Professional Documents

Culture Documents

Rina Prop Thickness

Rina Prop Thickness

Uploaded by

Andreas ArapakopoulosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rina Prop Thickness

Rina Prop Thickness

Uploaded by

Andreas ArapakopoulosCopyright:

Available Formats

Pt C, Ch 1, Sec 7

SECTION 7 PROPELLERS

1 General Figure 1 : Rake

1.1 Application

RAKE

1.1.1 Propulsion propellers

The requirements of this Section apply to propellers of any

size and any type intended for propulsion. They include

fixed and controllable pitch propellers, including those

ducted in fixed nozzles.

TRAILING EDGE

1.1.2 Manoeuvring thruster propellers

LEADING EDGE

For manoeuvring thruster propellers see Sec 11.

FACE

1.2 Definitions BACK

1.2.1 Solid propeller

A solid propeller is a propeller (including hub and blades)

cast in one piece.

1.2.2 Built-up propeller

A built-up propeller is a propeller cast in more than one

piece. In general, built up propellers have the blades cast

separately and fixed to the hub by a system of bolts and

studs.

1.2.3 Controllable pitch propellers

Controllable pitch propellers are built-up propellers which

include in the hub a mechanism to rotate the blades in

1.2.8 Skew angle

order to have the possibility of controlling the propeller

pitch in different service conditions. Skew angle is the angle between a ray starting at the centre

of the propeller axis and tangent to the blade midchord line

1.2.4 Nozzle and a ray also starting at the centre of the propeller axis and

passing at the blade tip (see Fig 3).

A nozzle is a circular structural casing enclosing the propel-

ler. 1.2.9 Skewed propellers

Skewed propellers are propellers whose blades have a skew

1.2.5 Ducted propeller

angle other than 0.

A ducted propeller is a propeller installed in a nozzle.

1.2.10 Highly skewed propellers and very highly

1.2.6 Rake skewed propellers

Rake is the horizontal distance between the line connecting Highly skewed propellers are propellers having blades with

the blade tip to the blade root and the vertical line crossing skew angle between 25o and 50o. Very highly skewed pro-

the propeller axis in the same point where the prolongation pellers are propellers having blades with skew angle

of the first line crosses it, taken in correspondence of the exceeding 50o.

blade tip (see Fig 1). Aft rakes are considered positive, fore

rakes are considered negative. 1.2.11 Leading edge

The leading edge of a propeller blade is the edge of the

1.2.7 Rake angle blade at side entering the water while the propeller rotates

Rake angle is the angle at any point between the tangent to (see Fig 1).

the generating line of the blade at that point and a vertical

line passing at the same point. If the blade generating line is 1.2.12 Trailing edge

straight, there is only one rake angle; if it is curved there are The trailing edge of a propeller blade is the edge of the

an infinite number of rake angles (see Fig 2). blade opposite the leading edge (see Fig 1).

RINA Rules for Charter Yachts 2006 87

Pt C, Ch 1, Sec 7

Figure 2 : Rake angle 1.3 Documentation to be submitted

RAKE ANGLE 1.3.1 Solid propellers

AT SPECIFIED The documents listed in Tab 1 are to be submitted for solid

RADIUS

propellers intended for propulsion.

All listed plans are to be constructional plans complete with

all dimensions and are to contain full indication of types of

materials employed.

Table 1 : Documents to be submitted

SPECIFIED

RADIUS for solid propellers

Nr A/I (1) ITEM

1 A Sectional assembly

2 A Blade and hub details

3 I Rating (power, rpm, etc.)

4 A Data and procedures for fitting propeller to

the shaft

(1) A = to be submitted for approval in four copies

I = to be submitted for information in triplicate

1.3.2 Built-up and controllable pitch propellers

The documents listed in Tab 2, as applicable, are to be sub-

mitted for built-up and controllable pitch propellers

intended for propulsion.

Table 2 : Documents to be submitted

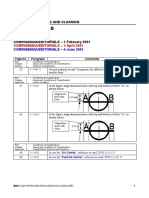

Figure 3 : Skew angle for built-up and controllable pitch propellers

Nr A/I (1) ITEM

MIDCHORD LINE 1 A/I Same documents requested for solid pro-

pellers

SKEW ANGLE 2 A Blade bolts and pre-tensioning procedures

3 I Pitch corresponding to maximum propeller

thrust and to normal service condition

4 A Pitch control mechanism

5 A Pitch control hydraulic system

(1) A = to be submitted for approval in four copies

I = to be submitted for information in triplicate

1.3.3 Very highly skewed propellers and propellers

of unusual design

For very highly skewed propellers and propellers of unusual

design, in addition to the documents listed in Tab 1 and

Tab 2, as applicable, a detailed hydrodynamic load and

stress analysis is to be submitted (see [2.4.2]).

2 Design and construction

1.2.13 Blade developed area

Blade developed area is the area of the blade surface 2.1 Materials

expanded in one plane.

