Professional Documents

Culture Documents

Atomic Arrangement Imperfections in Engineered Materials

Uploaded by

محمود علي0 ratings0% found this document useful (0 votes)

9 views18 pagesOriginal Title

chap 4

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views18 pagesAtomic Arrangement Imperfections in Engineered Materials

Uploaded by

محمود عليCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 18

Imperfections in the Atomic Arrangements

• The arrangement of the atoms or ions in engineered

materials contains imperfections or defects.

• There are three basic types of imperfections: point

defects, line defects (or dislocations), and surface

defects.

• In many applications, the presence of such defects is

useful. For example, defects known as dislocations are

useful for increasing the strength of metals and alloys; in

single crystal silicon, used for manufacturing computer

chips, the presence of dislocations is undesirable.

• Defects may be created intentionally to produce a

desired set of electronic, magnetic, optical, or

mechanical properties. For example, pure iron is

relatively soft. When we add a small amount of carbon,

we create defects in the crystalline arrangement of iron

and transform it into carbon steel with considerably

higher strength. On the other hand, we use a high purity

copper as a conductor for microelectronics. This is

because even small levels of impurities will cause an

appreciable increase in the electrical resistivity of copper.

Point Defects

• it is the movement of the atoms or ions when

they gain energy by heating, during processing

of the material, or by the intentional or

unintentional introduction of impurities. Point

defect could be a vacancy or an interstitial

site, or substituting an atom with another

atom of different type.

• Impurities are elements or compounds that are

present from raw materials or processing. Dopants,

on the other hand, are elements or compounds that

are deliberately added, in known concentrations, at

specific locations in the microstructure, with an

intended beneficial effect on properties or

processing.

• In general, the effect of impurities is harmful,

whereas the effect of dopants on the properties of

materials is useful.

Vacancies

• A vacancy is produced when an atom or an ion is

missing from its normal site in the crystal structure as

in Figure (a).

• Vacancies are introduced into metals and alloys during

solidification, at high temperatures, or as a

consequence of radiation damage.

• At room temperature (_298 K), the concentration of

vacancies is small, but the concentration of vacancies

increases exponentially as the temperature increases,

as shown by the following equation:

• Note that this equation provides the

equilibrium concentration of vacancies at a

given temperature. It is also possible to retain

the concentration of vacancies produced at a

high temperature by quenching the material

rapidly. Thus, in many situations, the

concentration of vacancies observed at room

temperature is not the equilibrium

concentration predicted by the above equation.

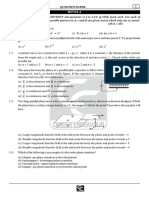

Example 1

(The effect of temperature on vacancy concentration):

• Calculate the concentration of vacancies in copper at

room temperature (25°C). What temperature will be

needed to heat treat copper such that the

concentration of vacancies produced will be 1000

times more than the equilibrium concentration of

vacancies at room temperature? Assume that

20,000 cal are required to produce a mole of

vacancies in copper.

• By heating the copper slightly above 100°C,

waiting until equilibrium is reached, and then

rapidly cooling the copper back to room

temperature, the number of vacancies

trapped in the structure may be one thousand

times greater than the equilibrium number of

vacancies at room temperature.

Example 2

(vacancy concentration in BCC iron):

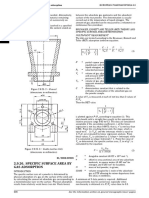

• Calculate the theoretical density of iron, and then

determine the number of vacancies needed for a BCC

iron crystal to have a density of 7.874 g cm3. The

lattice parameter of iron is 2.866 * 10-8 cm.

• Solution:

• The theoretical density of iron can be calculated from

the lattice parameter and the atomic mass. Since the

iron is BCC, two iron atoms are present in each unit

cell.

Interstitial Defects

• An interstitial defect is formed when an extra atom or ion is

inserted into the crystal structure at a normally unoccupied

position, as in the Figure above.

• Interstitial atoms or ions, although much smaller than the atoms

or ions located at the lattice points, are still larger than the

interstitial sites that they occupy; consequently, the surrounding

crystal region is compressed and distorted.

• the introduction of interstitial atoms is one important way of

increasing the strength of metallic materials.

• Unlike vacancies, once introduced, the number of interstitial

atoms or ions in the structure remains nearly constant, even

when the temperature is changed.

• The interstitial site in BCC iron is smaller than

the interstitial site in FCC iron. Although both

are smaller than the carbon atom, carbon

distorts the BCC crystal structure more than

the FCC structure. As a result, fewer carbon

atoms are expected to enter interstitial

positions in BCC iron than in FCC iron.

Substitutional Defects

• A substitutional defect is introduced when one atom or

ion is replaced by a different type of atom or ion as in

Figure (c) and (d).

