Professional Documents

Culture Documents

Engine Service Bulletin

Engine Service Bulletin

Uploaded by

Dave MotykaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Service Bulletin

Engine Service Bulletin

Uploaded by

Dave MotykaCopyright:

Available Formats

t´• i _ _

#0: 1389

m. n. 1

EPIGINE

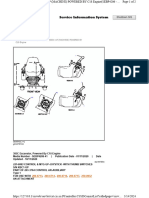

POWER TURBINE SHAFT HOUSING AND NO. 3 BEARING COVER IMPROVED ANTIROTATION

FEATURE INTRODUCTION OF

1, Planning Information

A. Effectivit~

Models Application

(1) Serials

8 PT6A-6 ,-20A, All engines ~th 17-thousand

R -2 OB ,-2 1 ,-2 5 ,-2 5A,-2 50, prior to ~BA)

PC-E

R -27,-28,-34,-34AC,-34B,

R -36,-114,-135,-135A (2) All engines with 20-thousand Serials

R prior to PC-E (TBA)

R (3) All engines with 24-thousand Serials

R prior to PC-E (TBA)

R (4) All engines with 24301 Serials prior

R´• to PC-E (TBA)

R (5) All engines with 26-thousand Serials

R prior to PC-E (TBA)

R (6) All engines with 38-thousand Serials

R prior to PC-E38172

R (7) All engines with 40-thousand Serials

R prior to PC-E42296

R (8) All engines with 47-thousand S~rials

R prior to PC-E (TBA)

R (9) All engines with 48-thousand Serials

R prior to PC-E (TBA)

R (10) All engines with 50-thousand Serials

R prior to PC-E (TBA)

R (11) All engines with 54-thousand Serials

R prior to PC-E (TBA)

R (12) All PT6A-34,-34AG engines with

R 57-thousand Serials prior to PC-E

R 57176 and -3411 engines prior to PC-E

(TBA)

C A01-562

ISSUeO: 12 July 1984 PRATT 8 WHITNEY CANADA P~OE 1 Oi: 8

8LV. )10. BOX 10, LONOUEUIL, QUEBEC,

i, 28 February 1985

CAMADA J4K 4X9

PRATT WHITNEY CANADA

S.B, No. 1389

Rev. No. 1

-´•I´•.

POWER TURBINE SHAFT HOUSING AND NO, 3 BEARING COVER IMPROVED ANTIROTATION.

FEATURE INTRODDCTION OF

Application (Cont’d)

R (13) All PWV engines with 58-thousand

R Serials prior to PC-E (TBA)

R (14) All engines with 92-thousand Serials

R prior to PC-E (TBA)

B. Reason

The original bulletin was issued to modify existing arrangement to

improve durability,

R Rev. No. 1 is issued to include additional engine models, amend Paras.

R 1.D. and 1,G, and update Part 2, Accomplishment Instructions and Part 3,

R Material Information,

C. Description

(1) The power turbine shaft housing is modified by incorporating slete

on the small diameter.

(2) The existing No. 3 bearing cover is removed and replaced with a

similar cover manufactured from a different material and also

incorporating a lugged spacer.

D, Compliance

R (1) For PT6A-34/-34AC/-34B/-36 Engines

R Recommended Desirable. PbWC recommends accomplishment when

R disassembly of engine issufficlent to afford access to the

R affected part,

R (2) For all other engine models

R Optional At the discretion of an operator. PCWC recommends

R accomplishment based on operator’s experience with prior

R configuration parts.

E. Approval

ov

D.O.T./D.A.R. approved.

F. Manpower

Approximately 1.5 man-hours required to accomplish at engine overhaul.

