Professional Documents

Culture Documents

FYP Presentation Template

Uploaded by

Ali0 ratings0% found this document useful (0 votes)

21 views20 pagesOriginal Title

FYP Presentation Template (1) (1)

Copyright

© © All Rights Reserved

Available Formats

PPTX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views20 pagesFYP Presentation Template

Uploaded by

AliCopyright:

© All Rights Reserved

Available Formats

Download as PPTX, PDF, TXT or read online from Scribd

You are on page 1of 20

Desgin and energy analysis of

HVAC system using

simulation at MTM

Supervisor : Sir M.Naheed Javed

Ali Raza (18-MCE-18)

Shavaiz ul Hassan (16-mce-16)

M.Umair Saeed (18-mce-08)

Junaid Arshad (18-mce-17)

History of HVAC

• It’s hard to imagine but not too long ago people were living without any sort of

HVAC. The summers were steamy and the winters were chilly..

• Then the idea of a HVAC system first came about in the mid 1800’s when an

inventor, Dr. John Gorrie, proposed the idea of cooling cities during high

temperature months. He eventually designed a system that controlled humidity

using cooling coils.

• Fast forward 50 years and the idea officially took off at the St. Louis World’s Fair

in 1904. It was at this time that a refrigeration system was used.

• Despite the great reception for commercial HVAC, it was still expensive. So, in

1932 H.H. Schultz and J.Q. Sherman created a unit that could fit in window sills.

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 2

Problem Statement

• Our main aim is to provide optimum indoor thermal comfort and guarantee

improvement of indoor air quality using HVAC system at Garments Processing

Unit.

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 3

Introduction of HVAC system

• The term HVAC stands for heating, ventilating, and air-conditioning.

• It describes the field that is concerned with the indoor environment in

order to meet the comfort and health needs of building occupants

and the environmental needs of indoor equipment or processes.

• Although HVAC systems are required for airplanes, ships,

automobiles, and other special applications, but our project will focus

on HVAC systems for commercial buildings.

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 4

Classification of HVAC systems

1. Central system

2. Decentralized or local system

Central HVAC system

• A central HVAC system may serve one or more thermal zones, and its major

equipment is located outside of the served zone(s) in a suitable central location

whether inside, on top, or adjacent to the building.

• Central systems must condition zones with their equivalent thermal load. Central

HVAC systems will have as several control points such as thermostats for each

zone.

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 5

• The sub-classification of the central HVAC system is shown in following figure

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 6

HVAC System Basic Components

An HVAC System may include the following basic components or units.

• HVAC water chillers and heaters

• Hot water generator (if chiller does produce chilled water only) or furnace

• Chilled water pumps

• Cooling water pumps

• Electrical power supply control or Motor control center (MCC)

• Cooling towers

• Piping for chilled water and cooling water or condenser side water

• Valves for chilled water and cooling water sides

• Air handling units (AHUs), heating coils and cooling Coils

• Ducts in ventilation system (supply ducts and return ducts)

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 7

Air handling units (AHUs), heating coils and cooling Coils

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 8

• Fan Coil Units (FCUs) and thermostats

• HVAC Diffusers and grills

• HVAC controls (instrumentation & Control components) installed at various

locations

• HVAC software for building loading calculation(HAP,Excel worksheet)

• An Assembly of all above components forms an HVAC system.

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 9

Refrigeration cycles

An environmental control system that includes cooling and dehumidification will

require a means of removing heat from the conditioned spaces. Because heat flows

only from a higher to a lower temperature, a fluid with a temperature lower than

the room design temperature must be made available, to which the excess room

heat can be transferred. Refrigeration produces this low temperature fluid.

There are two types of refrigeration cycle

• Vapor compression cycle

• Vapor absorption cycle

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 10

Vapor compression cycle

It consists of following four steps

• Compression

• Condensation

• Expansion

• Evaporation

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 11

Factors involved in designing of HVAC

system

• Calculating the Heating and Cooling Load

• Piping System Arrangement

• Flow Rates

• Temperatures

• Selection of Terminal Units

• Pipe Sizing

• Piping or Duct Layout

• Boiler Selection

• Pump Selection

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 12

Factors involved in designing of HVAC

system

• Energy Use and Conservation

• Type of System

• Equipment and Duct Locations

• Duct Sizes

• Air Distribution Devices

• Equipment

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 13

Selecting a system

Defined by ASHRAE Standard 55

Process heating, space heating, cooling, and ventilation criteria should be

considered and should include the following:

• Temperature

• Humidity

• Air motion

• Air purity or quality

• Air changes per hour

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 14

Selecting a system

• Air and/or water velocity requirements

• Local climate

• Space pressure requirements

• Capacity requirements, from a load calculation analysis

• Redundancy

• Spatial requirements

• Economical concerns

• Air purity or quality

• Air changes per hour

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 15

Selecting a System

• First cost

• Energy costs

• Operator labor costs

• Maintenance costs

• Reliability

• Flexibility

• Controllability

• Life-cycle analysis

• Sustainability of design

• Acoustics and vibration

• Mold and mildew prevention

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 16

System Constraints

• Existing conditions (e.g., floor load, access into and through a building)

• Rigging into and out of a building

• Maintaining existing building occupancy and operation

• Construction budget

• Construction schedule

• Ability to phase HVAC system installation

• Equipment availability (i.e., delivery lead times)

• Equipment ingress into designated space

• Equipment maintainability

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 17

Operational Conditions

The operational conditions of the Garments Processing Unit are stated as:

• Temperature

(In Summers 48 ℃ ) (In Winters 24 ℃) Required Temperature 28 ℃ -30 ℃

• Air Quality Index → 172 US AQI

• Humidity →60%

• Number of Employees →500

• Number of Working Machines →138

• Area →300*180 or 54000 Sqft

• Compressed Air Consumption 0.01 Nm3/Kg for Material Processed

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 18

Operational Conditions

• Machine Installed Power → 48 KW

• Sound Emission by Dyeing Machine → 70 dB

• Process Efficiency → 88%

• Dyeing Machine Basket RPM → 10

• Dyeing Machine Bath Volume → 1600 m3

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 19

Acknowledgements

• Acknowledge your supervisor, colleagues, collaborators and the Lab staff for the

advice and support you received from them for your project.

• Put logos, if applicable, of the companies and institutes that provided you the

support.

Tuesday, February 1, 2022 NFC-IEFR ME FYP Project No. 2019-ME-000 Page 20

You might also like

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- FYP Presentation TemplateDocument20 pagesFYP Presentation TemplateAliNo ratings yet

- Proposal HVAC DefenceDocument15 pagesProposal HVAC DefenceThapa PramodNo ratings yet

- Facilitiy StandardDocument83 pagesFacilitiy StandardRahul DubeyNo ratings yet

- Mechanical Services HVAC Design MES v2017.05Document14 pagesMechanical Services HVAC Design MES v2017.05Elie BaradhyNo ratings yet

- Basic HVAC System Design - DS V2.2015.0525Document14 pagesBasic HVAC System Design - DS V2.2015.0525Erika SantosNo ratings yet

- Sabb Design ReportDocument8 pagesSabb Design Reportabdullah amanullahNo ratings yet

- Heating, Ventilation and Air Conditioning: Building Design 2Document8 pagesHeating, Ventilation and Air Conditioning: Building Design 2Darren MartinezNo ratings yet

- HVAC Designing Training in HyderabadDocument4 pagesHVAC Designing Training in Hyderabadfuturegen technologies100% (1)

- Sample Mechanical Basis of Design For UW - Chiller SystemsDocument4 pagesSample Mechanical Basis of Design For UW - Chiller SystemsdaveleyconsNo ratings yet

- Cooling Load Estimation For Hibir BoatDocument10 pagesCooling Load Estimation For Hibir BoatAdi WahyudiNo ratings yet

- HVAC System Design Report Master DocumentDocument7 pagesHVAC System Design Report Master DocumentHisham MustafaNo ratings yet

- PrecisionAir ConditioningDocument11 pagesPrecisionAir ConditioningAzmi PatarNo ratings yet

- Ishrae PDFDocument39 pagesIshrae PDFShivraj SawantNo ratings yet

- Ventilation Electrical RoomsDocument4 pagesVentilation Electrical Roomsvalentinlupascu33No ratings yet

- Hvac Design EngineeringDocument4 pagesHvac Design Engineeringmohamednavavi100% (2)

- Commission HVAC SystemsDocument9 pagesCommission HVAC Systemsizzat555No ratings yet

- Mechanical SystemsDocument3 pagesMechanical SystemsonspsnonsNo ratings yet

- Design Options For HVAC Distribution Systems R1Document68 pagesDesign Options For HVAC Distribution Systems R1ramon duldulaoNo ratings yet

