Professional Documents

Culture Documents

03 - C (JOB SAFETY ANALYSIS For LOX Tank-C)

03 - C (JOB SAFETY ANALYSIS For LOX Tank-C)

Uploaded by

AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 - C (JOB SAFETY ANALYSIS For LOX Tank-C)

03 - C (JOB SAFETY ANALYSIS For LOX Tank-C)

Uploaded by

AhmedCopyright:

Available Formats

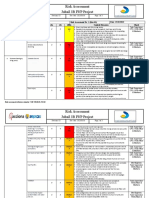

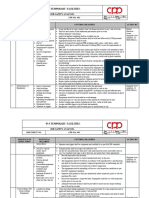

DOC.

#: LION-01-16PQ

PAKISTAN OXYGEN

FORM Issue # 01 Date:

JOB SAFETY ANALYSIS Page 1 of 2 13-Jun-2022

JOB SAFETY ANALYSIS JOB TITLE: Heavy Lift Activity of LOX Tank-C

ANALYSIS BY: HSE Team Lead (GASCO) REVIEWED BY: Project Safety Engineer (POL) DATE: 25-06-2022

Scope (Description of work):

Required and recommended Personal Protective Equipment: Coverall, Safety shoes, Safety helmet ,Safety Gloves, Barricade

safety signage’s, SWL,

Basic Job Steps Potential Hazards Control Measures Responsibility

01 Work Permitting -Human injury PTW signed by authorized person Construction

-Uncontrolled activity Crane must be TPI certified Manager/

-Electrocution HSE team to assess continuously the conditions of Site Supervisor

- Unsafe act work in the assigned area /HSE Represen-

- Unsafe condition Toolbox talks tative

Competency of personnel and supervisory for the

activity

Rigger must be certified

Define hierarchy and reporting flowcharts

Define proper PPE to be used for the work

Check inspection certificates of equipment for the

job

02 Lifting Area Preparation -Uneven ground pavement Hard and level ground

-Material scattered Ensure area is properly prepared for job

-Bed housekeeping Good housekeeping done

-Slip & Trip Material properly segregated and stored

-Overhead utilities Provide proper barricade

-Unauthorized entry Safety signage’s displayed at site

Maintain safe distance from trenches and excava-

tions

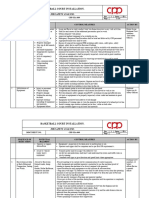

03 Tandem Lifting of LOX Tank-C (Use of - Personal Injury JSA meeting.

Crawler Cranes) - Uncertified Cranes / unin- Follow PTW

spected lifting gears Obtain lifting certificate and follow Rigging Study

Inspection of Cranes prior to start the job

Proper inspection of appropriate lifting gears.

All lifting gears shall be color coded.

Rejected lifting gears to be segregated and re-

moved from worksite.

-Crane failure, improper No reverse without look out. Use of reverse alarm

movement of Trailer Banks man shall be deputed for safe movement

of equipment.

Close monitoring by Area supervisor

Safety slogans to be constructed at work-site.

-Suspended Load Approved lifting plan must be applied before job

- Crane Movement with sus- execution.

pended Load There must be no work under suspended load

Area shall be barricaded and safety signs shall in

place

Use of tag line to control load

Stop working in heavy wind

Supervisor to ensure no Personnel movement un-

der the suspended load including riggers.

Support/suspension must be provided.

-Improper Rigging and Proper rigging/ only rigger is to direct the Lifting

lifting / signal error operation.

Rigger must be certified.

Brief working procedure.

Proper two tag lines should be used during lifting

operation.

Rigging Plan to be made by Gasco and approved

from POL

Direct eye-to-eye contact between signalman and

operator.

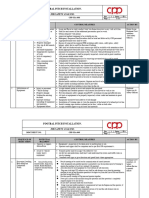

04 Improper Refueling of equipment’s -Fire / ignition source Use proper PPEs

Ensure housekeeping.

Proper refueling arrangements shall be in place

Follow spill control protocol

Diesel fuel operated vehicles should be used at

site.

