Professional Documents

Culture Documents

TSA-004-Rev 0 - Concrete Pouring Work

Uploaded by

Musadiq Hussain0 ratings0% found this document useful (0 votes)

6 views3 pagesConcrete Pouring Work

Original Title

TSA-004-Rev 0- Concrete Pouring Work

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentConcrete Pouring Work

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesTSA-004-Rev 0 - Concrete Pouring Work

Uploaded by

Musadiq HussainConcrete Pouring Work

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

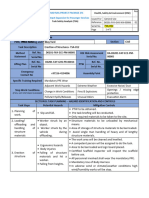

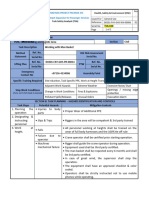

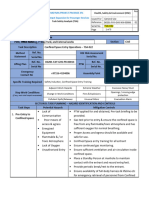

Health, Safety & Environment (HSE) Rev.

ETIHAD RAIL PROJECT PACKAGE 2F1

Issued For General Use

Operation & Maintenance (O&M) Facilities

Reference No. D0201-SO2-GHS-WX-00090 01

FORM Serial No. TSA-004

Task Safety Analysis (TSA) 1 of 3

Page

SECTION A: GENERAL INFORMATION

Work Area Admin Building/ GMB Area/ Berthing North & Section Civil

South

Task Description Concrete Pouring Works (TSA 004)

D0201-S02-EAS-PM-00004

Method Ref. No. D0201-S02-EAS-PM-00002 HSE Risk Assessment RA-D0201-SO2-EAS-PM-00007-01

RA-D0201--SO2-EAS-PM-00005-

Statement Serial No. Serial No. 01

D0201-S02-

Ref. No. D0201-S02-GHS-PR-00014 D0201-S02-GHS-PR-00007

Lifting Plan PTW GHS-PR-00007

Serial No Serial No. 001

Emergency +97156-4134006 Assembly Point GMB/ Admin Building/

Contact No Berthing North & South

Specific Training

MANDATORY PPE Wear, Competent Electrician Designated

Required

Stop Work Conditions Adjacent Work Hazards Extreme Weather Excessive Noise

Change in Work

(if any, work shall Fires & Explosions Excessive Dust

stop& re-assessed) Conditions

Pollutant Spills/Releases Unusual Odors Evacuation Alarm

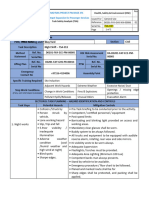

SECTION B: TASK PLANNING – HAZARD IDENTIFICATION AND CONTROLS

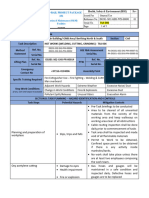

Task Steps Potential Hazards Mitigation Controls

Pre-Task Briefings to be conducted prior to the

activity

Proper Signals from the vehicle

Driver/Operator have proper visibility of

personnel

Man – Machine

1. Truck mixer Authorized personnel should be allowed

Interface

arriving the spot Work area should be barricaded with proper

Traffic Accident

signage

Be sure that trucks and other vehicles are in

good working order, including audible back-up

warning signals, before operating them.

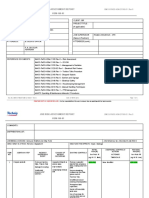

Health, Safety & Environment (HSE) Rev.

ETIHAD RAIL PROJECT PACKAGE 2F1

Issued For General Use

Operation & Maintenance (O&M) Facilities

Reference No. D0201-SO2-GHS-WX-00090 01

FORM Serial No. TSA-004

Task Safety Analysis (TSA) 2 of 3

Page

Pre-Task Briefings to be conducted prior to the

activity

Only authorized personnel to be allowed in the

working area

People hurt during

Work area should be barricaded with proper

pouring, Spit of

2. Cement signage

Concrete, Personnel fall

Pouring Minimize body and eye contact by any means of

Exposure to wet cement

PPE like Eye googles, Gum boots and rubber

Skin Irritation

gloves

Wash contaminated skin area with cold running

water as soon as possible.

