuildtechNo ratings yet

- TR Interface Work Permit HFW-31001Document2 pagesTR Interface Work Permit HFW-31001Mohammed NouzalNo ratings yet

- Stanghellini & Aragona (2016) - An Experiential Approach To Psychopathology (Springer) PDFDocument378 pagesStanghellini & Aragona (2016) - An Experiential Approach To Psychopathology (Springer) PDFjhavvo23100% (1)

- HPCL Erdmp PDFDocument167 pagesHPCL Erdmp PDFVarun SharmaNo ratings yet

- Enclosed/ Confined Space Entry Permit: As Per ISGOTT - Chapter 10Document4 pagesEnclosed/ Confined Space Entry Permit: As Per ISGOTT - Chapter 10irakli100% (2)

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- MPSS 2015 1 PDFDocument63 pagesMPSS 2015 1 PDFLisna WidiyantiNo ratings yet

- Ch10 AttA R2Document18 pagesCh10 AttA R2JazielNo ratings yet

- S 9.28L - Pump Room and BT Space Entry Record BookDocument4 pagesS 9.28L - Pump Room and BT Space Entry Record BookWILLIAMNo ratings yet

- Per 01a - Cargo Pumproom Entry PermitDocument3 pagesPer 01a - Cargo Pumproom Entry PermitRajesh NairNo ratings yet

- Iman - Safe Work Procedure-Format Ver C-Sample MCO Rev2Document13 pagesIman - Safe Work Procedure-Format Ver C-Sample MCO Rev2nursharunNo ratings yet

- Electrical Safety - HT and Poweplants 20.12.23Document14 pagesElectrical Safety - HT and Poweplants 20.12.23Truegoodness GirlNo ratings yet

- SMP For DP TransmitterDocument4 pagesSMP For DP TransmitterROHIT SINGHNo ratings yet

- Images - H07 Health Safety and EnvDocument29 pagesImages - H07 Health Safety and EnvHSE PETECSNo ratings yet

- SGI SIMOPS EER PlanDocument2 pagesSGI SIMOPS EER Planjames thornNo ratings yet

- Jha For Loop Check MonioringDocument6 pagesJha For Loop Check MonioringChinedu AchilikeNo ratings yet

- Confined Space Entry Permit Sample 1Document2 pagesConfined Space Entry Permit Sample 1Ri OzNo ratings yet

- C R A D M P: Reen Lanet HemicalsDocument74 pagesC R A D M P: Reen Lanet HemicalsRavindra V. LakhapatiNo ratings yet

- SP - DS PTDocument4 pagesSP - DS PTsakhr fahdNo ratings yet

- JHA of Ultrasonic Test For GPP Pipeline Project (750) - CompressedDocument9 pagesJHA of Ultrasonic Test For GPP Pipeline Project (750) - Compressedبسام كريمNo ratings yet

- Hse Inspection/ Audit Close Out Report: HSEF-51Document2 pagesHse Inspection/ Audit Close Out Report: HSEF-51Sriram BaskaranNo ratings yet

- SP - DS LSDocument5 pagesSP - DS LSsakhr fahdNo ratings yet

- Case Study 5 PetroleumDocument15 pagesCase Study 5 PetroleumAlexNo ratings yet

- Tpl-Pcipl JV: Operational Control Procedure For Hard Rock BlastingDocument7 pagesTpl-Pcipl JV: Operational Control Procedure For Hard Rock BlastingNirbhay KumarNo ratings yet

- 16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.02Document1 page16052-TGC-MTH-ARC-00021 - Engineer's Comments - Rev.02Mohammad MohammadNo ratings yet

- SP - DS LT FinalDocument4 pagesSP - DS LT Finalsakhr fahdNo ratings yet

- 10 Cep SopDocument14 pages10 Cep SopSiddhant SatpathyNo ratings yet

- General Work Permit - HSE-CTN-HPP-FMT-021Document3 pagesGeneral Work Permit - HSE-CTN-HPP-FMT-021Radha BuildtechNo ratings yet