Page 2 of 6 28 February 1985

PRATT WHITNEV CANADA

S.B. No. 1389

Rev. No. 1

POWER TURBINE SHAFT HOUSING AND NO. 3 BEARING COVER IMPROVED ANTIROTATION

FEATURE INTRODUCTION OF

R G. References

R PT6A-6/-20 (Combined) Maintenance Manual P/N 3015442

R PT6A-21/-27/-28 Maintenance Manual P/N 3013242

R PT6A-25/-25A Maintenance Manual P/N 3027542

R PT6A-25C Maintenance Mar~ual P/N 3032142

R PTsA-34/-34Ac/-34B/-36/-114/-135/-135A Maintenance Manual P/N 3021242

R PT6A-6 Overhaul Manual P/N 3008103

R PT6A-20/-20A/-20B Overhaul Manual P/N 3011403

R PT6A-21/-27/-28 Overhaul Manual P/N 3013243

R PT6A-25/-25A Overhaul Manual P/N 3027543

R PT6A-25C Overhaul Mallual P/N 3032143

R PTsA-34/-34Ac/-34B/-36/-114/-135 Overhaul Manual P/N 3021243

R PT6A-6/-20 (Combined) Parts Catalog P/N 3015444

R PT6A-21/-27/-28 Parts Catalog P/N 3013244

R PT6A-25/-25A Parts Catalog P/N 3027544

R PT6A-25C Parts Catalog P/N 3032144

R PTsA-34/-~4Ac/-34B/-36/-114/-135/-135A Parts Catalog P/N 3021244

R Service Bulletin No. 1287

R Parts Digest No. 2444A

2. Accomplishment Instructions

A. At engine disassembly, remove and discard existing No. 3 bearing cover

P/N 3020745, 3029974 or 3012520 and spacer P/N 3013338.

B. Rework serviceable power turbine shaft housing assembly P/N 3018379,

R 3010548 or 3029979 as follows:

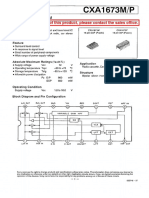

(1) Machine four slots in power turbine shaft housing assembly to

dimensions shown on Figure 1, View ’B’.

(2) Break all sharp edges 0.003 to 0.010 inch.

(3) Fluorescent penetrant inspect after machining per SPOP62

instructions.

(4) Reidentify reworked power turbine shaft housing assembly: as

follows:

R (a) For housing assembly P/N 3029979 or 3018379, strike out

existing part number and reidentify with new P/N 3104279-01,

in same general area, using vibropeen method of marking.

R (b) For housing assembly P/N 3010548, add "SB1389" after

existing part r~umber, using vibropeen method of marking.

28 February 1985 Page 3 of 6

PRATT WHlfNEY CANADA

S.B. No. 1389

Rev. No. 1

POWER TURBINE SHAFT HOUSING AND NO. 3 BEARING COVER IMPROVED ANTIROTATION

FEATURE INTRODUCTION OF

C. At engine assembly, install new No. 3 bearing cover assembly P/N

3104278-01 on reworked power turbine shaft housing assembly and secure

R with retaining ring.

D. Field Level Maintenance and HSI

(1) Remove power turbine in accordance with Maintenance Manual

instructions.

R (2) Remove and retain power turbine rotor air seal P/N 3020035 or

R equivalent.

(3) Remove and retain, if serviceable, No. 3 bearing cover retaining

ring.

(4) Remove and dtscard No. 3 bearing cover Pre and Post-SB1287.

(5) For Post-SB1287, using an approved marking method, index mark at

one location/position of new slots.

NOTE: For Post-SB1287, new slots must be located 45 f 50 away from

existing scallops.

(6) Install grinding fixture PWC32270 and align index mark with one

slot in fixture; then secure with dummy bolt.

(7) Using an angle drive hand grinder with a suitable cutting wheel,

grind four (4) slots to dimension shown on Figure 1,

NOTE: Exercise care when grinding to avoid material removal from

fixture.

(8) Using a suitable suction cleaner, remove all grinding residue to

ensure cleanliness of turbine area.

(9) Remove fixture, blank off power turbine shaft housing air seal

diameter and break sharp edges 0.003 to 0.010 inch.

(10) Repeat Subparagraph 2,D.(8) and remove blank.

(11) Reinstall power turbine rotor air seal P/N 3020035.

(12) Install new No. 3 bearing cover P/N 3104278-01 and secure with

retaining ring.

Page 4 of 6 28 February 1985

PRATT WHITNEY CANADA

S.B. No. 1389

Rev. No. 1

(e POWER TURBINE SHAFT HOUSING AND NOI 3 BEARING COVER IMPROVED ANTIROTATION

FEATURE INTRODUCTION OF

(13) Reinstall power turbine in accordance with Maintenance Manual

instructions.