• The substitutional atoms or ions occupy the normal lattice

site. Substitutional atoms or ions may either be larger than

the normal atoms or ions in the crystal structure, in which

case the surrounding interatomic spacings are reduced, or

smaller causing the surrounding atoms to have larger

interatomic spacings.

• The substitutional defect can be introduced either as an

impurity or as a deliberate alloying addition

• Examples of substitutional defects include

incorporation of dopants such as phosphorus

(P) or boron (B) into Si. Similarly, if we add

copper to nickel, copper atoms will occupy

crystallographic sites where nickel atoms

would normally be present.

• The substitutional atoms will often increase

the strength of the metallic material.

You might also like

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- Imperfections in SolidsDocument36 pagesImperfections in SolidsRowEll CañEtaNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred Experiments Performed with Simple, Home-made ApparatusNo ratings yet

- Imperfections & Application of CeramicDocument23 pagesImperfections & Application of CeramicAlexander DavidNo ratings yet

- Electroplating for Amateurs: Classic Reference for Small WorkshopsFrom EverandElectroplating for Amateurs: Classic Reference for Small WorkshopsNo ratings yet

- Imperfections in The Atomic ArrangementDocument20 pagesImperfections in The Atomic Arrangementdaisyclare vernyuyNo ratings yet

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsFrom EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNo ratings yet

- Point Defects in Solids ExplainedDocument36 pagesPoint Defects in Solids ExplainedAbdul RehmanNo ratings yet

- Imperfections in The Atomic and Ionic ArrangementsDocument66 pagesImperfections in The Atomic and Ionic Arrangementssusanweb100% (1)

- The Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelFrom EverandThe Working of Steel Annealing, Heat Treating and Hardening of Carbon and Alloy SteelRating: 5 out of 5 stars5/5 (4)

- CH 4Document145 pagesCH 4Najam Ul QadirNo ratings yet

- ES1021 Lecture 17Document12 pagesES1021 Lecture 17kyledang277No ratings yet

- Atomic and Crystal Structure of MaterialsDocument52 pagesAtomic and Crystal Structure of Materialscharles makasabiNo ratings yet

- Homework Problems: Density, Structure, and Atomic RadiiDocument2 pagesHomework Problems: Density, Structure, and Atomic RadiiDAVID MAURICIO MUÑOZ D�AZNo ratings yet

- Lecture 4Document117 pagesLecture 4Sam ThorNo ratings yet

- All Unit Cells Consist of The: Ideal Arrangement of Atoms or Molecules Specific OrderDocument75 pagesAll Unit Cells Consist of The: Ideal Arrangement of Atoms or Molecules Specific Orderkhare_girishNo ratings yet

- 4 Lecture 4Document23 pages4 Lecture 4Ahmed EssamNo ratings yet

- Government Engineering College, GandhinagarDocument28 pagesGovernment Engineering College, GandhinagarJaynish IdhariyaNo ratings yet

- Imperfections in SolidsDocument50 pagesImperfections in Solidsavutu_kunduruNo ratings yet

- Electroplating: Electroplating Is A General Name For Processes That Create A MetalDocument9 pagesElectroplating: Electroplating Is A General Name For Processes That Create A MetalLollllNo ratings yet

- EE Final Draft: How Does Carbon Content Affect The Hardness of Steel After Heat Treatment?Document19 pagesEE Final Draft: How Does Carbon Content Affect The Hardness of Steel After Heat Treatment?goinbe fanNo ratings yet

- Arc Welding in DetailDocument34 pagesArc Welding in DetailSohen PatelNo ratings yet

- 1 Crystal Defects - Ch04Document72 pages1 Crystal Defects - Ch04Kimberly Joy FerrerNo ratings yet

- STRUCTURES AND PROPERTIES OF CERAMIC MATERIALSDocument42 pagesSTRUCTURES AND PROPERTIES OF CERAMIC MATERIALSangelo macatangayNo ratings yet

- Crystallographic Imperfections PDFDocument17 pagesCrystallographic Imperfections PDFAmitNo ratings yet

- Electroplating GuideDocument27 pagesElectroplating GuideBayan O. Abu SaadaNo ratings yet

- Electroplating - WikipediaDocument51 pagesElectroplating - WikipediaCaleb AsharleyNo ratings yet

- 2023MSEII Handout8Document17 pages2023MSEII Handout8王竣右No ratings yet

- CHPT 5: Imperfections in Solids: Issues To Address..Document27 pagesCHPT 5: Imperfections in Solids: Issues To Address..Asim TheTru BlueNo ratings yet

- Electric Induction FurnaceDocument23 pagesElectric Induction FurnaceVaidNo ratings yet