2.1.1 Normally used materials for propeller hubs

1.2.14 Developed area ratio and blades

Developed area ratio is the ratio of the total blade devel- a) Tab 3 indicates the minimum tensile strength Rm (in

oped area to the area of the ring included between the pro- N/mm2), the density δ (in kg/dm3) and the material fac-

peller diameter and the hub diameter. tor f of normally used materials.

88 RINA Rules for Charter Yachts 2006

Pt C, Ch 1, Sec 7

b) Common bronze, special types of bronze and cast steel l : Developed width of blade section at 0,25

used for the construction of propeller hubs and blades radius from propeller axis, in mm

are to have a minimum tensile strength of 400 N/mm 2. z : Number of blades

c) Other materials are subject of special consideration by Rm : Minimum tensile strength of blade material,

RINA following submission of full material specifica- in N/mm2.

tion.

b) The maximum thickness t0.6, in mm, of the solid propel-

Table 3 : Normally used materials ler blade at the section at 0,6 radius from the propeller

for propeller blades and hub axis is not to be less than that obtained from the follow-

ing formula:

Material Rm δ f D 3

0 ,5

1 ,5 .10 6 .ρ 0 ,6 .M T + 18 ,4 .δ. ⎛ ----------⎞ .B .l.N .h

2

⎝ 100⎠

Common brass 400 8,3 7,6 t 0 ,6 = 1 ,66 f ---------------------------------------------------------------------------------------------------------------

l 0 ,6 ⋅ z ⋅ R m

Manganese brass (Cu1) 440 8,3 7,6

Nickel-manganese brass (Cu2) 440 8,3 7,9 where:

Aluminium bronze (Cu3 and 590 7,6 8,3 ρ0,6 : D/H0.6

Cu4) H0.6 : Pitch at 0,6 radius from the propeller axis, in

Steel 440 7,9 9,0 m

l0.6 : Developed width of blade section at 0,6

2.1.2 Materials for studs radius from propeller axis, in mm.

In general, steel (preferably nickel-steel) is to be used for c) The radius at the blade root is to be at least ¾ of the

manufacturing the studs connecting steel blades to the hub minimum thickness required in that position. As an

of built-up or controllable pitch propellers, and high tensile alternative, constant stress fillets may also be consid-

brass or stainless steel is to be used for studs connecting ered. When measuring the thickness of the blade, the

bronze blades. increased thickness due to the radius of the fillet at the

root of the blade is not to be taken into account. If the

2.2 Solid propellers - Blade thickness propeller hub extends over 0,25 radius, the thickness

calculated by the formula in a) is to be compared with

2.2.1 the thickness obtained by linear interpolation of the

a) The maximum thickness t0.25, in mm, of the solid propel- actual blade thickness up to 0,25 radius.

ler blade at the section at 0,25 radius from the propeller d) As an alternative to the above formulae, a detailed

axis is not to be less than that obtained from the follow- hydrodynamic load and stress analysis carried out by

ing formula: the propeller designer may be considered by RINA, on a

0 ,5 case by case basis. The safety factor to be used in this

D 3

1 ,5 .10 6 .ρ.M T + 51.δ. ⎛ ----------⎞ .B .l.N .h

2

⎝ 100⎠

analysis is not to be less than 8 with respect to the ulti-

t 0 ,25 = 2 ,8 f ⋅ ----------------------------------------------------------------------------------------------------- mate tensile strength of the propeller material Rm.

l ⋅ z ⋅ Rm

2.3 Built-up propellers and controllable

where:

pitch propellers

f : Material factor as indicated in Sec 8, Tab 3

ρ : D/H 2.3.1 Blade thickness

H : Mean pitch of propeller, in m. When H is a) The maximum thickness t0.35, in mm, of the blade at the

not known, the pitch H0.7 at 0,7 radius from section at 0,7 radius from the propeller axis is not to be

the propeller axis, may be used instead of less than that obtained from the following formula:

H. 0 ,5

D 3

1 ,5 .10 .ρ 0 ,7 .M T + 41 .δ ⎛ ----------⎞ B.l 0 ,35 .N h

6 2

D : Propeller diameter, in m ⎝ 100⎠

MT : Continuous transmitted torque, in kN.m; t 0 ,35 = 2 ,36 f -----------------------------------------------------------------------------------------------------------

l 0 ,35 ⋅ z ⋅ R m

where not indicated, the value given by the

following formula may be assumed for MT :

where:

P ρ0,7 : D/H0.7

M T = 9 ,55 ⋅ ⎛ ----⎞

⎝ N⎠

H0.7 : Pitch at 0,7 radius from the propeller axis, in

P : Power, in KW, of propulsion machinery, m. The pitch to be used in the formula is the

according to Sec 1, [2.6] actual pitch of the propeller when the pro-

N : Rotational speed of the propeller, in rev/min peller develops the maximum thrust.

δ : Density of blade material, in kg/dm 3, as l0.35 : Developed width of blade section at 0,35

indicated in Sec 8, Tab 3 radius from propeller axis, in mm.

