Professional Documents

Culture Documents

.Formats Numbers List and File No's

.Formats Numbers List and File No's

Uploaded by

quality30 ratings0% found this document useful (0 votes)

3 views1 pageOriginal Title

.formats Numbers List And File No's

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 page.Formats Numbers List and File No's

.Formats Numbers List and File No's

Uploaded by

quality3Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 1

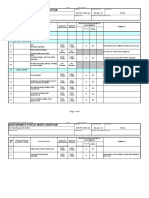

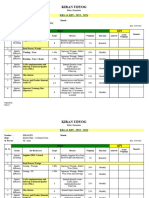

Kiran Udyog, Bidar

Section :- Yarn Incoming, Winding Section And Braiding Section Coating & Final Inspection / PDI (List Of File's)

S.No Doc. No Document Section Remark

SECTION:- ALL SECTION CONTROL PLAN

1 KU/QA - CP/001 INCOMING INSPECTION PROCESS INCOMING INSPECTION

2 KU/QA - CP/002 WINDING PROCESS WINDING SECTION

3 KU/QA - CP/003 BRADING PROCESS BRADING SECTION

4 KU/QA - CP/004 Cord Process BRADING SECTION

5 KU/QA - CP/005 CUSTOMER WISE PROCES PARAMETER COATING SECTION

Yarn Incoming Process File No 01

6 KU/QA - CP/001 INCOMING INSPECTION PROCESS CONTROL PLAN INCOMING INSPECTION

7 KU/QA/004 INCOMING INSPECTION SAMPLING PLAN INCOMING INSPECTION

8 KU/QA/012 List of Instrument & Equipment INCOMING INSPECTION

9 KU/QA/004 INCOMING QUALITY PLAN INCOMING INSPECTION

QAD-T-3.17 /

10 WORK INSRUCTIONS – INCOMING INSPECTION INCOMING INSPECTION

F/KU/QAD/1-R00

11 KU/QA/IIR-004 YARN INCOMING INSPECTION REPORT INCOMING INSPECTION

Winding Process File No 02

12 KU/QA - CP/002 WINDING PROCESS WINDING SECTION

13 KU/QA/003 WINDING INSPECTION SAMPLING PLAN WINDING SECTION

14 KU/QA/005 YARN TENSION SETTING PARAMETERS WINDING SECTION

15 KU/QA/006 METER SETTING PARAMETERS IN WEIGHT WINDING SECTION

16 KU/QA/IIR-001 SET UP APRPOVAL & INPROCESS INSPECTION REPORT WINDING SECTION

17 KU/QA/007 WORK INSRUCTIONS FOR YARN TENSION CHECKING WINDING SECTION

18 KU/PD/WS COLOUR IDENTIFICATION CODE FOR TRACKING SYSTEM WINDING SECTION

19 KU/QA/008 DEFECTS BOBBIN WINDING SECTION WINDING SECTION

KU/QA/009 / Production

20 OPERATOR LIST - SKILL MATRIX WINDING SECTION WINDING SECTION

KU/QA/010 (Mr. Ravi M)

21 KU/QA/011 TRAINING CALENDAR PLAN WINDING SECTION

22 KU/QA/012 List of Instrument & Equipment WINDING SECTION

Braiding Process File No 03

23 KU/QA - CP/003 BRADING PROCESS CONTROL PLAN BRADING SECTION

24 KU/QA - CP/004 Cord Process CONTROL PLAN BRADING SECTION

BRADING SECTION - PRODUCT MACHINE PARAMETERS

25 KU/QA/013 BRADING SECTION

(Braid, Fire Braid, F.g Cord, Flat hose.)

26 KU/QA/003 QUALITY DEPT – BRAIDING INSPECTION SAMPLING PLAN BRADING SECTION

27 KU/QA/027 BRADING SECTION - BRAID BUNDAL LENGTH BRADING SECTION

28 KU/QA/012 Braiding Section - List of Instrument & Equipment BRADING SECTION

29 KU/QA/IIR-002 MACHINE SETUP APPROVAL INSPECTION REPROT BRADING SECTION

30 KU/QA/IIR-005 BRAIDING SECTION INPROCESS INSPECTION REPORT BRADING SECTION

31 KU/QA/014 QUALITY DEPT – BRAID / CORD DEFECTS – BRADING SECTION BRADING SECTION

KU/QA/016 Minimum Skill Matrix. Year 2023-24 (Braiding) Operators Production

32 BRADING SECTION

KU/Braiding/Prod.-001 APPROVED OPERATOR LIST - BRAIDING SECTION (Mr. Ravi M)

