Professional Documents

Culture Documents

SHWW

Uploaded by

dgm0 ratings0% found this document useful (0 votes)

3 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageSHWW

Uploaded by

dgmCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

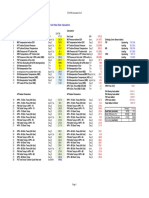

Steam Required for SHWW System

Sr.no. Description Equipment Qty Unit Total

1 Crushing Rate TPH 180

2 "A" massccuite % Cane % 27

3 SHWW Qty 5% on Massccuite % 5

4 Total Massccuite qty TPH 48.6

5 SHWW Qty TPH 2.43

6 Water inlet temp. deg 80

7 SHWW Temp deg 120

8 Heating media( Exhaust) deg 125

9 Heating media latent heat at 125 deg Kcal/kg 522.5

10 Take 100% extra SHWW qty TPH 4.86

11 Steam req.for SHWW System TPH 0.418564593

12 Batch type machine (1750kg/hr+1250kg/hr+1250kg/hr) kg/hr 4250

13 No.of Cycles no. 20

14 SHWW req.for batch machine kg/hr 2065.5

15 Take 50% extra for recirculation kg/hr 3098.25

TPH 3.09825

16 Total steam required per day TPD 74.358

17 Steam to fuel ratio 2

18 Total baggasse required TPD 63.099

19 Steam to power ratio Tons/MW 6.6

20 Total power generation MW 11.26636364

Steam required to reduce sugar moisture for

21 Hot Air blower TPH 2.16

22 Total steam required per day TPD 126.198

After Installing Electric SHWW system

21 Steam consumption per kw kg 8

Total steam consumption for heating water

22 upto 120 deg kg/hr 258.1875

23 Power Consumption per day KWH 6196.5

24 Total power saving MW 5.069863636

25 Total extra revenue per day Rs. 22865.085

You might also like

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDocument9 pagesDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminNo ratings yet

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNo ratings yet

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- Feasibility Study For Indonesia LNG Gas PlantDocument18 pagesFeasibility Study For Indonesia LNG Gas PlantMocha Setia100% (1)

- ResumeDocument3 pagesResumeAstig Kuging63% (8)

- Fuel, Steam & Power Balance - Jengka 21 03Document24 pagesFuel, Steam & Power Balance - Jengka 21 03khairuddinNo ratings yet

- TSD CogenDocument5 pagesTSD CogenGaurav SushrutNo ratings yet

- Progressive Muscle Relaxation ExerciseDocument2 pagesProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- Multi V Water IV Outside Unit Service Manual Exploded View Model Arwb Las4Document33 pagesMulti V Water IV Outside Unit Service Manual Exploded View Model Arwb Las4Jose CuevasNo ratings yet

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDocument6 pagesGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDurga PrasadNo ratings yet

- Exhaust and Jacket Water Heat Recovery From GeneratorDocument8 pagesExhaust and Jacket Water Heat Recovery From GeneratorMuhammad Abdul Samad50% (2)

- Cost Calculation TCG 2020 V16K With CNGDocument2 pagesCost Calculation TCG 2020 V16K With CNGR_afflyNo ratings yet

- ERC Refinery Project: 1. Process Unit Purpose 2. Unit Description & Capacity 3. Overall Block Diagram 4. Unit SchematicsDocument16 pagesERC Refinery Project: 1. Process Unit Purpose 2. Unit Description & Capacity 3. Overall Block Diagram 4. Unit SchematicsRamakrishnan AmbiSubbiahNo ratings yet

- 6FA CC UnitDocument10 pages6FA CC UnittonytrujilloNo ratings yet

- Savings From Surface Condenser Usage Instead of Venting The SteamDocument9 pagesSavings From Surface Condenser Usage Instead of Venting The SteamManoj BNo ratings yet

- Effect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyDocument2 pagesEffect of Primary Reformer Steam To Carbon Ratio On Ammonia Plant EfficiencyManish GautamNo ratings yet

- SHWWDocument2 pagesSHWWdgmNo ratings yet

- 03.report CCPP Luwuk 150 MWDocument2 pages03.report CCPP Luwuk 150 MWgancanNo ratings yet

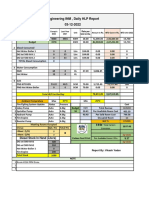

- Daily HLP Report 01 Dec 2022Document1 pageDaily HLP Report 01 Dec 2022Vicky YadavNo ratings yet

- Payback Sheet For 110 KW BPTDocument2 pagesPayback Sheet For 110 KW BPTMohammed Sultan SalahuddinNo ratings yet

- Daily HLP 02 Report Dec 2022Document1 pageDaily HLP 02 Report Dec 2022Vicky YadavNo ratings yet

- GTCGR & Boiler Efficiciency During Trial Opn Tanda U#5Document1 pageGTCGR & Boiler Efficiciency During Trial Opn Tanda U#5om prakash pathakNo ratings yet

- Example - Coal Fire Power PlantDocument17 pagesExample - Coal Fire Power PlantChristian DelfinNo ratings yet

- Hot Oil System FinalDocument6 pagesHot Oil System FinalbharatmorwaniNo ratings yet