(14) Annotate engine logbook that SB1389 has been incorporated.

3. Material Information

NEW OLD

PART NO. qTr NOMENCLATURE QTY PART NO.

R X3010548 1 Housing Assy Power Turbine Shaft 1 3010548

R (881389)

R X3104279-01 1 Housing Assy Power Turbine Shaft 1 3029979

R X3 10427 9-0 1 1 Housing Assy Power Turbine Shaft 1 3018379

R 3104278-01 1 Cover Assy No. 3 Bearing 1 3020745

or 3029974

3012520

Spacer No. 3 Bearing Cover 1 3013338

Obtained by rework and reidentification of

existing parts,

4. Special Tools

Grinding Fixture PWC32270

28 February 1985 Page 5 of 6

PRATT W~IITNEY CANADA

S.B. No. 1389

No. 1

POWER TURBINE SHAFT HOUSING AND NO. 3 BEARING COVER IMPROVED ANTIROTATION

FEATURE INTRODUCTION OF

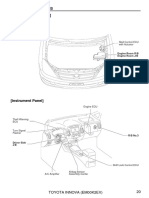

REIDENTIFY POWER TURBINE SHAFT

IN THIS AREA HOUSING ASSEMBLY

a a 1

i

a

a eA

a 0.060

FACE ’_N’ (4 PLACES)

a 0.055

a 4 SLOTS EQUALLY

R´•

SPACED AND LOCATED

a 0.215

WITHIN 0.004 INCH

a 0.210

OF TRUE POSITION

aa

f! POST 88128.7 ONLY

-1- 2 450 50

R 0.030 RADIUS

a (8 PCACES)

IVIAXIMUM

a

B\

VIEW B

YIMI A

R Power Turbine Shaft Housing Assembly Incorporating No. 3 Bearing Cover

R Antirotation Slots

R Figure 1

~-´•:´•´•i-

28 February 1985

Page 6 of 6

You might also like

- John Deere 4230 Tractor (PDFDrive)Document980 pagesJohn Deere 4230 Tractor (PDFDrive)احمد الشبراوى الشبراوى100% (3)

- Humvee 4L80 4L85 Transmission Parts Overhaul Repair NMWR 9 2520 582Document334 pagesHumvee 4L80 4L85 Transmission Parts Overhaul Repair NMWR 9 2520 582Jorge BolañosNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Trator 8430 04out05Document856 pagesTrator 8430 04out05joaobargasNo ratings yet

- 3406C GenSetDocument4 pages3406C GenSetLeonardo Martínez67% (3)

- Kubrick - Red A.memoir Simon - RoyDocument161 pagesKubrick - Red A.memoir Simon - RoySakis BwanasNo ratings yet

- Wiring Diagrams: VR6 Voltage RegulatorDocument21 pagesWiring Diagrams: VR6 Voltage Regulatorgeorgi15685No ratings yet

- John Deere 1640 2040 2040SDocument1,448 pagesJohn Deere 1640 2040 2040Sbga187583% (6)

- Start-Up and Operations Report PDFDocument3 pagesStart-Up and Operations Report PDFdennis_ugarte100% (1)

- Uncertainty in MeasurementDocument58 pagesUncertainty in MeasurementDijo PaulNo ratings yet

- Activity 3Document2 pagesActivity 3Robert Garland100% (1)

- 2888 450CLCDocument589 pages2888 450CLCAlfredo ZablahNo ratings yet

- 0415621488Document166 pages0415621488aliouecheNo ratings yet

- Gen First Sync Procedure - Rev01Document12 pagesGen First Sync Procedure - Rev01O P Sridharan PerumalNo ratings yet

- Burke-4 - 319 Iconography and Iconology PDFDocument226 pagesBurke-4 - 319 Iconography and Iconology PDFbogdanaNo ratings yet

- Does Culture Matter? E.M. Forster: Instructor: Abdul GhaffarDocument8 pagesDoes Culture Matter? E.M. Forster: Instructor: Abdul GhaffarAbdulGhaffar Jat0% (1)

- Ptr8000ii Service Man A#be0Document170 pagesPtr8000ii Service Man A#be0Mauricio CruzNo ratings yet