BRADING SECTION - CORD AND FLOTHOSE FINAL PACKIG FLOTHOSE - CORD

33 KU/QA/018

STANDARD LENTH BRAIDING SECTION

KU/QA/017 BRADING SECTION - WORK INSRUCTIONS

34 BRADING SECTION

QAD-T-3.18 SOP

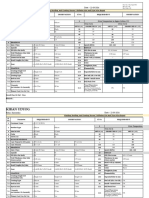

Coating Process File No 04

35 KU/QA - CP/005 CUSTOMER WISE PROCES PARAMETER CONTROL PLAN Coating Section

36 KU/QA/020 COATING SECTION - PRODUCT PROCESS PARAMETERS Coating Section

37 QMS-T-3.12 CALIBRATION PLAN FOR THE YEAR OF 2023-24 Coating Section

38 KU/QA/021 Coating & Tasting Lab Section - List of Instrument & Equipment Coating Section

39 QAD-T-3.12 PROCESS START UP APPROVAL / ONLINE INSPECTION REPORT Coating Section

40 KU/QA/023 QUALITY DEPARTMENT - TOWER WISE TEMPERATURE SETTING Coating Section

QUALITY DEPARTMENT - VISCOSITY CHART FOR ACRYLIC CLASS

41 KU/QA/019 Coating Section

SLEEVES

KU/QA/022

42 SOP's Lab, And Coating, / Work Instruction, Quality Plan's. Coating Section

F/KU/QAD/1-R00

PDI / Final Inspection File No 05

43 KU/QA/026 QUALITY DEPARTMENT - CUSTOMER WISE CODES Final Inspection

44 KU/QA/025 QUALITY DEPARTMENT - CUSTOMER WISE STICKERS Final Inspection

45 KU/QA/024 QUALITY DEPARTMENT - STANDARD PACKING DETAILS Final Inspection

46 QAD-T-3.19 TC (Test Report) Final Inspection

47 QAD-T-3.19 Final Inspection Report Final Inspection

48 CAPA Customer Complaint Register - 2023-24 PDI

Organization Chart

49 KU/SLEEVE/HR - 001 Organization Chart Winding, Braiding, Coating And Final PDI Inspection

50 DWM (Daily Work Management)

Quality Skill Matrix 2023-24 File 04

Quality Inspectors Winding, Braiding

51 KU/QA/026

Lab Tasting Inspectors Coating

KRA - KPI 2023-24 File 04

52 KU/MR/01 Process and Product Internal Audit NC

53 --- Kaizen

54 --- Braiding & Winding Training Record

55 --- Supplier PPM - Yarn

Quality In Process Wastage - NC

Winding - Yarn

56 ---

Braiding - Yarn + Braid

Coating - Wastage

Quality In Process

57 ---

CAPA implementation and follow-up of Internal Quality issues (Min.).

Quality In Process

58 ---

Operator Training (Min. Operators')

You might also like

- Coating ProcuduresDocument15 pagesCoating ProcuduresThinh NguyenNo ratings yet

- Chilled Water Piping SystemDocument36 pagesChilled Water Piping Systemchetanvmak100% (2)

- Understanding AutismDocument50 pagesUnderstanding AutismKaren Bray WellsNo ratings yet

- 028120-SPL-005 Pipeline Installation Rev. CDocument36 pages028120-SPL-005 Pipeline Installation Rev. CRokan Pipeline100% (7)

- Risk AssessmentDocument8 pagesRisk AssessmentSubhransu Mohapatra50% (2)

- Saudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilDocument2 pagesSaudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilSatheesh Rama SamyNo ratings yet

- Holistic DentistryDocument13 pagesHolistic Dentistrydnybell50% (2)

- Form RegisterDocument12 pagesForm RegisterCRISTIAN SILVIU IANUCNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- SATIP-P-104-02 Rev 7 FinalDocument3 pagesSATIP-P-104-02 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Quality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Document9 pagesQuality Assurance Plan FOR Hot Induction Bend: Format No. Rev. No. 01 Rev. Date 20.02.2020 RMTL-KCS-QA&C-FF-001Sachin KumarNo ratings yet

- Method Statement For Data & Communication Equipments & FOC InstallationDocument13 pagesMethod Statement For Data & Communication Equipments & FOC InstallationziaurrehmanNo ratings yet