B : Expanded area ratio b) The maximum thickness t0.6, in mm, of the propeller

h : Rake, in mm blade at the section at 0,6 radius from the propeller axis

RINA Rules for Charter Yachts 2006 89

Pt C, Ch 1, Sec 7

is not to be less than that obtained from the formula in 2.4.2 Highly skewed propellers

[2.2.1], item b, using the value of l0,35 in lieu of l. a) For solid and controllable pitch propellers having skew

c) The radius at the blade root is to be at least ¾ of the angles between 25o and 50o, the blade thickness, in

minimum thickness required in that position. As an mm, is not to be less than that obtained from the follow-

alternative, constant stress fillets may also be consid- ing formulae:

ered. When measuring the thickness of the blade, the 1) For solid propellers

increased thickness due to the radius of the fillet at the

t S – 0 ,25 = t 0 ,25 ⋅ ( 0 ,92 + 0 ,0032 ϑ )

root of the blade is not to be taken into account.

2) For built-up and controllable pitch propellers

d) As an alternative to the above formulae, a detailed

hydrodynamic load and stress analysis carried out by t S – 0 ,35 = t 0 ,35 ⋅ ( 0 ,9 + 0 ,004ϑ )

the propeller designer may be considered by RINA, on a 3) For all propellers

case by case basis. The safety factor to be used in this

t S – 0 ,6 = t 0 ,6 ⋅ ( 0 ,74 + 0 ,0129ϑ – 0 ,0001ϑ )

2

analysis is not to be less than 8 with respect to the ulti-

mate tensile strength of the propeller blade material Rm. t S – 0 ,9 = t 0 ,6 ⋅ ( 0 ,35 + 0 ,0015ϑ )

where:

2.3.2 Flanges for connection of blades to hubs

tS-0,25 : Maximum thickness, in mm, of skewed pro-

a) The diameter DF, in mm, of the flange for connection to

peller blade at the section at 0,25 radius

the propeller hub is not to be less than that obtained from the propeller axis

from the following formula:

t0,25 : Maximum thickness, in mm, of normal

D F = D C + 1 ,8 d PR shape propeller blade at the section at 0,25

where: radius from the propeller axis, obtained by

the formula in [2.2.1]

DC : Stud pitch circle diameter, in mm

tS-0,35 : Maximum thickness, in mm, of skewed pro-

dPR : Diameter of studs. peller blade at the section at 0,35 radius

b) The thickness of the flange is not to be less than 1/10 of from the propeller axis

the diameter DF. t0,35 : Maximum thickness, in mm, of normal

shape propeller blade at the section at 0,35

2.3.3 Connecting studs radius from the propeller axis, obtained by

the formula in [2.3.1]

a) The diameter dPR, in mm, at the bottom of the thread of

the studs is not to be less than that obtained from the tS-0,6 : Maximum thickness, in mm, of skewed pro-

following formula: peller blade at the section at 0,6 radius from

the propeller axis

0 ,5

7 D3 2

⎛ 4 ,6 .10 .ρ 0 ,7 .M T + 0 ,88 .δ. ------ .B.l 0 ,35 .N .h 1⎞ t0,6 : Maximum thickness, in mm, of normal

10

⎜ ---------------------------------------------------------------------------------------------------------------

d PR = -⎟ ⋅ 0,9 shape propeller blade at the section at 0,6

⎜ n PR ⋅ z ⋅ D C ⋅ R m ,PR ⎟

⎝ ⎠ radius from the propeller axis, obtained by

the formula in [2.2.1]

where:

tS-0,9 : Maximum thickness, in mm, of skewed pro-

h1 : h + 1,125 DC

peller blade at the section at 0,9 radius from

nPR : Total number of studs in each blade, the propeller axis

Rm,PR : Minimum tensile strength of stud material, ϑ : Skew angle.

in N/mm2. b) As an alternative, highly skewed propellers may be

b) The studs are to be tightened in a controlled manner accepted on the basis of a stress analysis, as stated in

such that the tension on the studs is approximately 60- [2.4.3] for very highly skewed propellers.

70 % of their yield strength.

2.4.3 Very highly skewed propellers

c) The shank of studs may be designed with a minimum For very highly skewed propellers, the blade thickness is to

diameter equal to 0,9 times the root diameter of the be obtained by a stress analysis according to a calculation

thread. criteria accepted by RINA. The safety factor to be used in

this direct analysis is not to be less than 9 with respect to

d) The studs are to be properly secured against uninten-

the ultimate tensile strength of the propeller blade material,

tional loosening.

Rm .

2.4 Skewed propellers

2.5 Ducted propellers

2.4.1 Skewed propellers 2.5.1 The minimum blade thickness of propellers with

The thickness of skewed propeller blades may be obtained wide tip blades running in nozzles is not to be less than the

by the formulae in [2.2] and [2.3.1], as applicable, pro- values obtained by the applicable formula in [2.2] or

vided the skew angle is less than 25o. [2.3.1], increased by 10%.