No permission allowed for gasoline vehicles.

Ensure switch off engine while refueling the

equipment’s

Inspected Fire extinguisher will be provided.

05 Demobilization Poor housekeeping Ensure the area is left tidy and clean after finish-

ing the job.

Area should be rehabilitated in the original con-

dition.

PTW to be closed on completion of job.

Supervisor:_______________________________

You might also like

- Jsa Welding and Sleeve InstallationDocument5 pagesJsa Welding and Sleeve Installationshinto Lawrence100% (2)

- Color Code For Piping Material IdentificationDocument7 pagesColor Code For Piping Material IdentificationMcmiltondmordomNo ratings yet

- JSA For Coating and Raping Activity in TankDocument7 pagesJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNo ratings yet

- Hydro Jetting and Sludge RemovalDocument18 pagesHydro Jetting and Sludge Removalmarvin100% (1)

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos80% (5)

- Pneumothorax, Tension and TraumaticDocument29 pagesPneumothorax, Tension and TraumaticicaNo ratings yet

- 4.assembly & Erection of StructureDocument3 pages4.assembly & Erection of StructureFrancis Vinoj100% (2)

- Job Safety Analysis - Cone ErectionDocument7 pagesJob Safety Analysis - Cone ErectionMohammed MinhajNo ratings yet

- CTRA TK 64 003 Scaffolding Inside OutsideDocument6 pagesCTRA TK 64 003 Scaffolding Inside OutsideMohamed RizwanNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- Material Lifting Shifting by Farana/craneDocument1 pageMaterial Lifting Shifting by Farana/craneAKBAR ALINo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument17 pagesJSA For Scaffolding Erection Dismantling and Modification Workshane.ramirez1980No ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- JSA Hot Work and ModificationDocument19 pagesJSA Hot Work and ModificationBrings MotoVlogNo ratings yet

- JSA For Erection and Repair Work of TanksDocument19 pagesJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- Fill-Up This Card Before Commencement of Critical WorksDocument4 pagesFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- WPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingDocument4 pagesWPRA No. 2221-TK-61-273 - Scaffolding Erection and DismatlingMohamed RizwanNo ratings yet

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- ARK-JSA-06 Concrete FDN PDFDocument8 pagesARK-JSA-06 Concrete FDN PDFREMYA100% (1)

- Red Tile Placing JSADocument5 pagesRed Tile Placing JSAShahid BhattiNo ratings yet

- ARK JSA Manual Excavation A 3Document9 pagesARK JSA Manual Excavation A 3REMYANo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- MS - Inspection of PenstockDocument19 pagesMS - Inspection of Penstockanishdev6No ratings yet

- JSA-for-Construction Works For Tank 10Document18 pagesJSA-for-Construction Works For Tank 10Gaurav DixitNo ratings yet

- Adr Jsa 1711 002Document7 pagesAdr Jsa 1711 002Dada KhalandarNo ratings yet

- Jsa For Basket Ball C Ourt Installation.Document6 pagesJsa For Basket Ball C Ourt Installation.Anna JisabaNo ratings yet

- JSA For Materia/equipment Loading Unloading & Shifting Work JsaDocument3 pagesJSA For Materia/equipment Loading Unloading & Shifting Work JsaAKBAR ALINo ratings yet

- Cooling Tower BiomateDocument8 pagesCooling Tower BiomateJavid AaqibNo ratings yet

- 1 Scaffolding Work PDFDocument16 pages1 Scaffolding Work PDFfadliNo ratings yet

- JSA BOOM TRUCK 197iDocument3 pagesJSA BOOM TRUCK 197iImamul HaqueNo ratings yet

- JSA For Scaffolding.Document16 pagesJSA For Scaffolding.jeswinimanualNo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationREMYA50% (2)

- Scaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedDocument3 pagesScaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedkrishnakumarNo ratings yet

- JSA For Hydro Jetting, Removal and Cleaning of SludgeDocument18 pagesJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidNo ratings yet

- Risk Assessment GRP Tank InstallationDocument19 pagesRisk Assessment GRP Tank Installationanwer.ahmadNo ratings yet