- MS AND JSA SG6427-SY-CN0P-MTD-736-005 - Method Statement of Conduit Installation - RevbDocument25 pagesMS AND JSA SG6427-SY-CN0P-MTD-736-005 - Method Statement of Conduit Installation - Revbbrian sanchezNo ratings yet

- Multiple AllelesDocument12 pagesMultiple AllelesAmy LalringhluaniNo ratings yet

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDocument15 pagesQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNo ratings yet

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- Itp - Rev eDocument36 pagesItp - Rev ezaki_saddarNo ratings yet

- Field Quality Control PlanDocument59 pagesField Quality Control Plan1339979100% (2)

- SATIP D 001 01 (Revision 4)Document3 pagesSATIP D 001 01 (Revision 4)Anonymous 4e7GNjzGW100% (1)

- Satip-K-001-12 - Tab of Hvac SystemDocument2 pagesSatip-K-001-12 - Tab of Hvac Systemimrankhan22No ratings yet

- Site Acceptance Test (SAT) ProcedureDocument12 pagesSite Acceptance Test (SAT) Procedurealokc100% (2)

- 219-295-Complete MRB PDFDocument220 pages219-295-Complete MRB PDFMuthazhagan SaravananNo ratings yet

- Valves Annexure - Ii Sotr GT25110000MDocument92 pagesValves Annexure - Ii Sotr GT25110000MSrinivas KundrapuNo ratings yet

- 1 SATIP-L-108-01 Valve Installation-Rev 2Document15 pages1 SATIP-L-108-01 Valve Installation-Rev 2Md ShariqueNo ratings yet

- HAZOP Analysis of Group 15: Isaac Law Shek Xiang Harvind Rajamanickam Shanmugam MuthusamyDocument2 pagesHAZOP Analysis of Group 15: Isaac Law Shek Xiang Harvind Rajamanickam Shanmugam Muthusamyvijaymoorthy14No ratings yet

- Mumps PresentationDocument15 pagesMumps PresentationMoney MotivationNo ratings yet

- Plant Pathology McGrawDocument865 pagesPlant Pathology McGrawAnjali OjhaNo ratings yet

- Mabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkDocument38 pagesMabruk Phase 4 Project: Procedure For Welded Joints of Process and Utility PipeworkJabel Oil Services Technical DPTNo ratings yet

- SA JER PI 801 GCCC 59 0035 Custody Metering System Rev.03Document17 pagesSA JER PI 801 GCCC 59 0035 Custody Metering System Rev.03sivin001100% (2)

- CPM Coc 22 010Document16 pagesCPM Coc 22 010Mark Darrel AranasNo ratings yet

- SATIP-K-001-08 - Air Filtration Devices and Grease FilterDocument2 pagesSATIP-K-001-08 - Air Filtration Devices and Grease Filterimrankhan22No ratings yet

- T80-ZA-E-2204072 - Installation of Cable Tray, PDFDocument19 pagesT80-ZA-E-2204072 - Installation of Cable Tray, PDFNezinNo ratings yet

- SATIP-K-001-02 Rev 6 Air-Handling Unit (AHU)Document4 pagesSATIP-K-001-02 Rev 6 Air-Handling Unit (AHU)imrankhan22No ratings yet

- SG6427-SY-CK0P-MTD-736-001 - Rev.B-Method Statement For Instrument Cabling WorksDocument12 pagesSG6427-SY-CK0P-MTD-736-001 - Rev.B-Method Statement For Instrument Cabling Worksbrian sanchezNo ratings yet

- Aptis G&V Old WB Tests 1,2,3 and AnswersDocument35 pagesAptis G&V Old WB Tests 1,2,3 and AnswersOlivia Marie McardleNo ratings yet

- MD1-0-T-030-05-00370-C - ITP For CFBC Boiler Installation-ICDocument151 pagesMD1-0-T-030-05-00370-C - ITP For CFBC Boiler Installation-ICTran KhuynhNo ratings yet

- IONE-AA00-PE-QA-0021 UT Procedure - Rev - 0Document29 pagesIONE-AA00-PE-QA-0021 UT Procedure - Rev - 0Firas AlbaweiNo ratings yet

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Document3 pages1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Ione-Aa00-Pe-Cm-0032 Mechanical Run-In Test Procedure - Rev. ADocument20 pagesIone-Aa00-Pe-Cm-0032 Mechanical Run-In Test Procedure - Rev. AYusuf100% (1)

- Cold Cut Tie-In Procedure 24'' Bypass LineDocument14 pagesCold Cut Tie-In Procedure 24'' Bypass LineMahaboob Pasha100% (1)

