Professional Documents

Culture Documents

Tapping Procedures: MACH 112: Cutting Tools & Measurement

Uploaded by

G. Dancer Gh0 ratings0% found this document useful (0 votes)

414 views14 pagesTapping is used to cut internal threads in holes. It can be done by hand using a tap wrench or machine using a tapping attachment. The correct tap drill size is determined based on the thread size and desired thread percentage. Hand tapping requires starting the tap in the hole, checking for squareness, applying cutting fluid, and reversing rotation periodically to break chips. Precautions like countersinking and clearing chips must be taken to avoid damaging the tap or threads.

Original Description:

Original Title

TAPPING PROCEDURES

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTapping is used to cut internal threads in holes. It can be done by hand using a tap wrench or machine using a tapping attachment. The correct tap drill size is determined based on the thread size and desired thread percentage. Hand tapping requires starting the tap in the hole, checking for squareness, applying cutting fluid, and reversing rotation periodically to break chips. Precautions like countersinking and clearing chips must be taken to avoid damaging the tap or threads.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

414 views14 pagesTapping Procedures: MACH 112: Cutting Tools & Measurement

Uploaded by

G. Dancer GhTapping is used to cut internal threads in holes. It can be done by hand using a tap wrench or machine using a tapping attachment. The correct tap drill size is determined based on the thread size and desired thread percentage. Hand tapping requires starting the tap in the hole, checking for squareness, applying cutting fluid, and reversing rotation periodically to break chips. Precautions like countersinking and clearing chips must be taken to avoid damaging the tap or threads.

Copyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 14

TAPPING PROCEDURES

MACH 112: Cutting Tools & Measurement

OBJECTIVES

tOBJECTIVES:

Select the correct tap drill for a specific percentage of

thread.

Select the correct cutting fluid for tapping.

Tap holes by hand or with a drill press.

Identify and correct common tapping problems.

Compiled by Ronald C. Schwartz

TAPPING PROCEDURES

Tap Use

Taps are used to cut internal threads in holes.

◦ tapping can be performed by hand or with a machine.

A tap wrench or a T-handle tap wrench provides driving

torque while hand tapping.

Fig. B-134 Tap wrench. Fig. B-135 T-handle tap wrench.

Compiled by Ronald C. Schwartz

TAPPING PROCEDURES

Tap Use

To obtain a greater accuracy

in hand tapping, a hand tapper is

used.

Fig. B-136a Hand tapper (Courtesy of Enco).

Compiled by Ronald C. Schwartz

TAPPING PROCEDURES

Tap Use

Drill presses can be used

for tapping with

a tapping attachment.

Fig. B-137 Drill press tapping attachment.

Compiled by Ronald C. Schwartz

TAPPING PROCEDURES

Thread Percentage and Hole Strength

Thread strength depends on the work-piece material,

percentage of full thread used, and the length of the

thread.

Percentage of thread produced is dependent on the

diameter of the drilled hole.

◦ Tap drill charts give drill sizes to produce 75% thread.

Common practice is to have a bolt engage a tapped

hole by 1 to 1-1/2 times its diameter.

◦ Threaded assemblies are usually designed so the

bolt breaks before the threaded hole strips.

Compiled by Ronald C. Schwartz

TAPPING PROCEDURES

Drilling the Right Hole Size

If a thread depth other than 75% is wanted, use the

following formula to determine the proper hole size:

Compiled by Ronald C. Schwartz

HOW TO DO IT… 3

Hand Tapping

Countersink the hole entrance to a diameter slightly larger

than the major diameter of the threads (Fig. B-139).

◦ This allows the tap to be started more easily & protects the start of

the threads from damage.

• Mount the work-piece in a bench

vise so the hole is in a vertical

position.

• Tighten the tap in the tap

wrench.

Fig. B-139 Preparing the workpiece.

Compiled by Ronald C. Schwartz

HOW TO DO IT… 4

Hand Tapping

Place the tap in the hole in a vertical position.

When the tap is started, it may

Start by turning 2 or 3 clockwise turns be turned as shown.

for a right-hand thread, keeping steady

downward pressure on the tap.