- HVAC Systems: Complying To ECBCDocument33 pagesHVAC Systems: Complying To ECBCHumaid ShaikhNo ratings yet

- Mechanical and Electrical Technical Specification: For TheDocument117 pagesMechanical and Electrical Technical Specification: For TheKo Pauk100% (1)

- Chapter 1Document39 pagesChapter 1الأردني JordanianNo ratings yet

- Chapter 2. Retail FacilitiesDocument16 pagesChapter 2. Retail FacilitiesMantenimientoValdezGutierrezNo ratings yet

- Design of Hvac System For Beverage IndustryDocument12 pagesDesign of Hvac System For Beverage IndustryKorn KcNo ratings yet

- Outline: Hvac System Baseline Information and AuditDocument5 pagesOutline: Hvac System Baseline Information and Auditnitin.duskstar100% (1)

- C SubramaniamDocument16 pagesC Subramaniamanjali shrivastavaNo ratings yet

- Daikin Presentation - VRV TechnologyDocument27 pagesDaikin Presentation - VRV TechnologySantosh Baladhye100% (1)

- (1-4) Design of HVAC system for a commercial building.Document4 pages(1-4) Design of HVAC system for a commercial building.Jayesh MahajanNo ratings yet

- 2014 July TP PDFDocument10 pages2014 July TP PDFVincent De GuzmanNo ratings yet

- 25-01-10 Networking Event EMS FinalDocument41 pages25-01-10 Networking Event EMS FinalajeeshsivanNo ratings yet

- Literature Mechanical Unit 10 & 11Document149 pagesLiterature Mechanical Unit 10 & 11Jabulani KitiNo ratings yet

- 3 Mitsubishi Electric-VRF Technology-PUCT EEIP 1-2012Document35 pages3 Mitsubishi Electric-VRF Technology-PUCT EEIP 1-2012Lee ChorneyNo ratings yet

- AERCODocument31 pagesAERCOAndrea NeufeldNo ratings yet

- USUAEManual Div23 HVACDocument31 pagesUSUAEManual Div23 HVACBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Comfort Design - HVAC BrochureDocument8 pagesComfort Design - HVAC Brochureshivam134019No ratings yet

- HVAC Handbook HVAC Design Brief (Singapore)Document26 pagesHVAC Handbook HVAC Design Brief (Singapore)Sam Wing Hong50% (2)

- Chiller Vs VRF 220811Document6 pagesChiller Vs VRF 220811Jebi Se100% (1)

- Design and Installation HVAC SystemsDocument36 pagesDesign and Installation HVAC SystemsSales and Promotions In KSANo ratings yet

- 1 Impact of Mechanical SystemsDocument28 pages1 Impact of Mechanical SystemsNeena VargheseNo ratings yet

- Mechanical Design Critria Technical Report 26-12-2021Document9 pagesMechanical Design Critria Technical Report 26-12-2021Krishna PATELNo ratings yet

- HVAC Refresher - Facilities Standard for Building Services (Part 1Document82 pagesHVAC Refresher - Facilities Standard for Building Services (Part 1mohammedNo ratings yet

- Cooling Load Calculation of New Academic Building of Asansol Engineering CollegeDocument5 pagesCooling Load Calculation of New Academic Building of Asansol Engineering CollegeRaj KhanNo ratings yet

- Marine AC CalculationDocument10 pagesMarine AC CalculationPratikno SajaNo ratings yet

- Environmental Services I Load EstimationDocument74 pagesEnvironmental Services I Load EstimationFaizul Zainudin100% (1)

- Portable Air Conditioner Cum Refrigerator ProjectDocument20 pagesPortable Air Conditioner Cum Refrigerator ProjectA.F. MominNo ratings yet

- Coaling Load HVAC PDFDocument10 pagesCoaling Load HVAC PDFIntan Luruh LarasatiNo ratings yet

- ASHRAE HVAC Equipment Efficiencies UpdatesDocument14 pagesASHRAE HVAC Equipment Efficiencies UpdatesPhuNguyenHoangNo ratings yet

- HVAC TrainingDocument9 pagesHVAC Trainingoth369No ratings yet

- 10-Air Conditioning Installations - Split UnitDocument76 pages10-Air Conditioning Installations - Split Unitsarathirv6100% (1)

- DBR For HVACDocument15 pagesDBR For HVACdhanu_lagwankar50% (2)