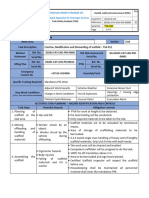

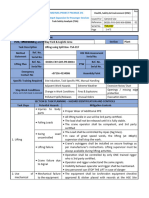

Pre-Task Briefings to be conducted prior to the

activity

Access will be maintained with timber boarding

Trips/Slips, Work in to provide a safe access and place of work

liquid floor – Slight Minimize body and eye contact by any means of

corrosive fluid PPE like Eye googles, Gum boots and rubber

Exposure to Wet gloves

3. Casting

cement Wash contaminated skin area with cold running

Skin Irritation water as soon as possible

Overexertion and Use of proper ergonomic techniques like

awkward postures appropriate clothing, positioning of feet, avoid

doing repetitive motion and reaching in

awkward position

Pre-Task briefings to be conducted prior to the

activity

Hierarchy controls to be implemented from

exposure to vibration

Vibration Syndrome Only competent persons are allowed to use the

Electric Shock or electrical equipment

4. Concrete

Electrocution Competent Mason shall be used on task

Vibrating

Mechanical failures of Electrical equipment to be inspected and fitness

equipment sticker or tag to be in place and updated

Whip connector shall be provided to the

pressure pipe at the place of each connection to

prevent any failure in the connection

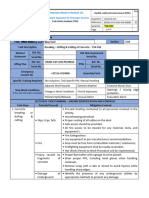

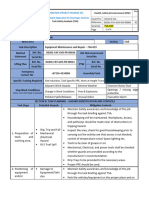

Health, Safety & Environment (HSE) Rev.

ETIHAD RAIL PROJECT PACKAGE 2F1

Issued For General Use

Operation & Maintenance (O&M) Facilities

Reference No. D0201-SO2-GHS-WX-00090 01

FORM Serial No. TSA-004

Task Safety Analysis (TSA) 3 of 3

Page

Name Signature Date

Completed By

Approved By

Representatives

You might also like

- TSA-012 - Erection of StructuresDocument2 pagesTSA-012 - Erection of StructuresMusadiq HussainNo ratings yet

- TSA-013 - Night ShiftDocument2 pagesTSA-013 - Night ShiftMusadiq HussainNo ratings yet

- TSA-011 - Erection, Modification and Dismantling of ScaffoldDocument2 pagesTSA-011 - Erection, Modification and Dismantling of ScaffoldMusadiq HussainNo ratings yet

- TSA-016 - Breaking - Drilling of ConcreteDocument3 pagesTSA-016 - Breaking - Drilling of ConcreteMusadiq HussainNo ratings yet

- TSA-020 - Concrete Core DrillDocument3 pagesTSA-020 - Concrete Core DrillMusadiq HussainNo ratings yet

- TSA-018 - Working With Man BasketDocument2 pagesTSA-018 - Working With Man BasketMusadiq HussainNo ratings yet

- Tsa-006 - Rev 0-Hot Works (Welding Cutting Grinding)Document5 pagesTsa-006 - Rev 0-Hot Works (Welding Cutting Grinding)Musadiq HussainNo ratings yet

- TSA-021 - Surveying WorksDocument2 pagesTSA-021 - Surveying WorksMusadiq HussainNo ratings yet

- TSA-009 - Fence InstallationDocument2 pagesTSA-009 - Fence InstallationMusadiq HussainNo ratings yet

- TSA-017 - Lifting Using Split BoxDocument2 pagesTSA-017 - Lifting Using Split BoxMusadiq HussainNo ratings yet

- TSA-015 - Installation of Pipes For Concrete WorksDocument2 pagesTSA-015 - Installation of Pipes For Concrete WorksMusadiq HussainNo ratings yet

