Professional Documents

Culture Documents

February 26-March 03 Report

Uploaded by

Tesfaye ejetaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

February 26-March 03 Report

Uploaded by

Tesfaye ejetaCopyright:

Available Formats

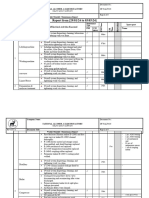

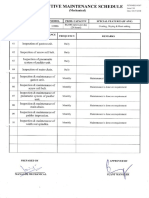

Company Name: Document No.

NATIONAL ALCOHOL & LIQUOR FACTORY OF/NALF/016

ብሔራዊ አልኮል ና አረቄ ፋብሪካ

Revision: 0 Document Title: Page 1 of 4

Weekly/Monthly Maintenance Report

Report from [26/02/24 to 03\03\24]

Downtime

No Machine/ Equipment Maintenance

PM Time

Type Spare part

Name Mechanical/Electrical Activities Executed

Time

PM CM/ Name

CM

BDM

1 Overall system Inspecting, cleaning, lubrication

08hrs

and tightening work was done.

Troubleshooting of the filling valves as well as

capping was done.

No. 40-50 and No. 33, 34, 53 filling valve have

been scattered.

Filling and capping Corkscrews 1-10 were loosened and soaked in

m/c diesel, cleaned and reassembled back.

Motor oil checked and top upping work 24hrs - 03 air pipes

performed.

Three pieces of filling valve air pipes were

replaced due to their bending problem.

Cleaned filling valves and centering guides were

reinstalled.

Overall system Inspecting, cleaning, and

07hrs

lubrication tightening work was done.

Labeling machine Labeling machine has been cleaned by removing

all the staples, glue drum, glue roller, gripper 24hrs

drum, ticket magazine and brushes.

Overall system Inspecting, cleaning, and o

06hrs

lubrication tightening work was done.

10 piece bottle basket carriers removed, cleaned

Washing machine

and reassembled back. 24hrs -

Circulation pump impeller cleaning work

performed.

conveyor Overall system Inspecting, cleaning, and 06hrs

tightening work was done.

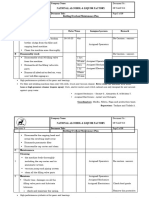

Company Name: Document No.:

NATIONAL ALCOHOL & LIQUOR FACTORY OF/NALF/016

ብሔራዊ አልኮል ና አረቄ ፋብሪካ

Revision: 0 Document Title: Page 2 of 4

Weekly/Monthly Maintenance Report

24rs

Overall system Inspecting, cleaning, and

06hrs

tightening work was done.

Liquor House

Water softener disassembling and reassembling -

24hrs

work performed.

Overall system Inspecting, cleaning, and

24hrs

tightening work was done.

Old Heat exchanger E-1200A/B disassembling - A set of plates

and the new plate assembled.

Fermentation & D-1404 man hole disassembled for cleaning and

molasses treatment reassembled after cleaning work. 8hrs 24hrs

All Electrical boards cleaning work performed.

Previously installed power alcohol transfer

pump replaced by another pump due its low

performance.

Overall system Inspecting, cleaning, and

2 24hrs

tightening work was done.

Mash column C-1510/20/30 Twelve (12) tray - Bible cups

and three plates disassembling and reassembling - starters

work performed.

Mash column Reboiler Top cover removing and

Distillery

reassembling. 24hrs

Some lighting point’s fluorescent lamps were

replaced.

Both E-1530 and E-1560 side cover

disassembling and reassembling work

performed after cleaning.

3 Boiler Overall system Inspecting, cleaning, and ✓ 10hrs

tightening work was done.

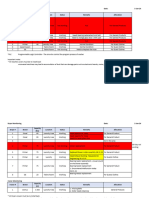

Company Name: Document No.:

NATIONAL ALCOHOL & LIQUOR FACTORY OF/NALF/016

ብሔራዊ አልኮል ና አረቄ ፋብሪካ

Revision: 0 Document Title: Page 3 of 4

Weekly/Monthly Maintenance Report

Water level electrode cleaning work performed. -

Both top and side man hole opened, cleaned and

reassembled back. 24hrs

Heavy oil feed pump motor power exchanging

and testing work.

All Electrical boards cleaning pork performed.

Overall system Inspecting, cleaning, and ✓ 10hrs

Compressor tightening work was done.

-

Fuel top upping and monitoring work. ✓ 10hrs

Generator

-

Overall system Inspecting, cleaning, and ✓ 10hrs

Water softener tightening work was done.