- Design Options for HVAC Distribution SystemsDocument58 pagesDesign Options for HVAC Distribution Systemsstressfree123No ratings yet

- Air Washer UnitDocument19 pagesAir Washer UnitAnonymous BbZceWkVn100% (1)

- HVACDocument20 pagesHVACMvk MvkNo ratings yet

- HVAC Design Course Covers Refrigeration, Psychrometrics & EquipmentDocument11 pagesHVAC Design Course Covers Refrigeration, Psychrometrics & EquipmentmahmadwasiNo ratings yet

- Mechanical Engineering Design GuidelinesDocument23 pagesMechanical Engineering Design GuidelinesTep PiNo ratings yet

- Group 2 PresentationDocument21 pagesGroup 2 PresentationDave MongayaNo ratings yet

- CITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)Document4 pagesCITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)FarisNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cooling Load Ceiling Height 22 FeetDocument27 pagesCooling Load Ceiling Height 22 FeetAliNo ratings yet

- GraphsDocument1 pageGraphsAliNo ratings yet

- Project Summary: Location and WeatherDocument10 pagesProject Summary: Location and WeatherAliNo ratings yet

- Matlab AssignmentDocument12 pagesMatlab AssignmentAliNo ratings yet

- Fea Cep 2018Document1 pageFea Cep 2018AliNo ratings yet

- New Microsoft Word DocumentDocument13 pagesNew Microsoft Word DocumentAliNo ratings yet

- Oil Cooling Water: AnswersDocument1 pageOil Cooling Water: AnswersAliNo ratings yet

- FEA ME-451L Lab Projects: CLO's: 1,5,7,8 PLO, S: 3,9,11,12Document3 pagesFEA ME-451L Lab Projects: CLO's: 1,5,7,8 PLO, S: 3,9,11,12AliNo ratings yet

- Titels WorkshopDocument1 pageTitels WorkshopAliNo ratings yet

- PP AliDocument7 pagesPP AliAliNo ratings yet

- Ijesrt: International Journal of Engineering Sciences & Research TechnologyDocument8 pagesIjesrt: International Journal of Engineering Sciences & Research TechnologyAliNo ratings yet

- ANSYS Workbench ReportDocument15 pagesANSYS Workbench ReportAliNo ratings yet

- Class 1Document16 pagesClass 1AliNo ratings yet

- JMDocument8 pagesJMAliNo ratings yet

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDocument3 pagesMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNo ratings yet

- Assignment No 1Document16 pagesAssignment No 1AliNo ratings yet

- Final Review Report For PV ProjectDocument27 pagesFinal Review Report For PV ProjectAliNo ratings yet

- Exp 13 PH AND ITS MEASUREMENTS Sp07Document12 pagesExp 13 PH AND ITS MEASUREMENTS Sp07AliNo ratings yet

- Water Test Ali PPDocument7 pagesWater Test Ali PPAliNo ratings yet

- FEA ME-451L Lab Projects: CLO's: 1,5,7,8 PLO, S: 3,9,11,12Document3 pagesFEA ME-451L Lab Projects: CLO's: 1,5,7,8 PLO, S: 3,9,11,12AliNo ratings yet

- BSc Final Year CFD Analysis of EconomizerDocument4 pagesBSc Final Year CFD Analysis of EconomizerAliNo ratings yet

- Introduction To Process Industry By: Engr. Dr. Syed Amjad AhmadDocument30 pagesIntroduction To Process Industry By: Engr. Dr. Syed Amjad AhmadAliNo ratings yet

- Mechengg 3Document35 pagesMechengg 3AliNo ratings yet

- Dave John Mike Quality Management Systems PPT 03Document22 pagesDave John Mike Quality Management Systems PPT 03Shubham GuptaNo ratings yet

- Experiment No 4: ObjectiveDocument4 pagesExperiment No 4: ObjectiveAliNo ratings yet

- Aircraft Design Conceptual AnalysisDocument76 pagesAircraft Design Conceptual AnalysisAliNo ratings yet

- 18 Mce 08Document2 pages18 Mce 08AliNo ratings yet

- Name HereDocument1 pageName HereAliNo ratings yet

- Earthing System ChecklistDocument1 pageEarthing System Checklistbon10No ratings yet

- PROJECT: SHOABA STAGE III DUCT NAME: SAC 10 AN008 & AN010Document6 pagesPROJECT: SHOABA STAGE III DUCT NAME: SAC 10 AN008 & AN010Mohamed AdelNo ratings yet