- TSA-019 - Equipment Maintenance and RepairDocument4 pagesTSA-019 - Equipment Maintenance and RepairMusadiq HussainNo ratings yet

- TSA 005 Rev 0 General LiftingDocument5 pagesTSA 005 Rev 0 General LiftingMusadiq HussainNo ratings yet

- TSA Carpentry WorksDocument2 pagesTSA Carpentry WorksMusadiq HussainNo ratings yet

- TSA-010 - Painting WorksDocument4 pagesTSA-010 - Painting WorksMusadiq HussainNo ratings yet

- TSA-023 - Working With Mobile Elevated Working Platforms (Man Lift)Document3 pagesTSA-023 - Working With Mobile Elevated Working Platforms (Man Lift)Musadiq HussainNo ratings yet

- TSA-008 - Electrical WorksDocument2 pagesTSA-008 - Electrical WorksMusadiq HussainNo ratings yet

- TSA-014 - Electrical Works - LOTODocument4 pagesTSA-014 - Electrical Works - LOTOMusadiq HussainNo ratings yet

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- 2. job Safety Analysis Excavation 挖土工作安全分析Document6 pages2. job Safety Analysis Excavation 挖土工作安全分析ADEN LIUNo ratings yet

- Job Safety Analysis Risk Summary SheetDocument10 pagesJob Safety Analysis Risk Summary SheetMohammad Fazal KhanNo ratings yet

- Air Jsa ExcavationsDocument13 pagesAir Jsa ExcavationsNIdhinNo ratings yet

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- JRA-CDA-PL-049-REV-0 - Carousel General MaintenanceDocument4 pagesJRA-CDA-PL-049-REV-0 - Carousel General MaintenanceMiller DutraNo ratings yet

- 3. job-safety Sheet piling 钢板桩工作安全分析Document3 pages3. job-safety Sheet piling 钢板桩工作安全分析ADEN LIUNo ratings yet

- PDF Maker 1697683662466Document5 pagesPDF Maker 1697683662466wantolis36No ratings yet

- Job Safety Analysis: Confined Space: Health, Safety Environmental Management System (SMS)Document5 pagesJob Safety Analysis: Confined Space: Health, Safety Environmental Management System (SMS)ADEN LIUNo ratings yet

- Tsa-001 - Rev 0 - ExcavationDocument2 pagesTsa-001 - Rev 0 - ExcavationMusadiq HussainNo ratings yet

- TSA-024 - Temporary WorksDocument4 pagesTSA-024 - Temporary WorksMusadiq HussainNo ratings yet

- 01 Loading, Unloading & Transportation of Heavy Equipment (Well Head)Document11 pages01 Loading, Unloading & Transportation of Heavy Equipment (Well Head)Pangky AbasoloNo ratings yet

- JSA TubingDocument9 pagesJSA TubingSubbu AbuNo ratings yet

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Document10 pagesJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- Soft Cut Saw Operations (Generic) : Job Safety AnalysisDocument1 pageSoft Cut Saw Operations (Generic) : Job Safety AnalysisBorislav VulićNo ratings yet

- 001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)Document13 pages001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)NIdhinNo ratings yet

- Air CompressorDocument4 pagesAir CompressorLajapathi RaiNo ratings yet

- JSA - Drilling ActivitiesDocument4 pagesJSA - Drilling ActivitiesAMIN100% (1)

- 19 X-Ray of Welded Pipe JointsDocument5 pages19 X-Ray of Welded Pipe JointsPangky AbasoloNo ratings yet

- Job Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantDocument9 pagesJob Safety Analysis: CONTRACT NO. 6600030489 Cogeneration Interconnection Facilities Bi-01252 Abqaiq PlantZia ur RehmanNo ratings yet

- Jha Piping Insulation Installation and Dismantle Work p28Document12 pagesJha Piping Insulation Installation and Dismantle Work p28AmirHakimRusli100% (1)