90 RINA Rules for Charter Yachts 2006

Pt C, Ch 1, Sec 7

2.6 Features rial which is insoluble in sea water and non-corrodible

or fitted with a rubber ring.

2.6.1 Blades and hubs e) All free spaces between the propeller shaft cone, pro-

a) All parts of propellers are to be free of defects and are to peller boss, nut and propeller cap are to be filled with a

be built and installed with clearances and tolerances in material which is insoluble in sea water and non-cor-

accordance with sound marine practice. rodible. Arrangements are to be made to allow any air

present in these spaces to withdraw at the moment of

b) Particular care is to be taken with the surface finish of

filling. It is recommended that these spaces be tested

the blades.

under a pressure at least equal to that corresponding to

2.6.2 Controllable pitch propellers pitch control the immersion of the propeller in order to check the

system tightness obtained after filling.

a) Where the pitch control mechanism is operated hydrau- f) For propeller keys and key area, see Sec 6, [2.5.5].

lically, two independent, power-driven pump sets are to

3.1.2 Shrinkage of keyless propellers

be fitted. For propulsion plants up to 220 kW, one

power-driven pump set is sufficient provided that, in In the case of keyless shrinking of propellers, the following

addition, a hand-operated pump is fitted for controlling requirements apply:

the blade pitch. a) The meaning of the symbols used in the subparagraphs

b) Pitch control systems are to be provided with an engine below is as follows:

room indicator showing the actual setting of the blades. A : 100% theoretical contact area between pro-

Further blade position indicators are to be mounted on peller boss and shaft, as read from plans and

the bridge and in the engine control room, if any. disregarding oil grooves, in mm 2

c) Suitable devices are to be fitted to ensure that an altera- dPM : Diameter of propeller shaft at the mid-point

tion of the blade setting cannot overload the propulsion of the taper in the axial direction, in mm

plant or cause it to stall. dH : Mean outer diameter of propeller hub at the

d) Steps are to be taken to ensure that, in the event of fail- axial position corresponding to dPM, in mm

ure of the control system, the setting of the blades K : K = dH/dPM

• does not change, or F : Tangential force at interface, in N

• assumes a final position slowly enough to allow the MT : Torque transmitted; in N.m, assumed as

emergency control system to be put into operation. indicated in [2.2.1]

e) Controllable pitch propeller systems are to be equipped C : • C = 1 for turbines, geared diesel engines,

with means of emergency control enabling the control- electrical drives and direct-drive recip-

lable pitch propeller to operate should the remote con- rocating internal combustion engines

trol system fail. This requirement may be complied with with a hydraulic, electromagnetic or

by means of a device which locks the propeller blades high elasticity coupling,

in the "ahead" setting. • C = 1,2 for diesel engines having cou-

plings other than those specified above.

f) Tab 4 indicates the monitoring requirements to be dis-

played at the control console. RINA reserves the right to increase the value

of C if the shrinkage needs to absorb an

extremely high pulsating torque,

3 Arrangement and installation

T : Temperature of hub and propeller shaft

material, in °C, assumed for calculation of

3.1 Fitting of propeller on the propeller shaft pull-up length and push-up load

V : yacht speed at P power, in knots

3.1.1 General

S : Continuous thrust developed for free run-

a) Screw propeller hubs are to be properly adjusted and fit-

ning yacht, in N

ted on the propeller shaft cone.

sF : Safety factor against friction slip at 35°C

b) The forward end of the hole in the hub is to have the

θ : Half taper of propeller shaft (for instance:

edge rounded to a radius of approximately 6 mm.

taper = 1/15, θ =1/30)

c) In order to prevent any entry of sea water under the liner µ : Coefficient of friction between mating sur-

and onto the end of the propeller shaft, the arrangement faces

of Fig 4 is generally to be adopted for assembling the

liner and propeller boss. p35 : Surface pressure between mating surfaces,

in N/mm2, at 35°C

d) The external stuffing gland is to be provided with a sea-

pT : Surface pressure, in N/mm 2, between mat-

water resistant rubber ring preferably without joints. The

clearance between the liner and the internal air space of ing surfaces at temperature T

the boss is to be as small as possible. The internal air p0 : Surface pressure between mating surfaces,

space is to be filled with an appropriate protective mate- in N/mm2, at 0°C

RINA Rules for Charter Yachts 2006 91

Pt C, Ch 1, Sec 7

pMAX : Maximum permissible surface pressure, in speed of rotation N of the propeller, plus pulsating

N/mm 2, at 0°C torque due to torsionals.

d35 : Push-up length, in mm, at 35°C i) For the oil injection method, the coefficient of friction µ

is to be 0,13 in the case of bosses made of copper-based

dT : Push-up length, in mm, at temperature T

alloy and steel. For other methods, the coefficient of

dMAX : Maximum permissible pull-up length, in friction will be considered in each case by RINA.

