Professional Documents

Culture Documents

BR120 Ope M511E020C

Uploaded by

김진오Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BR120 Ope M511E020C

Uploaded by

김진오Copyright:

Available Formats

Manual No.

: M511-E020

Revision :C

X-RAY RADIOGRAPHY STAND

BR-120

OPERATION MANUAL

Read this manual carefully to ensure appropriate use,

and keep it with the unit.

About the symbols appearing in this operation manual

Throughout the text in this manual, warnings and other information essential when using this unit,

such as cautionary or prohibited items, appear classified as per the following:

Mark Description

States a direct danger that may cause death or serious injury if

it is not avoided.

States an indirect or potential danger that may cause death or

serious injury if it is not avoided.

States a danger that may cause slight or medium injury or

may cause damage in equipment or fire if it is not avoided.

States the information which helps to use the system

correctly.

Provides useful information about operation of this system.

Please read the description when required.

Indicates reference sections and pages.

Original version is approved in English.

BR-120 OPERATION MANUAL

0Preface

This operation manual must be carefully read prior to using the

"X-RAY RADIOGRAPHY STAND BR-120" (after referred to

as "device") and thoroughly followed for proper use.

This manual should be kept available for future reference.

Copyright

Shimadzu Corporation reserves the copyright of this manual

and the whole or a part of the contents may not be copied or

reproduced without the company's permission.

The contents of this manual may be changed for improvement

without notice.

© 2004-2006 Shimadzu Corporation. All rights reserved.

Preface

Operating Precautions

"Operating Precaution (for Both the Safety and the Prevention of

Danger) in the Use of Electric Medical Equipment"

1. Only an experienced technician should operate the equipment.

2. When installing the equipment, pay attention to the following items:

(1) Do not install it near water faucet or similar equipment.

(2) Install it away from potential sources of problems such as abnormal pressure, temperature or

humidity, drafts, direct sunlight, dust, chlorine or sulphur gas.

(3) During transportation and operation of the equipment, avoid tilting, vibration and sharp impact

against it.

(4) Keep the equipment away from the areas where chemicals or gases are stored.

(5) Use only the correct electrical power source with matching frequency, voltage and current (or

wattage).

(6) Check the conditions of the battery power source (power and polarity) before operating the

equipment.

(7) Properly ground the equipment.

3. Before operating the equipment, pay attention to the following items:

(1) Check the conditions of switch contacts, polarity, dial settings, and meters, and make sure the

equipment performs correctly.

(2) Confirm that the ground is connected properly.

(3) Check all wiring for proper and correct connections.

(4) Pay attention when using more than one unit at a time, because it may lead to an incorrect

diagnosis and cause danger.

(5) Check the condition of the external electric circuit, which will be directly connected to a patient.

(6) Check the condition of the battery power source.

Introduction-2 BR-120 Operation Manual

Preface

4. While operating the equipment, pay attention to the following items:

(1) Do not over-exceed time or the amount of equipment use needed for diagnosis or therapy.

(2) Observe the equipment and patient continuously for early detection of problems.

(3) When a problem is detected with the equipment or patient, take proper action to stop the

equipment without harming the patient.

(4) Do not let the equipment touch the patient.

5. After operating the equipment, pay attention to the following items:

(1) Turn off the switches and return the dial to their original before use in the prescribed order. Then,

turn off the main power switch.

(2) Do not pull the power cable forcibly from the outlet.

(3) When storing the equipment, pay attention to the following items:

(i) Keep it away from the water.

(ii) Store it away from the potential causes of problems such as abnormal pressure, temperature

and humidity, draft, direct sunlight, dust, chlorine or sulphur gas.

(iii) During transportation and storage of the equipment, avoid tilting, vibration and sharp impact

against it.

(iv) Store the equipment away from areas where chemicals and gases are stored.

(4) Clean all attachments, cables and contacts, and store them in one place.

(5) Keep the equipment clean to avoid problems during the next use.

6. When the equipment is found to be out of order, do not try to repair it.

Display an appropriate sign to indicate that the equipment is out of order, and

contact Shimadzu Service Representative for repair.

7. Do not modify any part of the equipment.

8. Preventive maintenance

(1) The equipment and its parts should be periodically checked.

(2) If the equipment has not been in operation for an extended period of time, test it prior to actual

operation to make sure it works correctly and safely.

9. Concerning other items, operate properly according to the operation manual.

BR-120 Operation Manual Introduction-3

Preface

For Assurance of Safety during Operation

The responsibility for management of use and maintenance of

medical equipment lies in a user.

This device is restricted to be used by, or on the order of, a diagnostic

radiology technician or a person with a certificate indicating equal proficiency.

Never remodel the equipment.

In general, almost all of the modifications are strictly prohibited by the legal

stipulation of the country where the equipment is installed. Please contact the

Shimadzu Service Representative if any modification is necessary.

Perform periodic maintenace.

Regular maintenance and inspections must be arranged to retain the full

performance of the device. See Chapter 4 Maintenance for procedures.

Maintenance and inspections inside the equipment must be

performed by the expert.

Maintenance must be assigned to specially trained experts. The service is

available under a contract with Shimadzu Corporation. Contact Shimadzu

Service Representative for repair and maintenance.

Introduction-4 BR-120 Operation Manual

Preface

Guarantee

The guarantee period of this system is once year from the date of purchase.

Our copany is not responsible for the following failures and damages.

1. Failure/damage caused by installation, movement, maintenance and

repair performed by anyone other than our company and companies

specified by our company.

2. Failure/damage in a products of our company caused by a product of

other company which is not delivered by our company.

3. Failure/damage based on maintenance, repair, etc. using a spare part

other than the genuine parts specified by our company.

4. Failure/damage based on a result caused by disobedience to the cautions

and operating procedures described in this operation manual.

5. Failure/damage caused by the ambient condition beyond the service

condition of this system such as the power supply and installation

requirements described in this operation manual.

6. Failure/damage caused by natural disaster such as fire, earthquake, flood

damage and thunderbolt.

The servicing after expiration of the guarantee period will be offered with charge.

Contact our Shimadzu Service Representative nearest to you.

BR-120 Operation Manual Introduction-5

Preface

Precaution in Use

When using this equipment, please observe the following precautions for the safety of

the operator and patient.

Considerations against exposure to X-rays

Improper use of the X-ray equipment might cause the operator or patient to be

accidentally exposed to X-ray radiation. During X-ray radiation, any person

other than the subject patient should not stay in the irradiation room. If

circumstances compel any non-subject person to stay in the room, enough

protection should be provided for that person. Only radio-therapeutic or other

qualified personnel should handle the equipment.

Precautions on mechanical safety

Take care not to catch hands of patients or operators between the Bucky

device and strut when moving the Bucky device.

Emergency Procedures

To stop the all movement of the equipment in an emergency, push the "STOP"

switch (Option). The power supply to the equipment is cut off. The "STOP"

switch (red switches) is located on the side of the main body.

Don’t splash this equipment with water because there is a risk of electric

shock.

This operation manual does not cover the X-ray high voltage generator, X-ray tube

support, and X-ray collimator.

Introduction-6 BR-120 Operation Manual

Preface

Notes for Users

Use the following cassette for the Bucky device. Other cassette can not be used.

cm or inch size cassette based on IEC standard 60406.

Attenuation equivalent is not greater than 1.6Vmm Al.