Starting the tap. Tapping a thread by hand.

Compiled by Ronald C. Schwartz

HOW TO DO IT… 5

Hand Tapping

After the tap is started for several turns, remove the tap

wrench without disturbing the tap.

Place the blade of a square against

the solid shank of the tap to check

for squareness.

Check two positions 90 degrees apart.

If the tap is not square with the work,

it will ruin the thread & possibly break

in the hole if you continue tapping.

Back the tap out of the hole &restart.

Checking the tap for squareness.

Compiled by Ronald C. Schwartz

HOW TO DO IT… 6

Hand Tapping

Use the correct cutting oil on the tap when cutting threads.

Turn the tap clockwise one-quarter to one-half turn, then

turn back three-quarters of a turn to break the chip.

◦ Do this with a steady motion to avoid breaking the tap.

When tapping a blind hole, use the taps

in the order starting, plug, and then bottoming.

◦ Remove the chips from the hole before using the bottoming tap.

◦ Be careful not to hit the bottom of the hole with the tap.

Compiled by Ronald C. Schwartz

HOW TO DO IT… 7

Hand Tapping

A 60-degree point center chucked in a drill press to align a

tap squarely with the previously drilled hole.

Only very slight follow-up pressure

should be applied to the tap.

Too much downward pressure will

cut a loose, oversize thread.

Fig. B-143 Using the drill press as a tapping

fixture.

Compiled by Ronald C. Schwartz

HOW TO DO IT… 8

Common Tapping problems & Possible Solutions

See the entire table on page 75 of your textbook.

Compiled by Ronald C. Schwartz

Review

Name two types of tap wrenches

Calculate the following tap drill size:

◦ 60% thread for a ½-13 UNC

Calculate the following tap drill size:

◦ 5/8-11 UNC

Why must a hole be countersunk before tapping?

Why must the tap rotation be reversed while tapping?

What precaution(s) must be taken when tapping blind

holes?

How can you insure that a tapped hole is square when

tapping in a machine?

Compiled by Ronald C. Schwartz

You might also like

- F4a 2020 LEEA Assessments - Information For Members Students Nov 2019Document4 pagesF4a 2020 LEEA Assessments - Information For Members Students Nov 2019VishnuNo ratings yet

- 033 - Anchor Calibration of MV Adolfo Sr.Document3 pages033 - Anchor Calibration of MV Adolfo Sr.Mikhail Roy Dela CruzNo ratings yet

- 45 Samss 006Document8 pages45 Samss 006naruto256No ratings yet

- MPI Machine - SL 2016123864 - MPI Yoke - 27.05.2021Document1 pageMPI Machine - SL 2016123864 - MPI Yoke - 27.05.2021Naveen KumarNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- DEN-CON TOOL ELEVATOR MAINTENANCE INSPECTION DATADocument2 pagesDEN-CON TOOL ELEVATOR MAINTENANCE INSPECTION DATAHector BarriosNo ratings yet

- Contact China Construction for Quality ProjectsDocument2 pagesContact China Construction for Quality ProjectsKeeshia Elaine RonoloNo ratings yet

- PT Bhaita Wire Rope Inspection ProcedureDocument4 pagesPT Bhaita Wire Rope Inspection ProcedureSugianto TanNo ratings yet

- Identification of Risk and Providing GuiDocument5 pagesIdentification of Risk and Providing GuiJay PanitanNo ratings yet

- Naga 7: Velesto Drilling SDN BHDDocument2 pagesNaga 7: Velesto Drilling SDN BHDmuhammad zahlanNo ratings yet

- Quality Docs DEP 17 0803Document7 pagesQuality Docs DEP 17 0803Edwin MPNo ratings yet

- 1.wash Pipe 8-1-8 SN NNDocument1 page1.wash Pipe 8-1-8 SN NNMuhammad Rijal sembiringNo ratings yet

- Drill Pipe I.RDocument6 pagesDrill Pipe I.REdwin MPNo ratings yet

- RADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSDocument1 pageRADIANT NDT SERVICES REPORT PROVIDES ULTRASONIC TESTING RESULTSGoutam Kumar Deb100% (1)