- CoergyDocument32 pagesCoergyNguyen Thanh TrungNo ratings yet

- Energy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsDocument2 pagesEnergy Consumption Breakdown of An Industrial Plant Is Given Below: Measured Data For Existing Chiller SystemsMeriem NguirNo ratings yet

- Chapter 15 - Section A - Mathcad Solutions: 1 M 1 M (Table F.3)Document25 pagesChapter 15 - Section A - Mathcad Solutions: 1 M 1 M (Table F.3)Khalid M MohammedNo ratings yet

- Daily HLP Report 03 Dec 2022Document1 pageDaily HLP Report 03 Dec 2022Vicky YadavNo ratings yet

- 2 CognDocument3 pages2 CognnhjuiNo ratings yet

- The Blanks With Your Answers in The Items Below: 1. Equipment and TS Diagram of The CycleDocument1 pageThe Blanks With Your Answers in The Items Below: 1. Equipment and TS Diagram of The Cyclealvin domantayNo ratings yet

- FGC Heat DutyDocument11 pagesFGC Heat Dutypraso84No ratings yet

- Turbine InterlocksDocument36 pagesTurbine Interlocksdurga praveenNo ratings yet

- Up The Blanks With Your Answers in The Items Below: 1. Equipment and TS Diagram of The CycleDocument5 pagesUp The Blanks With Your Answers in The Items Below: 1. Equipment and TS Diagram of The CycleAlex QuirimitNo ratings yet

- PILLARD - Aktuell - YCC - MR - BoseDocument19 pagesPILLARD - Aktuell - YCC - MR - BosePradeep KumawatNo ratings yet

- CDI - Concept NoteDocument34 pagesCDI - Concept NoteRitche Lim BragaisNo ratings yet

- Comparision Between ACC and WCCDocument2 pagesComparision Between ACC and WCCdeepdaman18891No ratings yet

- Detailing For ATFE Installation For Xylene Distillation QPDocument27 pagesDetailing For ATFE Installation For Xylene Distillation QPPrathmesh GujaratiNo ratings yet

- Diesel Engine D 2842 LE21x Technical Data PreliminaryDocument3 pagesDiesel Engine D 2842 LE21x Technical Data PreliminaryAung MhNo ratings yet

- Up The Blanks With Your Answers in The Items Below: 1. Equipment and TS Diagram of The CycleDocument3 pagesUp The Blanks With Your Answers in The Items Below: 1. Equipment and TS Diagram of The Cyclejames absaludNo ratings yet

- Cost Solar BlendDocument3 pagesCost Solar BlendDaNi ThataNo ratings yet

- PUSH 400CTL K38热平衡表Document1 pagePUSH 400CTL K38热平衡表周庆卓No ratings yet

- Presentasi BFPT Dhimas A.D.H (Variation Inlet Steam Temperature To BFPT Performance)Document24 pagesPresentasi BFPT Dhimas A.D.H (Variation Inlet Steam Temperature To BFPT Performance)Dicky harsonoNo ratings yet

- Coal Fired Boiler OptionDocument1 pageCoal Fired Boiler OptionMukund PhapaleNo ratings yet

- Case I PDFDocument1 pageCase I PDFvinod kumarNo ratings yet

- Aleyna Ceyhan, İpek Erdinç, Nijat Tarverdiyev, Elif Toprak, İlayda Nur GüzelDocument2 pagesAleyna Ceyhan, İpek Erdinç, Nijat Tarverdiyev, Elif Toprak, İlayda Nur Güzelilayda güzelNo ratings yet

- 3412C 725 Ekw/ 906 kVA/ 60 HZ/ 1800 RPM/ 480 V/ 0.8 Power FactorDocument3 pages3412C 725 Ekw/ 906 kVA/ 60 HZ/ 1800 RPM/ 480 V/ 0.8 Power FactorMed ZidiNo ratings yet

- Data Sheet C250D6 PDFDocument3 pagesData Sheet C250D6 PDFEddo Rafael Carrion ValerioNo ratings yet

- Data Sheet C250D6 PDFDocument3 pagesData Sheet C250D6 PDFEddo Rafael Carrion ValerioNo ratings yet

- Energy and Economic SummaryDocument1 pageEnergy and Economic SummaryKrishna PATELNo ratings yet

- Daily Power - 15-07-2023Document11 pagesDaily Power - 15-07-2023Aryabhatt ThakurNo ratings yet

- Presentation For Sugar Mill Energy ReportDocument17 pagesPresentation For Sugar Mill Energy ReportTrinathBanikNo ratings yet

- N67 MNT F40 - Data SheetDocument4 pagesN67 MNT F40 - Data SheetMihai CatalinNo ratings yet

- OPERATIONAL COST COMPARISON 450RT Centrifugal and Steam Fired ChillerDocument1 pageOPERATIONAL COST COMPARISON 450RT Centrifugal and Steam Fired Chillerwindgust82No ratings yet

- Comparative Domestic Heating Cost Per Useful KWH: Prices Collected: 16 March 2018Document11 pagesComparative Domestic Heating Cost Per Useful KWH: Prices Collected: 16 March 2018Nos GoteNo ratings yet