Less than 15mm thickness.

All parts of the cassette such as hinges, locks and marking device shall be

within the minimum radii for carners and edges.

Flatness shall be less than 1mm warp.

Action for Environment

Contact Shimadzu service representative when disposing the product or parts.

Materials in the system may be discarded and pollute the environment upon improper

disposal.

To all user of Shimadzu equipment in the European Union:

Equipment marked with this symbol indicates that it was sold on or after 13th August

2005, which means it should not be disposed of with general household waste. Note

that our equipment is for industrial/professional use only.

WEEE Mark

Contact Shimadzu service representative when the equipment has reached the

end of its life. They will advise you regarding the equipment take-back.

With your co-operation we are aiming to reduce contamination from waste electronic

and electrical equipment and preserve natural resource through re-use and recycling.

Do not hesitate to ask Shimadzu service representative, if you require further

information.

BR-120 Operation Manual Introduction-7

Preface

No Text

Introduction-8 BR-120 Operation Manual

Contents

Contents

Chapter 1 Outline

1.1 Applications .................................................................................. 2

1.2 Feature ......................................................................................... 3

Chapter 2 Configuration

2.1 Configuration ................................................................................ 6

Chapter 3 Operation

3.1 Prior to Operation ....................................................................... 10

3.1.1 X-ray High Voltage Generator................................................................ 10

3.2 Shut Down of Power................................................................... 11

3.3 Emergency Operation................................................................. 12

3.3.1 Emergency Stop..................................................................................... 12

3.3.2 Recovery from emergency stop ............................................................. 13

3.4 Radiography Stand - Vertical Movement of Bucky Device ......... 14

3.5 Operation of Cassette Tray ........................................................ 15

3.5.1 Names and functions of Cassette tray ................................................... 15

3.5.2 Installing a cassette................................................................................ 16

3.5.3 Removal of Cassette.............................................................................. 18

3.6 Hand Grip (Option) ..................................................................... 19

3.7 Cassette Holder (Option)............................................................ 22

3.8 Operation of Tracking Device (Option) ....................................... 23

3.8.1 Vertical Tracking with X-ray tube support CH-200 ................................. 23

3.9 Operation of Oppression belt (Option)........................................ 27

3.10 Operation of Handy Switch Unit (Option) ................................. 28

Chapter 4 Maintenance

4.1 Daily Inspection (Inspected by User).......................................... 30

4.1.1 Check Sheet for Daily Inspection ........................................................... 30

4.1.2 Fuse ....................................................................................................... 31

4.1.3 Cleaning and disinfection ....................................................................... 31

4.2 Periodical Inspection

(Inspection by Shimadzu Service Representative)..................... 32

4.3 Consumable Parts List ............................................................... 33

4.4 The Operating Life of the Device................................................ 34

BR-120 OPERATION MANUAL Contents-1

Contents

Chapter 5 Specifications

5.1 Specifications..............................................................................36

5.1.1 Classification of equipment .................................................................... 37

5.2 Environmental Condition.............................................................39

5.2.1 Conditions for Operation ........................................................................ 39

5.2.2 Transport and Storage ........................................................................... 39

5.2.3 EMC (Electro-Magnetic Compatibility) [For Europe] .............................. 40

5.3 Statement of Compliance [For Europe].......................................41

5.4 Product safety .............................................................................42

5.5 Symbols and Labels....................................................................43

5.5.1 Package for Transport............................................................................ 46

5.6 Reference axis of unit .................................................................47

5.7 List of Associated Equipment [For Europe].................................48

Appendix

Check List for Trouble ......................................................................52

Safety Check Registry .....................................................................53

Revision History ...............................................................................54

Dimension

BR-120 (503-06335) ........................................................................ 56

Contents-2 BR-120 OPERATION MANUAL

1

Outline

This chapter deals with the applications and features

of BR-120.

1 Outline

1.1 Applications

• The X-ray radiography stand BR-120 can be applied to X-ray radiography for chest

of patients usually in the standing attitude when combined with X-ray tube unit,

collimator unit, X-ray tube support and X-ray high voltage generator.

• BR-120 have a function as servo tracking radiography system when combined with

the X-ray tube support CH-200; X-ray tube support will follow the Bucky device

automatically.

2 BR-120 Operation Manual

1.2 Feature

1.2 Feature

1

• Detail positioning is easy to perform as the Bucky device can be moved smoothly.

• The shorter size underneath the Bucky device than past eases the chest

•

radiographic of the wheelchair patient.

Plentiful option items allow the X-ray radiographic efficiency to improve.

1

BR-120 Operation Manual 3

1 Outline

No Text

4 BR-120 Operation Manual

2

Configuration

This chapter describes the configuration of the

device.

2 Configuration

2.1 Configuration

The X-ray radiography stand BR-120 consists of the following components.

Fig. 2.1

J Standard Components

① Stand (1 set)

Stand holds the Bucky device using the counter weight balance method, and allows to

position the Bucky device in accordance with the body size of a patient.

② Bucky device (1 set)

Bucky device accommodates a film cassette, and has a built-in moving X-ray grid

which removes scattered X-ray.

③ Brake release button

Bucky device can be moved manually by pressing button to release the brake lock.

J Optional Components (offered separately upon order)

④ Hand grip

Hand grip supports the attitude of a patient.

"3.6 Hand Grip (Option)" P19

6 BR-120 Operation Manual

2.1 Configuration

⑤ Cassette holder

Cassette holder is attached on Bucky device and holds a film cassette and grid plate.

Cassette holder is used to general radiography with film cassette not Bucky device. 2

"3.7 Cassette Holder (Option)" P22

⑥ Base plate 2

Base plate is installed when BR-120 cannot be mounted in the standard holes.

⑦ Front radiography handle

Front radiography handle supports the attitude of a patient.

2

⑧ Servo tracking device

By servo tracking device, the following functions are attached with CH-200 combined: 2

• X-ray tube unit focus of X-ray tube support tracks automatically the center on

height of Bucky device.

• Collimator for radiography radiation field operates automatically.

2

⑨ Oppression belt (not shown)

Oppression belt fixes the radiography area of a patient on the Bucky device.

"3.9 Operation of Oppression belt (Option)" P27

6

⑩ Handy switch unit

The collimator is controlled by handy switch unit. 2

"3.10 Operation of Handy Switch Unit (Option)" P28

BR-120 Operation Manual 7

2 Configuration

No Text

8 BR-120 Operation Manual

3

Operation

This chapter describes how to operate the device

and optional equipment.

3 Operation

3.1 Prior to Operation

3.1.1 X-ray High Voltage Generator

Before operating the radiography stand BR-120, perform the following procedure.

1 Set to ON ( ) the power switch "LINE" provided on the X-ray high

voltage generator combined with the BR-120, then press power ON

button.

When shutting down the power once and turning it on again, wait for 10 sec or

more after shutting down the power.

2 Select the technique key provided on the X-ray high voltage

generator to " ".

3 Set the radiography condition in accordance with the operation

manual of the X-ray high voltage generator.

Follow the operation manual for the X-ray high voltage generator provided.

10 BR-120 Operation Manual

3.2 Shut Down of Power

3.2 Shut Down of Power

To shut down the power, press the power OFF button provided on the X-ray high

voltage generator combined.