- Daily Report - (plumbing+FF) 11-04Document1 pageDaily Report - (plumbing+FF) 11-04abdulrahimNo ratings yet

- JMS - Alypz TENORM MonitoringDocument11 pagesJMS - Alypz TENORM MonitoringjialiangthegammaNo ratings yet

- Daily Report - (plumbing+FF) 12-04Document1 pageDaily Report - (plumbing+FF) 12-04abdulrahimNo ratings yet

- Cleaning BrushDocument13 pagesCleaning Brushkhairul89 TangguhNo ratings yet

- 34 CT FAN OperationDocument16 pages34 CT FAN OperationSiddhant SatpathyNo ratings yet

- Check List For Third Party Conformity Assessment Section-A. The Information To Be Provided by The EntityDocument11 pagesCheck List For Third Party Conformity Assessment Section-A. The Information To Be Provided by The EntityDeepak DubeyNo ratings yet

- Pre OH ChecklistDocument3 pagesPre OH Checklistpradeep kumarNo ratings yet

- Confined Space Permit FormDocument3 pagesConfined Space Permit FormEbenezer OpuniNo ratings yet

- Eil Daily Safety ChecklistDocument2 pagesEil Daily Safety ChecklistAvesh ChauahanNo ratings yet

- MS-temporary road-UniKL MIAT (YAKIN SERBA SDN BHD)Document65 pagesMS-temporary road-UniKL MIAT (YAKIN SERBA SDN BHD)Muhammad FarailhamNo ratings yet

- Hse Inspection/ Audit Close Out Report: HSEF-51Document2 pagesHse Inspection/ Audit Close Out Report: HSEF-51Sriram BaskaranNo ratings yet

- Safety 2018-19Document7 pagesSafety 2018-19SKITTLE BEASTNo ratings yet

- SWP-SF010A - 7 Daily Pumpcrete Insp Rev ADocument2 pagesSWP-SF010A - 7 Daily Pumpcrete Insp Rev ACliffordNo ratings yet

- PCA To Empty Out T-302 Below LL (Until Pump Cavitate)Document7 pagesPCA To Empty Out T-302 Below LL (Until Pump Cavitate)Muhammad Syukri Abdul AzizNo ratings yet

- Air BalancingDocument2 pagesAir BalancingPramod BhintedeNo ratings yet

- Confined Space Entry Procedure Worksheet PDFDocument5 pagesConfined Space Entry Procedure Worksheet PDFDaniel DDDNo ratings yet

- MN4 Log-Sheets 24-03-2024-6Document1 pageMN4 Log-Sheets 24-03-2024-6ibrahim hegazyNo ratings yet

- Ilovepdf - Merged - PDF RDC NNN-ilovepdf-compressedDocument6 pagesIlovepdf - Merged - PDF RDC NNN-ilovepdf-compressedEkansh AroraNo ratings yet

- Fine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlFrom EverandFine Particle (2.5 microns) Emissions: Regulations, Measurement, and ControlNo ratings yet

- Tunnel Planning For Health and Safety ChecklistDocument2 pagesTunnel Planning For Health and Safety Checklistvseem zahirNo ratings yet

- Tunnel Transport & Plant ChecklistDocument3 pagesTunnel Transport & Plant Checklistvseem zahirNo ratings yet

- Alison Transcript 4638 10003199Document2 pagesAlison Transcript 4638 10003199vseem zahirNo ratings yet

- Alison Transcript 1428 10003199Document2 pagesAlison Transcript 1428 10003199vseem zahirNo ratings yet

- Provisionalcertificate VSEEMZAHIRbtech EEkukhryDocument1 pageProvisionalcertificate VSEEMZAHIRbtech EEkukhryvseem zahirNo ratings yet

- Concept of Sex and Gender Class NoteDocument4 pagesConcept of Sex and Gender Class NoteShital BadhuNo ratings yet

- 7 8 9 10 LecturesDocument17 pages7 8 9 10 LecturesYahya AbdNo ratings yet

- Science Review - Unraveling The Mysteries of Feline Biology and BehaviorDocument2 pagesScience Review - Unraveling The Mysteries of Feline Biology and Behaviorrabi99999No ratings yet