mm, at 0°C

j) The maximum equivalent uni-axial stress in the boss at

WT : Push-up load, in N, at temperature T 0°C, based on the von Mises-Hencky criterion, is not to

σID : Equivalent uni-axial stress in the boss exceed 70% of the minimum yield strength (ReH), or

according to the von Mises-Hencky crite- 0,2% proof stress (Rp0,2), of the propeller material, based

rion, in N/mm 2 on the test piece value. For cast iron, the value of the

above stress is not to exceed 30% of the nominal tensile

αP : Coefficient of linear expansion of shaft

strength.

material, in mm/(mm°C)

k) For the formulae given below, the material properties

αM : Coefficient of linear expansion of boss

indicated in the following items are to be assumed:

material, in mm/(mm°C)

• Modulus of elasticity, in N/mm2:

EP : Value of the modulus of elasticity of shaft

Cast and forged steel: E = 206000

material, in N/ mm 2

Cast iron: E = 98000

EM : Value of the modulus of elasticity of boss

Type Cu1 and Cu2 brass: E = 108000

material, in N/ mm 2

Type Cu3 and Cu4 brass: E = 118000

νP : Poisson’s ratio for shaft material

• Poisson’s ratio:

νM : Poisson’s ratio for boss material Cast and forged steel: ν = 0,29

RS,MIN : Value of the minimum yield strength (ReH), Cast iron: ν = 0,26

or 0,2% proof stress (Rp 0,2), of propeller boss All copper based alloys: ν = 0,33

material, in N/mm2.

• Coefficient of linear expansion in mm/(mmoC)

For other symbols not defined above, see [2.2].

Cast and forged steel and cast iron: α = 12,0 10-6

b) The manufacturer is to submit together with the All copper based alloys: α = 17,5 10-6

required constructional plans specifications containing

l) For shrinkage calculation the formulae in the following

all elements necessary for verifying the shrinkage. Tests

items, which are valid for the ahead condition, are to be

and checks deemed necessary for verifying the charac-

applied. They will also provide a sufficient margin of

teristics and integrity of the propeller material are also to

safety in the astern condition.

be specified.

• Minimum required surface pressure at 35°C:

c) Moreover, the manufacturer is to submit an instruction

handbook, in which all operations and any precautions sF S F 2 0 ,5

- ⋅ – s F θ + ⎛ µ 2 + B ⋅ ----2-⎞

p 35 = -------

necessary for assembling and disassembling the propel- AB ⎝ S⎠

ler, as well as the values of all relevant parameters, are

to be specified. A copy, endorsed by RINA, is to be kept where:

on board each yacht where the propeller is installed. B = µ2-sF2θ2

d) The formulae and other provisions below do not apply • Corresponding minimum pull-up length at 35°C:

to propellers where a sleeve is introduced between shaft p 35 d PM 1 K 2 + 1- + ν ⎞ + 1 –ν

and boss or in the case of hollow propeller shafts. In d 35 = ---------------- ⋅ ------ ⋅ ⎛ -------------- M --------------P

2θ EM ⎝ K2 – 1 ⎠ EP

such cases, a direct shrinkage calculation is to be sub-

mitted to RINA. • Minimum pull-up length at temperature T (T<35°C):

e) The taper of the propeller shaft cone is not to exceed dP M

d T = d 35 + -------- ⋅ ( αM – α P ) ⋅ ( 35 – T )

1/15. 2θ

f) Prior to final pull-up, the contact area between the mat- • Corresponding minimum surface pressure at tem-

ing surfaces is to be checked and is not to be less than perature T:

70% of the theoretical contact area (100%). Non-con- d

tact bands extending circumferentially around the boss p T = p 35 ⋅ ------T-

d 35

or over the full length of the boss are not acceptable.

• Minimum push-up load temperature T:

g) After final push-up, the propeller is to be secured by a

WT = Ap T ⋅ ( µ + θ )

nut on the propeller shaft. The nut is to be secured to

the shaft. • Maximum permissible surface pressure at 0°C:

h) The safety factor sF against friction slip at 35°C is not to 0 ,7R S ,M I N ⋅ ( K 2 – 1 )

p M A X = -----------------------------------------------

be less than 2,8, under the combined action of torque ( 3 K 4 + 1 ) 0 ,5

and propeller thrust, based on the power P in kW, • Corresponding maximum permissible pull-up length

assumed as indicated in [2.2.1] at the corresponding at 0°C:

92 RINA Rules for Charter Yachts 2006

Pt C, Ch 1, Sec 7

pM A X 4.2 Testing and inspection

d M A X = d 35 ⋅ -----------

p 35

4.2.1 Inspection of finished propeller

• Tangential force at interface: Finished propellers are to be inspected at the manufac-

turer’s plant by the Surveyor. At least the following checks

2000C M

F = -------------------------T are to be carried out:

d PM

• visual examination of the entire surface of the propeller

• Continuous thrust developed for free running yacht; blades

if the actual value is not given, the value, in N, cal- • conformity to approved plans of blade profile

culated by one of the following formulae may be • liquid penetrant examination of suspected and critical

considered: parts of the propeller blade, to the satisfaction of the

P Surveyor.