Follow the operation manual for the X-ray high voltage generator provided. 3

3

Wait at least 10 seconds or more between turning off the power and

turning it on again. Wait 10 seconds or more before turning the power on 3

after pressing the stop switch and releasing it. Otherwise, the unit may

malfunction.

BR-120 Operation Manual 11

3 Operation

3.3 Emergency Operation

3.3.1 Emergency Stop

In case that the servo tracking device (Optional) is provided with the unit, the stop

switch is installed on the switch panel. When an emergency has occured in which the

vertical movement of the X-ray tube support CH-200 cannot be stopped due to failure

in switches, etc., press the stop switch provided on the control panel of BR-120 or

press the power OFF button provided on the X-ray high voltage generator. The vertical

movement will be stopped.

J Message of Emergency Stop

When operated the emergency stop procedure, the screen on X-ray tube support CH-

200 as shown below is displayed.

Stop button is pressed. Please wait!

Do not turn the stop switch to operate until the following message is displayed.

In case that the stop switch is operated, the error in unit may occur.

After 10 seconds, the screen as shown below is displayed. When this message is

displayed, release procedure can be operated.

Stop button is pressed. Release OK!

12 BR-120 Operation Manual

3.3 Emergency Operation

3.3.2 Recovery from emergency stop

To recover the BR-120 from the emergency stop status, turn the stop switch

clockwise after displayed the screen above-mentioned.

Make sure that the unit does not move abnormally when the stop switch

is turned clockwise to recover from the emergency stop. lf the unit

3

moves abnormally again, stop the unit immediately using the emergency

stop procedure.

BR-120 Operation Manual 13

3 Operation

3.4 Radiography Stand - Vertical

Movement of Bucky Device

1 Press the ( )brake release button on the rear side of Bucky.

The brake is released while the button is pressed. the position of brake release

button is varied from the insatallation condition.

2 Move the the Bucky device up and down by hand after released

brake.

Pressing the brake release button, the brake is released, the Bucky can be

moved up and down manually.

Brake Release Button

Fig. 3.1

When moving the Bucky device up and down, confirm always safety of

the patient.

When moving the Bucky device up and down, pay attention so that the

Bucky device does not come into contact with adjacent equipment.

Do not hang on the Bucky device applying a weight of more than 20 kgf.

The Bucky device goes down suddenly, attitude of the patient deteriorates.

14 BR-120 Operation Manual

3.5 Operation of Cassette Tray

3.5 Operation of Cassette Tray

Cassettes of up to 35 cm × 43 cm (14" × 17") is available for cassette radiography.

3

3.5.1 Names and functions of Cassette tray

3

1

2

6

3

4 3

Fig. 3.2

3

Name Function

1. Cassette tray Stores a cassette in the system.

2. Clamp Fixes a cassette. 3

3. Clamp handle Used to fix or remove a cassette.

4. Shelf Supports a cassette

BR-120 Operation Manual 15

3 Operation

3.5.2 Installing a cassette

1 Lift up the clamphandle of casstte tray in the direction of arrow.

2 Draw out the clamp in the direction of arrow.

Clamp Handle Clamp

Fig. 3.3

3 Fix the shelf at the position in accordance with the casstte size.

4 Lay a casstte on the shelf correctly.

Cassette

Shelf

Fig. 3.4

16 BR-120 Operation Manual

3.5 Operation of Cassette Tray

5 Align the center mark with the center notch.

6 Push the clamp handle forward until the cassette touches the

backside of the bracket.

7 Press the clamp handle down after the cassette is secured.

3

Cassette

Notch 6

3

Center Mark

3

Fig. 3.5

3

Use the following cassette for the Bucky device.

Other cassette can not be used.

• cm or inch size cassette based on IEC standard 60406.

• Attenuation equivalent is not greater than 1.6Vmm Al.

• Less than 15mm thickness.

• All parts of the cassette such as hinges, locks and marking device shall be within

the minimum radii for carners and edges.

• Flatness shall be less than 1mm warp.

BR-120 Operation Manual 17

3 Operation

3.5.3 Removal of Cassette

1 Draw out the cassette tray.

2 Lift the clamp handle to release locking and slide back.

The clamp is released.

3 Draw the clamp and remove the cassette.

4 Remove the cassette tray when finishing cassette radiography.

Cassette

Clamp handle Cassette tray

Fig. 3.6

18 BR-120 Operation Manual

3.6 Hand Grip (Option)

3.6 Hand Grip (Option)

The hand grip is used to keep the patient in radiographic of patient body side.

Fig. 3.7 3

3

The hand grip is used to hold patient position.

Do not hang on the hand grip applying a weight of more than 20 kgf.

The Bucky device goes down suddenly, attitude of the patient

3

deteriorates.

Be careful for patient’s head etc. not to collide with hand grip.

BR-120 Operation Manual 19

3 Operation

J Positioning of the hand grip

1 Insert the prism of hand grip into either square holes at upper both

sides of Bucky device.

The angle of handle is changeable by 90 degree in accordance with inserting

angle.

Hand grip

Clamp handle

Bucky device

Fig. 3.8

2 Pull the hand grip revolver in the direction of arrow to release the

lock, and then change the tilt angle.It is possible to rotate the handle

by pulling.

Hand grip revolver

Fig. 3.9

Confirm that the handle is fixed, prior to instruct the position of patients.

20 BR-120 Operation Manual

3.6 Hand Grip (Option)

The vertical movement of Bucky device may be unbalanced when the

hand grip is not attached. (When operating the Bucky device, it is upward

light and, downward, becomes heavy.

3

BR-120 Operation Manual 21

3 Operation

3.7 Cassette Holder (Option)

1 Hook the cassette holder to the fixing bar, and then fix the lower

portion by magnet.

2 Clamp the cassette with the cassette clamp, and then fix the holder

with turning knob.

Fixing

Bar

Cassette Clamp

Magnet Bucky

Device

Bracket

Knob

Grid

Magnet

Cassette Holder

Bucky Cassette

Device

Cassette

Holder

Magnet

Magnet Bracket

Fig. 3.10

When the cassette holder is mounted on the Bucky device, operation is a little

heavily for vertical movement.

22 BR-120 Operation Manual

3.8 Operation of Tracking Device (Option)

3.8 Operation of Tracking Device

(Option)

3

3.8.1 Vertical Tracking with X-ray tube support CH-200

J Operation of X-ray high voltage generator 3

1 Press the radiography program

key on the touch panel to select

the vertical Bucky radiography. 3

Confirm that the technique key indicates

the vertical Bucky radiography.

3

J Operation of X-ray tube unit

1 Press the detent mode button on 6

operation panel to turn detent

mode ON.

3

3

2 Move the X-ray tube support and then stop it to the preset

longitudinal/transversal position.

Longitudinal directional position is predefined radiography distance, and

3

transversal is the center of Bucky device. Face the X-ray tube of X-ray tube

support toward the X-ray radiography stand.

BR-120 Operation Manual 23

3 Operation

J Operation of X-ray radiography stand

Confirm no patient is positioned where the X-ray tube support declines.

Touching X-ray tube support may cause injury.

Two kinds of tracking operation with X-ray tube support are as follows:

For setting of full-automatic tracking operation or semi-automatic one, make a choice

between the two on installation. Consult Shimadzu service representative for setting the

function.

Full-automatic operation

• Moving upward/downward the Bucky device of X-ray radiography stand

manually, the X-ray tube support tracks with X-ray radiography stand.

