Professional Documents

Culture Documents

Hot Work Permit

Uploaded by

Musadiq HussainCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Work Permit

Uploaded by

Musadiq HussainCopyright:

Available Formats

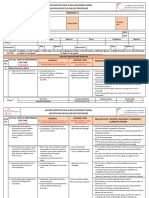

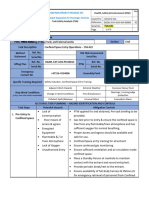

ETIHAD RAIL – 2F1

Hot Work Permit

THIS PERMIT IS FOR HOT WORK TASKS NOT UNDERTAKEN INSIDE A CLASSIFIED CONFINED SPACE.

CONFINED SPACE PERMIT IS TO BE USED FOR THIS PURPOSE – NOT TRANSFERABLE

To Date: Permit Number:

Valid from Date: Project Area/Zone:

To Time:

SECTION A – REQUESTED BY - TO BE COMPLETED BY PERMIT USER

Permit User Name: Foreman/Supervisor Company: Signature

SECTION B – TO BE COMPLETED BY PERMIT USER

Fabrication Modification Gas Cutting MMA Welding

Repair Electric Grinding/cutting Maintenance Others (State): __________________________________

Work Area and Location:

Provide Specific Details:

SECTION C – SAFETY PRECAUTIONS REQUIRED FOR THE WORK (X – Mandatory) – TO BE COMPLETED BY PERMIT PERFORMER

X Toolbox Talk X Fire watch (60 mins) X Fire Extinguisher X Flashback Arrestor (if using bottles)

X No combustibles Fire Hose Fire Blanket X Risk Assessment/JSEA Safety Meeting

Restricted access Forced Ventilation Installing Barriers Mechanical Lock-Out Electrical Lock Out

Grounding/Bonding Additional Lighting Spark Screen Others (State): ________________________________________

SECTION D – PERSONAL PROTECTIVE EQUIPMENT (X – Mandatory) – TO BE COMPLETED BY PERMIT PERFORMER

X Hard hat X Safety Boots X Coveralls X Eye Protection Safety Harness

Lifeline Face shield X Leather Apron Breathing Apparatus Ear Protection

Dust Mask Gloves Others: (State)_______________________________________________________________

SECTION E – TASK EQUIPMENT AND TOOLS – TO BE COMPLETED BY PERMIT PERFORMER

Scaffolds Ladders Grinding Equipment Welding Equipment Flame Cutting Equipment

Mobile/ Fixed Crane Lifting equipment Compressed Air Tools Hand Tools Drilling Equipment

HDPE Fusion Welding equipment Others (State): ________________________________

SECTION H –

SECTION G – APPROVAL BY PERMIT COORDINATOR

AUTHORIZATION OF PERMIT BY CONSTRUCTION/TASK MANAGER

The permit coordinator, have reviewed this permit and supporting doc’s and The approving authority, have inspected the work area and hereby confirm it is

confirm that they are in compliance with the permit procedure. safe to perform this task under the conditions of this permit

Name:

Name: Date: Date:

(Subcon)

Signature: Signature:

Hot Work Performer Name:

Name

Date:

(2F1JV)

Signature

Fire Watcher Name:

Signature:

Signature:

SECTION I –– TO BE COMPLETED BY PERFORMER

The performing authority, accept the conditions stipulated in this permit and confirm that all control measures and isolations are in place.

Name:

Designation: Date:

(Subcon)

Name

Designation: Date:

(2F1JV)

SECTION J – THE WORK IS COMPLETE THE WORK IS INCOMPLETE AND LEFT IN THE FOLLOWING CONDITION (STATE REASON)

Performing Authority: I declare that the work for which this permit was issued has been properly performed, and that the area has been left in Safe clean condition

Name: _____________________________ Signature: __________________________ Date: __________________________ Time: _______________________

Approving Authority: I have been inspected the area and declare that the work for which this permit was issued has been properly performed, and that the area has been left in Safe clean

condition

Name: _____________________________ Signature: __________________________ Date: __________________________ Time: _______________________

PTW COORDINATOR: I declare that this permit to work has been closed out as per permit to work procedure and been logged in to the permit to work register under the

document control group.