S = 1760 ⋅ ----

V

4.2.2 Controllable pitch propellers

P

S = 57 ,3 ⋅ 10 3 ⋅ ------------- The complete hydraulic system for the control of the con-

H⋅N

trollable pitch propeller mechanism is to be hydrotested at

a pressure equal to 1,5 times the design pressure. The

3.1.3 Circulating currents proper operation of the safety valve is to be tested in the

Means are to be provided to prevent circulating electric presence of the Surveyor.

currents from developing between the propeller and the

4.2.3 Balancing

hull. A description of the type of protection provided and its

Finished propellers are to be statically balanced. For built-

maintenance is to be kept on board.

up and controllable pitch propellers, the required static bal-

ancing of the complete propeller may be replaced by an

4 Testing and certification individual check of blade weight and gravity centre posi-

tion.

4.1 Material tests 4.3 Certification

4.1.1 Solid propellers 4.3.1 Certification of propellers

Material used for the construction of solid propellers is to be Propellers having the characteristics indicated in [1.1.1] are

tested in accordance with the requirements of Part D of the to be individually tested and certified. RINA’s inspection

Rules in the presence of the Surveyor. certificate (see Pt D, Ch 1, Sec 1, [4.2.1] and Pt D, Ch 1,

Sec 1, [4.2.2]) are required for material test of propeller and

each relevant component when intended to yachts to be

4.1.2 Built-up propellers and controllable pitch

propellers assigned with ✠ MACH notation.

In addition to the requirement in [4.1.1], materials for studs 4.3.2 Mass produced propellers

and for all other parts of the mechanism transmitting torque Mass produced propellers may be accepted within the

are to be tested in the presence of the Surveyor. framework of the type approval program of RINA.

Table 4 : Controllable pitch propeller monitoring

Symbol convention Automatic control

H = High, HH = High high, G = group alarm

Monitoring

L = Low, LL = Low low, I = individual alarm

Main Engine Auxiliary

X = function is required, R = remote

Slow- Shut- Stand

Identification of system parameter Alarm Indic Control Stop

down down by Start

Oil tank level L

RINA Rules for Charter Yachts 2006 93

Pt C, Ch 1, Sec 7

Figure 4 : Example of sealing arrangement

GLAND

PROPELLER

BOSS

MASTIC OR GREASE

OR RUBBER LINER

RUBBER JOINT

SHAFT

94 RINA Rules for Charter Yachts 2006

You might also like

- Astm f2506Document5 pagesAstm f2506rosanaNo ratings yet

- As-Nz 1170.2.2002 - WindloadDocument24 pagesAs-Nz 1170.2.2002 - WindloadQuang Hoành Lê100% (1)

- CAIP Vol II PropellersDocument32 pagesCAIP Vol II PropellersSHM 555No ratings yet

- Henle FYL Syllabus Year OneDocument4 pagesHenle FYL Syllabus Year OneJennifer Jones100% (2)

- Arma 3 Editor GuideDocument31 pagesArma 3 Editor Guideaaronsmith812732100% (1)

- Module 1: Flywheel Outcomes: Me 413A - Machine Design 2 (Isat U Lecture Notes)Document8 pagesModule 1: Flywheel Outcomes: Me 413A - Machine Design 2 (Isat U Lecture Notes)Geoffrey Golbeque100% (1)

- Central Flying School Volume - 12 - HelicoptersDocument163 pagesCentral Flying School Volume - 12 - Helicoptersuser100% (1)

- Austroads 92 Bridge Design Code PDFDocument7 pagesAustroads 92 Bridge Design Code PDFLachy NicolNo ratings yet

- Is 14846Document24 pagesIs 14846rinabiswas100% (1)

- General Controls: (Acc 401B - Auditing EDP Environment)Document9 pagesGeneral Controls: (Acc 401B - Auditing EDP Environment)Pines MacapagalNo ratings yet

- FM Patterson Driveshaft IOMDocument22 pagesFM Patterson Driveshaft IOMeaywdjw2070No ratings yet

- Michigan Wheel Propeller GeometryDocument18 pagesMichigan Wheel Propeller GeometryAdelia PratiwiNo ratings yet

- Pooyan Hydraulics: Description Symbol ApplicationDocument20 pagesPooyan Hydraulics: Description Symbol Applicationrmajdi2000100% (2)

- DIN 4132 SupplementDocument12 pagesDIN 4132 SupplementDylkanWingsNo ratings yet

- Machine Element Design Chapter 2 (Diploma)Document75 pagesMachine Element Design Chapter 2 (Diploma)Ahmad Luqman NurhakimNo ratings yet

- Asme Sec Viii D1 Nma App L PDFDocument57 pagesAsme Sec Viii D1 Nma App L PDFADRIANNo ratings yet