Semi-automatic operation

• Pressing both tracking switches of X-ray radiography stand and X-ray tube

support, the X-ray tube support tracks with X-ray radiography stand.

• During tracking operation, press either tracking switch of X-ray tube support

or X-ray radiography stand, so that the tracking operation will be stopped.

• If there is a possibility that the X-ray tube support contacts the X-ray

radiography stand, it once stops and continuous beep sounds

(Approx. 5 seconds).

If the tracking switch is pressed again, while the X-ray tube support will

sound beep, it descends at a low speed, and continues to descend until the

tracking switch is released. So, position the X-ray tube unit in contact with

X-ray radiography stand with care.

• It is not a malfunction that the X-ray tube support once goes beyond too far

and returns to the predetermined position for alignment.

24 BR-120 Operation Manual

3.8 Operation of Tracking Device (Option)

J For Oblique Projection Radiography

After tracking the X-ray tube support and X-ray radiography stand, operate the

following procedures for oblique projection radiography.

1 Adjusting the height of X-ray tube unit, tilt the unit with rotating a little

3

for upper or lower direction.

6

When the rotation angle is shifted over 4

Automatic

degree from axis, or the height of X-ray

tube unit is shifted the center of Bucky 3

device, the [Automatic] is displayed.

3

When not aligned the axis of X-ray tube unit with the center of Bucky device,

[Automatic]* is displayed on touch panel. When [Automatic]* is displayed, the

operator must have responsibility in carrying out exposure field adjustment and

performing X-ray radiography.

* For the specification of the products to the United States, [Manual], instead of

[Automatic], is displayed in the setting.

2 Press the collimator lamp button to light the collimator lamp up.

3 Lighting the collimator lamp, adjust the exposure field.

The collimator lamp lights for 30 seconds.

BR-120 Operation Manual 25

3 Operation

J Operation of X-ray high voltage generator (Radiography)

1 Set the X-ray radiography

conditions of X-ray high voltage

generator.

2 Hold down the radiography

preparation button.

3 When the radiography button or

radiography ready indicator lights,

Radiography Radiography

press the radiography button on Preparation Button

the operation panel while holding Button

down the radiography preparation

button.

• Radiography operation starts.

• The radiography button and the radiography indicator on the operation panel

light during radiography.

• The radiography is completed when the radiography indicator on the operation

panel lights off.

4 Release the radiography button.

In case that the tracking operation is not completed, [Automatic] is

displayed on touch panel. When [Automatic] is displayed, the operator

must have responsibility in carrying out exposure field adjustment and

performing X-ray radiography.

26 BR-120 Operation Manual

3.9 Operation of Oppression belt (Option)

3.9 Operation of Oppression belt

(Option)

1 Align the one end (Velcro tape) of oppression belt with Velcro tape 3

on back surface of Bucky device and then stick them firmly.

2 Tighten the oppression belt to contact the patient with Bucky device.

3 After tightening the belt, align the other end (Velcro tape) of 3

oppression belt with other Velcro tape on back surface of Bucky

device and then stick them firmly.

4 Remove the both ends of oppression belt from Bucky device after

3

use, and the keep it in the specified location.

3

Oppression belt

6

3

Velcro Tape Bucky device

Velcro Tape 3

BR-120 Operation Manual 27

3 Operation

3.10 Operation of Handy Switch Unit

(Option)

This handy switch unit is able to be operated leaf open/close of collimator and

illumination of lamp when combining with the ceiling tube support CH-200.

① Leaf open switch

Handy switch unit

Leaf open switch allows the throttle to be open.

② Leaf close switch

① Leaf close switch allows the leaf to throttle.

② ③ Leaf open switch

Leaf close switch allows the leaf to throttle.

③ ④ Leaf close switch

Leaf open switch allows the throttled leaf to be

④ open.

⑤ ⑤ Collimator lamp switch

Pressing the collimator lamp switch, the

collimator lamp will light up the collimator lamp.

The collimator leaf open/close operation is possible when the collimator key

switch of X-ray tube unit is in automatic mode ( ).

The leaves of collimator are designed to throttle collimation within the range

taking the cassette film size as the upper limit.

Automatic mode

Manual mode

Collimator

X-ray tube unit CH-200

28 BR-120 Operation Manual

4

Maintenance

This chapter describes points for daily and periodic

inspections as well as consumable parts.

4 Maintenance

4.1 Daily Inspection (Inspected by User)

Inspect the following items before operating the device, and if any abnormal points are

observed, please contact Shimadzu Service Representative:

4.1.1 Check Sheet for Daily Inspection

Date of inspection:

Inspected by:

1 Check the following points visually and perform the appropriate

procedure in case of any problems.

Verification Points Prizedure

□ Are all unnecessary objects removed from the vicinity of

Remove

the device?

□ Are the cables free of pinches, twists and scrapes? Fix the cables

Contact Shimadzu

□ Any breakage (dents, fractures, etc.) on the cover? Service

Representative

2 Check the following points by hand and perform the appropriate

procedure in case of any problems.

Verification Points Procedure

□ Any large shaking at overall structure?

□ Cassette tray is put in/out smoothly? Contact Shimadzu

Service

□ Cassette is fixed? Representative

□ Any jerk or creak while rotating of hand grip?

3 Turn ON the power supply and check the following points. Perform

the appropriate procedure in case of any problems.

Verification Points Procedure

□ Does the unit make any noise when moving ?

Contact

□ Does the interlock switch operate correctly? Shimadzu

Service

□ The brake can be released at up/down movement of Representative

Bucky device

30 BR-120 Operation Manual

4.1 Daily Inspection (Inspected by User)

4.1.2 Fuse

4

When the brake does not work well even when the power is ON, check the fuse on the

downside of column.

For replacement, the following fuse or the equivalent should be used. 4

• Fuse 313001 (072-01664-20) Rated 250V 1A (slow blow)

Prior replacing the fuse, "LINE" switch on the X-ray high voltage

4

generator should be turned OFF to shut off the power.

6

4.1.3 Cleaning and disinfection

4

Clean the hand grips using a clean cloth and alcohol or disinfectants.

4

Do not splash or spray any disinfectant onto the system.

Any disinfectants that leak into unit may cause failure or trouble with the

system.

4

BR-120 Operation Manual 31

4 Maintenance

4.2 Periodical Inspection

(Inspection by Shimadzu Service

Representative)

Even without any problem in daily inspection, the following items should be inspected

periodically in every 6 months by Shimadzu Service Representative or other

certificated persons.

Table 4.1 Periodical inspection (Inspection performed by Shimadzu Service Representative)

Item Inspection points

Loosening of bolts Bolts fixing and roller of each part

・Is the wire rope severed?

・Is the wire rope scratched or snagged?

・Is the wire pulley scratched?

Wire rope ・Are there any scratches or obstructions around the rail in the

wheels?

Remove

・Apply an aerosol oil (RO-300 or equivalent) to the wire ropes on

the

periodical inspection.

cover

and Power supply Is input/Output voltage appropriate?

check

Pulley, shaft,

Wear, deformation, breakage, looseness, dropping

pins, screws, etc.

Bearing Wear, rust oil shortage

Magnet Are there any damage or dirt on the magnet surface?