- Combinatorial Algorithms: For Computers and CalculatorsFrom EverandCombinatorial Algorithms: For Computers and CalculatorsRating: 4 out of 5 stars4/5 (2)

- Tabelle Lubrificazione McCormick INGDocument48 pagesTabelle Lubrificazione McCormick INGMarian TarasNo ratings yet

- Adobe Scan Nov 16, 2021Document7 pagesAdobe Scan Nov 16, 2021Mohammad AliNo ratings yet

- Adobe Scan Nov 16, 2021Document7 pagesAdobe Scan Nov 16, 2021Mohammad AliNo ratings yet

- TLC555 LinCMOS™ Technology Timer Datasheet (Rev. J) - tlc555Document1 pageTLC555 LinCMOS™ Technology Timer Datasheet (Rev. J) - tlc555jagajack33No ratings yet

- r5f2021 Micro ControladorDocument73 pagesr5f2021 Micro Controladormauricio zamoraNo ratings yet

- JoystickDocument2 pagesJoystickRashid MahmoodNo ratings yet

- Oscillators Part 2Document24 pagesOscillators Part 2Tinyiko ChaukeNo ratings yet

- Master Chart 962 42990Document1 pageMaster Chart 962 42990Rudy HerreraNo ratings yet

- SCRs Make Servi-WPS OfficeDocument1 pageSCRs Make Servi-WPS OfficeRenalyn AblingNo ratings yet

- Conventional and Improved 4-Bit Ripple Carry Adder ComparisonDocument4 pagesConventional and Improved 4-Bit Ripple Carry Adder ComparisonBienvenido LasacaNo ratings yet

- IEEE Definitions For Excitation Systems 6Document3 pagesIEEE Definitions For Excitation Systems 6Emmanuel ZamoranoNo ratings yet

- Modbus Table RegisterDocument15 pagesModbus Table RegistersaltwetNo ratings yet

- Chapter2-2 - Types of DC MotorDocument38 pagesChapter2-2 - Types of DC Motorjamil4861100% (1)

- KoplakDocument9 pagesKoplakmslagung17No ratings yet

- AIS Panel DetailsDocument4 pagesAIS Panel DetailsMahipal YadavNo ratings yet

- CS 61C: Great Ideas in Computer Architecture Lecture 13: PipeliningDocument47 pagesCS 61C: Great Ideas in Computer Architecture Lecture 13: Pipelininganon_192140810No ratings yet

- THWS15 Series 136-174 Simplex - Duplex Combiners - TK039.01Document1 pageTHWS15 Series 136-174 Simplex - Duplex Combiners - TK039.01ayhantNo ratings yet

- Prelim Lec ACDCDocument18 pagesPrelim Lec ACDCRaia SeoNo ratings yet

- EnginesDocument32 pagesEnginesUncle John's GarageNo ratings yet

- Differential/Cascode Amplifier For Commercial and Industrial Equipment From DC To 120Mhz FeaturesDocument11 pagesDifferential/Cascode Amplifier For Commercial and Industrial Equipment From DC To 120Mhz FeaturesBenny AlconnNo ratings yet

- 15-20W Class AB Audio AmplifierDocument4 pages15-20W Class AB Audio AmplifierhsNo ratings yet

- DC MotorDocument84 pagesDC MotorMuhammad Fajar PrakasaNo ratings yet

- Power Converters Lab ManualDocument89 pagesPower Converters Lab ManualHari PrasadNo ratings yet

- HCF4538B: Dual Monostable MultivibratorDocument10 pagesHCF4538B: Dual Monostable MultivibratorHector Rafael MirandaNo ratings yet

- RQ SX46 56Document4 pagesRQ SX46 56Chef KaiserNo ratings yet

- Tayangan Ke 3 DC MotorDocument38 pagesTayangan Ke 3 DC MotorReni DamayantiNo ratings yet

- Induction MotorDocument28 pagesInduction Motorsumithra100% (2)

- Tishchenko's Method - 2: Lift To Drag Ratio Propulsive Efficiency Component Weight EstimationDocument38 pagesTishchenko's Method - 2: Lift To Drag Ratio Propulsive Efficiency Component Weight EstimationDeepak Paul TirkeyNo ratings yet