- Mechanical Drive of The Separator Sepol: Machine Manual En-22455.202-FDocument25 pagesMechanical Drive of The Separator Sepol: Machine Manual En-22455.202-FRahmat HidayatNo ratings yet

- Satip-X-600-02 Rev 1 For CP SystemDocument4 pagesSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedNo ratings yet

- Air Jet Leak Test ProcedureDocument9 pagesAir Jet Leak Test ProceduredanangNo ratings yet

- Inspection & Test Plan For Boxes, (Pull, Junction, Terminal) & EnclosuresDocument2 pagesInspection & Test Plan For Boxes, (Pull, Junction, Terminal) & EnclosuressartajNo ratings yet

- Qa/Qc Organization Chart: Office SiteDocument5 pagesQa/Qc Organization Chart: Office SitefahrudinNo ratings yet

- MS For Field Instrument, IA Piping & Tubing InstallationDocument10 pagesMS For Field Instrument, IA Piping & Tubing InstallationnoelNo ratings yet

- 1000-Igcc-G000-Isgp-G00000-Qa-6050-00002 03aDocument28 pages1000-Igcc-G000-Isgp-G00000-Qa-6050-00002 03aAhmedNo ratings yet

- BST Gen Cns Mos Aip 10003 10002 00 Pin BrazingDocument67 pagesBST Gen Cns Mos Aip 10003 10002 00 Pin BrazingRao DharmaNo ratings yet

- Satip D 100 01Document11 pagesSatip D 100 01Mirza BaigNo ratings yet

- AMNIT-CU-100-PRC-1022-A1 - Instrument Loop Test Procedure 0210Document10 pagesAMNIT-CU-100-PRC-1022-A1 - Instrument Loop Test Procedure 0210nailulfalah17No ratings yet

- Field Engineering Limited: Ogabiri Gas Gathering ProjectDocument27 pagesField Engineering Limited: Ogabiri Gas Gathering ProjectAry PutraNo ratings yet

- Table of ContentDocument12 pagesTable of ContentFaysalNo ratings yet

- QT1 0 Q 030-05-00056 - C - ITP For Pulverizer InstallationDocument27 pagesQT1 0 Q 030-05-00056 - C - ITP For Pulverizer InstallationLâm HuyNo ratings yet

- Final IndexDocument30 pagesFinal Indexaravindhana1a1No ratings yet

- CPM Coc 22 014Document4 pagesCPM Coc 22 014Mark Darrel AranasNo ratings yet

- Ebs1 Aaaa00 Saqa Plin 0006Document31 pagesEbs1 Aaaa00 Saqa Plin 0006SERT-QA/QC- BUZNo ratings yet

- Test Package - NEWDocument14 pagesTest Package - NEWDilshad AhemadNo ratings yet

- Itp FGP 2Document21 pagesItp FGP 2fusionndtNo ratings yet

- Compiled Vol IIDocument69 pagesCompiled Vol IIashish.mathur1No ratings yet

- SQAP For Valves - 01 May 20Document32 pagesSQAP For Valves - 01 May 20Muhammad Zaheer NaivasalNo ratings yet

- QT1 0 Q 030-05-00036 - D - ITP For ESP InstallationDocument26 pagesQT1 0 Q 030-05-00036 - D - ITP For ESP InstallationLâm HuyNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionDocument10 pagesProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiNo ratings yet

- MOS-0570-5685619-00 CombinedDocument11 pagesMOS-0570-5685619-00 Combinedarmsarabia01No ratings yet

- CPM Coc 22 009Document3 pagesCPM Coc 22 009Mark Darrel AranasNo ratings yet

- Quality AuditDocument1 pageQuality AuditDS ChaudharyNo ratings yet

- Method Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Document19 pagesMethod Statement - Installation of Piping (AG & RTR) and Equipments (Pump & Loading Arm)Habib ur rahmanNo ratings yet

- Satip A 004 04Document3 pagesSatip A 004 04Ahmed GamalNo ratings yet

- Yazaki, Chennai New Test Report - 2023Document12 pagesYazaki, Chennai New Test Report - 2023quality3No ratings yet

- TRACKINGDocument4 pagesTRACKINGquality3No ratings yet

- Coating Rejection Report April 2024 GmailDocument49 pagesCoating Rejection Report April 2024 Gmailquality3No ratings yet

- CGT, Ahmednagr New Test Report - 2023Document67 pagesCGT, Ahmednagr New Test Report - 2023quality3No ratings yet