- Chem ReviewerDocument18 pagesChem ReviewerKnight VelasquezNo ratings yet

- Covalent Network Compounds and Their PropertiesDocument19 pagesCovalent Network Compounds and Their PropertiesmuhajireenNo ratings yet

- Electroplating IIDocument53 pagesElectroplating IIGarima UppadhyayNo ratings yet

- Lecture 15 PDFDocument5 pagesLecture 15 PDFrahulNo ratings yet

- Crystal DefectsDocument75 pagesCrystal DefectsAshok PradhanNo ratings yet

- Mse2104 Lab06Document6 pagesMse2104 Lab06মোহাম্মদ ইসমাইল হোসেনNo ratings yet

- Introduction To Electrolysis: 2H 0 + 2SO 2H SO + 0Document14 pagesIntroduction To Electrolysis: 2H 0 + 2SO 2H SO + 0Priyadarshi MNo ratings yet

- the History of The Modern Steel Making Really Started From 1760, When HuntsmanDocument19 pagesthe History of The Modern Steel Making Really Started From 1760, When HuntsmanvzschoudharyNo ratings yet

- Engineering Materials and Metallurgy: Unit - IDocument18 pagesEngineering Materials and Metallurgy: Unit - Imuthupecmec4908No ratings yet

- Chapter 13 - Heat Treatment of SteelsDocument60 pagesChapter 13 - Heat Treatment of Steelsahmedmagdi2009100% (1)

- Carbon Nanotubes: First Author: Wasim Khan Second Author: Aniket.v.WarnoolkarDocument5 pagesCarbon Nanotubes: First Author: Wasim Khan Second Author: Aniket.v.WarnoolkarAniket WarnoolkarNo ratings yet

- Electric Arc Welding or Smaw: Fernando O. Paras JRDocument17 pagesElectric Arc Welding or Smaw: Fernando O. Paras JRMirasol Nilo GumbaNo ratings yet

- (A) - Describe The Method of Cathodic Protection, and The Advantages and Disadvantages of The MethodDocument3 pages(A) - Describe The Method of Cathodic Protection, and The Advantages and Disadvantages of The MethodDon WillzNo ratings yet

- Heat Treatment and Properties of Steels ExplainedDocument14 pagesHeat Treatment and Properties of Steels Explained035K Ayush ChoudharyNo ratings yet

- Callister SolutionsDocument122 pagesCallister SolutionsJ.Srinivas RaoNo ratings yet

- Lab 7 Fracture Ductile To Brittle TransitionDocument4 pagesLab 7 Fracture Ductile To Brittle TransitionTommy MilesNo ratings yet

- Chapter 13 - Heat Treatment of SteelsDocument60 pagesChapter 13 - Heat Treatment of SteelsRecep VatanseverNo ratings yet

- Carbon Nanotubes: Properties That Make Them Special 1.chemicalDocument6 pagesCarbon Nanotubes: Properties That Make Them Special 1.chemicalPrateek MallNo ratings yet

- Electric Arc Furnaces: CapacityDocument4 pagesElectric Arc Furnaces: CapacityAkmal MuzakkiNo ratings yet

- Arc Welding FundamentalsDocument49 pagesArc Welding FundamentalsNordiana IdrisNo ratings yet

- Classification and Properties of Ceramic MaterialsDocument36 pagesClassification and Properties of Ceramic MaterialsMadhumita KumarNo ratings yet

- Green Book SolutionDocument44 pagesGreen Book SolutionCaleb RaphaelNo ratings yet

- 1b2 - Cahill Et Al - Common Root Causes For Anode ProblemsDocument20 pages1b2 - Cahill Et Al - Common Root Causes For Anode ProblemsAnnelize Schoeman TrollipNo ratings yet

- Cathodic ProtectionDocument22 pagesCathodic ProtectionFakhr-e-Alam100% (1)

- CERAMICDocument92 pagesCERAMICRuby Lyn Alcaide LazaNo ratings yet

- Metals Alloys and Semiconductors DayDocument46 pagesMetals Alloys and Semiconductors Dayapi-182809945No ratings yet

- Assignment - 2Document15 pagesAssignment - 2padhiyararpitaNo ratings yet

- Crystal Imperfection CH 4Document44 pagesCrystal Imperfection CH 4anapguerraNo ratings yet

- Eee Module 1Document75 pagesEee Module 1Anitha BRNo ratings yet

- Chap 3Document32 pagesChap 3محمود عليNo ratings yet

- Chap 3Document32 pagesChap 3محمود عليNo ratings yet

- Chap 2Document23 pagesChap 2محمود عليNo ratings yet

- Why study materials engineering in 40 charactersDocument15 pagesWhy study materials engineering in 40 charactersDuaa GadoraaNo ratings yet