- PledgeDocument2 pagesPledgeSteve SalibNo ratings yet

- Rayleigh PotDocument10 pagesRayleigh PotNikhilesh ShajiNo ratings yet

- Contactor Safety Combination 3TK2803, 3TK2804 3TK2907, 3TK29.3Document3 pagesContactor Safety Combination 3TK2803, 3TK2804 3TK2907, 3TK29.3anas alsatyNo ratings yet

- General Specification: GS 80B81S01E 1 EML500-HS, HD, HV Sea Valve and EquipmentsDocument9 pagesGeneral Specification: GS 80B81S01E 1 EML500-HS, HD, HV Sea Valve and EquipmentsNguyen Phuoc HoNo ratings yet

- Kit Preamp Audio Tub PDFDocument28 pagesKit Preamp Audio Tub PDFChelaru CosminNo ratings yet

- Catalogo Ricambi Spare Parts Catalogue: Minipack-Torre S.p.ADocument14 pagesCatalogo Ricambi Spare Parts Catalogue: Minipack-Torre S.p.AJaroslav KolářNo ratings yet

- Instrumentation - Aeroplanes: 22.01. Flight InstrumentsDocument27 pagesInstrumentation - Aeroplanes: 22.01. Flight InstrumentsveenadivyakishNo ratings yet

- Lathe OperationsDocument93 pagesLathe OperationsLeo Dev WinsNo ratings yet

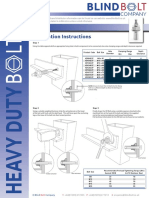

- HD InstallDocument1 pageHD InstallAnte CrnicaNo ratings yet

- BO23 User DocumentationDocument58 pagesBO23 User DocumentationzhafranNo ratings yet

- 6620 Crane Manual 700 20013Document108 pages6620 Crane Manual 700 20013desgnhpNo ratings yet

- Metode Pelaksanaan Pekerjaan Test Pile: According To ASTM D 1143/D 1143M-07)Document22 pagesMetode Pelaksanaan Pekerjaan Test Pile: According To ASTM D 1143/D 1143M-07)popiNo ratings yet

- Komatsu Pc800 8k Parts BookDocument20 pagesKomatsu Pc800 8k Parts Bookedward100% (50)

- Fuse TypesDocument6 pagesFuse Typesphild2na2No ratings yet

- Tag 0240-BH-0103-0104Document1 pageTag 0240-BH-0103-0104Alexander AcuñaNo ratings yet

- Fasteners DIN en ISO Standards PDFDocument32 pagesFasteners DIN en ISO Standards PDFsardarNo ratings yet

- Datasheet 20 20ti Series 20 2013 05 20v1 20A4 20HiRes 20pressDocument2 pagesDatasheet 20 20ti Series 20 2013 05 20v1 20A4 20HiRes 20pressEduardo FeitosaNo ratings yet

- J160 ManualDocument64 pagesJ160 ManualdonNo ratings yet

- (3360604) Seminar On: Building ServicesDocument21 pages(3360604) Seminar On: Building ServicesSparsh ShukalNo ratings yet

- Instruction Manual - FL11 LED Flood Light PDFDocument2 pagesInstruction Manual - FL11 LED Flood Light PDFSasikumar SivarajNo ratings yet

- RST Kalibrasi Alat MedisDocument10 pagesRST Kalibrasi Alat MedisSofian RNo ratings yet

- Unolux 2010 enDocument152 pagesUnolux 2010 enJohn SmithNo ratings yet

- Whirlpool Maytag Amana Jenn Air Defrost SystemsDocument94 pagesWhirlpool Maytag Amana Jenn Air Defrost Systemsputsitout100% (3)

- KUKA ErnergieZufuehrung EN SCREENDocument35 pagesKUKA ErnergieZufuehrung EN SCREENantonio vukeNo ratings yet

- Havells - E-Plus Electrician PointsDocument1 pageHavells - E-Plus Electrician Pointspattumkp83% (60)

- TS300 1800OperationManualDocument120 pagesTS300 1800OperationManualДмитрий ДехановNo ratings yet

- Manual Book PC300-8 PBDocument824 pagesManual Book PC300-8 PBNafrizal Suhendrik100% (1)

- Location of Electrical Components Cs533eDocument4 pagesLocation of Electrical Components Cs533eSteven Y.MNo ratings yet