- List of FiguresDocument11 pagesList of FiguresShamsMohdNo ratings yet

- Cummins C275D5 - Datasheet 250kva 275kvaDocument3 pagesCummins C275D5 - Datasheet 250kva 275kvalam101185No ratings yet

- MPOCGT-01-MB-PD-M1200 A HEAT AND MASS BALANCE DIAGRAM (1) RemovedDocument2 pagesMPOCGT-01-MB-PD-M1200 A HEAT AND MASS BALANCE DIAGRAM (1) RemovedTheekshana MalalasekaraNo ratings yet

- TS J420 E900 at BMEP 12bar, Pure H2Document12 pagesTS J420 E900 at BMEP 12bar, Pure H2d_macuraNo ratings yet

- Cost Control of Unit Generation by Improvement of Gross Heat Rate in Coal Based Thermal Power PlantDocument15 pagesCost Control of Unit Generation by Improvement of Gross Heat Rate in Coal Based Thermal Power PlantRitesh MokhadeNo ratings yet

- Diesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- Regular Paper 3 - Set A: Section - Iii: Long Descriptive Questions Marks: 6 X 10 60Document32 pagesRegular Paper 3 - Set A: Section - Iii: Long Descriptive Questions Marks: 6 X 10 60YogaAnandNo ratings yet

- 0.5 MLD PlantDocument1 page0.5 MLD PlantvinodNo ratings yet

- V94.2 Beggenum Experience & Improve Concept For Syngas Application PDFDocument24 pagesV94.2 Beggenum Experience & Improve Concept For Syngas Application PDFEliyanto E BudiartoNo ratings yet

- Wet ScrubberDocument2 pagesWet ScrubberdgmNo ratings yet

- Steam CostingDocument5 pagesSteam CostingdgmNo ratings yet

- Final PRDSDocument7 pagesFinal PRDSdgmNo ratings yet

- Steam Required To Batch MachineDocument5 pagesSteam Required To Batch MachinedgmNo ratings yet

- Mill VFD PanelDocument16 pagesMill VFD PaneldgmNo ratings yet

- Carrier Calculation For ReferenceDocument1 pageCarrier Calculation For ReferencedgmNo ratings yet

- Practicewith Argument Athletesas ActivistsDocument30 pagesPracticewith Argument Athletesas ActivistsRob BrantNo ratings yet

- NiftDocument3 pagesNiftMegha Nair PillaiNo ratings yet

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxNo ratings yet

- 4 PDFDocument81 pages4 PDFMohammad K. NassouraNo ratings yet

- Auto CadDocument67 pagesAuto CadkltowerNo ratings yet

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiNo ratings yet

- Matsusada DC-DC ConvertersDocument4 pagesMatsusada DC-DC ConvertersAP SinghNo ratings yet

- T54125ADocument64 pagesT54125ARaúl FroddenNo ratings yet

- Design of Footing R1Document8 pagesDesign of Footing R1URVESHKUMAR PATELNo ratings yet

- 3DD5036 Horizontal.2Document6 pages3DD5036 Horizontal.2routerya50% (2)

- TR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance DataDocument2 pagesTR60 RIGID ENG. 6/13/03 10:38 AM Page 1: Performance Databayu enasoraNo ratings yet

- 448 Authors of Different Chemistry BooksDocument17 pages448 Authors of Different Chemistry BooksAhmad MNo ratings yet

- Mobility StrategyDocument38 pagesMobility StrategySoubhagya PNo ratings yet

- Permanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Document2 pagesPermanent Magnet Motor Surface Drive System: Maximize Safety and Energy Efficiency of Progressing Cavity Pumps (PCPS)Carla Ayelen Chorolque BorgesNo ratings yet

- 74 Series Logic ICsDocument6 pages74 Series Logic ICsanon-466841No ratings yet

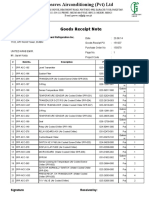

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNo ratings yet

- Reviewer in PE&H 1st Quarter 18-19Document7 pagesReviewer in PE&H 1st Quarter 18-19rhex minasNo ratings yet

- Dredge Yard Gate Valve BrochureDocument5 pagesDredge Yard Gate Valve BrochureFederico BabichNo ratings yet

- Harriet Tubman Lesson PlanDocument7 pagesHarriet Tubman Lesson PlanuarkgradstudentNo ratings yet

- HCH - 15 04 004Document5 pagesHCH - 15 04 004NarvaxisNo ratings yet

- SoundsDocument61 pagesSoundsJemabel RosarioNo ratings yet

- Emcee Script For Recognition DayDocument3 pagesEmcee Script For Recognition DayRomeo Jr. LaguardiaNo ratings yet

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugNo ratings yet

- Moc3040 MotorolaDocument3 pagesMoc3040 MotorolaBryanTipánNo ratings yet

- 22 Thành NG Quen Thu C Trên Ielts - FirefighterDocument2 pages22 Thành NG Quen Thu C Trên Ielts - FirefighterNinh NguyễnNo ratings yet