- MI18-03 Volvo I-Shift RS4S June2018Document2 pagesMI18-03 Volvo I-Shift RS4S June2018Endry ValerioNo ratings yet

- 110 KV Line and Transformer Protection RelaysDocument2 pages110 KV Line and Transformer Protection RelaysSrimayi YelluripatiNo ratings yet

- Relay - Fuse LocationsDocument14 pagesRelay - Fuse Locationstuan anh nguyễnNo ratings yet

- Ae2413y Fz1aDocument2 pagesAe2413y Fz1aMageon7No ratings yet

- Globe Brochure - Air MotorDocument2 pagesGlobe Brochure - Air MotorHarshal shahNo ratings yet

- April-May 2017 PDFDocument3 pagesApril-May 2017 PDFkarthickpjceNo ratings yet

- Ae4456e Es1bDocument1 pageAe4456e Es1bWellton PecanhaNo ratings yet

- Ca741, Ca741c, Ca1458, Ca1558, LM741, LM741C, LM1458Document6 pagesCa741, Ca741c, Ca1458, Ca1558, LM741, LM741C, LM1458rrr2013No ratings yet

- CA3100TDocument7 pagesCA3100THisham MehremNo ratings yet

- Ae4430y Fz1aDocument2 pagesAe4430y Fz1aninda febriyaniagustinaNo ratings yet

- Crankshaft C9Document2 pagesCrankshaft C9Irwanto ManafNo ratings yet

- SONY,,: For The Availability of This Product, Please Contact The Sales OfficeDocument8 pagesSONY,,: For The Availability of This Product, Please Contact The Sales OfficeERNANIPARNOWNo ratings yet

- Advanced Power Electronics Corp.: Adjustable Precision Shunt RegulatorDocument10 pagesAdvanced Power Electronics Corp.: Adjustable Precision Shunt RegulatorLuis Mariano TovillasNo ratings yet

- 09 Nutiny-Nuc029 UartDocument16 pages09 Nutiny-Nuc029 UartDharmendra SavaliyaNo ratings yet

- TDA8809TDocument17 pagesTDA8809Tjustclick5625No ratings yet

- Dokumen - Tips - 555 Timer PPT by VishnuDocument14 pagesDokumen - Tips - 555 Timer PPT by VishnuRamNo ratings yet

- TDA7265SA STMicroelectronicsDocument12 pagesTDA7265SA STMicroelectronicsAbdurashid tillaevNo ratings yet

- Pumpd Up Fuzz FaceDocument3 pagesPumpd Up Fuzz FaceLéo HerbreteauNo ratings yet

- CI CA1458 DatasheetDocument6 pagesCI CA1458 DatasheetRogerio EngelNo ratings yet

- Byte 1979 08Document268 pagesByte 1979 08Viliux Y (viliux80)No ratings yet

- D D D D D D D D: Description/ordering InformationDocument12 pagesD D D D D D D D: Description/ordering InformationLinda_Daniele_1465No ratings yet

- M39016/M5757 MicrominiDocument1 pageM39016/M5757 MicrominiDave MotykaNo ratings yet

- White Industries Avionics DisclaimerDocument1 pageWhite Industries Avionics DisclaimerDave MotykaNo ratings yet

- Гребень ГА - 80113Document1 pageГребень ГА - 80113Dave MotykaNo ratings yet

- Гребень ГА - 80115Document1 pageГребень ГА - 80115Dave MotykaNo ratings yet

- ZA Varistor SeriesDocument14 pagesZA Varistor SeriesDave MotykaNo ratings yet

- Xmd076 Typical Wiring Reference Diagram: 5 XMD Receiver, Rs232 Type 4 8 6Document1 pageXmd076 Typical Wiring Reference Diagram: 5 XMD Receiver, Rs232 Type 4 8 6Dave MotykaNo ratings yet

- XM Plans Overview - SiriusXM CanadaDocument2 pagesXM Plans Overview - SiriusXM CanadaDave MotykaNo ratings yet