- Jsa For Football Pitch InstallationDocument4 pagesJsa For Football Pitch InstallationAnna JisabaNo ratings yet

- AE-SWM - 12B-LG-Marine-Rev-02Document61 pagesAE-SWM - 12B-LG-Marine-Rev-02Planning C7100% (1)

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- Jsa For Temporary Facility Installations PS5Document9 pagesJsa For Temporary Facility Installations PS5Anna JisabaNo ratings yet

- Job Hazard Analysis PaintngDocument11 pagesJob Hazard Analysis PaintngRadhakrishnan SreerekhaNo ratings yet

- 2..loading Unloading and Installation of PipingDocument3 pages2..loading Unloading and Installation of PipingFrancis VinojNo ratings yet

- ARK JSA Manual ExcavationDocument8 pagesARK JSA Manual ExcavationMohammed Ali QaziNo ratings yet

- FPS 015 - Installation of valvesREV1Document4 pagesFPS 015 - Installation of valvesREV1grantNo ratings yet

- ARK-JSA-08 Manual Tie-In Welding Rev-3Document9 pagesARK-JSA-08 Manual Tie-In Welding Rev-3REMYANo ratings yet

- Risk Assessment CG 4750 Installation of Lighting Protection Pole Street Lighting Pole and Light FittingsDocument5 pagesRisk Assessment CG 4750 Installation of Lighting Protection Pole Street Lighting Pole and Light FittingsEm NiaxNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- WMS Summary EnglishDocument1 pageWMS Summary EnglishKarthik babuNo ratings yet

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- JSA Tank Modification and Repair Work 1683009539 PDFDocument12 pagesJSA Tank Modification and Repair Work 1683009539 PDFLabroratoirNo ratings yet

- SEOT JSA For Vehicle EntryDocument3 pagesSEOT JSA For Vehicle EntryArchana SoorajNo ratings yet

- Job Safety AnalysisDocument19 pagesJob Safety AnalysisVineet Agrawal100% (1)

- PARCO - Mid Country Refinery: Job Safety AnalysisDocument6 pagesPARCO - Mid Country Refinery: Job Safety AnalysisGyanendra Narayan NayakNo ratings yet

- WSF 008 Crane Loading OffloadingDocument11 pagesWSF 008 Crane Loading OffloadingRajesh BeheraNo ratings yet

- Jsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsDocument7 pagesJsa For Mobilization of Crane, Erection of Spools and Welding Cutting and Grinding and Tie in On Existing SpoolsMohammed Minhaj100% (1)

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- Jsa For Concreate and CivilworksDocument7 pagesJsa For Concreate and CivilworksAnna JisabaNo ratings yet

- Drawing Home1-ModelDocument1 pageDrawing Home1-ModelAhmedNo ratings yet

- (Ec0842) Pipeline Divr of Bbn-1& Bbn-2 Flow To Bnc-1 (Ifc)Document20 pages(Ec0842) Pipeline Divr of Bbn-1& Bbn-2 Flow To Bnc-1 (Ifc)AhmedNo ratings yet

- Activities Method Statement 2023Document1 pageActivities Method Statement 2023AhmedNo ratings yet

- Parvaiz Ali HSE Additional CertificationDocument9 pagesParvaiz Ali HSE Additional CertificationAhmedNo ratings yet

- Bituminous SolutionDocument2 pagesBituminous SolutionAhmedNo ratings yet

- GEL HSE CL 01 Ambulance Inspection ChecklistDocument1 pageGEL HSE CL 01 Ambulance Inspection ChecklistAhmedNo ratings yet

- Hopper SR USA83255Document1 pageHopper SR USA83255AhmedNo ratings yet

- Acetylene enDocument8 pagesAcetylene enAhmedNo ratings yet

- LAS SHS DRRR MELC 7 Q2 Week-3Document7 pagesLAS SHS DRRR MELC 7 Q2 Week-3Atalanta LeeNo ratings yet