- 0 - BV - OCTG - Pre Rig Inspection Procedure .Rev - GEMDocument4 pages0 - BV - OCTG - Pre Rig Inspection Procedure .Rev - GEMEduard GadzhievNo ratings yet

- Oil India Tender for Supply of Drill PipesDocument13 pagesOil India Tender for Supply of Drill Pipesifebrian100% (1)

- T4 Drill Pipe Colour Code Classification Chart NS2Document1 pageT4 Drill Pipe Colour Code Classification Chart NS2Josue Fish100% (1)

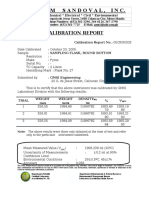

- Manual Lathe Calibration Procedure: 1.0 Standards and EquipmentDocument3 pagesManual Lathe Calibration Procedure: 1.0 Standards and EquipmentG. Dancer GhNo ratings yet

- Almansoori Inspection Services: Travelling Block AssemblyDocument2 pagesAlmansoori Inspection Services: Travelling Block AssemblyRanjithNo ratings yet

- Joint Declaration Under para 26 (6) of The Epf Scheme, 1952Document2 pagesJoint Declaration Under para 26 (6) of The Epf Scheme, 1952prakash reddyNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name Daterohitbhat2345No ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument8 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- Method of Statement PDFDocument7 pagesMethod of Statement PDFSakib AyubNo ratings yet

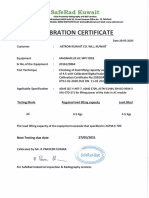

- Calibration CertificateDocument2 pagesCalibration CertificatemangengueyNo ratings yet

- Stabilizer Selection Guidelines QG Wrap Taper AngelsDocument19 pagesStabilizer Selection Guidelines QG Wrap Taper AngelsAhmed Mushtaq100% (1)

- API5b Changes in 16th EditionDocument4 pagesAPI5b Changes in 16th EditionMostafa FikryNo ratings yet

- Drawn by Date RevisionDocument10 pagesDrawn by Date RevisionИван ВасильевNo ratings yet

- Phased Array UT Weld Inspection and Crack DetectionDocument3 pagesPhased Array UT Weld Inspection and Crack DetectionGistek MarcoNo ratings yet

- Microcheck Calibration Services Presentation on Importance of Machine Tool CalibrationDocument19 pagesMicrocheck Calibration Services Presentation on Importance of Machine Tool CalibrationSunilNo ratings yet

- WEIR Product ListDocument4 pagesWEIR Product ListSaurabhNo ratings yet

- Pressure Test Sample Form R2Document1 pagePressure Test Sample Form R2Ruel fernandezNo ratings yet

- Thread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTDocument38 pagesThread Protector Testing - PTR-7.3.10-7-LCSG-FULL-PLASTIC-API-5-CT-PERFORMANCE-TEST-REPORTInChy Rencarnation PoseidonNo ratings yet

- 06d AppendixB4 (550HP) 1582536012902Document94 pages06d AppendixB4 (550HP) 1582536012902Harsh TiwariNo ratings yet

- MPI Reports for ROMFOR Oilfield EquipmentDocument21 pagesMPI Reports for ROMFOR Oilfield EquipmentMehmet SoysalNo ratings yet

- Catalogo 511Document4 pagesCatalogo 511Luis Oswaldo R PNo ratings yet

- 5 Welding Processes 1Document62 pages5 Welding Processes 1adelNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Oil Field: Main CatalogueDocument176 pagesOil Field: Main CatalogueM. Aguiar100% (1)

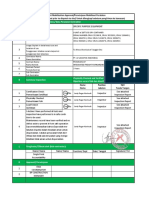

- QAP for Flange InspectionDocument2 pagesQAP for Flange InspectionGOPINATH KRISHNAN NAIRNo ratings yet

- Design CalculationsDocument4 pagesDesign CalculationsEDWIN M.P50% (2)

- Protect Industrial Chemical Tanks Under 40 CharactersDocument16 pagesProtect Industrial Chemical Tanks Under 40 CharactersChonTicha'100% (1)