32 BR-120 Operation Manual

4.3 Consumable Parts List

4.3 Consumable Parts List

4

The consumable parts used for this device are as follows:

When exchanging the parts, use the regular parts with following part number:

4

Table 4.2 Consumable parts list

4

Required

Name Part number

quantity

Consumable Fuse, 313001

072-01664-20 1

parts (250VAC, 1A, SLOWBLOW)

4

If any damages are found on wire ropes at inspection, replace it immediately.

Contact Shimadzu Service Representative for replacement.

BR-120 Operation Manual 33

4 Maintenance

4.4 The Operating Life of the Device

This device's operating life of the device is approximately 10 years (on average).

An overhaul is necessary to use the device beyond its operating life in order to ensure

the safety.

Please contact Shimadzu Service Representative before the device exceeds its

operating life.

Do not use this device past its operating life without an overhaul.

34 BR-120 Operation Manual

5

Specifications

This chapter describes specifications.

5 Specifications

5.1 Specifications

Item Description

Construction

①

① Bucky Device

② Stand h

Bucky device BF-11VP

Distance between

Bucky device guathal h = 627 - 2147 mm

hub and floor surface

By manual.

Operation Electromagnetic lock provided is released while power is

supplied.

Distance between

Bucky device guathal 247 mm

hub and film upper end

Distance between

Bucky device front 40 mm

face and film

cm 18 × 24, 24 × 24, 24 × 30, 35 × 35, 35 × 43

Application film

inch 8 × 10, 9.5 × 9.5, 10 × 12, 11 × 14, 14 × 14, 14 × 17

size

Film can be located in either vertical or horizontal direction.

Cassette fixing size Center reference

Except

North America

North America

Grid ratio R = 12 : 1 R = 10 : 1

X-ray grid Grid density N = 40 Lines/cm N = 40 Lines/cm

(It functions as a

moving grid within Focusing

Fo = 170 cm Fo = 150 cm

irradiation field.) *1 distance

Intermediate

AL AL

material

Dimensions 479 mm × 438 mm 479 mm × 438 mm

Tray which can be QJC or QJS (POERSCH Metal Manufacturing Co.)

combined Size sensing tray

36 BR-120 Operation Manual

5.1 Specifications

Item Description

Installation conditions

5

Outer dimension Refer to 503-06335

Required space Approx. 650 mm (L) × 400 mm (D)

Required ceiling height 2350 mm or more 5

Mass Approx. 120 kg

Single phase, 100V, 0.1kVA, 50/60Hz

Power Supply

(Supplied from X-ray high voltage generator)

5

*1 When radiography is performed without an object for time (40msec or less), lead stripes shadow

may appear.

Note: Contents of the specifications are subjected to change for further improvement without notice. 5

J Dose Information

Attenuation by Items in the X-ray Beam

5

Measurement conditions:

• X-ray tube voltage: 100 kV

•

•

X-ray tube current: 1.8 mA

X-ray beam: Half value layer is 3.7 mmAl

6

• Front panel: 0.63 mmAleq.

5

5.1.1 Classification of equipment

J The class of protection against electric shock 5

Class I equipment

5

It means that CLASS I EQUIPMENT, that is, equipment in which protection

against electric shock does not rely on BASIC INSULATION only, but which

includes an additional safety precaution in that means are provided for the

connection of the equipment to the protective earth conductor in the fixed wiring

of the installation in such a way that accessible metal parts can not become live

in the event of a failure of the basic insulation. (International standard

IEC60601-1 Second edition 1988).

BR-120 Operation Manual 37

5 Specifications

J The degree of protection against electric shock

Type B equipment

It means TYPE B EQUIPMENT, that is, equipment providing a particular degree

of protection against electric shock, particularly regarding:

- allowable leakage current;

- reliability of the protective earth connection.

(International standard IEC60601-1 Second edition 1988).

J The degree of protection against harmful ingress of water

Ordinary equipment

The main body of this unit is not protected against immersion of liquid.

Never use this unit in a place in which immersion of liquid may occur.

Never spill liquid on the surface or in the inside of this unit. Otherwise,

electrical shock may occur. When liquid is split, contact our office or

representative described on the back cover of the operation manual.

J The degree of safety of application in the presence of a

flammable anesthetic mixture with air or with oxygen or nitrous

oxide

Equipment not suitable for use in the presence of a flammable anesthetic mixture with

air or with oxygen or nitrous oxide

Risk of explosion if used in the presence of flammable anesthetics.

J The mode of operation

Continuous operation with intermittent loading

38 BR-120 Operation Manual

5.2 Environmental Condition

5.2 Environmental Condition

5

5.2.1 Conditions for Operation

5

Use the BR-120 in the following condition so that it can offer its full performance.

J Radiography condition 5

• Temperature : +10 to +40°C

• Humidity : 30 to 85%

• Atmospheric pressure : 700 to 1060hPa

5

J Power supply

• Single-phase, 100V, 0.1kVA, 50/60Hz

5

J Grounding

• Grounding to the ground resistance of less than 100Ωwith annealed copper wire of

1.6mm diameter for grounding wire. 6

5

Do not expose the device to drastic temperature or humidity fluctuations

even under the above mentioned conditions.

Such a rapid ambient fluctuation causes the occurrence of condensation

resulting in damages rust and corrosion in the device.

5

Also, condensation within the device may cause rust and corrosion.

Under a low temperatures, frosts may damage the internal circuit.

5

5.2.2 Transport and Storage

The environmental conditions for transport and storage are described as below.

Item Condition

Ambient temperature -10°C to 60°C

Ambient humidity 10 to 95 %

Atmospheric pressure 700 to 1060hPa

BR-120 Operation Manual 39

5 Specifications

Rust and corrosion may be generated caused by dew inside this unit.

The internal circuits may be damaged by frozen dew caused by low

temperature. Pay rigid attention when this unit is stored in a place with

drastic difference in temperature and humidity such as warehouse.

5.2.3 EMC (Electro-Magnetic Compatibility) [For Europe]

• This system belongs to Group 1 and Class A equipment in accordance to

EN60601-1-2:1993.

• The system uses radio-frequency energy only for its internal function and is not

intended to deliver enrgy to patient. But little leakage radio-frequency energy

does harm to high-sensitive equipment.

• The system main power line in the clinical site should be connected to the

domestic power sources which are separated from the public main network.

40 BR-120 Operation Manual

5.3 Statement of Compliance [For Europe]

5.3 Statement of Compliance

5

[For Europe]

This unit conforms the following international standards.

5

J 93/42/EEC

• EN60601-1: 1990 + A1: 1993 + A2: 1995 +A13: 1996

• IEC60601-1: 1988 + A1: 1991 + A2: 1995 5

• EN60601-1-1: 2001

• IEC60601-1-1: 2000

•

•

EN60601-1-2: 1993

IEC60601-1-2: 1993

5

• EN55011: 1998 (group1, class A)

• IEC801-2: 1991/EN61000-4-2: 1995 (contact: level 3, air: level 3)

• IEC801-3: 1984 with reference to EN61800-3: 1996/A11: 2000

Clause 5.3.3.2

5

• IEC801-4: 1988/EN61000-4-4: 1995 (power lines: level 3, signal lines:

level 3)

• IEC1000-4-5: 1995/EN61000-4-5: 1995 (power lines: class 3) 6

• EN61000-4-6: 1996 (power lines: level 2, signal lines: level 2)

• EN61000-4-8: 1993 (level 2)

• EN60601-1-3: 1994

• IEC60601-1-3: 1994 5

• EN60601-2-32: 1994

• IEC601-2-32: 1994

BR-120 Operation Manual 41

5 Specifications

5.4 Product safety

Do not operate this unit if there is any uncertainty as to the proper

functioning of the system. refer all servicing to qualified service

personnel.