- Symptoms of Parkinson's Disease - Korisnik1Document212 pagesSymptoms of Parkinson's Disease - Korisnik1raplyhollow_68780740No ratings yet

- Environmental VocabularyDocument4 pagesEnvironmental VocabularyEngel EspinozaNo ratings yet

- 2022 Grade 10 - Term 2 JIT Actvities 1Document46 pages2022 Grade 10 - Term 2 JIT Actvities 1anelisafaith6077No ratings yet

- Bella Rahal Letter of RecommendationDocument1 pageBella Rahal Letter of Recommendationapi-503911568No ratings yet

- The Role of Working Memory in SportDocument25 pagesThe Role of Working Memory in SportChrisNo ratings yet

- Tempnote T32: Economical Reusable Temperature Data Logger For Cold Chain MonitoringDocument2 pagesTempnote T32: Economical Reusable Temperature Data Logger For Cold Chain Monitoringakshay gargNo ratings yet

- Ananas Comosus Var. Comosus: The Biology of (Pineapple)Document43 pagesAnanas Comosus Var. Comosus: The Biology of (Pineapple)J Alberto LucasNo ratings yet

- Emotional Happiness - Pastor-Teacher Jim Borchert - (AG)Document27 pagesEmotional Happiness - Pastor-Teacher Jim Borchert - (AG)ilacatdNo ratings yet

- At The Doctor's OfficeDocument5 pagesAt The Doctor's OfficetasleeeNo ratings yet

- Chemistry Form 5: 4541/3 Chemistry Paper 3 May 2008 1 HoursDocument5 pagesChemistry Form 5: 4541/3 Chemistry Paper 3 May 2008 1 HoursElly EllynaNo ratings yet

- Ocean Aquamarine Products EnterprisesDocument19 pagesOcean Aquamarine Products EnterpriseseggsNo ratings yet

- Baypren New Development With Old PolymerDocument30 pagesBaypren New Development With Old PolymerMarcos ROSSINo ratings yet

- 5th Unit ppt1Document36 pages5th Unit ppt1Shwetank SinghNo ratings yet

- Araneta V GatmaitanDocument1 pageAraneta V GatmaitanJohn BasNo ratings yet

- Proposal For Improvement of Infant Toddler Weighing ScaleDocument6 pagesProposal For Improvement of Infant Toddler Weighing ScaleYuna-chan KatsuraNo ratings yet

- Isolation and Characterization of ProteinsDocument3 pagesIsolation and Characterization of ProteinsVern NuquiNo ratings yet

- Chem 204 Syllabus SPR 2013Document3 pagesChem 204 Syllabus SPR 2013Chen CaoNo ratings yet

- 2Document17 pages2api-3814389No ratings yet

- RMP ConsolidatedDocument59 pagesRMP ConsolidatedSuhail IqbalNo ratings yet

- Science Class 10TH Sample Unauthorised TestDocument6 pagesScience Class 10TH Sample Unauthorised TestVisual lordNo ratings yet

- Little Abt Amul AssignmentDocument5 pagesLittle Abt Amul AssignmentpunkjmorNo ratings yet

- PWHT Exemption Thickness Criteria CS Connect Items 08-179 (B31.1) 03-1453 (B31.3) 05-1182 (B31 TC/F&E)Document19 pagesPWHT Exemption Thickness Criteria CS Connect Items 08-179 (B31.1) 03-1453 (B31.3) 05-1182 (B31 TC/F&E)Tusar KoleNo ratings yet

- Sealing Technology June 2015Document16 pagesSealing Technology June 2015daniel.skydog1562No ratings yet

- (F) (N) Hds Series: DimensionsDocument4 pages(F) (N) Hds Series: DimensionsElliot AldersonNo ratings yet

- Series 90 Pumps: Service ManualDocument79 pagesSeries 90 Pumps: Service ManualSekar.SNo ratings yet

- Mh-Fj-P1 Automatic Case SealerDocument3 pagesMh-Fj-P1 Automatic Case SealerZaky SyawaliNo ratings yet

- Appendicular SkeletonDocument27 pagesAppendicular SkeletonSheena SapaoNo ratings yet