- Braid ComparisonsDocument7 pagesBraid ComparisonsluyawinNo ratings yet

- Uso, Instalación de CardanDocument14 pagesUso, Instalación de Cardansemagor100% (1)

- BV Prop ThicknessDocument8 pagesBV Prop ThicknessAndreas ArapakopoulosNo ratings yet

- F1005-91 (2013) Standard Practice For HVAC Duct Shapes Identification and Description of Design ConfigurationDocument19 pagesF1005-91 (2013) Standard Practice For HVAC Duct Shapes Identification and Description of Design ConfigurationislamakthamNo ratings yet

- HVAC Duct Shapes Identification and Description of Design ConfigurationDocument19 pagesHVAC Duct Shapes Identification and Description of Design ConfigurationDarwin DarmawanNo ratings yet

- THURUSTERSDocument5 pagesTHURUSTERSHari RamNo ratings yet

- (Stering Gear)Document13 pages(Stering Gear)Hari RamNo ratings yet

- BKI Vol3 - Section04Document6 pagesBKI Vol3 - Section04Iwan BopengNo ratings yet

- Roller CleanedDocument2 pagesRoller CleanedalexforteNo ratings yet

- Abs Prop ThicknessDocument12 pagesAbs Prop ThicknessAndreas ArapakopoulosNo ratings yet

- (Gearing)Document13 pages(Gearing)Hari RamNo ratings yet

- Corrigendas 2001Document26 pagesCorrigendas 2001AndréMenezesNo ratings yet

- Asme B18.1.2 2001Document3 pagesAsme B18.1.2 2001Jesse ChenNo ratings yet

- RINA PartBCap10Sect01Document23 pagesRINA PartBCap10Sect01ilgirasolepozzalloNo ratings yet

- 100-32-14 Rev 0 K0654Document4 pages100-32-14 Rev 0 K0654mohsenhfdNo ratings yet

- S27 Strength Requirements For Fore Deck Fittings and Equipment S27Document7 pagesS27 Strength Requirements For Fore Deck Fittings and Equipment S27dsrfgNo ratings yet

- Project 2Document36 pagesProject 2Adekunte OluwasolafunmiNo ratings yet

- Assembly Instruction IRB 840/ADocument54 pagesAssembly Instruction IRB 840/Aredoctober24No ratings yet

- 100 007 528c - RotaryActuator215Document20 pages100 007 528c - RotaryActuator215Andrean SuryaNo ratings yet

- Modu 20 PropellerDocument56 pagesModu 20 PropellerHAFIDY RIZKY ILHAMSYAHNo ratings yet

- ApplicationDocument2 pagesApplicationHari RamNo ratings yet

- Selection of Structural Details For Ship ConstructionDocument19 pagesSelection of Structural Details For Ship ConstructionEduardoNo ratings yet

- S10 Rudders, Sole Pieces and Rudder Horns S10Document37 pagesS10 Rudders, Sole Pieces and Rudder Horns S10mohammed attiaNo ratings yet

- IS 802 (Part 1 Sec 1) 2015 - 1Document25 pagesIS 802 (Part 1 Sec 1) 2015 - 1mohammad zuefNo ratings yet

- Design and Testing of Fixed-Pitch or Ground Adjustable Light Sport Aircraft PropellersDocument4 pagesDesign and Testing of Fixed-Pitch or Ground Adjustable Light Sport Aircraft PropellersAhmad Zubair RasulyNo ratings yet

- Ur S10rev6Document37 pagesUr S10rev6Maan MrabetNo ratings yet

- A 503 - A 503M - 99 Qtuwmy05oqDocument3 pagesA 503 - A 503M - 99 Qtuwmy05oqCHRISTIAN ZAVALANo ratings yet

- 421 1r-08webDocument2 pages421 1r-08webdhiNo ratings yet

- BS 185-9Document8 pagesBS 185-9SugiharnoNo ratings yet

- Aircraft Propellers: Arnaud GrandfilsDocument8 pagesAircraft Propellers: Arnaud GrandfilsVishnu RamNo ratings yet

- 60m Roshan TowDesgnRprtDocument93 pages60m Roshan TowDesgnRprtkamrankhanNo ratings yet

- Annular Ball Bearings For Instruments and Precision Rotating ComponentsDocument145 pagesAnnular Ball Bearings For Instruments and Precision Rotating ComponentsDarwin DarmawanNo ratings yet

- Ships For Dredger ActivityDocument1 pageShips For Dredger ActivityJon LopezNo ratings yet

- Design and Analysis Trends of Helicopter Rotor SystemsDocument40 pagesDesign and Analysis Trends of Helicopter Rotor SystemsHasan ÖzgenNo ratings yet

- Design Bladed Darrieus Rotor River Turbines: StraightDocument6 pagesDesign Bladed Darrieus Rotor River Turbines: StraightBorja Garcia SastreNo ratings yet

- A 503 - A 503M - 01 R01 Qtuwmy9bntaztqDocument3 pagesA 503 - A 503M - 01 R01 Qtuwmy9bntaztqCHRISTIAN ZAVALANo ratings yet