Overall system Inspecting, cleaning, and ✓ 10hrs

Cooling tower tightening work was done.

24hr -

Final alcohol storage, Overall system Inspecting, cleaning, and

10hrs

Process water, and tightening work was done.

submersible pump

Overall system Inspecting, cleaning, and

10hrs

tightening work was done.

4 Waste treatment Unit

Company Name: Document No.:

NATIONAL ALCOHOL & LIQUOR FACTORY OF/NALF/016

ብሔራዊ አልኮል ና አረቄ ፋብሪካ

Revision: 0 Document Title: Page 4 of 4

Weekly/Monthly Maintenance Report

Mekanisa

Full bottle storage floor work was under

progress.

Building water supply system maintenance

carried out.

Workshops, old boiler

Ground cafeteria dishwasher damaged

5 maintenance & Civil 24hrs

works atakini replacing work performed.

7th floor |CEO office window manila

replacing work performed.

Cafeteria workers shower gate valve replacing

work performed.

10th gym room shower head replaced.

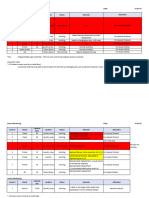

Total time (min.) 175hrs 216hrs

Planned STD 75 % Executed 66.66% Availability Average 50%

Bottling 100 % Bottling 50%

Distillery 75% Distillery 50%

Factory utility & others 75 % Factory utility & others 50 %

Waste treatment 50 % Waste treatment 50%

Prepared By Approved By

Name ___________________ Name __________________

Date ____________________ Date ___________________

Sign ____________________ Sign ___________________

You might also like

- JCB VM115 Single Drum RollerDocument9 pagesJCB VM115 Single Drum Roller江柄宏100% (1)

- Nitrogen Pump SM1 Checklist - Controlled Document PDFDocument4 pagesNitrogen Pump SM1 Checklist - Controlled Document PDFMaxim KanibetovNo ratings yet

- ADAMS - HA 8180V - Operation and Maintenance (2020 - 08 - 20 02 - 50 - 44 UTC)Document51 pagesADAMS - HA 8180V - Operation and Maintenance (2020 - 08 - 20 02 - 50 - 44 UTC)Arnoldo Felix0% (1)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Hortors Online ManualDocument11 pagesHortors Online Manualtshepang4228No ratings yet

- CasesDocument4 pagesCasesSheldonNo ratings yet

- February Month ReportDocument5 pagesFebruary Month ReportTesfaye ejetaNo ratings yet

- Feb.Document4 pagesFeb.Tesfaye ejetaNo ratings yet

- Bottling Maintenance Schedule Oct 2023Document19 pagesBottling Maintenance Schedule Oct 2023Tesfaye ejetaNo ratings yet

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- Cleaning and Assembly of Compression Machine - 1Document5 pagesCleaning and Assembly of Compression Machine - 1SolomonNo ratings yet

- 001 Management and Requalification of Sterilisation ProcessesDocument12 pages001 Management and Requalification of Sterilisation Processesمحمد علاء عبدالرزاق عبدالحيNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil SystemDocument2 pagesChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Lub Oil Systemjp mishraNo ratings yet

- 3.2b Waste Oil Filter Replacement and DisposalDocument2 pages3.2b Waste Oil Filter Replacement and DisposalJaime jr MillanNo ratings yet

- Livret GBDocument16 pagesLivret GBилья100% (1)

- Sop For Membrane Filtration UnitDocument4 pagesSop For Membrane Filtration UnitMusyoka Urbanus100% (1)

- Ship Name: LNG River Orashi TASK: C34.1 DATE: 03/09/2019Document3 pagesShip Name: LNG River Orashi TASK: C34.1 DATE: 03/09/2019Austin UdofiaNo ratings yet

- Legal Register and Compliance TableDocument34 pagesLegal Register and Compliance Tableheikal hajazie100% (1)

- Diesel Generator (4,000 Maintenance Work Order No: Inspection Date: Diesel Generator No: Diesel Gen Run HrsDocument2 pagesDiesel Generator (4,000 Maintenance Work Order No: Inspection Date: Diesel Generator No: Diesel Gen Run HrsMohamed AfsalNo ratings yet

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsDocument1 pageChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraNo ratings yet

- SOP For Operation of Rotary Bottle Washing MarchingDocument3 pagesSOP For Operation of Rotary Bottle Washing MarchingSolomonNo ratings yet

- BlastingtDocument1 pageBlastingtArjuna GamingNo ratings yet

- General InformationDocument6 pagesGeneral InformationJose A PerezNo ratings yet