- API 5CT Scope For Pup JointsDocument3 pagesAPI 5CT Scope For Pup JointsKapil HarchekarNo ratings yet

- Safety Alert Space HeatersDocument2 pagesSafety Alert Space HeatersRamadan KareemNo ratings yet

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianNo ratings yet

- Memo To: Memo No: From: Date: Prep. By: Copied ToDocument3 pagesMemo To: Memo No: From: Date: Prep. By: Copied Tojogi oscar sinagaNo ratings yet

- INSPECTION RESULTS AND RECOMMENDATIONSDocument5 pagesINSPECTION RESULTS AND RECOMMENDATIONSBayu Aringga putra100% (1)

- Understanding Api 4f StructuresDocument16 pagesUnderstanding Api 4f StructuresGordan KanižajNo ratings yet

- Manual - Tenaris - Dimensiones Tubing Joint CasingDocument10 pagesManual - Tenaris - Dimensiones Tubing Joint CasingPatricio JNo ratings yet

- Allied Piping Catalouge 2018Document8 pagesAllied Piping Catalouge 2018ArshadNo ratings yet

- Rotary Table Feeder Data SheetDocument1 pageRotary Table Feeder Data SheetclxNo ratings yet

- WPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)Document1 pageWPQP 6g Smaw A135 Gr.a Od2inch 5.54mm (Approved)ufomskiNo ratings yet

- SS Pipe Welding ProcedureDocument5 pagesSS Pipe Welding Procedureamit rajputNo ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Specification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness TestingDocument4 pagesSpecification: 70.78412 Revision: I Date: August 13, 2010 Specification - General Procedure - Brinell and Rockwell Hardness Testingstephen lewellenNo ratings yet

- Msheireb General Rig InfoDocument2 pagesMsheireb General Rig InfoAftandil QarmonNo ratings yet

- Summary TER of 13 Unit 20FT ISO Dry ContainerDocument219 pagesSummary TER of 13 Unit 20FT ISO Dry ContainerGhilman0529No ratings yet

- NC50 PinDocument1 pageNC50 PinEduard GadzhievNo ratings yet

- API LIcenseDocument9 pagesAPI LIcenseNadeem AnsariNo ratings yet

- JMW 12.6 ManualDocument8 pagesJMW 12.6 ManualMurillo MoreiraNo ratings yet

- Drill PressDocument4 pagesDrill PressSaurabh SharmaNo ratings yet

- Drilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inDocument9 pagesDrilling: Drilling Is A Cutting Process That Uses A Drill Bit To Cut or Enlarge A Hole of Circular Cross-Section inAekanshNo ratings yet

- Thermocouple - أحمد نادر ابراهيم الغوانمةDocument9 pagesThermocouple - أحمد نادر ابراهيم الغوانمةG. Dancer GhNo ratings yet

- Exp.1 Linear MeasurementsDocument8 pagesExp.1 Linear MeasurementsG. Dancer GhNo ratings yet

- Iare Heat Transfer Lecture NotesDocument215 pagesIare Heat Transfer Lecture NotesG. Dancer GhNo ratings yet

- Exp.2 Angular MeasurementsDocument10 pagesExp.2 Angular MeasurementsG. Dancer GhNo ratings yet

- Block Gauges - احمد نادر إبراهيم الغوانمةDocument10 pagesBlock Gauges - احمد نادر إبراهيم الغوانمةG. Dancer GhNo ratings yet

- Heat Transfer From Extended Surfaces (Fins)Document41 pagesHeat Transfer From Extended Surfaces (Fins)G. Dancer GhNo ratings yet

- Chapter 6 - Temperature MeasurementsDocument16 pagesChapter 6 - Temperature MeasurementsG. Dancer GhNo ratings yet

- Tafila Technical University Faculty of Engineering Department of Mechanical EngineeringDocument7 pagesTafila Technical University Faculty of Engineering Department of Mechanical EngineeringG. Dancer GhNo ratings yet

- Chapter 5Document6 pagesChapter 5tabloid07No ratings yet

- Chemistry 520L: Polymer Chemistry Lab: Spring 2018 Friday, 1:25 - 5:15 PM in Morehead Labs 303Document7 pagesChemistry 520L: Polymer Chemistry Lab: Spring 2018 Friday, 1:25 - 5:15 PM in Morehead Labs 303G. Dancer GhNo ratings yet