Name: _____________________________ Signature: __________________________ Date: __________________________ Time: _______________________

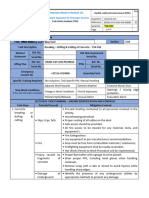

Hot Work Permit | Page 2 of 2

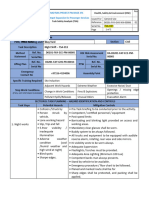

HOTWORK PERMIT CHECKLIST

Sl.

Description YES NO NA

No.

1

The area immediately below the work spot has been cleared

from all combustible materials.

2

All flammable materials/ chemicals cleared from the hot work

area

3

Firefighting equipment and water are available at hot work

area.

4

Tin sheet / fire blanket is available to prevent sparks from

spreading.

5

Welding area screening done to prevent UV rays

6

Flash back arrester installed to the gas cylinder.

7

Gas cylinder and fittings are free from cracks, grease, etc.

8

Gas cylinders are kept upright and secured.

9

Arc welding machine is in good condition.

10

Welding cables are in good condition.

11

Stand-by fire watcher (Must be well trained on types and usage

of FEs)

12

H&S Risk Assessment, Environmental aspect/ impact & Control

measure are in place

13

Operators are in possession of the appropriate PPE specified

for the job.

14

Cutting/ grinding machine discs fitted with guards.

15

Power tools monthly inspection done, and colour coded

16

Power tools accessories available in good condition (i.e., disc

fitting key, extension cords with industrial sockets

17

Others if any:

Time of inspection Inspected by Comments observed & Action taken Signature

You might also like

- Understanding Named, Automatic and Additional Insureds in the CGL PolicyFrom EverandUnderstanding Named, Automatic and Additional Insureds in the CGL PolicyNo ratings yet

- Form 33 Electrical Isolation Testing PermitDocument1 pageForm 33 Electrical Isolation Testing PermitRoshan ZameerNo ratings yet

- Hotworks PermitDocument1 pageHotworks PermitGlorieNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitManesh MNo ratings yet

- Safety DocumentsDocument42 pagesSafety Documentsdan sealzaNo ratings yet

- Form 0004: Confined Space Permit: Section - I Details of The Permit Issuer & ReciverDocument1 pageForm 0004: Confined Space Permit: Section - I Details of The Permit Issuer & Reciverasem sawalmehNo ratings yet

- Ptw-Kec - Final v3 - SparkDocument1 pagePtw-Kec - Final v3 - SparkXiang JintaoNo ratings yet

- Permit To Work FormDocument4 pagesPermit To Work FormMohammed Shams TabrezNo ratings yet

- WP-HSE-010 (Bored Pile)Document1 pageWP-HSE-010 (Bored Pile)Armando AballeNo ratings yet

- SHELL Retail Permit To Work System - 5 1 - FormsDocument4 pagesSHELL Retail Permit To Work System - 5 1 - FormsAlberto Sánchez Armenta80% (5)

- Rin - Imaging Speak ThroughDocument1 pageRin - Imaging Speak ThroughnazriNo ratings yet

- Agreement by Permit Holder: I Understand and Agree That No Work Is Permitted Accept That Shown On The Permit. IDocument1 pageAgreement by Permit Holder: I Understand and Agree That No Work Is Permitted Accept That Shown On The Permit. ISameer YadavNo ratings yet

- IV. Non-Conformance Report FormDocument15 pagesIV. Non-Conformance Report FormAnduel SelamajNo ratings yet

- De-Shuttering PermitDocument1 pageDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- PTW - AG&P Delivery and Laydown (Weekly)Document1 pagePTW - AG&P Delivery and Laydown (Weekly)Caleb del MundoNo ratings yet

- GC Working at Heights FormDocument1 pageGC Working at Heights Formsafetyjulz14No ratings yet

- Rin - Audio Intercom For Icu Hdu CcuDocument1 pageRin - Audio Intercom For Icu Hdu CcunazriNo ratings yet