- Ur s10 r4 - Corr1 Dec 2015 CLNDocument37 pagesUr s10 r4 - Corr1 Dec 2015 CLNJanisha B L na20b024No ratings yet

- Segun GLDocument1 pageSegun GLfina ginoNo ratings yet

- Chapter 2 Unswept Wing Static Aeroelasticity 2.1. Typical Section ModelDocument30 pagesChapter 2 Unswept Wing Static Aeroelasticity 2.1. Typical Section ModelB K LNo ratings yet

- Design Procedure and Examples: TtachmentDocument12 pagesDesign Procedure and Examples: Ttachmentgtroad1No ratings yet

- Astm F 2332 2006Document143 pagesAstm F 2332 2006zulal.dogruelNo ratings yet

- Hydraulic Fluid Power - CylindersDocument6 pagesHydraulic Fluid Power - CylindersRenuNo ratings yet

- Blade Erato Blue OrıgınDocument14 pagesBlade Erato Blue OrıgınaircarmediaNo ratings yet

- Information For Construction Sites Installation of Bridge BearingsDocument15 pagesInformation For Construction Sites Installation of Bridge BearingsMiguel Belda DiezNo ratings yet

- Lndian Standard: Penstock and Turbine Inlet Butterfly Valves For Hydropower Stations and SystemsDocument12 pagesLndian Standard: Penstock and Turbine Inlet Butterfly Valves For Hydropower Stations and SystemsGREYHOUND ENGINEERS INDIA INDIA PVT.LTDNo ratings yet

- A503.2001 Ultrasonic Examination of Forged CrankshaftsDocument3 pagesA503.2001 Ultrasonic Examination of Forged CrankshaftsEHT pipeNo ratings yet

- Modeling of Complex Systems: Application to Aeronautical DynamicsFrom EverandModeling of Complex Systems: Application to Aeronautical DynamicsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- TransferCFT InstallationGuide Windows enDocument203 pagesTransferCFT InstallationGuide Windows enMoussa GbanetNo ratings yet

- 1.uniform BendingDocument16 pages1.uniform BendingAdrian GilbyNo ratings yet

- Lab Report Exp 1 Aishah Nazirah Ed260Document8 pagesLab Report Exp 1 Aishah Nazirah Ed260nuraishahnazirahzNo ratings yet

- Chapter-9-Simple Linear Regression & CorrelationDocument11 pagesChapter-9-Simple Linear Regression & Correlationdawitdafe4No ratings yet

- 4825D PDFDocument5 pages4825D PDFaldo_suvi100% (1)

- Catalogo Seko Tekna EvoDocument12 pagesCatalogo Seko Tekna EvoJonathan VillagraNo ratings yet

- Q3StatisticsProbability LESSONSDocument94 pagesQ3StatisticsProbability LESSONSRoshel Lopez0% (1)

- MAE 150 Homework 6Document12 pagesMAE 150 Homework 6Zerbin GisNo ratings yet

- DC-DC Simulation Lab 2Document4 pagesDC-DC Simulation Lab 2Hira SaghirNo ratings yet

- MR301 Series: DimensionsDocument3 pagesMR301 Series: DimensionsВолодя МачковNo ratings yet

- Chapter10 - Section3Document40 pagesChapter10 - Section3Đạt NguyễnNo ratings yet

- National Achievement Test 2 2022 2023Document67 pagesNational Achievement Test 2 2022 2023Jessie CentillasNo ratings yet

- DM Question Bank For - 2nd Mid ExamsDocument3 pagesDM Question Bank For - 2nd Mid ExamsGAJULA ANANDPRAVEENKUMARNo ratings yet

- Seminar Report Solar TreeDocument30 pagesSeminar Report Solar TreeAshish Kumar100% (1)

- DocumentDocument34 pagesDocumentHerberth SilitongaNo ratings yet

- Ics For Consumer ElectronicsDocument29 pagesIcs For Consumer ElectronicsEduardo SierraNo ratings yet

- DCCN Unit 1Document13 pagesDCCN Unit 1Dinesh PalavalasaNo ratings yet

- 180 Years of Atmospheric CO2 Gas Analysis by Chemical MethodsDocument25 pages180 Years of Atmospheric CO2 Gas Analysis by Chemical MethodsJack StrikerNo ratings yet

- Linear Model Predictive Control: Stability and RobustnessDocument98 pagesLinear Model Predictive Control: Stability and RobustnessKhawar RiazNo ratings yet

- Manual New PDFDocument58 pagesManual New PDFKumar SauravNo ratings yet

- Students DataDocument14 pagesStudents DatasnehalNo ratings yet

- Modulo Hart Ml200 Ug 2mlf-Ac4h Ai 200Document175 pagesModulo Hart Ml200 Ug 2mlf-Ac4h Ai 200rdelgariNo ratings yet

- Tinajeros National High SchoolDocument2 pagesTinajeros National High SchoolJoshua PorcadillaNo ratings yet