- Site OrientationDocument2 pagesSite OrientationHitesh VaghasiyaNo ratings yet

- JSA - ELLECTRICAL AINDAR LAYING TERMINATION - CompressedDocument8 pagesJSA - ELLECTRICAL AINDAR LAYING TERMINATION - Compressedmalikshoaib8528No ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- BP Toledo Inert EntryDocument32 pagesBP Toledo Inert EntrySam Mebarek100% (1)

- 14 Construction of Optf LineDocument9 pages14 Construction of Optf LinePangky AbasoloNo ratings yet

- Scaffolding JSADocument10 pagesScaffolding JSASubbu AbuNo ratings yet

- 231112-Gks-She-Jsa-05 ApDocument4 pages231112-Gks-She-Jsa-05 Apwantolis36No ratings yet

- JSA For HVAC WorkDocument8 pagesJSA For HVAC Worksathakathulla100% (3)

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- JSA Excavation For Lighting Pole FoundationDocument18 pagesJSA Excavation For Lighting Pole FoundationMohammad Al Masa'deh100% (1)

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- JHA-IPM-NTI-010 Construction of Reinforced Concrete WallDocument13 pagesJHA-IPM-NTI-010 Construction of Reinforced Concrete WallmohdnurasyraafNo ratings yet

- CTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingDocument3 pagesCTRA-23-STM-093 - TK - 11-995 - Bund Wall CuttingMohamed RizwanNo ratings yet

- JSA Road ConstructionDocument17 pagesJSA Road ConstructionMohammad Al Masa'dehNo ratings yet

- 12 Construction of Blowdown LineDocument11 pages12 Construction of Blowdown LinePangky AbasoloNo ratings yet

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Mobile Crane Lifting PermitDocument2 pagesMobile Crane Lifting PermitMusadiq HussainNo ratings yet

- TSA 005 Rev 0 General LiftingDocument5 pagesTSA 005 Rev 0 General LiftingMusadiq HussainNo ratings yet

- TSA-023 - Working With Mobile Elevated Working Platforms (Man Lift)Document3 pagesTSA-023 - Working With Mobile Elevated Working Platforms (Man Lift)Musadiq HussainNo ratings yet

- TSA Carpentry WorksDocument2 pagesTSA Carpentry WorksMusadiq HussainNo ratings yet

- Tsa-001 - Rev 0 - ExcavationDocument2 pagesTsa-001 - Rev 0 - ExcavationMusadiq HussainNo ratings yet

- 2F1.PMSR.3 27 Oct 2022 HSE Workers ConsultationDocument7 pages2F1.PMSR.3 27 Oct 2022 HSE Workers ConsultationMusadiq HussainNo ratings yet

- Form ADocument2 pagesForm AMusadiq HussainNo ratings yet

- 01 HSE Induction - VisitorDocument28 pages01 HSE Induction - VisitorMusadiq HussainNo ratings yet

- Jewett CrisisManagementPlan 2021Document30 pagesJewett CrisisManagementPlan 2021Musadiq HussainNo ratings yet

- Hooks in Odoo OWL FrameworkDocument9 pagesHooks in Odoo OWL FrameworkJohn JackNo ratings yet

- Random Walk Model of ConsumptionDocument22 pagesRandom Walk Model of Consumptionshahid_hussain_41100% (1)

- SBC For Dummies PreviewDocument10 pagesSBC For Dummies PreviewEGX Consultores100% (1)

- GSIS TEMPLATE Fire Insurance Application Form (TRAD)Document3 pagesGSIS TEMPLATE Fire Insurance Application Form (TRAD)Ronan MaquidatoNo ratings yet

- Question OneDocument2 pagesQuestion Onegoodluckpeterson864No ratings yet

- Explore Innovate DisruptDocument5 pagesExplore Innovate DisruptVaishnaviRaviNo ratings yet

- Law and Practice of BankingDocument34 pagesLaw and Practice of BankingAbdullah Al ShaqureNo ratings yet