- PTW - AG&P Piping Works (Weekly)Document2 pagesPTW - AG&P Piping Works (Weekly)Caleb del MundoNo ratings yet

- 3rd Floor Building FDocument8 pages3rd Floor Building FJePongNo ratings yet

- Excavation PermitDocument1 pageExcavation PermitEl Saleh newcapitalNo ratings yet

- Cold Work Permit: Smg1 Flowline ProjectDocument2 pagesCold Work Permit: Smg1 Flowline Projectghazi kallelNo ratings yet

- IDI-FRM-HSE-32-01 Permit To Work - Electrical WorkDocument1 pageIDI-FRM-HSE-32-01 Permit To Work - Electrical Workaulia chaniaNo ratings yet

- Form 0005: Hot Work Permit: Section - I Details of The Permit ReciverDocument1 pageForm 0005: Hot Work Permit: Section - I Details of The Permit Reciverasem sawalmehNo ratings yet

- BINDERDocument17 pagesBINDERprakashNo ratings yet

- PTW Associated Certificates KEC - Final v3-MECHANICALDocument3 pagesPTW Associated Certificates KEC - Final v3-MECHANICALXiang JintaoNo ratings yet

- PTW Associated Certificates KEC - Final V3-TotalDocument9 pagesPTW Associated Certificates KEC - Final V3-TotalXiang JintaoNo ratings yet

- Lifting Work PermitDocument2 pagesLifting Work PermitCharantej TejaNo ratings yet

- Rin - Audio Intercom For Operation TheatreDocument1 pageRin - Audio Intercom For Operation TheatrenazriNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitGreg GenoveNo ratings yet

- JSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaDocument11 pagesJSP For OHTL No. 11 Access Road and Structure Pad Preparation For High Terrain AreaJaafar LagayanNo ratings yet

- General Work PermitDocument1 pageGeneral Work PermitJohn Shane100% (5)

- Rin - Audio Intercom For CSSDDocument1 pageRin - Audio Intercom For CSSDnazriNo ratings yet

- Excavation permit-1-GREENDocument2 pagesExcavation permit-1-GREENAravind Babu Dasari100% (1)

- Cold Work Permit - Typical FormatDocument1 pageCold Work Permit - Typical FormatNagabhushanam Tammana100% (7)

- General Electric Work Permit - Attachment XXIIDocument2 pagesGeneral Electric Work Permit - Attachment XXIIFaiqah AzmirNo ratings yet

- 19.30 Height Work PermitDocument3 pages19.30 Height Work Permitgopi.bcimNo ratings yet

- A) Job Assessment List Down Job Step by Step in Details. Job Step Description Potential Accidents / Risks / Hazards What To Do To Prevent?Document1 pageA) Job Assessment List Down Job Step by Step in Details. Job Step Description Potential Accidents / Risks / Hazards What To Do To Prevent?NashrulNo ratings yet

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanNo ratings yet

- General Work PermitDocument2 pagesGeneral Work Permitloganathan0% (1)

- Cme Iraq CF Oi 5 1 Cold Work PermitDocument1 pageCme Iraq CF Oi 5 1 Cold Work Permitmurtadanajem1999No ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitJareem PeesNo ratings yet

- 47.HDEC-HSE-F0047 Pressure Test PermitDocument1 page47.HDEC-HSE-F0047 Pressure Test PermitRonn CaiNo ratings yet

- General Work PermitDocument2 pagesGeneral Work PermitAde Mazmur SilabanNo ratings yet

- General Forms.1aDocument44 pagesGeneral Forms.1aNoli BenongoNo ratings yet

- Work PermitDocument2 pagesWork PermitC P TiwariNo ratings yet

- MS-HS-FRM-0024 Electrical Energization Permit FormDocument1 pageMS-HS-FRM-0024 Electrical Energization Permit FormeladawyemadNo ratings yet

- Work at Height PermitDocument1 pageWork at Height PermitAldrin MNo ratings yet

- Height Work PermitDocument2 pagesHeight Work PermitPravin Gorse100% (6)

- Hot Work PermitDocument1 pageHot Work PermitVijayakumar KarunanidhiNo ratings yet