This instrument must grounded! To minimize the shock hazard, make

sure of performing the ground work according to Installation Manual

(M511-E319).

The operator must set the focal spot to skin distance as large as possible

in order to keep the absorbed does to the patient as low as reasonably

achievable.

42 BR-120 Operation Manual

5.5 Symbols and Labels

5.5 Symbols and Labels

5

J Symbols

Symbols used on this system are shown and described as follows.

5

Symbol Location Meaning

In name plate Alternating current

5

Inside the device, where

protective earth conductor Protective earth ground 5

in power cord is connected

In name plate Safety classification: Type B 5

On warning and caution

labels

Attention:

Refer to Operation Manual

6

5

J Labels

Locations where labels are attached are shown as follows.

Fig. 5.1

BR-120 Operation Manual 43

5 Specifications

① Name Plate A (Name Plate of BR-120)

② Certification Label A (for UL)

③ Warning Label, Fuse

④ Caution Label

⑤ CE Label (for CE)

44 BR-120 Operation Manual

5.5 Symbols and Labels

⑥ EU Representative Label (for CE)

5

⑦ Label EMC

5

⑧ Label TÜV USA (for UL) 5

5

⑨ TÜV GM Label (for CE)

⑩ WEEE Mark Label (for CE)

BR-120 Operation Manual 45

5 Specifications

5.5.1 Package for Transport

Label that is described about storage environment and transport environment on

package for transport is shown.

保管環境 温 度:-10 - 60°C

相対湿度:10 - 95%

気 圧:700 - 1060hPa

輸送環境 温 度:-10 - 60°C

相対湿度:10 - 95%

気 圧:700 - 1060hPa

Storage Environment Temperature : -10 - 60°C

Relative Humidity : 10 - 95%

Atmospheric Pressure : 700 - 1060hPa

Transport Environment Temperature : -10 - 60°C

Relative Humidity : 10 - 95%

Atmospheric Pressure : 700 - 1060hPa

46 BR-120 Operation Manual

5.6 Reference axis of unit

5.6 Reference axis of unit

5

The reference axis which employed in normal operation of X-ray radiography stand

means the incident X-ray axis from X-ray tube unit to Bucky device (Film) vertically as

shown below.

At this point, 90° as X-ray axis angle is displayed on the touch panel of X-ray tube 5

support CH-200, and the angle indication varies in proportion as the angle which the X-

ray tube unit is tilted.

When the vertical Bucky radiography technique is selected on the X-ray high voltage

generator, the same indication is displayed on the touch panel of X-ray tube support 5

CH-200 correspondingly.

5

Vertical Bucky radiography technique

5

6

X-ray axis

BR-120 Operation Manual 47

5 Specifications

5.7 List of Associated Equipment

[For Europe]

X-ray High Voltage

Equipment

BR-120 CH-200 Generator

Model

UD150B-40 /L-40

Manufacturer Shimadzu Shimadzu Shimadzu

Single phase :

Single phase : • AC200V, 1kVA, 50/ Three-phases :

Supply mains • AC100V, 0.1kVA, 50/ 60Hz • AC400V, 80kVA, 50/

60Hz • AC100V, 0.2kVA, 50/ 60Hz

60Hz

Classification Class I, Type B equipment

Mode of Continuous operation with

operation Intermittent loading

• Ambient temperature : • Ambient temperature :

+10 to 40 ℃ +5 to 35 ℃

Condition of • Relative humidity : • Relative humidity :

use 30 to 85% 45 to 85%

• Atmospheric pressure : • Atmospheric pressure :

700 to 1060hPa 700 to 1060hPa

Storage environment

• Temperature :

-10 to 60 ℃

• Relative humidity :

10 to 95%

• Atmospheric pressure :

Protective 700 to 1060hPa

packing Transport environment

• Temperature :

-10 to 60 ℃

• Relative humidity :

10 to 95%

• Atmospheric pressure :

700 to 1060hPa

• Hand Grip • Servo tomo option • Photo timer option

• Compression belt • Servo tracking option

• Cassette holder

Option

• Front radiography

handle

• Interlocking device

48 BR-120 Operation Manual

5.7 List of Associated Equipment [For Europe]

Equipment

Model

X-ray Collimator R-30H 0.6/1.2P324DK-120PF BK-200 5

Manufacturer Shimadzu Shimadzu Shimadzu

Supply mains

Single phase :

• AC12V, 0.1kVA, 50/

• Power is supplied from

X-ray high voltage

Single phase :

• AC200V, 1kVA, 50/

5

60Hz generator

60Hz

• DC12V, 6VA

Classification

Mode of

Class I, Type B equipment

Continuous operation with

5

operation Intermittent loading

• Ambient temperature :

+10 to 40 ℃ 5

Condition of • Relative humidity :

use 30 to 85%

• Atmospheric pressure :

700 to 1060hPa 5

Storage environment

• Temperature :

-10 to 60 ℃

• Relative humidity : 6

10 to 95%

• Atmospheric pressure :

Protective 700 to 1060hPa

packing Transport environment 5

• Temperature :

-10 to 60 ℃

• Relative humidity :

•

10 to 95%

Atmospheric pressure :

5

700 to 1060hPa

• Hand grip

• Grip switch 5

Option None None • Servo tomo option

• Compression band

• Cassette holder

BR-120 Operation Manual 49

5 Specifications

No Text

50 BR-120 Operation Manual

Appendix

Check List for Trouble

Fill following blanks and contact the SHIMADZU Service Representative.

Hospital :

Phone :

FAX :

Serial Number:

Date of Installation:

Item Check

□ Someone injured

□ When is the trouble occurred?

□ Is there a sign of the trouble?

□ Is there a power failure or thunderbolt when the

trouble is occurred?

□ The device has been watered?

□ The device has been given an impact upon?

□ The number of patients a day with the device?

□ When is the last periodic inspection?

52 BR-120 Operation Manual

Safety Check Registry

6

□ Name

□ Phone

6

□ Extension number

Hospital

□ FAX

□ Address

6

□ Room number

Device

□ Name

6

□ Serial number

□ Date of installation

□ Affiliation 6

Instructor □ Phone

□ FAX

6

This device's

maintenance and Instructor

Date Description

operation staff 6

Signature Signature

• At the time of installation or when changing the designated operator, the

SHIMADZU Service Representative will explain this manual's safety description

of this device's maintenance to operation staff and record the new information.

• This manual is important. We request all maintenance personnel to keep it in a

safe place close to the device.

BR-120 Operation Manual 53

Revision History

This manual's revision history is shown in the table below.