- Lime DosingDocument16 pagesLime Dosingthiru84No ratings yet

- DP 1 FA 2 - Chemistry - HLDocument9 pagesDP 1 FA 2 - Chemistry - HLSpider grubbyNo ratings yet

- 2017 Icchmt HP ModelingDocument9 pages2017 Icchmt HP ModelingArih FadiNo ratings yet

- NEXUS 2104brownsgasDocument8 pagesNEXUS 2104brownsgaswxcvbnnbvcxwNo ratings yet

- Semester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDocument22 pagesSemester Syllabus For M. Sc. in Chemistry: School of Chemistry (AutonomousDachou GeetuNo ratings yet

- Sources of SulphurDocument3 pagesSources of SulphurMadonnaAdanna UdokaluNo ratings yet

- Dr. Shikha Baskar: CHE154: Physical Chemistry For HonorsDocument22 pagesDr. Shikha Baskar: CHE154: Physical Chemistry For HonorsnishitsushantNo ratings yet

- Antacid - Film Canister LabDocument2 pagesAntacid - Film Canister LabTanish bossNo ratings yet

- Lab Report of Heat ExchangerDocument8 pagesLab Report of Heat ExchangerSalam Albaradie100% (7)

- Infrared Spectroscopy EceDocument50 pagesInfrared Spectroscopy EceRavi KumarNo ratings yet

- Module 01Document6 pagesModule 01Regina Alcantara ReyesNo ratings yet

- CHAPTER 6 PRACTICE PROBLEMSDocument3 pagesCHAPTER 6 PRACTICE PROBLEMSAlwyn Dave AmbataliNo ratings yet

- Experiment 3 Fourier Transform Infrared Spectroscopy (FTIR)Document7 pagesExperiment 3 Fourier Transform Infrared Spectroscopy (FTIR)Muhammad Azri HaziqNo ratings yet

- Davies 1973Document4 pagesDavies 1973Shu YanNo ratings yet

- SUMSEM2-2018-19 ECE1006 ETH VL2018199000757 Reference Material I 02-Jun-2019 Statistical Mechanics Bose Einstein and Fermi Dirac DistributionsDocument18 pagesSUMSEM2-2018-19 ECE1006 ETH VL2018199000757 Reference Material I 02-Jun-2019 Statistical Mechanics Bose Einstein and Fermi Dirac Distributionsaghil ashokan aghilNo ratings yet

- Time-Reversal-Violating Optical GyrotropyDocument30 pagesTime-Reversal-Violating Optical GyrotropyCaha yANo ratings yet

- Paper 12: Organic Spectroscopy: Subject ChemistryDocument12 pagesPaper 12: Organic Spectroscopy: Subject ChemistryFaiza AnsariNo ratings yet

- Mathalino: Newton'S Law of CoolingDocument3 pagesMathalino: Newton'S Law of CoolingArnold ApostolNo ratings yet

- Hydrogen in 1 Shot - Class Notes - JEEDocument22 pagesHydrogen in 1 Shot - Class Notes - JEESaurabh KumarNo ratings yet

- Thermal Conductivity of Alumina-Toughened Zirconia CompositesDocument14 pagesThermal Conductivity of Alumina-Toughened Zirconia CompositesMihai MarinNo ratings yet

- Chapter 8: Atomic Electron Configurations and PeriodicityDocument40 pagesChapter 8: Atomic Electron Configurations and PeriodicityRuben FelicianoNo ratings yet

- Reid Vapour PressureDocument6 pagesReid Vapour PressureTeal TealyNo ratings yet

- McQuarrie Chapter 7 ProblemsDocument7 pagesMcQuarrie Chapter 7 ProblemsUpakarasamy LourderajNo ratings yet

- Evonik Additives For PU Shoe SoleDocument12 pagesEvonik Additives For PU Shoe SoleSigneyWangNo ratings yet

- Thermodynamics concepts and processes explainedDocument3 pagesThermodynamics concepts and processes explainedEstefy LaglaNo ratings yet

- Information/Data Required For Wax Modelling: A) B) C) D) E)Document6 pagesInformation/Data Required For Wax Modelling: A) B) C) D) E)AYAUWU LOVEDAY100% (1)

- Stoichiometry Lab Report 1Document7 pagesStoichiometry Lab Report 1โดยคี ซูบาNo ratings yet

- IJSO Question Paper 2007 (MCQ)Document17 pagesIJSO Question Paper 2007 (MCQ)Science Olympiad Blog75% (4)

- Volumetric Gas Adsorption Technique - Magnesium Stearate - EP6.0 - 01 - 231Document4 pagesVolumetric Gas Adsorption Technique - Magnesium Stearate - EP6.0 - 01 - 231Debahis BoseNo ratings yet

- Gate 2000 PHDocument9 pagesGate 2000 PHPasupuleti AnilNo ratings yet