- Maintenance Schedule of Stenter Machine: ObjectsDocument14 pagesMaintenance Schedule of Stenter Machine: ObjectsAbel TayeNo ratings yet

- Methodology, O&M PhylosophyDocument11 pagesMethodology, O&M PhylosophyVuthpalachaitanya KrishnaNo ratings yet

- RT Inspection & Lubrication Service Log 242-00Document46 pagesRT Inspection & Lubrication Service Log 242-00hananmeliani79No ratings yet

- 05 Equipment Maintenance ScheduleDocument2 pages05 Equipment Maintenance ScheduleMagda MargaNo ratings yet

- Maintenance of Hydraulic SystemsDocument9 pagesMaintenance of Hydraulic Systemsابو المعالي الهمامNo ratings yet

- Compressor Preventive MaintenanceDocument26 pagesCompressor Preventive MaintenanceMohamed Hamed100% (1)

- Cavitation Cleaning - ValquaDocument4 pagesCavitation Cleaning - ValquaEurotech Tra TranNo ratings yet

- Service Schedules: Routine MaintenanceDocument10 pagesService Schedules: Routine MaintenanceDaniel AguirreNo ratings yet

- Changover Lube Oil Duplex FilterDocument5 pagesChangover Lube Oil Duplex FilterIan B. YtomNo ratings yet

- MNT 017-04 Cleaning of Ahu1finalDocument2 pagesMNT 017-04 Cleaning of Ahu1finalAniket kopateNo ratings yet

- Standard Maintenance Procedure For Bag Filter/Vent Filter: Mel Power PlantDocument9 pagesStandard Maintenance Procedure For Bag Filter/Vent Filter: Mel Power PlantMurthy VvnNo ratings yet

- Hydro PlantDocument11 pagesHydro PlantSagar PatilNo ratings yet

- Service Sheet Tadano Cto1Document4 pagesService Sheet Tadano Cto1ainul arifNo ratings yet

- Alfa Laval Ocm304Document4 pagesAlfa Laval Ocm304The ProfessionalNo ratings yet

- 00 - Dri Operations Update To Damam Delegation - Aak - 04102010Document27 pages00 - Dri Operations Update To Damam Delegation - Aak - 04102010SalmanEjazNo ratings yet

- Washer and Dryer Status Jan 05 2024Document4 pagesWasher and Dryer Status Jan 05 2024j.lanete0806No ratings yet

- Service Data MontacargaDocument32 pagesService Data MontacargaVictor NunezNo ratings yet

- Service/Inspection Checklist and ReportDocument10 pagesService/Inspection Checklist and ReportSolidworks DesingNo ratings yet

- What Actions Will You Follow To Ensure That The Crank Case Oil of The Main Engine Is Always in Satisfactory Condition?Document16 pagesWhat Actions Will You Follow To Ensure That The Crank Case Oil of The Main Engine Is Always in Satisfactory Condition?arjun singhNo ratings yet

- PM 05-MinDocument1 pagePM 05-MinUsman HassanNo ratings yet

- BAN0007EN12 CS Tabriz 1Document5 pagesBAN0007EN12 CS Tabriz 1Manel MontesinosNo ratings yet

- Reactor Maintenance: Before Batch Daily Weekly Monthly 3 Month 6 Month Yearly Maintenance FrequencyDocument1 pageReactor Maintenance: Before Batch Daily Weekly Monthly 3 Month 6 Month Yearly Maintenance FrequencyUrvashiNo ratings yet

- Som 10.1 C Me Machinery PmsDocument2 pagesSom 10.1 C Me Machinery PmsAmit BhadauriaNo ratings yet

- MT55 - Service ScheduleDocument2 pagesMT55 - Service Schedulesernamu85No ratings yet

- Maintenance Schedules SBVM 628Document21 pagesMaintenance Schedules SBVM 628Amani Geepalem100% (2)

- HandlingManual TORAYDocument106 pagesHandlingManual TORAYthanhhuyenNo ratings yet

- Overhaul of PurifierDocument37 pagesOverhaul of PurifierSayem kaif100% (1)

- On-Board Machine FiltrationDocument4 pagesOn-Board Machine FiltrationCarlos LoboNo ratings yet

- Washer and Dryer Status Jan 06 2024Document4 pagesWasher and Dryer Status Jan 06 2024j.lanete0806No ratings yet

- Washing Machine: Installation, 2-3-4-5-6-7Document20 pagesWashing Machine: Installation, 2-3-4-5-6-7jbloggs2007No ratings yet

- Transformer: Power/TractionDocument9 pagesTransformer: Power/Tractionappy sagarNo ratings yet