- fORMAT NoDocument1 pagefORMAT Noquality3No ratings yet

- Files IndexDocument1 pageFiles Indexquality3No ratings yet

- Quality KRA - KPIDocument3 pagesQuality KRA - KPIquality3No ratings yet

- DWM - Daily Work ManagementDocument1 pageDWM - Daily Work Managementquality3No ratings yet

- CGT 2.5kv Process Validation Report 12345Document7 pagesCGT 2.5kv Process Validation Report 12345quality3No ratings yet

- List of Instrument & EquipmentDocument1 pageList of Instrument & Equipmentquality3No ratings yet

- List of Operators WindingDocument2 pagesList of Operators Windingquality3No ratings yet

- Machine Breakdown Report - August - 22Document10 pagesMachine Breakdown Report - August - 22quality3No ratings yet

- August 2022 Braid Sent To KU & PackingDocument8 pagesAugust 2022 Braid Sent To KU & Packingquality3No ratings yet

- Yarn DETAILSDocument8 pagesYarn DETAILSquality3No ratings yet

- Yarn AcountbillityDocument2 pagesYarn Acountbillityquality3No ratings yet

- BlackRock Global Investor Pulse Core ReleaseDocument3 pagesBlackRock Global Investor Pulse Core ReleaseJoshua MaherNo ratings yet

- Azolla ZS 68 MSDS PDFDocument5 pagesAzolla ZS 68 MSDS PDFMohamed ElnagdyNo ratings yet

- Instant Download Managerial Economics Theory Applications and Cases Eighth Edition 8th Edition Ebook PDF PDF FREEDocument33 pagesInstant Download Managerial Economics Theory Applications and Cases Eighth Edition 8th Edition Ebook PDF PDF FREEraymond.heras709100% (46)

- 1408 Unit 3 Study Guide Campbell 8thDocument19 pages1408 Unit 3 Study Guide Campbell 8thFaith Palmer100% (1)

- Cancer Writing AssignmentDocument2 pagesCancer Writing AssignmentChege AmbroseNo ratings yet

- 10 1016@j Rser 2015 02 052Document9 pages10 1016@j Rser 2015 02 052salah hamdyNo ratings yet

- Try Out 2 SMK Tahun 2018/2019 Mapel Bahasa InggrisDocument10 pagesTry Out 2 SMK Tahun 2018/2019 Mapel Bahasa InggrisEvans Sii Jr.50% (2)

- Imran Et Al 2022 Development Molecular Docking and in Silico Adme Evaluation of Selective Alr2 Inhibitors For TheDocument12 pagesImran Et Al 2022 Development Molecular Docking and in Silico Adme Evaluation of Selective Alr2 Inhibitors For TheBudi AbutNo ratings yet

- Spe 129157 MsDocument16 pagesSpe 129157 MsFelipe BañosNo ratings yet

- Jesús Pacheco González - Question Sheets City of Glass Fight Club Naked LunchDocument6 pagesJesús Pacheco González - Question Sheets City of Glass Fight Club Naked LunchZúh Malheur BonheurNo ratings yet

- The Effect of Learning Styles On Academic Performance Among MMMC Student: A Cross Sectional StudyDocument11 pagesThe Effect of Learning Styles On Academic Performance Among MMMC Student: A Cross Sectional StudyRedz Der Tsar100% (2)

- NLP-K Brochure - Neuro Linguistic Programming KinesiologyDocument2 pagesNLP-K Brochure - Neuro Linguistic Programming KinesiologyHomeschooling in IndiaNo ratings yet

- Project - (Shoppers Stop)Document48 pagesProject - (Shoppers Stop)Subhrodip GhoshNo ratings yet

- Process of PhotosynthesisDocument2 pagesProcess of PhotosynthesisJennifer Dizon100% (1)

- 3M Scotchweld 10 Universal Contact AdhesiveDocument18 pages3M Scotchweld 10 Universal Contact AdhesiveVictor CarrascoNo ratings yet

- Gulf Stream Could Collapse As Early As 2025Document3 pagesGulf Stream Could Collapse As Early As 2025johnosborneNo ratings yet

- Compact Stainless Steel Water Regulators Specification SheetDocument2 pagesCompact Stainless Steel Water Regulators Specification SheetWattsNo ratings yet

- Pacific Southbay College, IncDocument7 pagesPacific Southbay College, IncRichard FlorentinoNo ratings yet

- Vaccination Act, 1919Document6 pagesVaccination Act, 1919owuraniNo ratings yet

- Digital AddictionDocument3 pagesDigital AddictionTefroy DimayalNo ratings yet