- Ricka2024 Ace y DelincuenciaDocument10 pagesRicka2024 Ace y DelincuenciaKaren CárcamoNo ratings yet

- Endoscopic Release of The Piriformis TendonDocument6 pagesEndoscopic Release of The Piriformis TendonKinjal SharmaNo ratings yet

- Mountain Province Vaccination Monitoring: Data (As of October 24-30, 2021)Document14 pagesMountain Province Vaccination Monitoring: Data (As of October 24-30, 2021)Janice DinesNo ratings yet

- BRIGHT StudyDocument8 pagesBRIGHT Studynilatac acinNo ratings yet

- Charles Woods ResolutionDocument1 pageCharles Woods ResolutionNews 5 WCYB100% (1)

- Typhoid Test ReportDocument4 pagesTyphoid Test ReportDEEPAK DubeyNo ratings yet

- Consumer Behavior and Purchase Intentions For Home Fitness Equipment-2Document11 pagesConsumer Behavior and Purchase Intentions For Home Fitness Equipment-2Pragya Singh BaghelNo ratings yet

- Locs IiiDocument6 pagesLocs IiiGabriel Antonio Moreno ZubietaNo ratings yet

- Systematic Review and Meta-Analysis of The Prevalence of The Maternity Blues in The Postpartum PeriodDocument11 pagesSystematic Review and Meta-Analysis of The Prevalence of The Maternity Blues in The Postpartum Periodsuci triana putriNo ratings yet

- 3 Speech and Language Therapy DDocument2 pages3 Speech and Language Therapy DBárbara FerreiraNo ratings yet

- Dental Patient Coordinator ResumeDocument4 pagesDental Patient Coordinator Resumeusjcgcnbf100% (2)

- Managing Surgical Patients With A COVID-19 Infection in The Operating Experience Indonesia - Gezy Elsevier 2021Document9 pagesManaging Surgical Patients With A COVID-19 Infection in The Operating Experience Indonesia - Gezy Elsevier 2021Fransisca Dewi KumalaNo ratings yet

- Retail and Wholesale Employee Safety ManualDocument24 pagesRetail and Wholesale Employee Safety ManualjarreangkingNo ratings yet

- WLP - Q4 - Music 10 - Week 4Document8 pagesWLP - Q4 - Music 10 - Week 4Gladys GutierrezNo ratings yet

- Name: Muhamad Aiman Bin Mohd Azman Matrix ID: 2019717423 Class: AS229 3A Date of Submission: 5 April 2020Document12 pagesName: Muhamad Aiman Bin Mohd Azman Matrix ID: 2019717423 Class: AS229 3A Date of Submission: 5 April 2020Muhamad Aiman Mohd AzmanNo ratings yet

- Script For Webinar On Team Development: Nurturing Youth Leadership and Independent JournalismDocument5 pagesScript For Webinar On Team Development: Nurturing Youth Leadership and Independent JournalismNel BorniaNo ratings yet

- U3A5 Practitioner's Handbook Organizing ChartDocument3 pagesU3A5 Practitioner's Handbook Organizing Chartkael9010 kael9010No ratings yet

- Ynares-Santiago (Chairperson), Chico-Nazario, Nachura Judgment Rendered in Accordance With Compromise AgreementDocument41 pagesYnares-Santiago (Chairperson), Chico-Nazario, Nachura Judgment Rendered in Accordance With Compromise AgreementFelix TumbaliNo ratings yet

- NUTR 356 - Nutrition Education in The Community - A Peer Review of TDocument69 pagesNUTR 356 - Nutrition Education in The Community - A Peer Review of Tnajeeb0% (1)

- Appendix B: Original Interview GuideDocument5 pagesAppendix B: Original Interview Guideapi-476199344No ratings yet

- 2023 Biology f3 p2 Qs t2 Exam Teacher - Co .KeDocument12 pages2023 Biology f3 p2 Qs t2 Exam Teacher - Co .Kealooben2100% (1)