- Chapter 4-Bulk Deformation ProcessesDocument38 pagesChapter 4-Bulk Deformation ProcessesG. Dancer GhNo ratings yet

- l31 Welding TechnologyDocument25 pagesl31 Welding TechnologyG. Dancer GhNo ratings yet

- One Dimensional, Steady-State Heat ConductionDocument53 pagesOne Dimensional, Steady-State Heat ConductionG. Dancer GhNo ratings yet

- Production Layout Improvement by Using Line BalancDocument8 pagesProduction Layout Improvement by Using Line BalancG. Dancer GhNo ratings yet

- 2016 Bookmatter FundamentalsOfMachineTheoryAndDocument43 pages2016 Bookmatter FundamentalsOfMachineTheoryAndRaj PatilNo ratings yet

- Manufacturing Processes FormabilityDocument6 pagesManufacturing Processes FormabilityG. Dancer GhNo ratings yet

- CNC Programming Turning GuideDocument9 pagesCNC Programming Turning GuideG. Dancer GhNo ratings yet

- Chapter 1-IntroductionDocument6 pagesChapter 1-IntroductionG. Dancer GhNo ratings yet

- سنوات قطع معادنDocument34 pagesسنوات قطع معادنG. Dancer GhNo ratings yet

- Chapter 2-Review of Mechanical PropertiesDocument6 pagesChapter 2-Review of Mechanical PropertiesG. Dancer GhNo ratings yet

- Extrusion Process: 6.3.1 Direct Extrusion (Also Called Forward Extrusion) Is Illustrated in Figure (6.1) - ADocument6 pagesExtrusion Process: 6.3.1 Direct Extrusion (Also Called Forward Extrusion) Is Illustrated in Figure (6.1) - AchandanNo ratings yet

- Lab Report of Drill MachineDocument6 pagesLab Report of Drill MachineAhtisham AmjadNo ratings yet

- NPTEL Online Course: Control Engineering Assignment-8 SolutionsDocument7 pagesNPTEL Online Course: Control Engineering Assignment-8 SolutionsG. Dancer GhNo ratings yet

- Experiment N 3Document4 pagesExperiment N 3G. Dancer GhNo ratings yet

- Experiment N 5: Surface RoughnessDocument3 pagesExperiment N 5: Surface RoughnessG. Dancer GhNo ratings yet

- College of Science Department of Mathematics Course Syllabus: Statistical Methods Spring Semester 2020/2021Document3 pagesCollege of Science Department of Mathematics Course Syllabus: Statistical Methods Spring Semester 2020/2021G. Dancer GhNo ratings yet

- Sorry: Please Downloa DDocument1 pageSorry: Please Downloa DG. Dancer GhNo ratings yet

- Surface Roughness - أحمد نادر ابراهيم الغوانمةDocument3 pagesSurface Roughness - أحمد نادر ابراهيم الغوانمةG. Dancer GhNo ratings yet

- Strain Measurements - أحمد نادر ابراهيم الغوانمةDocument3 pagesStrain Measurements - أحمد نادر ابراهيم الغوانمةG. Dancer GhNo ratings yet

- Experiment N 6Document3 pagesExperiment N 6G. Dancer Gh100% (1)

- High End Property Refurbishment & Renovation Company in Preston, Lancashire, Merseyside and The UKDocument1 pageHigh End Property Refurbishment & Renovation Company in Preston, Lancashire, Merseyside and The UKAfian PermanaNo ratings yet

- Olana Cement Based Construction Materials Business PlanDocument29 pagesOlana Cement Based Construction Materials Business PlanLeulNo ratings yet

- STC-SC-BEC-LTR-0272 Water Supply PPR Piping Mock-Up WIR PDFDocument2 pagesSTC-SC-BEC-LTR-0272 Water Supply PPR Piping Mock-Up WIR PDFAdel MorsyNo ratings yet

- Specification Estimation and ValuationDocument71 pagesSpecification Estimation and ValuationRitika RituNo ratings yet