- Gestion Mantenimiento Puente GruaDocument11 pagesGestion Mantenimiento Puente GruaBryan Esteban Casas ZapataNo ratings yet

- Ewe 81283Document60 pagesEwe 81283Jeovanne CabralNo ratings yet

- FMG 723Document36 pagesFMG 723mehdimehdimehdiNo ratings yet

- Iwc 6093Document60 pagesIwc 6093Remigild PeterNo ratings yet

- 0 - Introduction CCC Rev0Document16 pages0 - Introduction CCC Rev0Dev0009No ratings yet

- Beckman Coulter Immage - Maintenance LogbookDocument4 pagesBeckman Coulter Immage - Maintenance LogbookRastateNo ratings yet

- RENCANA KERJA Serious Inspeksi#3 Maret-April 2019Document2 pagesRENCANA KERJA Serious Inspeksi#3 Maret-April 2019Nur Ali SaidNo ratings yet

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging UnitDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenace Department Main Centrifuging Unitjp mishraNo ratings yet

- PAM Assignment 02 Final - Om.enDocument32 pagesPAM Assignment 02 Final - Om.enTesfaye ejetaNo ratings yet

- Job Application Letter1Document4 pagesJob Application Letter1Tesfaye ejetaNo ratings yet

- Job Application LetterDocument4 pagesJob Application LetterTesfaye ejetaNo ratings yet

- Strategic Management Chapter 5 A InternalDocument39 pagesStrategic Management Chapter 5 A InternalTesfaye ejetaNo ratings yet

- Strategic Management Chapter 4 External EnvironmentDocument32 pagesStrategic Management Chapter 4 External EnvironmentTesfaye ejetaNo ratings yet

- Strategic Management Chapter 5 B InternalDocument50 pagesStrategic Management Chapter 5 B InternalTesfaye ejetaNo ratings yet

- Department of MBA in Business Administration 1 Year 2 Semester Course Code:-MBA652 Assignment One (01) :-Business PlanDocument24 pagesDepartment of MBA in Business Administration 1 Year 2 Semester Course Code:-MBA652 Assignment One (01) :-Business PlanTesfaye ejetaNo ratings yet

- Lecture 3Document25 pagesLecture 3Tesfaye ejetaNo ratings yet

- Strategic Management Chapter 6 Strategic Analysis and ChoiceDocument40 pagesStrategic Management Chapter 6 Strategic Analysis and ChoiceTesfaye ejetaNo ratings yet

- Lecture 8Document37 pagesLecture 8Tesfaye ejetaNo ratings yet

- Lecture 2Document30 pagesLecture 2Tesfaye ejetaNo ratings yet

- Lecture 9Document26 pagesLecture 9Tesfaye ejetaNo ratings yet

- Strategic Management Chapter 3 FormulationDocument26 pagesStrategic Management Chapter 3 FormulationTesfaye ejetaNo ratings yet

- Lecture 10Document29 pagesLecture 10Tesfaye ejetaNo ratings yet

- Organizational Behavior Chapter-4: Personality and ValuesDocument15 pagesOrganizational Behavior Chapter-4: Personality and ValuesTesfaye ejetaNo ratings yet

- Financial Management Lecture 2Document27 pagesFinancial Management Lecture 2Tesfaye ejetaNo ratings yet

- OM Chapter 02 DR B DayalDocument44 pagesOM Chapter 02 DR B DayalTesfaye ejetaNo ratings yet

- Chapter 1 Over ViewDocument38 pagesChapter 1 Over ViewTesfaye ejetaNo ratings yet

- Department of MBA in Business Administration MIS Assignment 01Document9 pagesDepartment of MBA in Business Administration MIS Assignment 01Tesfaye ejetaNo ratings yet

- Financial Management Lecture 3 Valuation of SecuritiesDocument30 pagesFinancial Management Lecture 3 Valuation of SecuritiesTesfaye ejetaNo ratings yet

- Fiim s11 FinalDocument24 pagesFiim s11 FinalTesfaye ejetaNo ratings yet

- Department of MBA in Business Administration HRM Assignment 01Document20 pagesDepartment of MBA in Business Administration HRM Assignment 01Tesfaye ejetaNo ratings yet

- Burner ManualDocument28 pagesBurner ManualTesfaye ejetaNo ratings yet

- Department of MBA in Business Administration - HRM Assignment TwoDocument4 pagesDepartment of MBA in Business Administration - HRM Assignment TwoTesfaye ejetaNo ratings yet