- 11 - Work Notification - Template RDocument1 page11 - Work Notification - Template RImran ZamanNo ratings yet

- General Work Permit S3-F7: Start Date: End Date: Start Time: End TimeDocument1 pageGeneral Work Permit S3-F7: Start Date: End Date: Start Time: End TimeHareekirishnan LrkNo ratings yet

- JSP For OHTL No. 17 Underline Gantry Installation and ErectionDocument15 pagesJSP For OHTL No. 17 Underline Gantry Installation and ErectionJaafar LagayanNo ratings yet

- General Work Permit - HSEMS-OCP-01-F-01Document2 pagesGeneral Work Permit - HSEMS-OCP-01-F-01rajubiswashseNo ratings yet

- PTW - AG&P Main (Weekly)Document10 pagesPTW - AG&P Main (Weekly)Caleb del MundoNo ratings yet

- HOT Work Permiy - NCC-Project Seabird Phase IIA, DB-03Document4 pagesHOT Work Permiy - NCC-Project Seabird Phase IIA, DB-03Farman ShaikhNo ratings yet

- Work Authorization Permit.Document1 pageWork Authorization Permit.Gabriel TanNo ratings yet

- Work - Permit - CometDocument1 pageWork - Permit - CometElhdry GRNo ratings yet

- EHSWP004 - Hot Work Permit PDFDocument2 pagesEHSWP004 - Hot Work Permit PDFRand raiNo ratings yet

- JSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsDocument10 pagesJSP For OHTL No. 13 Pilot Wire Paying Out For ConductorsJaafar LagayanNo ratings yet

- Excavation Permit FormDocument2 pagesExcavation Permit FormNash C. Usop100% (1)

- Mobile Crane Lifting PermitDocument2 pagesMobile Crane Lifting PermitMusadiq HussainNo ratings yet

- TSA-016 - Breaking - Drilling of ConcreteDocument3 pagesTSA-016 - Breaking - Drilling of ConcreteMusadiq HussainNo ratings yet

- TSA 005 Rev 0 General LiftingDocument5 pagesTSA 005 Rev 0 General LiftingMusadiq HussainNo ratings yet

- TSA-023 - Working With Mobile Elevated Working Platforms (Man Lift)Document3 pagesTSA-023 - Working With Mobile Elevated Working Platforms (Man Lift)Musadiq HussainNo ratings yet

- TSA-013 - Night ShiftDocument2 pagesTSA-013 - Night ShiftMusadiq HussainNo ratings yet

- TSA-004-Rev 0 - Concrete Pouring WorkDocument3 pagesTSA-004-Rev 0 - Concrete Pouring WorkMusadiq HussainNo ratings yet

- Tsa-001 - Rev 0 - ExcavationDocument2 pagesTsa-001 - Rev 0 - ExcavationMusadiq HussainNo ratings yet

- TSA Carpentry WorksDocument2 pagesTSA Carpentry WorksMusadiq HussainNo ratings yet

- Form ADocument2 pagesForm AMusadiq HussainNo ratings yet

- 2F1.PMSR.3 27 Oct 2022 HSE Workers ConsultationDocument7 pages2F1.PMSR.3 27 Oct 2022 HSE Workers ConsultationMusadiq HussainNo ratings yet

- 01 HSE Induction - VisitorDocument28 pages01 HSE Induction - VisitorMusadiq HussainNo ratings yet

- Jewett CrisisManagementPlan 2021Document30 pagesJewett CrisisManagementPlan 2021Musadiq HussainNo ratings yet

- Penjelasan Tentang Direct and Indirect Speech TerlengkapDocument11 pagesPenjelasan Tentang Direct and Indirect Speech TerlengkapHasby HasbyNo ratings yet

- Part Two: Speaking TreeDocument5 pagesPart Two: Speaking TreeAngella3No ratings yet

- Wiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition System2 w202Document4 pagesWiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition System2 w202mathexscribdNo ratings yet

- A Users Guide To Intrinsic Safety AN9003-9Document20 pagesA Users Guide To Intrinsic Safety AN9003-9a_m_shihaNo ratings yet