Revision Date Changes

First revision Sep. 2004 First edition released

Application film size revised in

A Nov. 2004

"5.1 Specifications"

"3.8 Operation of Tracking Device (Option)"

B Apr. 2006 revised

"5.5 Symbols and Labels" revised

Warning is revised that [Manual], instead of

[Automatic] is displaying for the specification

C Sep. 2006 of the products to the United States in item

"For Oblique Projection Radiography" on

3.8.1 heading

54 BR-120 Operation Manual

Dimension

BR-120 (503-06335)

56 BR-120 Operation Manual

7

BR-120 Operation Manual 57

No Text

58 BR-120 Operation Manual

You might also like

- Basic Operation SectionDocument364 pagesBasic Operation SectionAndrei DumitruNo ratings yet

- Ecoray hf-525 Plus Service Manual PDFDocument105 pagesEcoray hf-525 Plus Service Manual PDFandrea lizeth martinez camacho100% (6)

- Service Manual Uf-450axDocument163 pagesService Manual Uf-450axHành chính Quản trị75% (8)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Surgical Mobile C-Arm Imaging System OPESCOPE ACTENO Operation enDocument268 pagesSurgical Mobile C-Arm Imaging System OPESCOPE ACTENO Operation enTuchilo Viorel100% (4)

- BS-800 Operation Manual PDFDocument685 pagesBS-800 Operation Manual PDFVladimir Borja50% (4)

- Diagnostic Ultrasound System: Instruction ManualDocument78 pagesDiagnostic Ultrasound System: Instruction ManualJoseph War100% (2)

- PX-300HF Operation Manual (111018)Document57 pagesPX-300HF Operation Manual (111018)Daniel Valderrama100% (1)

- HF-525Plus Service Manual (Rev. 2.2 Latest) 16 11 2011 PDFDocument142 pagesHF-525Plus Service Manual (Rev. 2.2 Latest) 16 11 2011 PDFFélix Nicolau100% (1)

- Operation Manual M503E027ADocument216 pagesOperation Manual M503E027ALuis Alberto Díaz Olmedo50% (2)

- Drtech EVS 4343 / EVS 4343G: Safety and Regulatory Information With User's ManualDocument108 pagesDrtech EVS 4343 / EVS 4343G: Safety and Regulatory Information With User's Manualqazxsw100% (1)

- Diagnostic Ultrasound System: Instruction ManualDocument158 pagesDiagnostic Ultrasound System: Instruction ManualJoseph War100% (1)

- Humaroll: - User ManualDocument20 pagesHumaroll: - User ManualMaherNo ratings yet

- Instruction Manual8 XT777Document27 pagesInstruction Manual8 XT777paputo27No ratings yet

- PX-300HF Service Manual (111018)Document85 pagesPX-300HF Service Manual (111018)Julian Vargas100% (3)

- GCSE AstronomyDocument30 pagesGCSE Astronomyharris123mc100% (1)

- MUX100H Ope M503E020HDocument138 pagesMUX100H Ope M503E020HBilal ghebaNo ratings yet

- Shimadzu MUX-100D Operation ManualDocument154 pagesShimadzu MUX-100D Operation ManualевгенийNo ratings yet

- Operation Manual X-Ray Tube Assembly 0.7/1.3U163C-36Document40 pagesOperation Manual X-Ray Tube Assembly 0.7/1.3U163C-36Aknouch AbdelmoujibNo ratings yet

- Operation Manual X-Ray Tube Assembly 0.7/1.3U163C-36Document40 pagesOperation Manual X-Ray Tube Assembly 0.7/1.3U163C-36fernandNo ratings yet

- M517-E102 (DAR-7500 DR Console OperationManual)Document208 pagesM517-E102 (DAR-7500 DR Console OperationManual)김진오No ratings yet

- SurdialDocument334 pagesSurdialngocbienk56No ratings yet

- M516-E011l Wha-200 Pleno Om PDFDocument218 pagesM516-E011l Wha-200 Pleno Om PDFbozza85No ratings yet

- UD150L-40E Ope M501-E053GDocument164 pagesUD150L-40E Ope M501-E053GMahmoud Mady100% (3)

- HF525 Plus Operation ManualDocument52 pagesHF525 Plus Operation ManualRashid Kh100% (2)

- 1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)Document207 pages1.HF-525Plus VET (32kW, 400ma, 230Vor110V, XR5)fortroniNo ratings yet

- ELMO-T3 Operation - E - 55Document34 pagesELMO-T3 Operation - E - 55nguyen minhNo ratings yet

- Analizador Químico BA-88ADocument105 pagesAnalizador Químico BA-88AMiguel FigueroaNo ratings yet

- Nihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Document144 pagesNihon Kohden TEC-5600 Defibrillator - Service Manual - Compressed-1-144Francisco BaezNo ratings yet

- TEC5600 Service Manual PDFDocument303 pagesTEC5600 Service Manual PDFwamala benjaminNo ratings yet

- HF-525Plus Service Manual (Rev. 2.2 Latest)Document149 pagesHF-525Plus Service Manual (Rev. 2.2 Latest)Franklyn Acevedo100% (1)

- 04-V1 (Q3E BW1316) - ECLOS Safety Instruction ManualDocument14 pages04-V1 (Q3E BW1316) - ECLOS Safety Instruction ManualJosé Manuel Valdez RevillaNo ratings yet

- TDI Analysis SectionDocument60 pagesTDI Analysis SectionAndrei DumitruNo ratings yet

- DS-22 - Operation Manual - E - 36Document19 pagesDS-22 - Operation Manual - E - 36houdaNo ratings yet

- Measurements 1 PDFDocument164 pagesMeasurements 1 PDFgiangNo ratings yet

- Model Hfs-4 Hydride Formation System: Instruction ManualDocument67 pagesModel Hfs-4 Hydride Formation System: Instruction ManualPrianurraufikachmadNo ratings yet

- Shear Wave Measurement SectionDocument22 pagesShear Wave Measurement SectionAndrei Dumitru100% (1)

- Um547490 SM Temp User Manual 2022Document22 pagesUm547490 SM Temp User Manual 2022Yu MaNo ratings yet

- Operator's Manual: BS-200 Chemistry AnalyzerDocument297 pagesOperator's Manual: BS-200 Chemistry AnalyzerBivaria GrupNo ratings yet

- BA-88A - Operation Manual - V4.0 - ENDocument107 pagesBA-88A - Operation Manual - V4.0 - ENelias martinez100% (2)

- HP TWIN8 User Manual 5-2014 V6Document28 pagesHP TWIN8 User Manual 5-2014 V6romeo baveraNo ratings yet

- Ud150 Operation ManualDocument168 pagesUd150 Operation ManualRadiology GTDMCNo ratings yet

- Lx8000 SeriesDocument100 pagesLx8000 Seriesmap50No ratings yet

- CHI SectionDocument112 pagesCHI SectionAndrei DumitruNo ratings yet

- User Manual 2555737Document116 pagesUser Manual 2555737Cristian Dante CastroNo ratings yet

- PM 9000 Express Service Manual 3 2 PDFDocument109 pagesPM 9000 Express Service Manual 3 2 PDFBetancur AlejandroNo ratings yet

- Solid-State Interstitial Liquid Sensor For Fiberglass Tanks: Installation GuideDocument9 pagesSolid-State Interstitial Liquid Sensor For Fiberglass Tanks: Installation GuideShalvaTavdgiridzeNo ratings yet

- F31-How To Use-1 PDFDocument366 pagesF31-How To Use-1 PDFJoseph WarNo ratings yet

- 【E】HANABI-SA5000 UsersManual 2 4Document21 pages【E】HANABI-SA5000 UsersManual 2 4ass.biotecNo ratings yet