- Lecture 12Document16 pagesLecture 12Tesfaye ejetaNo ratings yet

- Lecture 1Document23 pagesLecture 1Tesfaye ejetaNo ratings yet

- Organizational Behavior Chapter-6 Motivation Concepts: By:Berihun Muche (PHD)Document30 pagesOrganizational Behavior Chapter-6 Motivation Concepts: By:Berihun Muche (PHD)Tesfaye ejetaNo ratings yet

- SWOT Analysis For Dairy Farm PDFDocument2 pagesSWOT Analysis For Dairy Farm PDFTesfaye ejetaNo ratings yet

- BancassuranceDocument41 pagesBancassuranceanand_lamaniNo ratings yet

- Point of View Task CardsDocument7 pagesPoint of View Task Cardsapi-660227300No ratings yet

- LIC Product PositioningDocument15 pagesLIC Product PositioningRasika Pawar-HaldankarNo ratings yet

- Introduction and Instructions: ForewordDocument20 pagesIntroduction and Instructions: ForewordDanang WidoyokoNo ratings yet

- Reaching Different Learning Styles ThrouDocument29 pagesReaching Different Learning Styles ThrouKENNETH HERRERANo ratings yet

- Tarlac - San Antonio - Business Permit - NewDocument2 pagesTarlac - San Antonio - Business Permit - Newarjhay llave100% (1)

- Genesis and Development of The Network Arch Consept - NYDocument15 pagesGenesis and Development of The Network Arch Consept - NYVu Phi LongNo ratings yet

- Datasheet HFS60Document3 pagesDatasheet HFS60RajeswaranNo ratings yet

- Determination of Sales Force Size - 2Document2 pagesDetermination of Sales Force Size - 2Manish Kumar100% (3)

- Lesson For SpreadsheetsDocument69 pagesLesson For SpreadsheetsCrisna Rivera PundanoNo ratings yet

- Agenda 9Document46 pagesAgenda 9Bala Gangadhar TilakNo ratings yet

- BSC IT SyllabusDocument32 pagesBSC IT Syllabusஜூலியன் சத்தியதாசன்No ratings yet

- The 9 Best Reasons To Choose ZultysDocument13 pagesThe 9 Best Reasons To Choose ZultysGreg EickeNo ratings yet

- Navi Mumbai C.A. ListDocument48 pagesNavi Mumbai C.A. ListManish Shetty67% (9)

- UT Dallas Syllabus For cs4341.001.09s Taught by (Moldovan)Document4 pagesUT Dallas Syllabus For cs4341.001.09s Taught by (Moldovan)UT Dallas Provost's Technology GroupNo ratings yet

- Retail Marketing Course Work 11Document5 pagesRetail Marketing Course Work 11Ceacer Julio SsekatawaNo ratings yet

- (The Nineteenth Century Series) Grace Moore - Dickens and Empire - Discourses of Class, Race and Colonialism in The Works of Charles Dickens-Routledge (2004) PDFDocument223 pages(The Nineteenth Century Series) Grace Moore - Dickens and Empire - Discourses of Class, Race and Colonialism in The Works of Charles Dickens-Routledge (2004) PDFJesica LengaNo ratings yet

- Media ReportDocument46 pagesMedia ReportAndrew AB BurgoonNo ratings yet

- ShapiroDocument34 pagesShapiroTanuj ShekharNo ratings yet

- Man 3Document38 pagesMan 3Paylo KatolykNo ratings yet

- ABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Document18 pagesABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Zoren Jovillanos EmbatNo ratings yet

- Final Exam - Comprehensive - 10.24.16Document5 pagesFinal Exam - Comprehensive - 10.24.16YamateNo ratings yet

- Discovering Computers 2016: Operating SystemsDocument34 pagesDiscovering Computers 2016: Operating SystemsAnonymous gNHrb0sVYNo ratings yet

- Allergies To Cross-Reactive Plant Proteins: Takeshi YagamiDocument11 pagesAllergies To Cross-Reactive Plant Proteins: Takeshi YagamisoylahijadeunvampiroNo ratings yet

- Ultra Wideband TechnologyDocument21 pagesUltra Wideband TechnologyAzazelNo ratings yet

- Chapter 3 - A Top-Level View of Computer Function and InterconnectionDocument8 pagesChapter 3 - A Top-Level View of Computer Function and InterconnectionChu Quang HuyNo ratings yet

- Inv69116728 45926324Document1 pageInv69116728 45926324dany.cantaragiuNo ratings yet

- MTBE - Module - 3Document83 pagesMTBE - Module - 3ABHIJITH V SNo ratings yet