- Tefra Corporate BrochureDocument20 pagesTefra Corporate BrochurepmpintoisqNo ratings yet

- Routing - HVAC 2007 T660 ISX F95-1096 - 01: DWG SizeDocument3 pagesRouting - HVAC 2007 T660 ISX F95-1096 - 01: DWG SizeMiguel CardenasNo ratings yet

- CAM Magazine Special Issue 2009: The Best of Michigan ConstructionDocument112 pagesCAM Magazine Special Issue 2009: The Best of Michigan ConstructionCAM MagazineNo ratings yet

- BK117 - Ipc - Section2-1 - Lifting SystemDocument108 pagesBK117 - Ipc - Section2-1 - Lifting Systemamir ghaznaviNo ratings yet

- ARKAN SHADES Welding Inspection & Paint InspectionDocument2 pagesARKAN SHADES Welding Inspection & Paint InspectionSpectex dubaiNo ratings yet

- Updated Up To ACS 38 Dtd. 14.01.2020Document368 pagesUpdated Up To ACS 38 Dtd. 14.01.2020Hermann LoweNo ratings yet

- EFFECT OF ADVERTISING & OUTDOOR MEDIA OF BIRLA CEMENT LTDDocument71 pagesEFFECT OF ADVERTISING & OUTDOOR MEDIA OF BIRLA CEMENT LTDAbhay JainNo ratings yet

- Pushpangan Architecture-R0Document1 pagePushpangan Architecture-R0ajit_archi4nitNo ratings yet

- Amaia 09-20-2022 RevisedDocument16 pagesAmaia 09-20-2022 RevisedKris TolentinoNo ratings yet

- Arbitration award upheld for construction project cost adjustmentsDocument13 pagesArbitration award upheld for construction project cost adjustmentsKrisia OrenseNo ratings yet

- 12-Detailed Estimate of RCC Framed StructuresDocument9 pages12-Detailed Estimate of RCC Framed Structuresfarheen ahmadNo ratings yet

- 2-Concrete Blocks and TestingDocument8 pages2-Concrete Blocks and TestingZhiwar oramariNo ratings yet

- Dhana CV - Mechanical SupervisorDocument6 pagesDhana CV - Mechanical SupervisorpreanandNo ratings yet

- Internship Report On Harshit LandmarkDocument32 pagesInternship Report On Harshit LandmarkABHISHEK SINGHNo ratings yet

- Preferred Practices For Steel Bridge Design, Fabrication, and ErectionDocument58 pagesPreferred Practices For Steel Bridge Design, Fabrication, and ErectionMario Guevara Ubidia- IngenieroCivilNo ratings yet

- EHS Training Matrix - Rev2finalDocument1 pageEHS Training Matrix - Rev2finalMalik Khuram ShazadNo ratings yet

- Lifting & Installation Pipes Plan - Romp 05Document6 pagesLifting & Installation Pipes Plan - Romp 05syed khaja misbhuddinNo ratings yet

- Section - I: Cover Page Section - II:: IndexDocument21 pagesSection - I: Cover Page Section - II:: Indexamit rajputNo ratings yet

- NHBC Standards 2020 Complete PDFDocument401 pagesNHBC Standards 2020 Complete PDFRam Kumar100% (1)

- Scaffold Inspection ChecklistDocument2 pagesScaffold Inspection ChecklistAshique pNo ratings yet

- Construction Waste Management in IndiaDocument4 pagesConstruction Waste Management in IndiaHarshal GunjalNo ratings yet

- Design and Build of Six-Storey MEZ Administration Office BuildingDocument89 pagesDesign and Build of Six-Storey MEZ Administration Office BuildingKarl MoralejoNo ratings yet

- Services For Construction CompanyDocument19 pagesServices For Construction CompanyUzair Maqbool Khan100% (1)

- Fidic Questions and AnwersDocument35 pagesFidic Questions and AnwersRajendra TharmakulasinghamNo ratings yet

- Cable Tray Certification for Gonvarri ColombiaDocument3 pagesCable Tray Certification for Gonvarri ColombiaPool RiveroNo ratings yet