- ADR1500 Manual EngDocument152 pagesADR1500 Manual Engshd btbNo ratings yet

- Manual aDR 1500Document154 pagesManual aDR 1500Marcelo AraujoNo ratings yet

- Manuale Di Istruzioni Instruction ManualDocument24 pagesManuale Di Istruzioni Instruction ManualJulia Montelin PowersNo ratings yet

- F31 Measurement 2 PDFDocument348 pagesF31 Measurement 2 PDFJoseph WarNo ratings yet

- Diagnostic Ultrasound System: Instruction ManualDocument144 pagesDiagnostic Ultrasound System: Instruction ManualJoseph WarNo ratings yet

- 2010 - 05 - 2912 - 22 - 06BS-400 Operation Manual (v12.0)Document413 pages2010 - 05 - 2912 - 22 - 06BS-400 Operation Manual (v12.0)RemNo ratings yet

- F37-How To Use-1Document372 pagesF37-How To Use-1Sukrisdianto DiantoNo ratings yet

- HP TWIN8 User Manual 1-2015 V8 PDFDocument28 pagesHP TWIN8 User Manual 1-2015 V8 PDFBruno SouzaNo ratings yet

- ALPHA7-How To Use-1Document386 pagesALPHA7-How To Use-1José Luis MontoyaNo ratings yet

- Fluorospectrometer RF-20A:20Axs Prominence User ManualDocument352 pagesFluorospectrometer RF-20A:20Axs Prominence User ManualChristos Georgiou100% (1)

- The Construction Safety Guide: Injury and Illness Prevention through DesignFrom EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignRating: 4 out of 5 stars4/5 (6)

- X Ray22Document1 pageX Ray22김진오No ratings yet

- X Ray6Document2 pagesX Ray6김진오No ratings yet

- X Ray21Document1 pageX Ray21김진오No ratings yet

- X Ray23Document2 pagesX Ray23김진오No ratings yet

- X Ray11Document1 pageX Ray11김진오No ratings yet

- X Ray4Document1 pageX Ray4김진오No ratings yet

- Ultrasound 10Document2 pagesUltrasound 10김진오No ratings yet

- Ultrasound 21Document4 pagesUltrasound 21김진오No ratings yet

- Ultrasound 5Document3 pagesUltrasound 5김진오No ratings yet

- Ultrasound 6Document1 pageUltrasound 6김진오No ratings yet

- M517-4021 (FPD17-R1 Parts List)Document16 pagesM517-4021 (FPD17-R1 Parts List)김진오No ratings yet

- S517-E066 (DAR-7500 - DRConsole Specification)Document23 pagesS517-E066 (DAR-7500 - DRConsole Specification)김진오No ratings yet

- M517-E101A (DAR7500 DR Console OperationGuide)Document44 pagesM517-E101A (DAR7500 DR Console OperationGuide)김진오No ratings yet

- FPD17 Instal M517E483EDocument101 pagesFPD17 Instal M517E483E김진오No ratings yet

- M517-E102 (DAR-7500 DR Console OperationManual)Document208 pagesM517-E102 (DAR-7500 DR Console OperationManual)김진오No ratings yet

- M517-E126 (DAR-7500 DR Console Tiling QA Function)Document16 pagesM517-E126 (DAR-7500 DR Console Tiling QA Function)김진오No ratings yet

- Global RF 회로도 (B type) - 01Document4 pagesGlobal RF 회로도 (B type) - 01김진오No ratings yet

- Global RF 회로도 (B type) - 02Document4 pagesGlobal RF 회로도 (B type) - 02김진오No ratings yet

- Someone Who Believes in YouDocument1 pageSomeone Who Believes in YouMANOLO C. LUCENECIONo ratings yet

- Release From Destructive Covenants - D. K. OlukoyaDocument178 pagesRelease From Destructive Covenants - D. K. OlukoyaJemima Manzo100% (1)

- Biology Accel Syllabus 2011-2012Document3 pagesBiology Accel Syllabus 2011-2012Mike DeleonNo ratings yet

- Biophoton RevolutionDocument3 pagesBiophoton RevolutionVyavasayaha Anita BusicNo ratings yet

- Paediatric Intake Form Modern OT 2018Document6 pagesPaediatric Intake Form Modern OT 2018SefNo ratings yet

- De Vault 1996Document22 pagesDe Vault 1996Harumi OONo ratings yet

- Unit 3Document12 pagesUnit 3Erik PurnandoNo ratings yet

- HCPL 316J 000eDocument34 pagesHCPL 316J 000eElyes MbarekNo ratings yet

- 12/1/2014 Powder MetallurgyDocument29 pages12/1/2014 Powder Metallurgysofyan sam0% (2)

- DOC-20161226-WA0009 DiagramaDocument61 pagesDOC-20161226-WA0009 DiagramaPedroNo ratings yet

- Halfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PDocument92 pagesHalfen Cast-In Channels: HTA-CE 50/30P HTA-CE 40/22PTulusNo ratings yet

- 1970 - Transformer FMEA PDFDocument7 pages1970 - Transformer FMEA PDFSing Yew Lam0% (1)

- PEH Q3 Long QuizDocument1 pagePEH Q3 Long QuizBenedict LumagueNo ratings yet

- SCM (Subway Project Report)Document13 pagesSCM (Subway Project Report)Beast aNo ratings yet

- JC Series Jaw Crusher PDFDocument8 pagesJC Series Jaw Crusher PDFgarrybieber100% (1)

- 41z S4hana2021 Set-Up en XXDocument46 pages41z S4hana2021 Set-Up en XXHussain MulthazimNo ratings yet

- Cecilia-Puff-Tee-Final-OUSM-Designs-12 MESES A TALLA 8Document19 pagesCecilia-Puff-Tee-Final-OUSM-Designs-12 MESES A TALLA 8Jose SanchezNo ratings yet

- Oil Whirl and Whip Instabilities - Within Journal BearingsDocument27 pagesOil Whirl and Whip Instabilities - Within Journal BearingsTalha AamirNo ratings yet

- 5G Transport Slice Control in End-To-End 5G NetworksDocument19 pages5G Transport Slice Control in End-To-End 5G NetworksmorganNo ratings yet

- Keiilf: Training ManualDocument53 pagesKeiilf: Training ManualGary GouveiaNo ratings yet

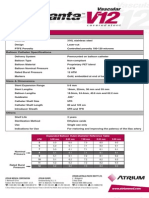

- Advanta V12 Data SheetDocument2 pagesAdvanta V12 Data SheetJuliana MiyagiNo ratings yet

- Standard Cost EstimateDocument21 pagesStandard Cost EstimateMOORTHYNo ratings yet

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Document31 pagesHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcNo ratings yet

- TreesDocument69 pagesTreesADITYA GEHLAWATNo ratings yet

- ZF-FreedomLine TransmissionDocument21 pagesZF-FreedomLine TransmissionHerbert M. Zayco100% (1)

- JKJKJDocument3 pagesJKJKJjosecarlosvjNo ratings yet

- Save Water SpeechDocument4 pagesSave Water SpeechHari Prakash Shukla0% (1)

- Safe Lorry Loader Crane OperationsDocument4 pagesSafe Lorry Loader Crane Operationsjdmultimodal sdn bhdNo ratings yet

- Proefschrift T. Steenstra - tcm24-268767Document181 pagesProefschrift T. Steenstra - tcm24-268767SLAMET PAMBUDINo ratings yet