- AMEX Global Meetings and Events Forecast 2023Document72 pagesAMEX Global Meetings and Events Forecast 2023luddie hardonoNo ratings yet

- Pushpanjali Case StudyDocument2 pagesPushpanjali Case StudyMohamed Mohamed AdelNo ratings yet

- The Nature of Economics of AgricultureDocument2 pagesThe Nature of Economics of AgricultureAhmad Zia TareqNo ratings yet

- ESG Explained - Article Series Exploring ESG From The Very Basics - #2 Where Do You Start With ESG ReportingDocument13 pagesESG Explained - Article Series Exploring ESG From The Very Basics - #2 Where Do You Start With ESG Reportingsujaysarkar85No ratings yet

- AWS To Azure Services Comparison High Level PDFDocument28 pagesAWS To Azure Services Comparison High Level PDFBhavanesh AsarNo ratings yet

- CoP Webinar Amtrak EAM Program Journey - Alex Berry 13th April 2023Document24 pagesCoP Webinar Amtrak EAM Program Journey - Alex Berry 13th April 2023Nico FriedmannNo ratings yet

- Service Bulletin 25-2016Document3 pagesService Bulletin 25-2016Leo ansinNo ratings yet

- The New Hire: A Pocket Guide For EmployersDocument10 pagesThe New Hire: A Pocket Guide For Employerskenny_jjjj100% (1)

- Bord Gáis Energy Gas & Electricity Supplier IrelandDocument1 pageBord Gáis Energy Gas & Electricity Supplier IrelandRomerson AmbrósioNo ratings yet

- Sergio 11-9-2015 #3605Document3 pagesSergio 11-9-2015 #3605Mirza RibićNo ratings yet

- This Study Resource Was: 1. in The Audit of The Heats Corporation's Financial Statements at December 31, 2005, TheDocument5 pagesThis Study Resource Was: 1. in The Audit of The Heats Corporation's Financial Statements at December 31, 2005, TheIvy BautistaNo ratings yet

- Competitor AnalysisDocument4 pagesCompetitor AnalysisKhadija TahirNo ratings yet

- 2021 Chubb Annual ReportDocument292 pages2021 Chubb Annual ReportMoiz SaeedNo ratings yet

- Chen PDFDocument23 pagesChen PDFAnonymous N8ktRfrp06No ratings yet

- Potato Cheese BallDocument3 pagesPotato Cheese BallEn Braganaza67% (3)

- Medical Shop Business PlanDocument8 pagesMedical Shop Business PlanPrajwal Vemala JagadeeshwaraNo ratings yet

- Discharge of Contracts and Remedies For Breach of Contract Discharge of Contracts - Meaning and DefinitionDocument12 pagesDischarge of Contracts and Remedies For Breach of Contract Discharge of Contracts - Meaning and DefinitionTitus ClementNo ratings yet

- Tourism in Africa:: Harnessing Tourism For Growth and Improved LivelihoodsDocument12 pagesTourism in Africa:: Harnessing Tourism For Growth and Improved LivelihoodsDIPIN PNo ratings yet

- Lesson 2 NON STOCK CORPORATIONSDocument9 pagesLesson 2 NON STOCK CORPORATIONSVanessa Evans CruzNo ratings yet

- FM RL 1.1.1Document10 pagesFM RL 1.1.1anandakumarNo ratings yet

- Resumen de Contactos y Sensores Q409533Document19 pagesResumen de Contactos y Sensores Q409533Francisco Javier BurgosNo ratings yet

- TVET Accreditation Handbook CompressedDocument102 pagesTVET Accreditation Handbook CompressedMartinNo ratings yet

- Functions of Travel Agencies and Tour Opera-Tions: Module - 6ADocument12 pagesFunctions of Travel Agencies and Tour Opera-Tions: Module - 6ARoy CabarlesNo ratings yet