- XMD076 S35 IcaDocument12 pagesXMD076 S35 IcaDave MotykaNo ratings yet

- USJADocument16 pagesUSJADave MotykaNo ratings yet

- German Universities234wrefwerfgDocument3 pagesGerman Universities234wrefwerfgAnsat JartybayevNo ratings yet

- SURVEY-QUESTIONNAIRE Roca CostcoDocument5 pagesSURVEY-QUESTIONNAIRE Roca CostcoNhânNo ratings yet

- Hexametrical Genres From Homer To Theocritus Christopher Athanasious Faraone Full ChapterDocument67 pagesHexametrical Genres From Homer To Theocritus Christopher Athanasious Faraone Full Chapterlouis.cook744100% (16)

- A Study of Technological Pedagogical Content Knowledge of Science Teachers at The Higher Secondary StageDocument8 pagesA Study of Technological Pedagogical Content Knowledge of Science Teachers at The Higher Secondary StageAnonymous CwJeBCAXpNo ratings yet

- J Gerontol A Biol Sci Med Sci-1997-Vitiello-M189-91Document3 pagesJ Gerontol A Biol Sci Med Sci-1997-Vitiello-M189-91Retno ManggalihNo ratings yet

- Aqueous Extract and Ethanol Extract PreparationDocument6 pagesAqueous Extract and Ethanol Extract PreparationMaria MudassirNo ratings yet

- Specification - FactoryDocument3 pagesSpecification - Factorythomas.rohanNo ratings yet

- Machining Parameters Optimization On The Die Casting Process of Magnesium Alloy Using The Grey-Based Fuzzy AlgorithmDocument9 pagesMachining Parameters Optimization On The Die Casting Process of Magnesium Alloy Using The Grey-Based Fuzzy AlgorithmjanakNo ratings yet

- Tutorial - Chapter 1 - Introduction - Questions 1Document4 pagesTutorial - Chapter 1 - Introduction - Questions 1NandiieNo ratings yet

- CCNA - Exploration Network Fundamentals - ENetwork Practice Final ExamDocument26 pagesCCNA - Exploration Network Fundamentals - ENetwork Practice Final Exambrone8No ratings yet

- Resume For PortfolioDocument3 pagesResume For Portfolioapi-547582127No ratings yet

- NDR Series Rotor PackDocument7 pagesNDR Series Rotor PackJustinNo ratings yet

- Name: Sisay Amare Nigussie Reg no:18BCM0149 Slot: D2 +TD2 Course Code: CHE1004 Faculty: D.R Aslam Abdullahi M Vellore Institute of Technology (VIT)Document23 pagesName: Sisay Amare Nigussie Reg no:18BCM0149 Slot: D2 +TD2 Course Code: CHE1004 Faculty: D.R Aslam Abdullahi M Vellore Institute of Technology (VIT)Sisay AmareNo ratings yet

- SDC Important QuestionsDocument5 pagesSDC Important QuestionsInstagramNo ratings yet

- Dell PowerEdge R820 and R910 Servers: Performance and ReliabilityDocument17 pagesDell PowerEdge R820 and R910 Servers: Performance and ReliabilityPrincipled TechnologiesNo ratings yet

- National Council of Teachers of Mathematics Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To The Mathematics TeacherDocument2 pagesNational Council of Teachers of Mathematics Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To The Mathematics TeacherPerpetual AmazinggirlNo ratings yet

- Risk Assessment/Management Form: Risk Assessment-Erection of Column, Stair Case and BracingDocument3 pagesRisk Assessment/Management Form: Risk Assessment-Erection of Column, Stair Case and BracingAhmed AbdulfatahNo ratings yet

- KoinX-Complete Tax Report - OptionsDocument13 pagesKoinX-Complete Tax Report - OptionsBhavsmeetforeverNo ratings yet

- Report On Intensive Reading ProgrammeDocument2 pagesReport On Intensive Reading ProgrammezuraidiNo ratings yet

- RMC No. 10-2020Document2 pagesRMC No. 10-2020Volt LozadaNo ratings yet

- Gut Reset - Workshop ManualDocument7 pagesGut Reset - Workshop ManualAtique HussainNo ratings yet

- The Marketing Function's Main RolesDocument11 pagesThe Marketing Function's Main RolesNga Nga NguyenNo ratings yet