- Cambodia V ThailandDocument22 pagesCambodia V ThailandMaria QadirNo ratings yet

- Rukmini Devi Institute of Advance Studies: Summer Training Report BBA-311Document7 pagesRukmini Devi Institute of Advance Studies: Summer Training Report BBA-311Shivam NarulaNo ratings yet

- Senarai Nama Murid Ikut Kelas 2023 Tahun 1 Hingga 6 1 Mac 2023Document23 pagesSenarai Nama Murid Ikut Kelas 2023 Tahun 1 Hingga 6 1 Mac 2023SUSANIAHNo ratings yet

- Empowerment of Mortal and Divine Females in The Iliad - A FeministDocument21 pagesEmpowerment of Mortal and Divine Females in The Iliad - A FeministGiovanni SuárezNo ratings yet

- REV615 - CapacitorDocument56 pagesREV615 - CapacitorthiagodorockkNo ratings yet

- 11-801 Traning Course - DeaeratorDocument26 pages11-801 Traning Course - Deaeratorpbarri100% (1)

- Radiation From An Oscillating Electric DipoleDocument15 pagesRadiation From An Oscillating Electric DipoleRayan Nezar100% (1)

- Bible - To Love, Honor and Vacuum PDFDocument9 pagesBible - To Love, Honor and Vacuum PDFDiana ArunNo ratings yet

- Xlathlete Wingate Pro Hockey Combine Prep WorkoutDocument5 pagesXlathlete Wingate Pro Hockey Combine Prep WorkoutNigel MH Adrian ManobandaNo ratings yet

- 3749 - E - 020102 - NSC25-34 RadarDocument316 pages3749 - E - 020102 - NSC25-34 RadarMariosNo ratings yet

- Case Study in Architectural Structures: A-7E Avionics System - ADocument36 pagesCase Study in Architectural Structures: A-7E Avionics System - Ajckz8No ratings yet

- Lecture HW 5 ProbText Moran2003 Chp11 FluidStaticsDocument2 pagesLecture HW 5 ProbText Moran2003 Chp11 FluidStaticsPanawit HanpinitsakNo ratings yet

- EPR Paradox ContestedDocument6 pagesEPR Paradox ContestedAlfonso FlórezNo ratings yet

- Construction Safety and Health ProgramDocument17 pagesConstruction Safety and Health ProgramJohny Lou Luza100% (2)

- Recreational Drug Discovery: Natural Products As Lead Structures For The Synthesis of Smart DrugsDocument26 pagesRecreational Drug Discovery: Natural Products As Lead Structures For The Synthesis of Smart DrugsStiven DestNo ratings yet

- Drones 06 00147Document27 pagesDrones 06 00147Prescoe LungreeNo ratings yet

- EDU30001 Imagining The World Through Language and Literature Assignment 2B Folio Part 2 Copy Copy - DoDocument11 pagesEDU30001 Imagining The World Through Language and Literature Assignment 2B Folio Part 2 Copy Copy - Donaima fadilyyt7i8 please 0tlNo ratings yet

- SSTMZG528: Assignment 1Document4 pagesSSTMZG528: Assignment 1D V BHASKARNo ratings yet

- On Student Support System: Roject EportDocument20 pagesOn Student Support System: Roject EportarunNo ratings yet

- Iodine Content in Clove OilDocument5 pagesIodine Content in Clove OilleahNo ratings yet

- Jacking Pipe DesignDocument15 pagesJacking Pipe DesignEWheelerFKNo ratings yet

- Hartnell Governor Isochronous Speed Equations - Engineers EdgeDocument1 pageHartnell Governor Isochronous Speed Equations - Engineers Edgestallone21No ratings yet

- maxDPUTools A1Document117 pagesmaxDPUTools A1Deepak GuptaNo ratings yet

- Econometric Theory StachurskiDocument377 pagesEconometric Theory StachurskiImam slaouiNo ratings yet

- TFT Proto Manual v200Document4 pagesTFT Proto Manual v200albertNo ratings yet

- Camera Mouse ManualDocument23 pagesCamera Mouse ManualJoe Lassie El-KhouriNo ratings yet